Please check the build logs for design details.

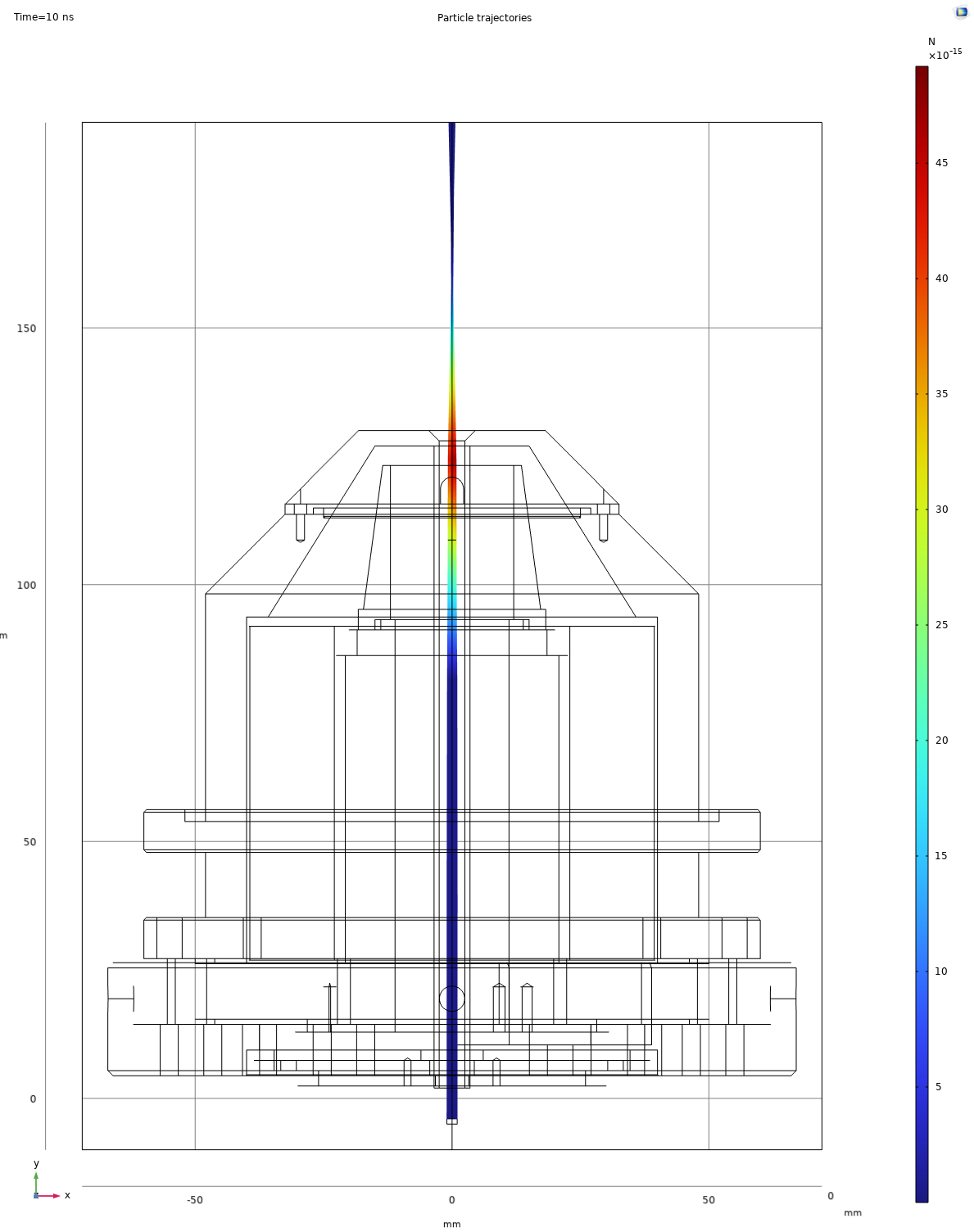

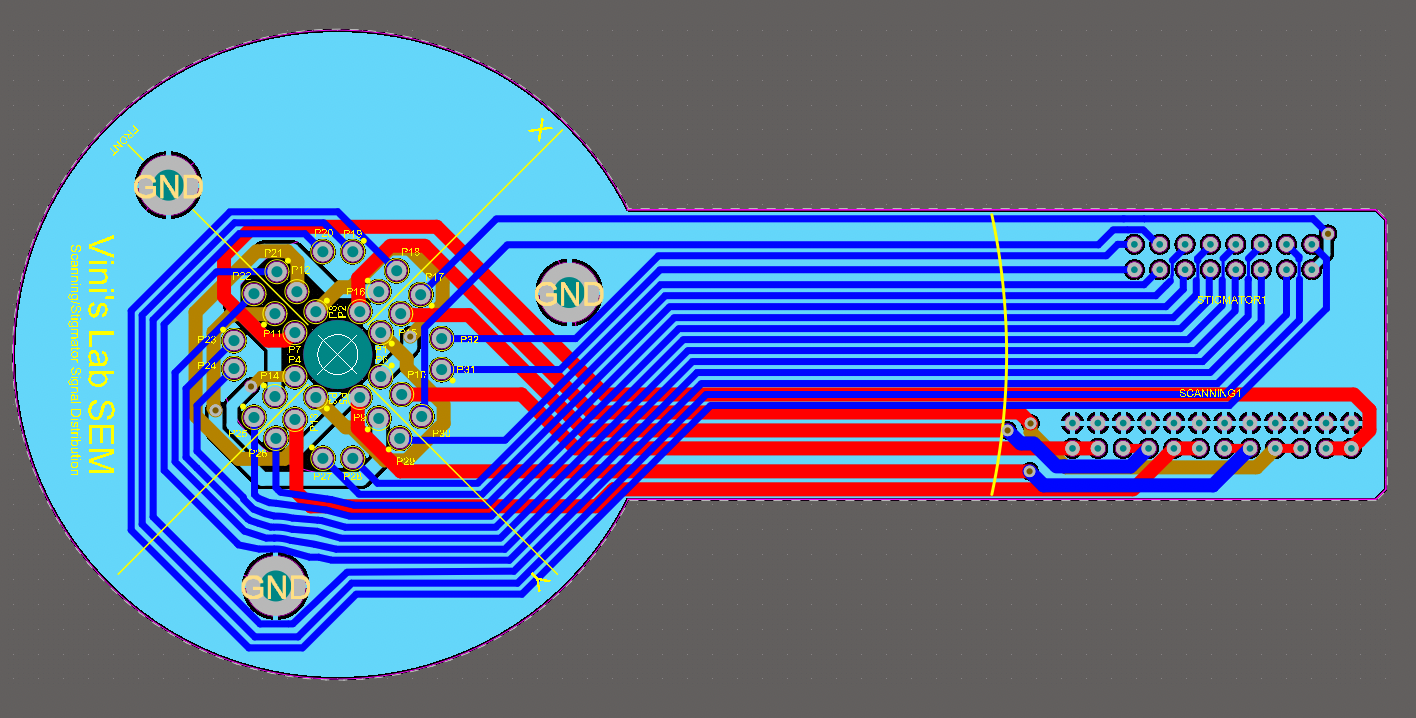

