The Game Plan

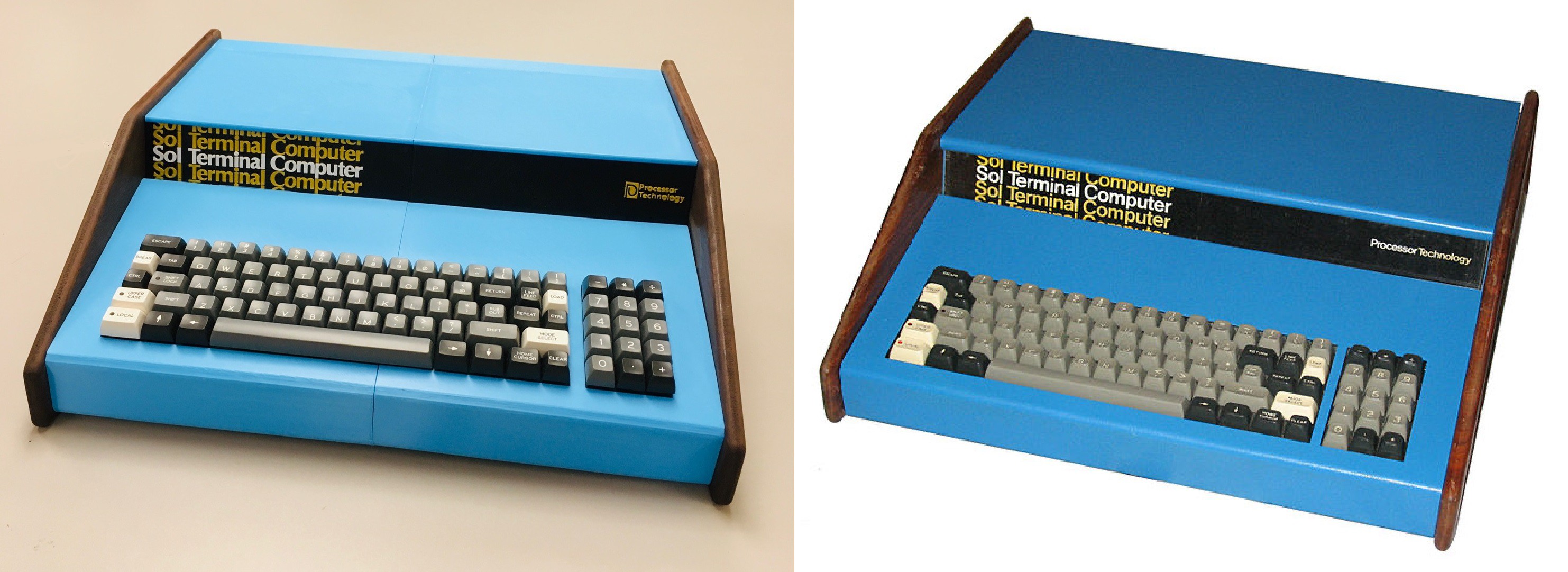

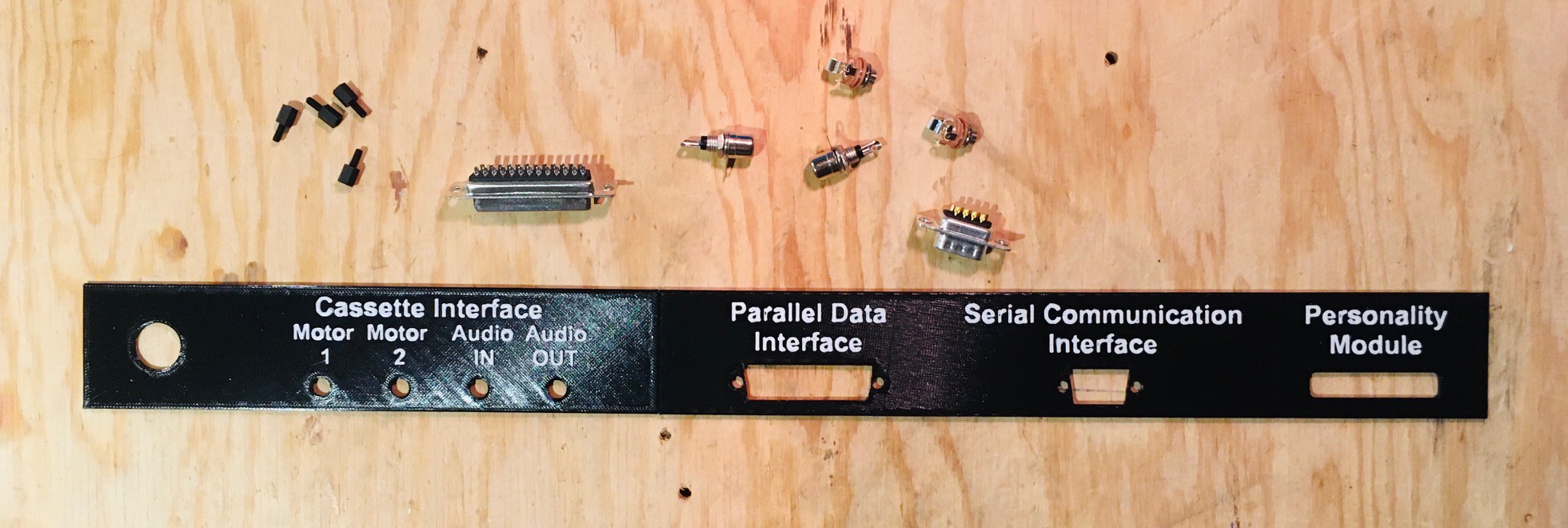

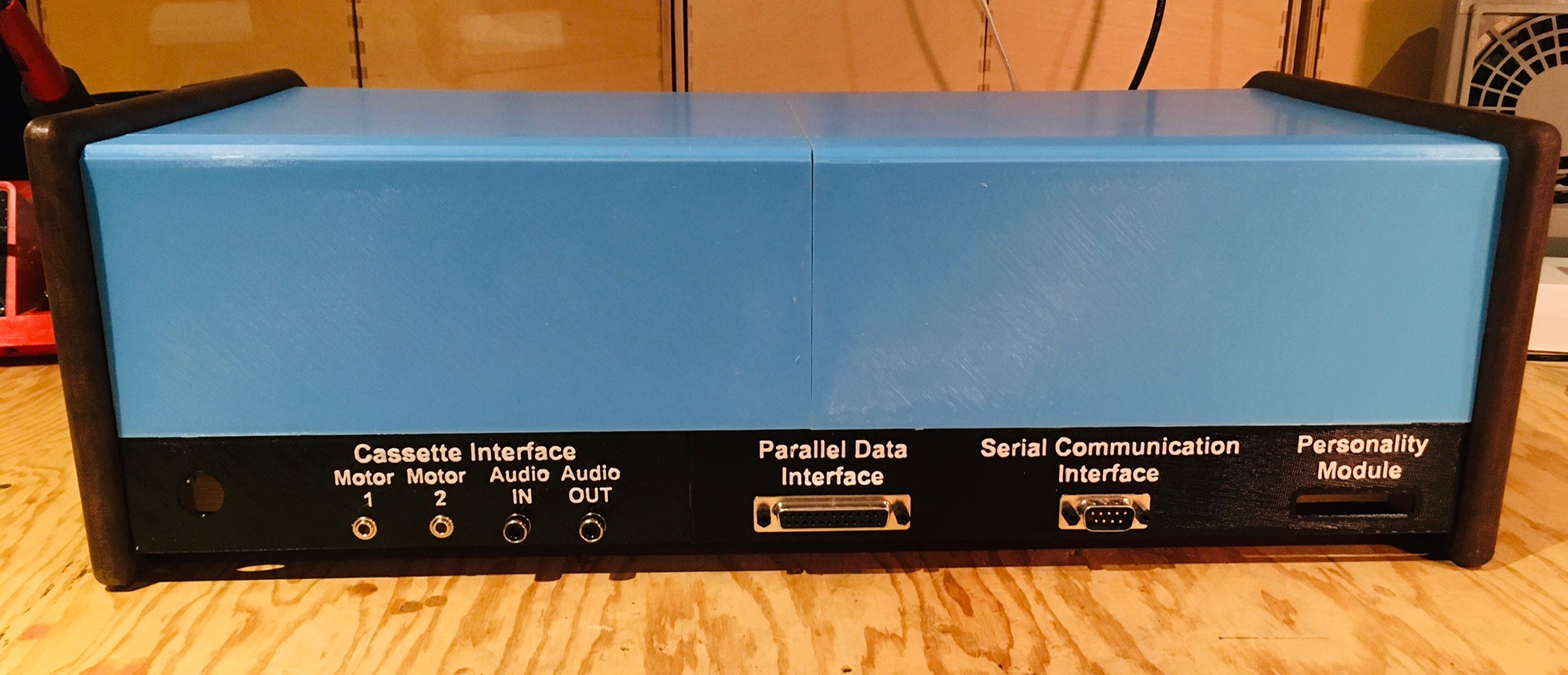

