Its my first time trying to document something. Sorry in advance if its a bit chaotic...

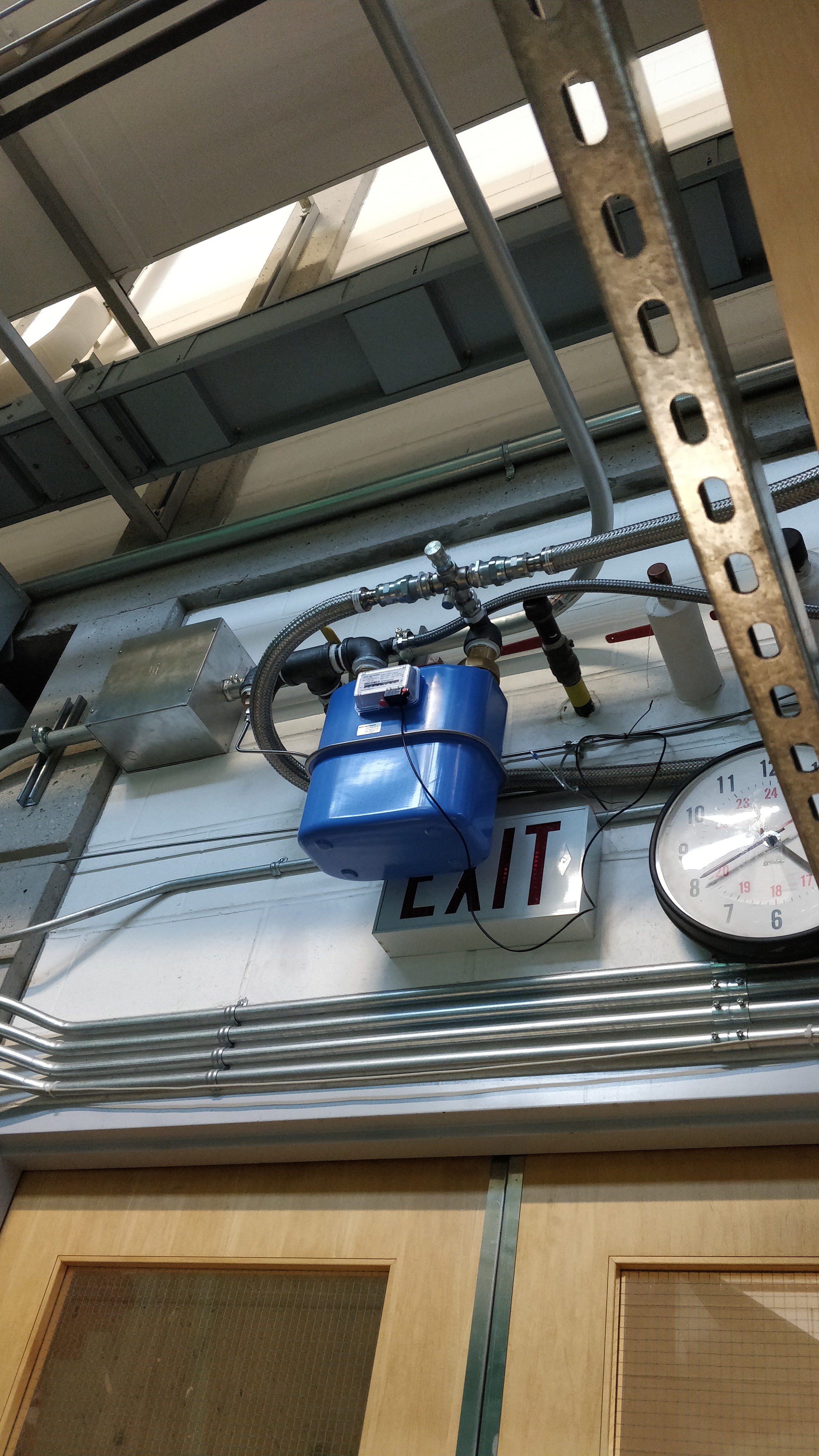