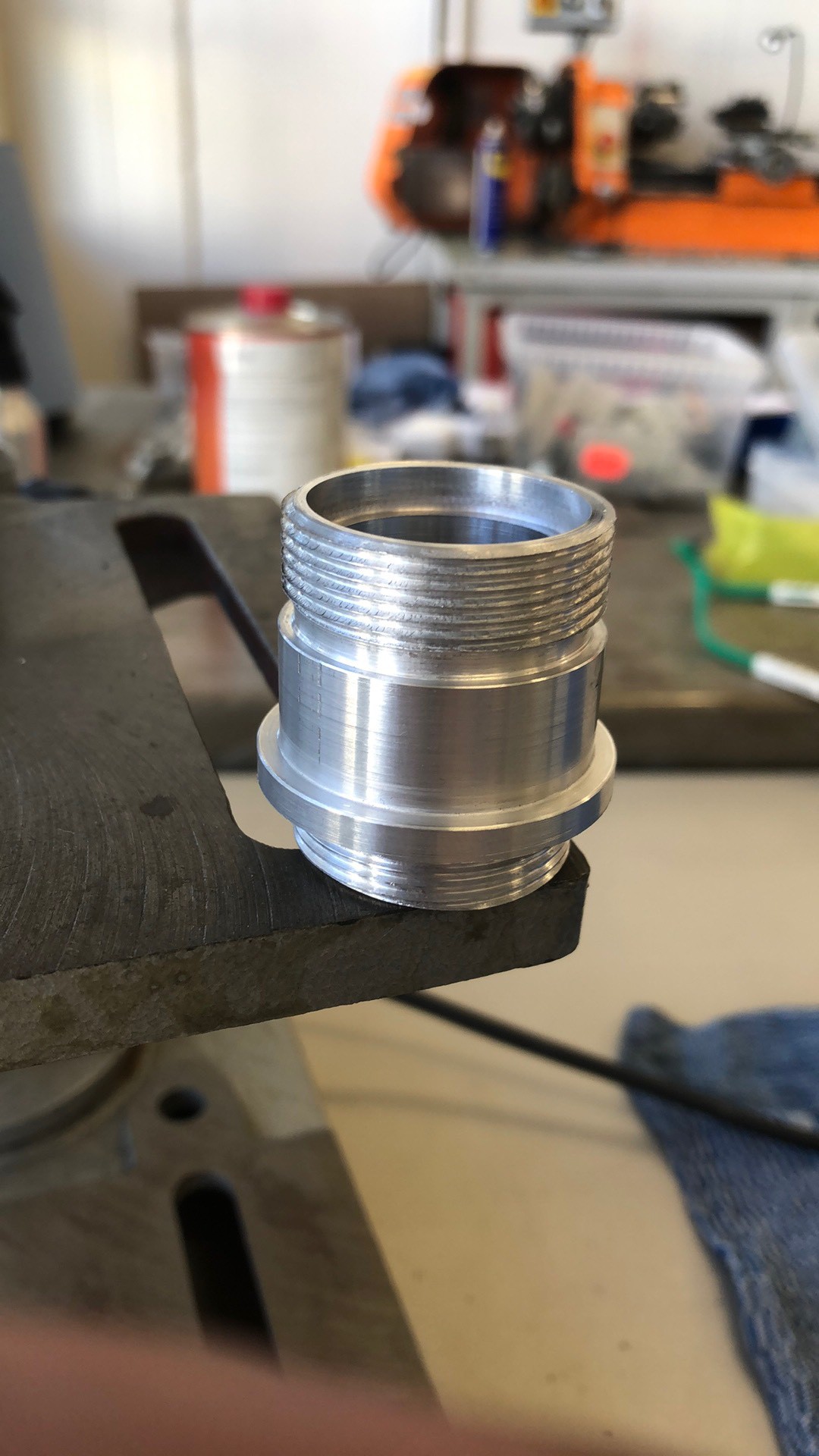

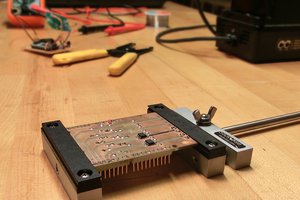

In 2011 Ben from Applied Science YouTube channel built his own SEM and since them I wanted to replicate his project but in a less hacky matter, something I could use in future science projects.

