After some time I decided to present some of my last custom made device, the Spot Welder. Maybe there is nothing special to present, but I will try to describe it anyway.

Device is used for spot welding batteries and made some accu-packs from them.

Features:

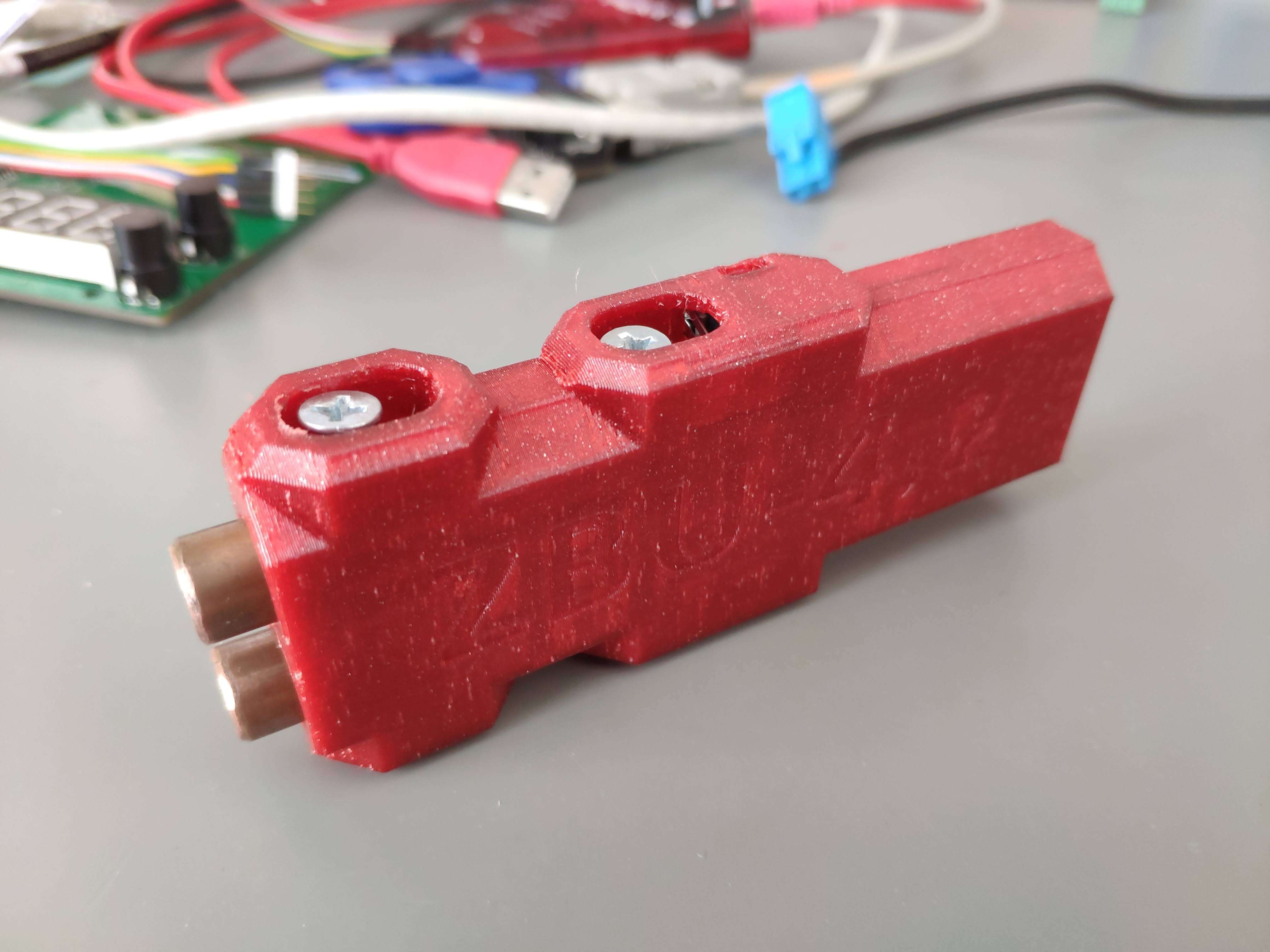

- custom handle

- pre-welding

- pulse/pulse mode

- simple user-interface

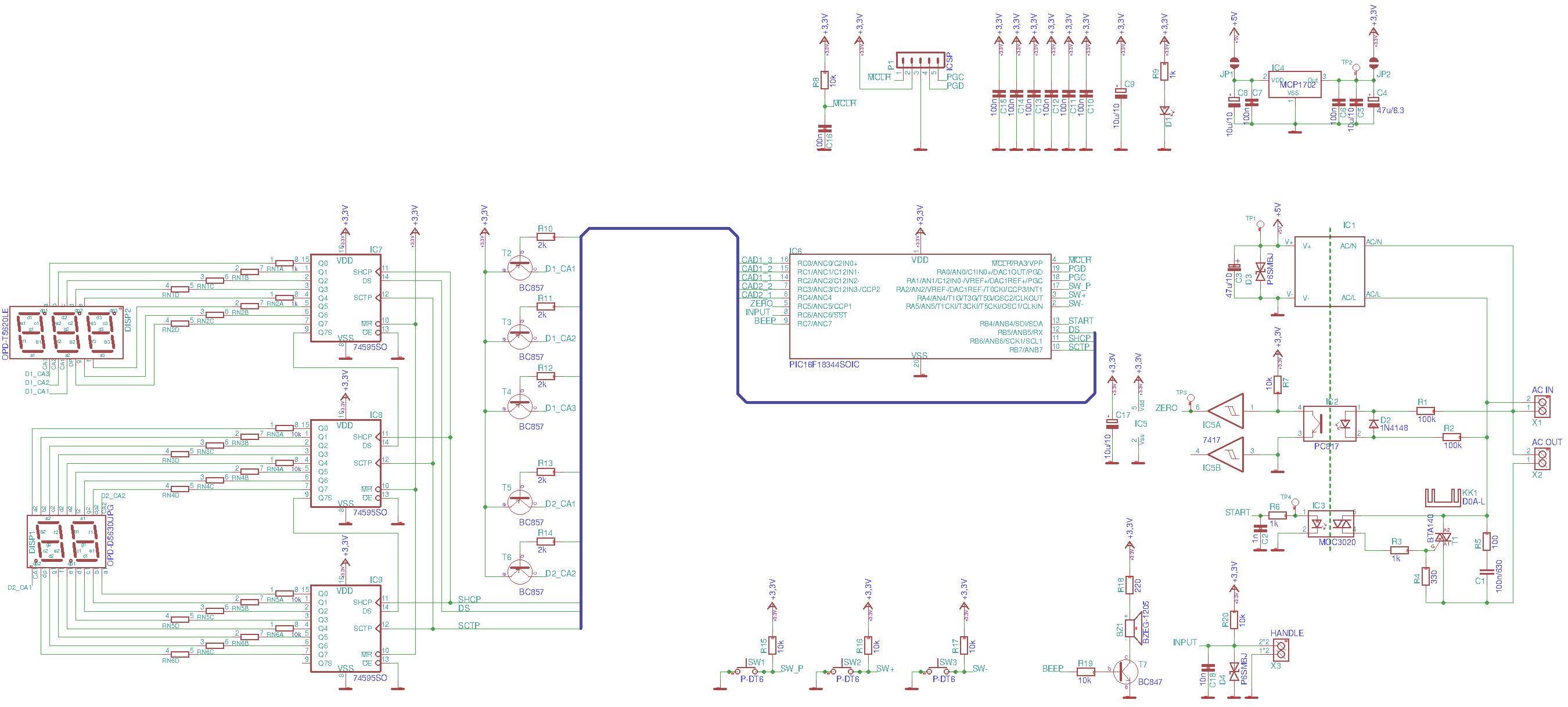

I used 1kW MOT (Microwave transformer) as a power source. (It was really a problem to find such a device with 800W power at least.) The MOT is switched by optocoupler + triac. There is nothing special behind, just a triac regulation, or better triac switching.

As I said, there is nothing special behind, maybe the SW... . Switching is based on zero-cross witch time calculation. If you chose the pulse mode, times are calculated with 50Hz period respecting. (60Hz needs some SW modifications.) Switch is not starting at zero-cross (as it looks like from first point of view), but at the maximum, 1/50Hz = 20ms -> 5ms or 15ms. Triac has enough power to switch such a load.

The pre-weld feature is used for clean the contacts before "full" weld.