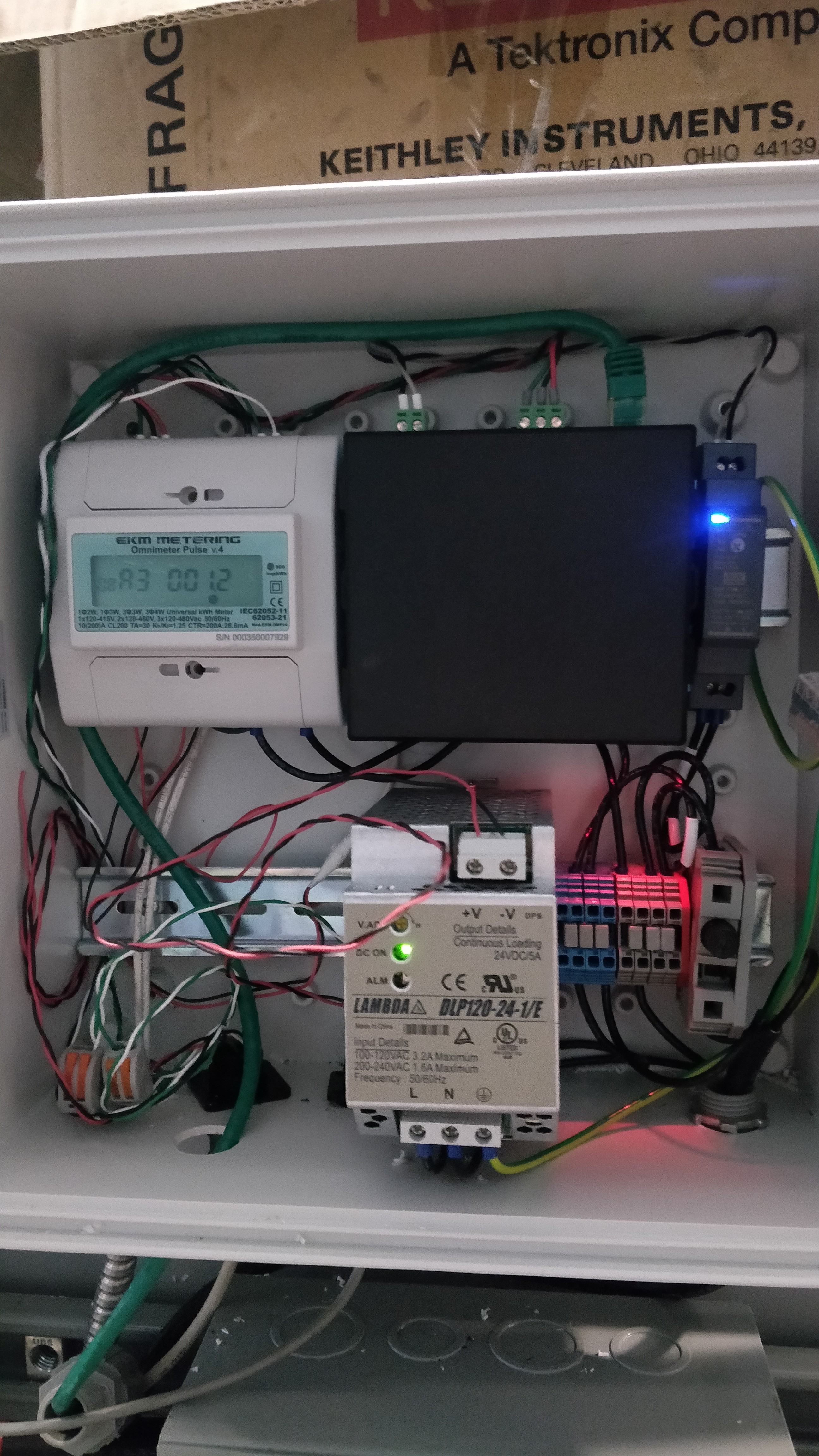