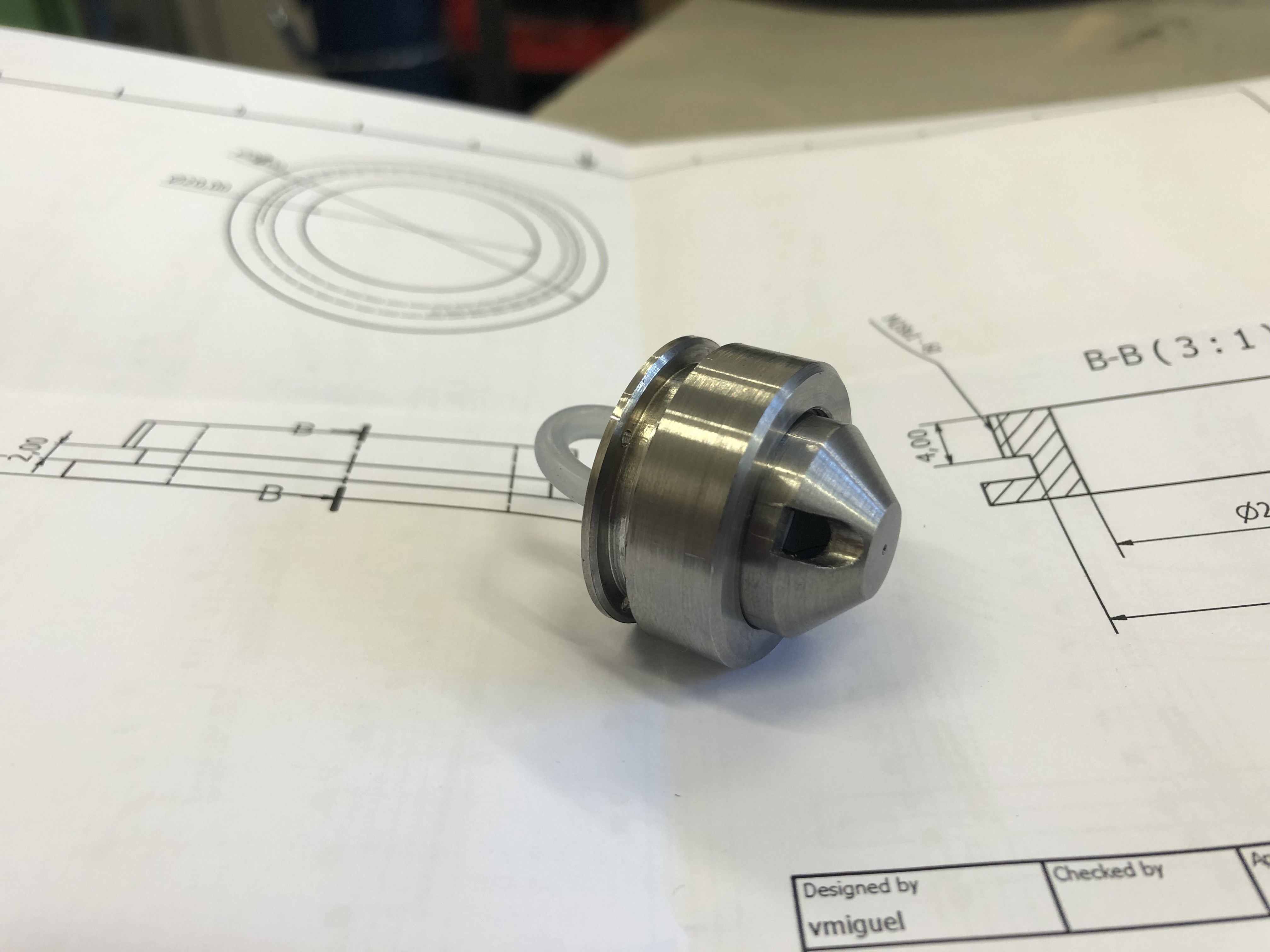

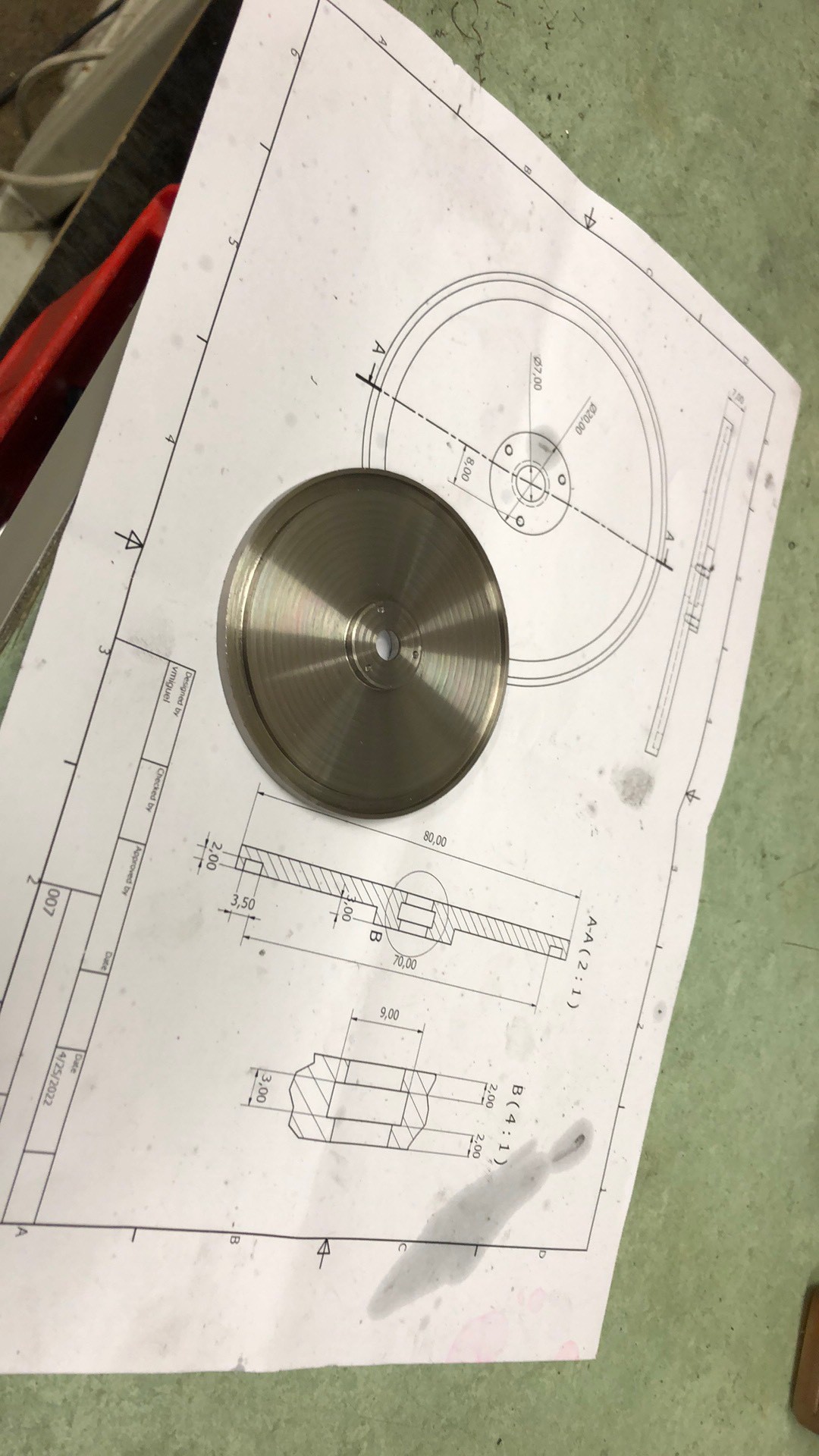

It's a quite expensive project even if you have all the tooling to make the parts yourself so took me a long time to be able to afford building this instrument and many countries lived, until now, living in Germany I have better access to tooling and parts to be able to fabricate this.

It's been almost an year since I start to collect ideas and started to fabricate the first parts, it will take many months still until the first image shows up, but I decided was time to start to document this project and share with you guys my journey.

Regards,

Vini

Vini's Lab

Vini's Lab

Andy

Andy

Alex Rich

Alex Rich

zapwizard

zapwizard