The first thing I changed out was the bow. I wanted MOAR POWER! So I decided to go for a double bow. Each bow is a 3/4" PVC pipe with different lengths of fiberglass rods inside. I simply scaled this bow to 4 feet, and made two of them:

A few tips if you're making this (i forget if he covers this in the video):

- - fiberglass is nasty. Wear an n95 mask (we've all go lots of those now haha).

- - wrap masking tape around where you're cutting to prevent spintering

- - go light on the tape holding the rods together - it's a tight fit into the PVC pipe! A good way to do this is to make the helix angle of your tape wrapping relatively high.

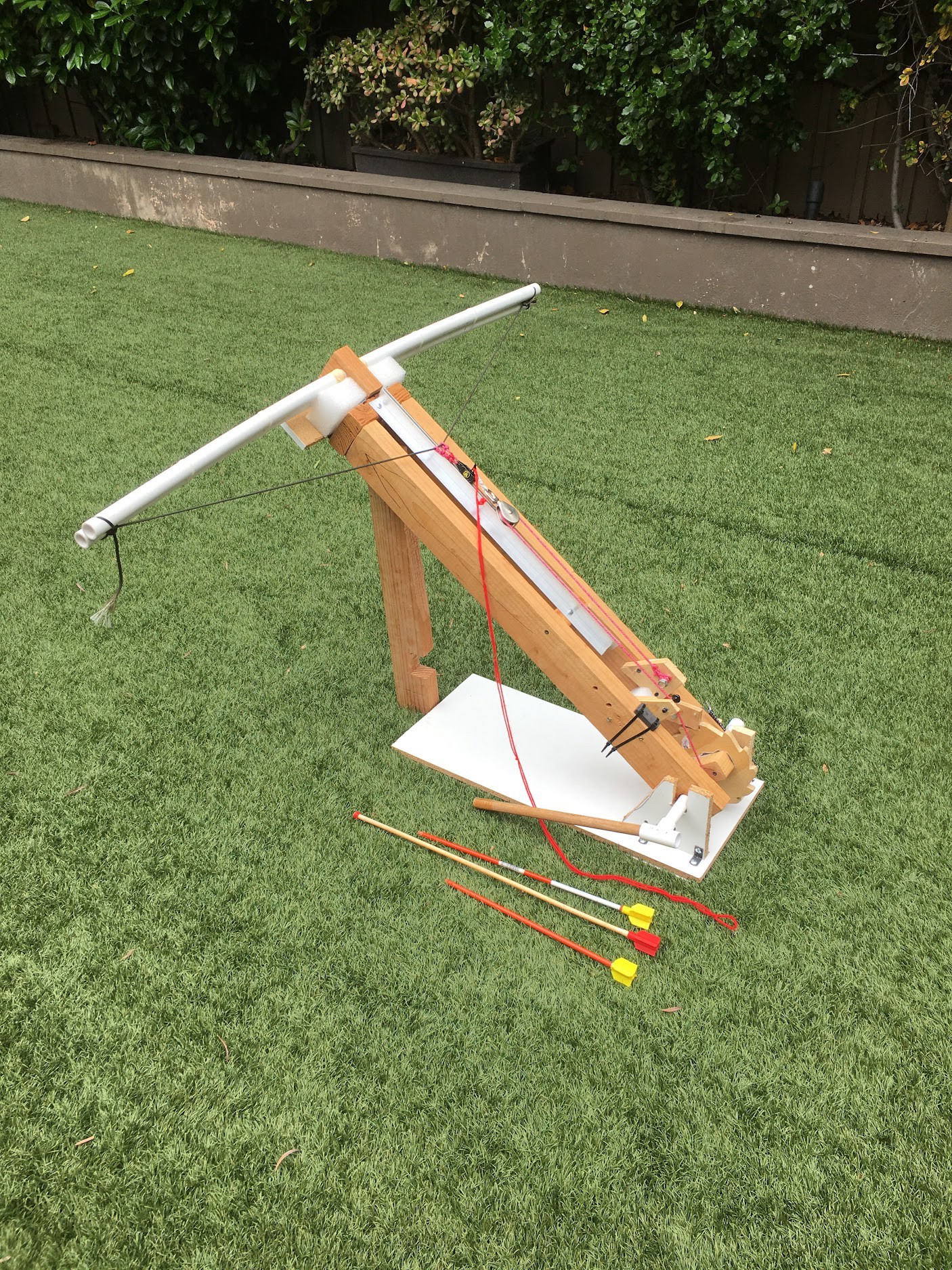

Once I finished the bows, it was on to the hard part: mounting them! The original bow didn't have fiberglass rods inside, so we had just drilled holes in it and screwed it in. To mount the new bows, I simply drilled two holes into a short 2x4 and put the bows in. I used a hodgepodge of whatever mounting hardware I could find around my garage to mount this onto the 2x4 block onto the front of the ballista. I had to reinforce it later because the bow tore itself off the front of the frame upon the first fire:

This means that there's a lot of energy left over at the end of the firing, so the efficiency of this bow is probably very low. To fix this, I shifted from wooden arrows/bolts to using leftover fiberglass rod, which happened to be the perfect diameter. I also 3d printed fins for the back to give the bowstring something to push against.