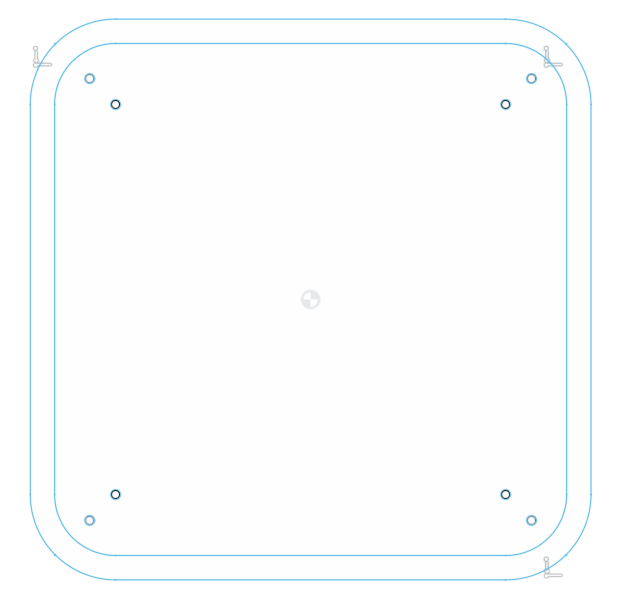

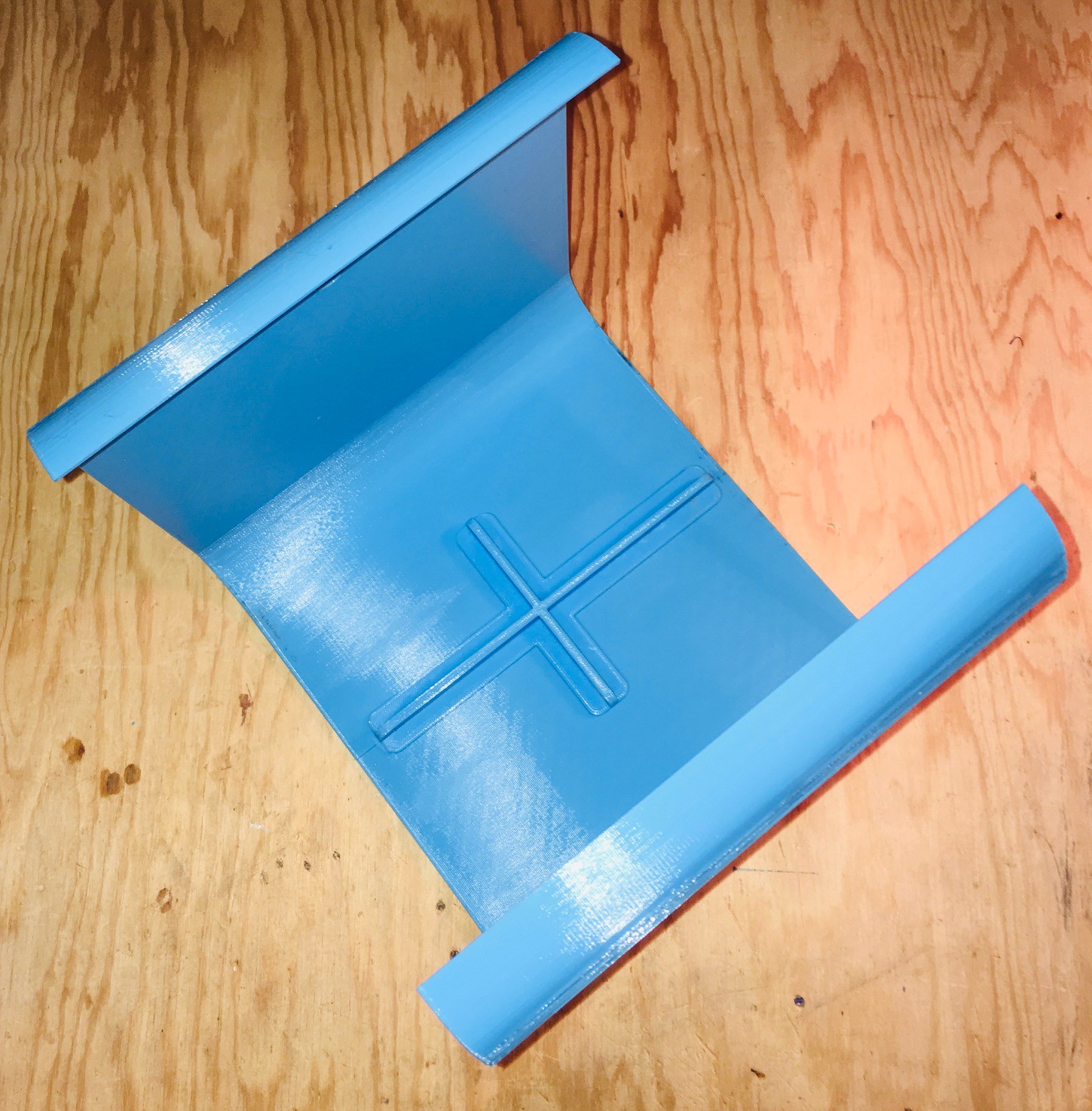

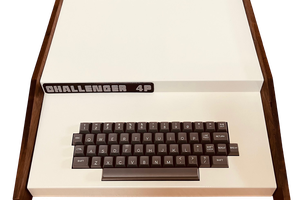

So my plan is to make a full size case that will be as authentic looking as possible, with beautiful walnut sides for sure. I will 3D print the blue panels instead of using sheet metal so the build will be accessible to more people should they decide to make one.

