Almost 1 year after I saw the beginning of the end for #SecSavr Sublime [gd0036], this project has overtaken it's 99 logs. There's only one other project -- a prism laser scanner -- that I know is in the triple digits. I'm not entirely sure how such a number of logs has accumulated and I'm only now looking to turn concept into reality, but I've got to take the few-and-far small wins on this journey whenever possible.

The 3.2mm "Used, Like New" ball chain just came in the mail from Amazon, and... it's certainly different from the image in 2 ways:

The 3.2mm "Used, Like New" ball chain just came in the mail from Amazon, and... it's certainly different from the image in 2 ways: Firstly, there were no connectors in the bag I've got (or the packaging). That's fine since I wasn't planing on using them anyway. Secondly, as can be seen next to my calipers, it's visibly darker than anything I know to be stainless steel.

Firstly, there were no connectors in the bag I've got (or the packaging). That's fine since I wasn't planing on using them anyway. Secondly, as can be seen next to my calipers, it's visibly darker than anything I know to be stainless steel.

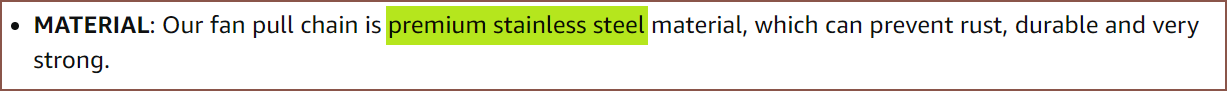

I've changed the texture of one of the ball chain loops to try and match what they look like in contrast to the default stainless steel texture. I think it looks a tad more premium this way, so I'll let it slide up until it starts rusting (implying that it was never stainless steel to begin with). Actually, it could just be more susceptible to lighting conditions than other metals. If I go under a brighter light, the chain still looks darker than other metals but it no longer has that slight brownish tint.

I've changed the texture of one of the ball chain loops to try and match what they look like in contrast to the default stainless steel texture. I think it looks a tad more premium this way, so I'll let it slide up until it starts rusting (implying that it was never stainless steel to begin with). Actually, it could just be more susceptible to lighting conditions than other metals. If I go under a brighter light, the chain still looks darker than other metals but it no longer has that slight brownish tint.Other measurements are that the spacing between balls seems to be 4.9mm (measuring 14 balls to be 68.8mm), the linkages are 0.75mm and the balls are in the range of 3.18 - 3.24mm.

I'm going to need to model a sprocket to replace the small pulley. The reason is because, unlike in simplified physics calculations, friction is not negligible. It seems that, when taught, the ball bead binds on the linkage, resulting in a turning diameter of about 26mm.