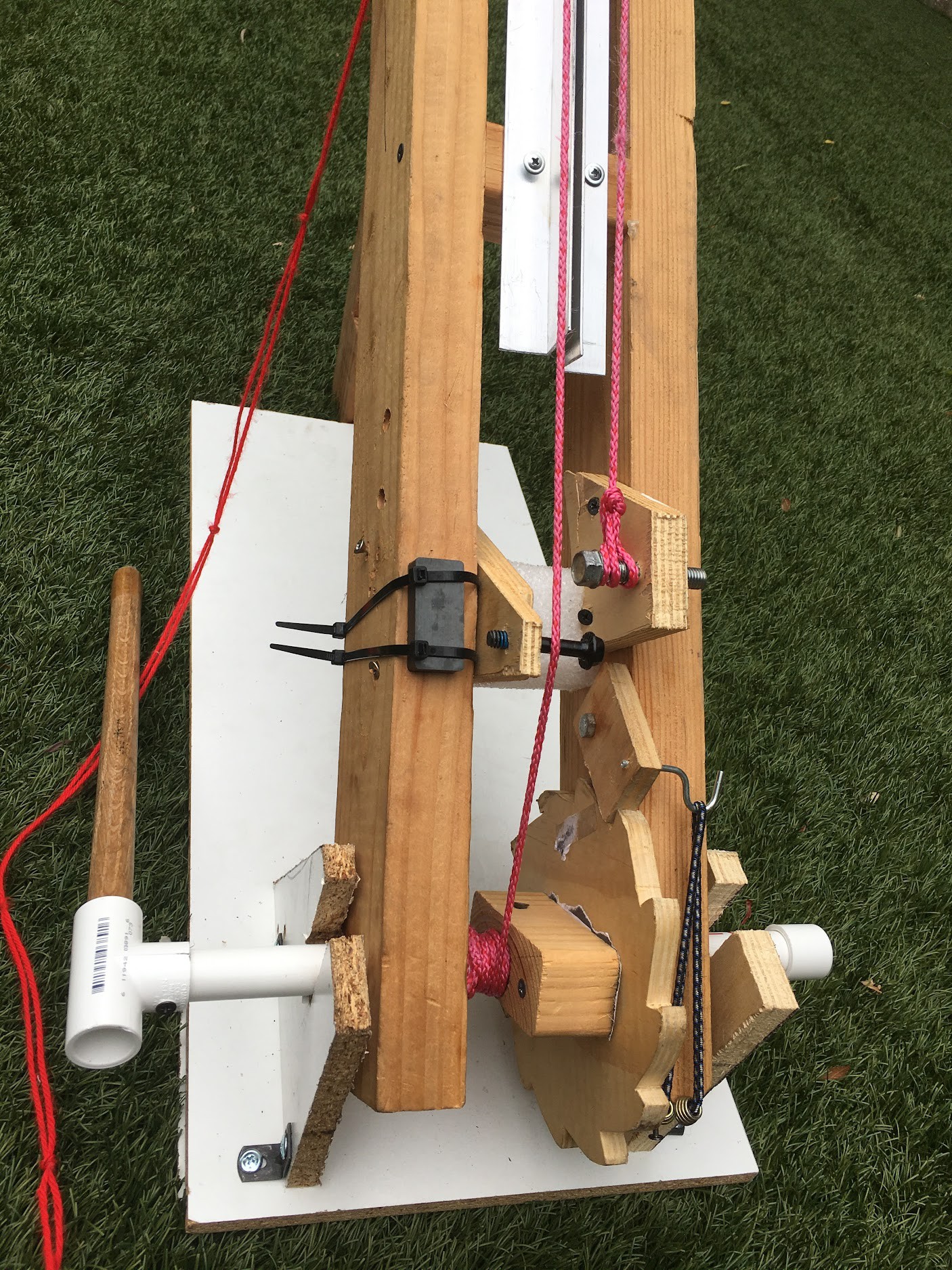

The next problem was the draw weight. It was too heavy! The rachet system, which uses just a 1/2" pvc pipe as an axle and spool, was binding in the wooden hole that it spun in. To fix this, I added a pulley to half the effective draw weight on the rachet system. I also had to add some sketchy idlers to keep the pulling rope level with the frame:

problem solved! Now onto the next problem: the trigger. The original trigger was an L-shaped hook that latched into a small carabiner on the bowstring. To fire, you used a string to pull the L out of the eye, releasing the string. I don't have a picture, so here's something similar I found on the interwebs:

With the new bow, the L hook thing was bending, and when I replaced it with a stronger version, the friction between it and the eye was too strong and I couldn't pull it out. So I bought a cheap archery arrow release from amazon, removed the strap, and used that. It's designed to be able to hold strong loads but still release with very little force. It's almost as if it were designed to draw and release bowstrings! Anyway, that worked great.

The final change I made was the base, which you can see in the earlier photo. There's also a hinge-mounted 2x4 on the front that props up the whole thing.

The hinge allows the whole thing to fold flat for storage.

With all of these changes, it works great. I was able to embed one of the fiberglass rods into the fence in my backyard from about thirty feet away, shooting flat! Overall, I'm really happy with the power I managed to add in such a sort time and for so cheap.

ReidDye

ReidDye

Quinn

Quinn

load.nikon

load.nikon

Tim Wilkinson

Tim Wilkinson

rawe

rawe