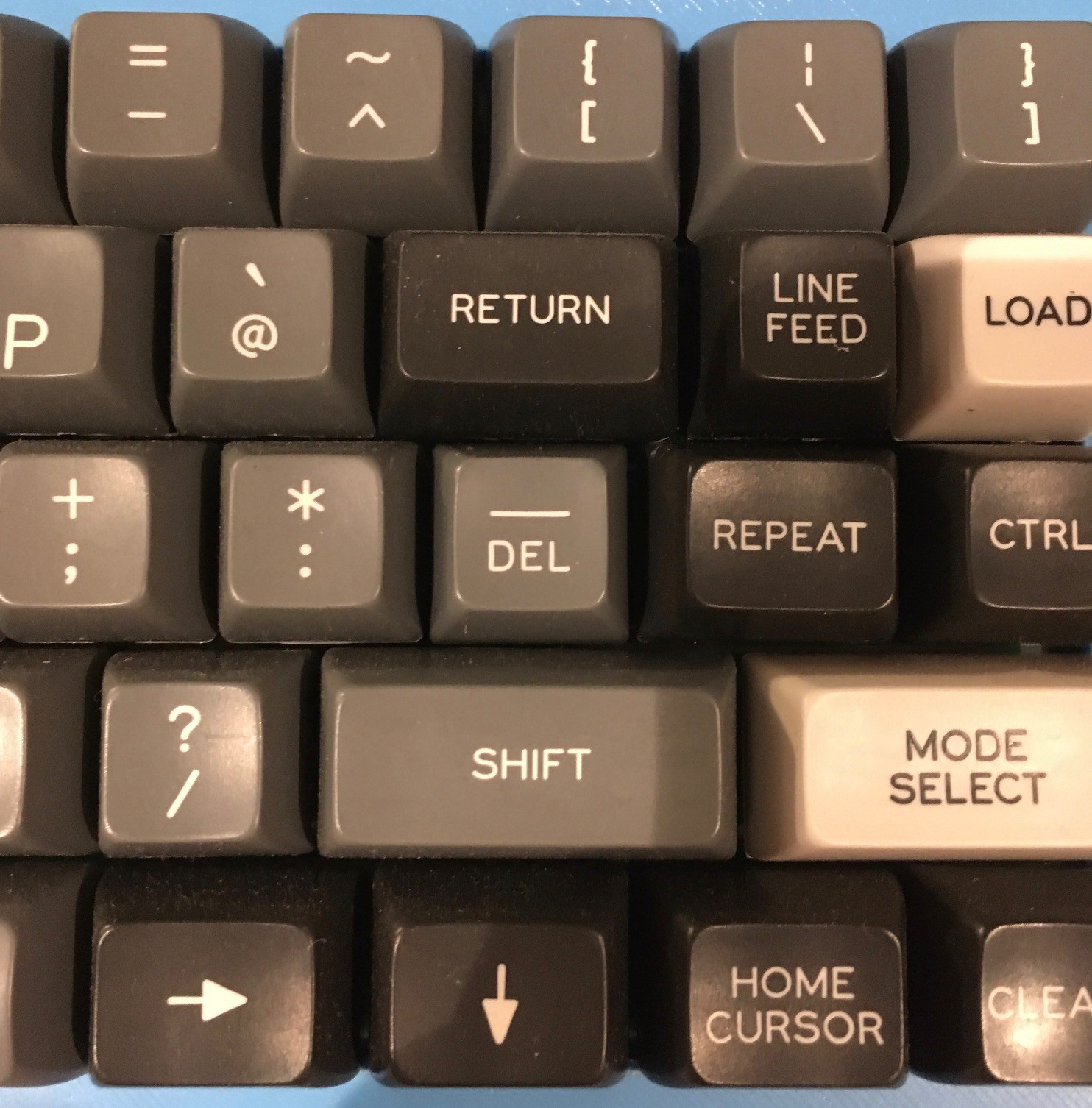

For the keyboard I have been in touch with Dave from osiweb.org who has designed a complete replacement keyboard for the Sol-20 using modern Cherry key switches. From the Unified Retro Keyboard Project:

The keyboard is not a replica of the original. It doesn't use the same capacitive circuit or keys. But it does have exactly the same layout with the same functionality, including the 3 LEDs (UPPER CASE, SHIFT LOCK, LOCAL) and 3 outputs (RESET, BREAK, LOCAL). It uses cherry MX or Futaba MD-4PCs keys. Neither has quite the same feel as the capacitive keys, but the Futaba keys approach the travel of the keytronic switches, and do have a nice feel.

I'm getting the keyboard as a kit and looking forward to putting it together.

On the inside I'm going to emulate the Sol-20 hardware on a Raspberry Pi 4. To that end I have a working (very basic at this point) Python based emulator I'm going to post to GitHub shortly.

I haven't decided what to do for a monitor yet. Certainly a CRT of some sort would be ideal, but I may have to go with a LCD.

Is Emulation the Sincerest Form of Flattery?

While I was researching the project and planning the build I was working a Sol-20 emulator. I thought about using Jim Battle's Solace emulator, but it is Windows based and ultimately I hope to run my Sol-20 reproduction on a Raspberry Pi 4.

Since the Sol-20 was based on the Intel 8080 microprocessor I thought that would be the logical place to start. Fortunately for me, Space Invaders and some of the other early arcade machines also used the 8080. Because there is a very active gaming community helping to preserve these retro classics, there are a number of great 8080 emulators to be found on GitHub. I ended up cloning py8080 because it's Python based and I'm more comfortable right now with Python than I am with C++.