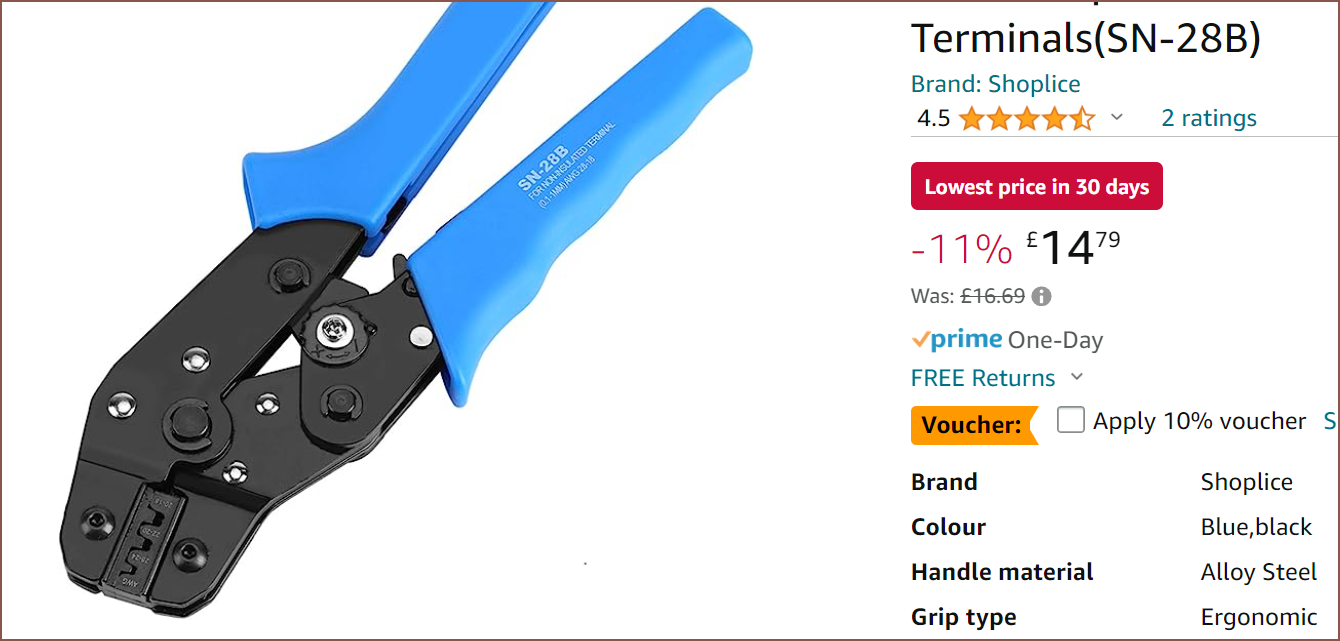

I'm also going to have to stop and think about the splicing situation. It certainly seems that I need the mechanical advantage of a crimp tool to actually do anything to these balls, but I'm sure not going to get the correct outcome from them:

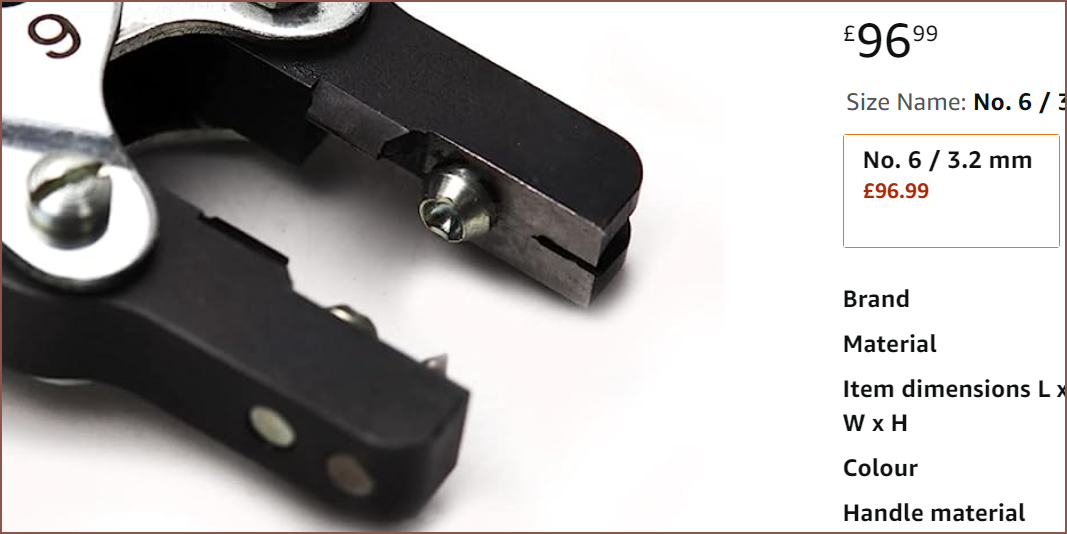

I think the first strat I'm going to try is to replace the jaws of the SN-28B to be more similar to the splicer tools:

Obviously, this isn't a critical problem like the pulley is, since I could always fastpass my way to spliced chains by just buying the tool instead of inventing yet another thing here. It's not like I want this to be the difference between walking out of summer break empty handed or not.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.