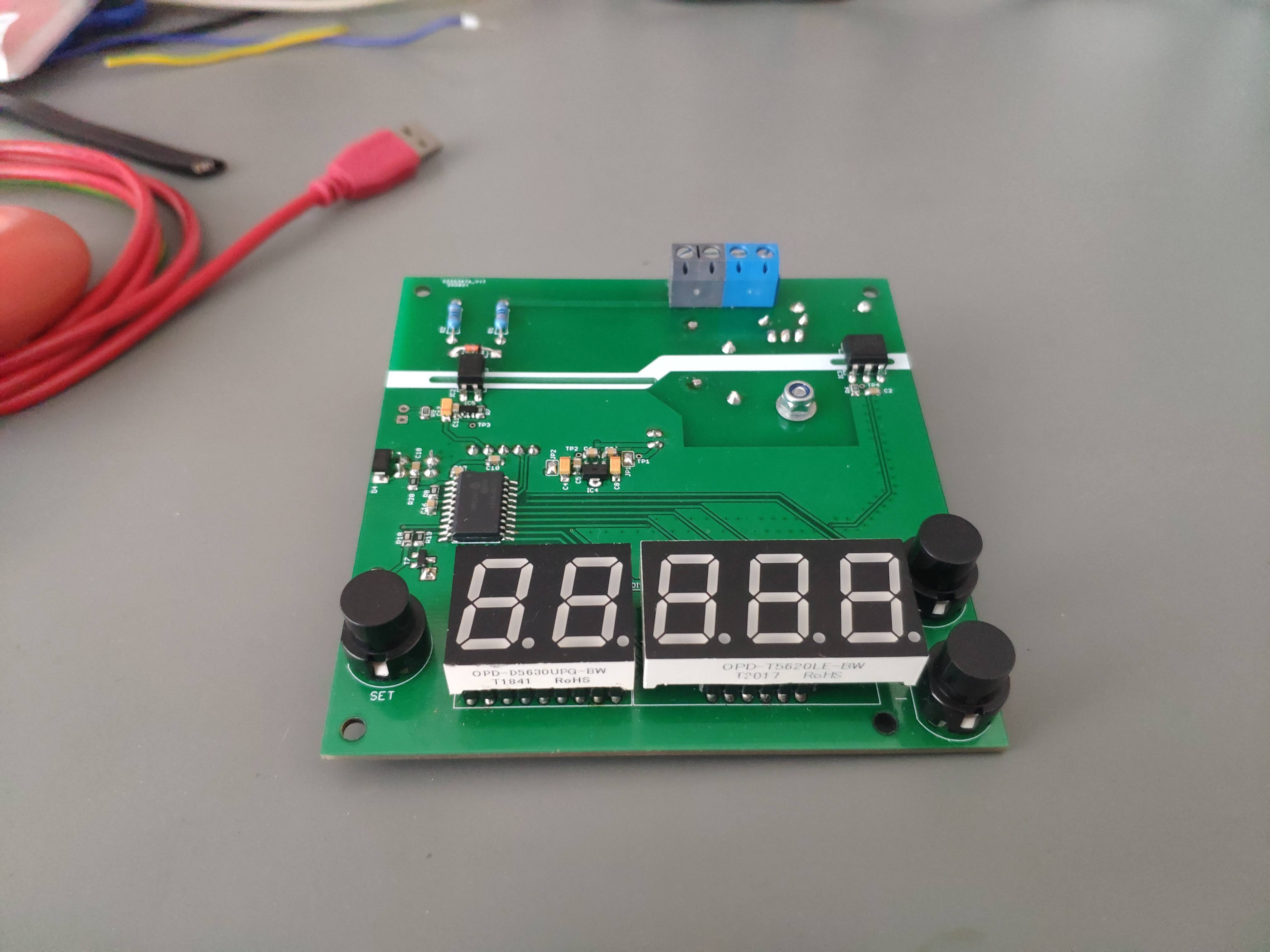

If we look the user interface... there are just two buttons for increase/decrease the value and one for "set" selection. If you want to save the new value into EEPROM, you have to press and hold +/- buttons together. One feature is, that you don't need to wait lot of time to get the higher value. After some seconds without button releasing, the increment/decrements is much faster ;).

There was a little bit of research regarding to handle. The main requirement had to be the floating electrodes. So each of them will get the same contact. Fortunately I founded the right one at the thingiverse. Both are floating and switch is integrated too. So I printed the testing model. After some modifications I was able to use it as it is now.

As a wire I used truth coppered one (not some kind of cheap Chinese variant or something like that). Yes, the price was incredible 50€ for 2m of 1x25mm^2.

Friend of mine told me, that 4 rounds should be enough. So I had to replace the isolation (It was really a pain), but I was successful.

I designed a custom housing from 2.5mm steel plate. Yes 2.5mm, because the MOT is really heavy.

I was also thinking to add some front panel with description, but to be honest. I think is intuitive enough.

Ok, that's it. Maybe a last picture, how the the weld looks like.

Andy

Andy

AKA

AKA

origamimavin

origamimavin

Jeremy Gilbert

Jeremy Gilbert

Excellent!! Can you post a video showing what the led display shows? Is it dual pulse or single pulse? Can a pneumatic system be added to it?