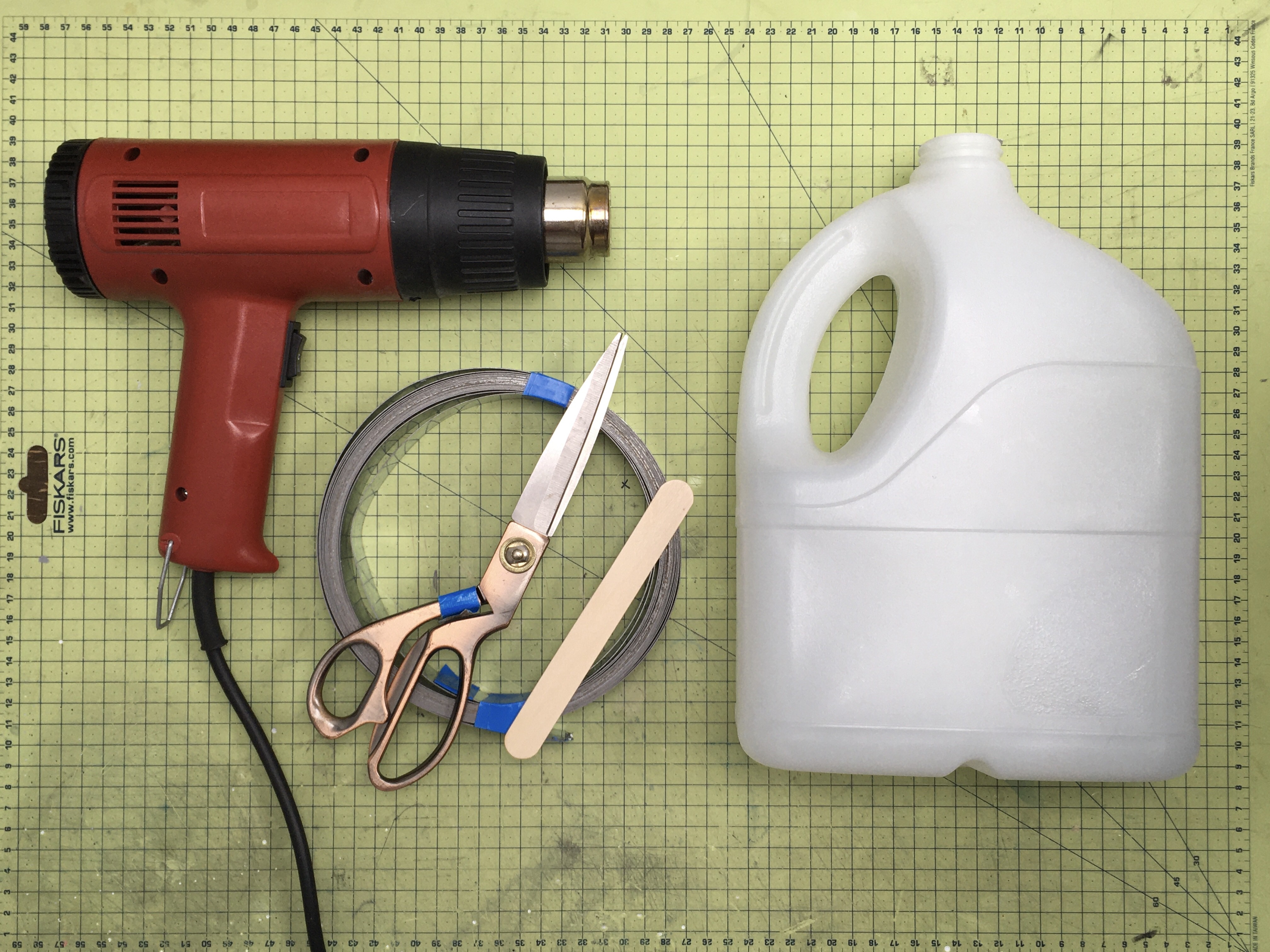

The process of Vac Forming with HDPE was pretty straightforward - the slightly tricky part was getting it into a flat sheet! To do this I cut out a section of the milk jug as show, with the approximate dimension of the size used in my Mayku Formbox (~225mm square), and used a heatgun (or a hairdryer will work) to warm up the plastic gently. Given that thermoplastics have 'memory' they will naturally try to revert to their original form. Taking care not to create any hotspots by keeping the heatgun moving around, the plastic becomes warm enough to flatten out and even stretch slightly (wearing gloves) to the right form factor.

From this 'rough' square, it can be clamped into the Formbox (or any other Vac Former), and if given a little heat, it will 'level out'. You could actually stop here and create a 'ready to go' sheet for future moulds, or indeed, keep hearing up and form as you would in a Vac Forming process as usual. More images here.

One thing I did notice was that Vac Forming with HDPE is slightly at the limit of the max temp of the Formbox (though many industrial Vac Formers go higher, so this is not an issue), but to speed up the warming I simply made a small 'heat shield' from some metal from a biscuit tin, and this meant it warmed up faster. Indeed, Mayku were so impressed by this little trick that they now sell it in their shop!

I hope you have great fun making this, and please share any results from this or other plastics. One safety note is to check what fumes might be given off when heating plastics - luckily HPDE is not toxic, (another great reason to work with it!), but do read the MSDS first!

Disclosure & Disclaimer: I was given a Formbox by Mayku to experiment with, but this project was done under my own initiative, and is not directly affiliated with them, so please know you do this at your own risk with Formbox or indeed any other Vac Former, and neither Mayku nor myself can accept responsibility for any damage or harm caused by attempting this 'hack'.

CC: Attribution-NonCommercial-ShareAlike 4.0 International (CC BY-NC-SA 4.0)

jude_pullen

jude_pullen

Brainy.Baboon

Brainy.Baboon

Quinn

Quinn

Michael Barton-Sweeney

Michael Barton-Sweeney

xdylanm

xdylanm

Having had a look at your project, it would seem fine to form over something as small as a sweet... Perhaps the smallest (realistic) size would be like a 10x10x10mm cube? It's probably about 0.5mm thick, so keep that in mind also, and avoid sharp edges (even a 1mm radius helps).