So with a working virtual 8080 processor it was a pretty easy task to allocate some memory for it (64K because why not), load a monitor program (Solos since it was the default shipped), set the instruction pointer to the start of the program (0xC000), and run the emulator. Success! Technically I had a Sol-20 running in emulation, but it was pretty boring since I had no way to interact with it. Time to create some virtual devices.

The Display

The system memory used by the Sol-20 is as follows:

C000-C7FF - System ROM. Sol-20 "Personality Modules" like Solos are mapped here. C800-CBFF - System RAM. Reserved by the system. CC00-CFFF - Display RAM. Shared memory between the CPU and VDM-1 video circuit.

Although most systems shipped with only 8K or 16K of memory (or less) in those days, I have to wonder why they didn't map these addresses up into the F000-FFFF space to allow a contiguous 60K memory space for user programs. At any rate the important thing to note for display purposes is the CC00-CFFF shared video RAM. This 1K space was used to store 16 lines of text each of which is 64 characters long. Any text written to this memory would automatically be displayed on the screen.

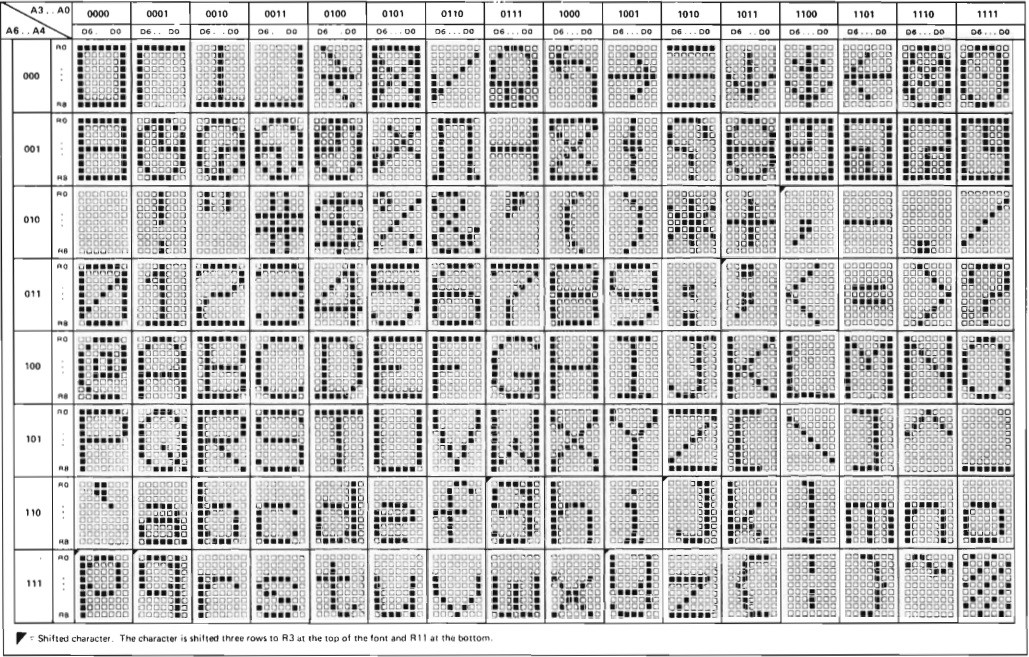

Using PyGame I created my virtual screen. I could have written the characters from the shared video memory directly to the screen but the Sol-20 used a lot of unique character glyphs.

So based on the original 6574 character ROM I created a set of character tiles that I could easily "blit" to the screen. I wrote a function to iterate over the 64 x 16 array of characters in the shared video memory and write them out to the screen and added this function to the main loop of my emulator. When I did that I was rewarded with this. I know the aspect ratio is off here....

Read more » Michael Gardi

Michael Gardi

RasmusB

RasmusB

I'm wondering if the Raspberry Pi Zero W2 could be used for this?