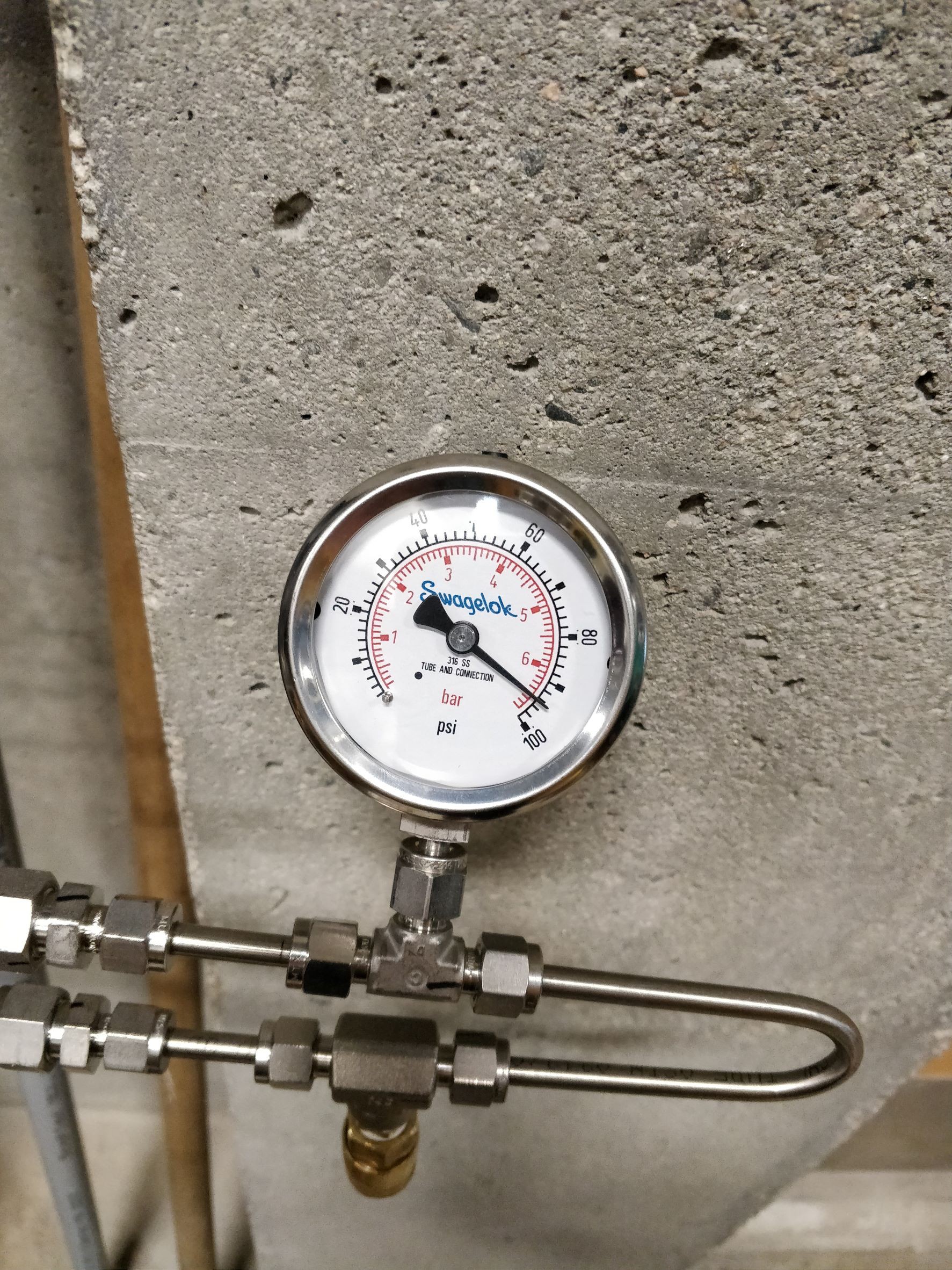

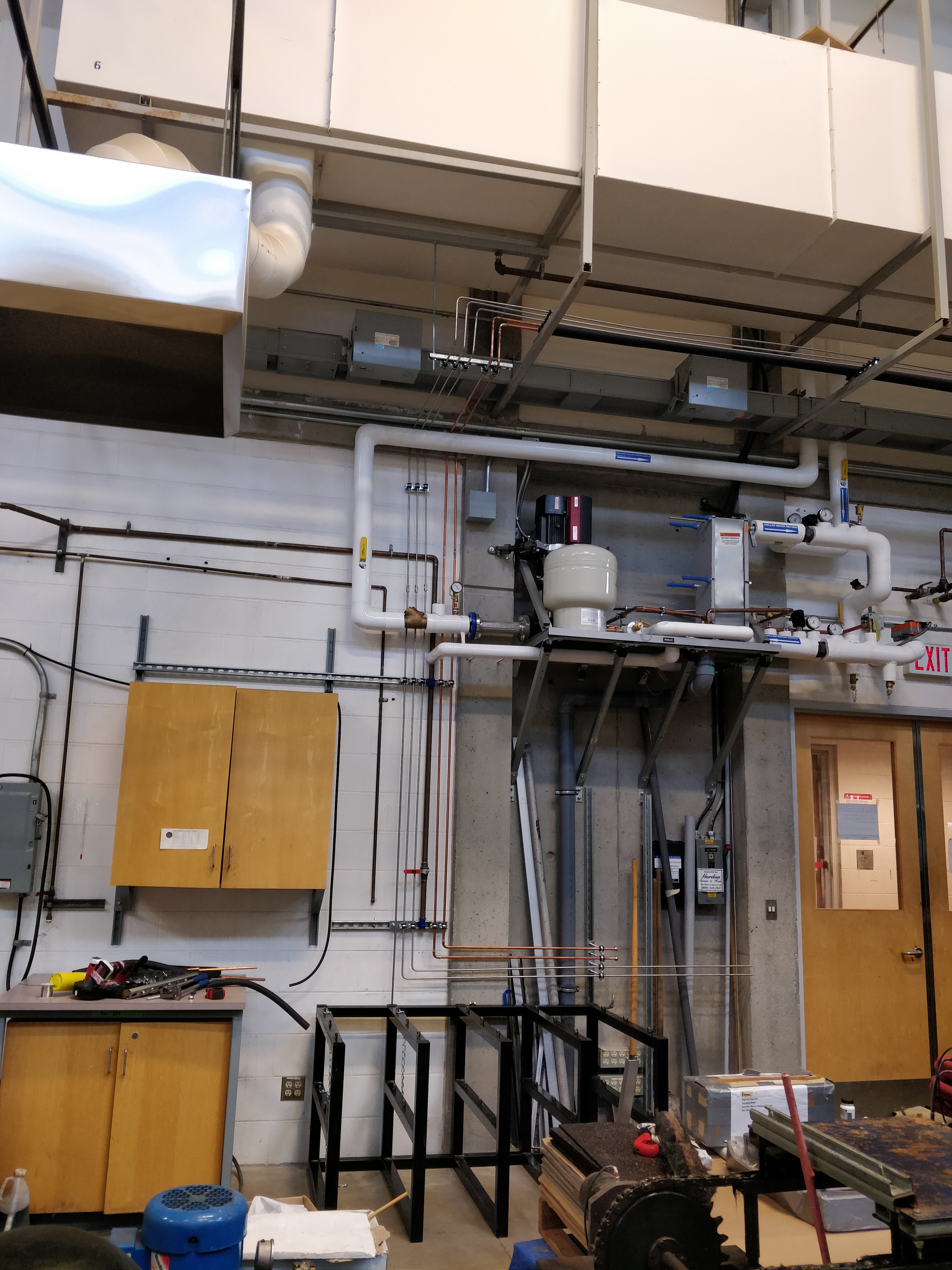

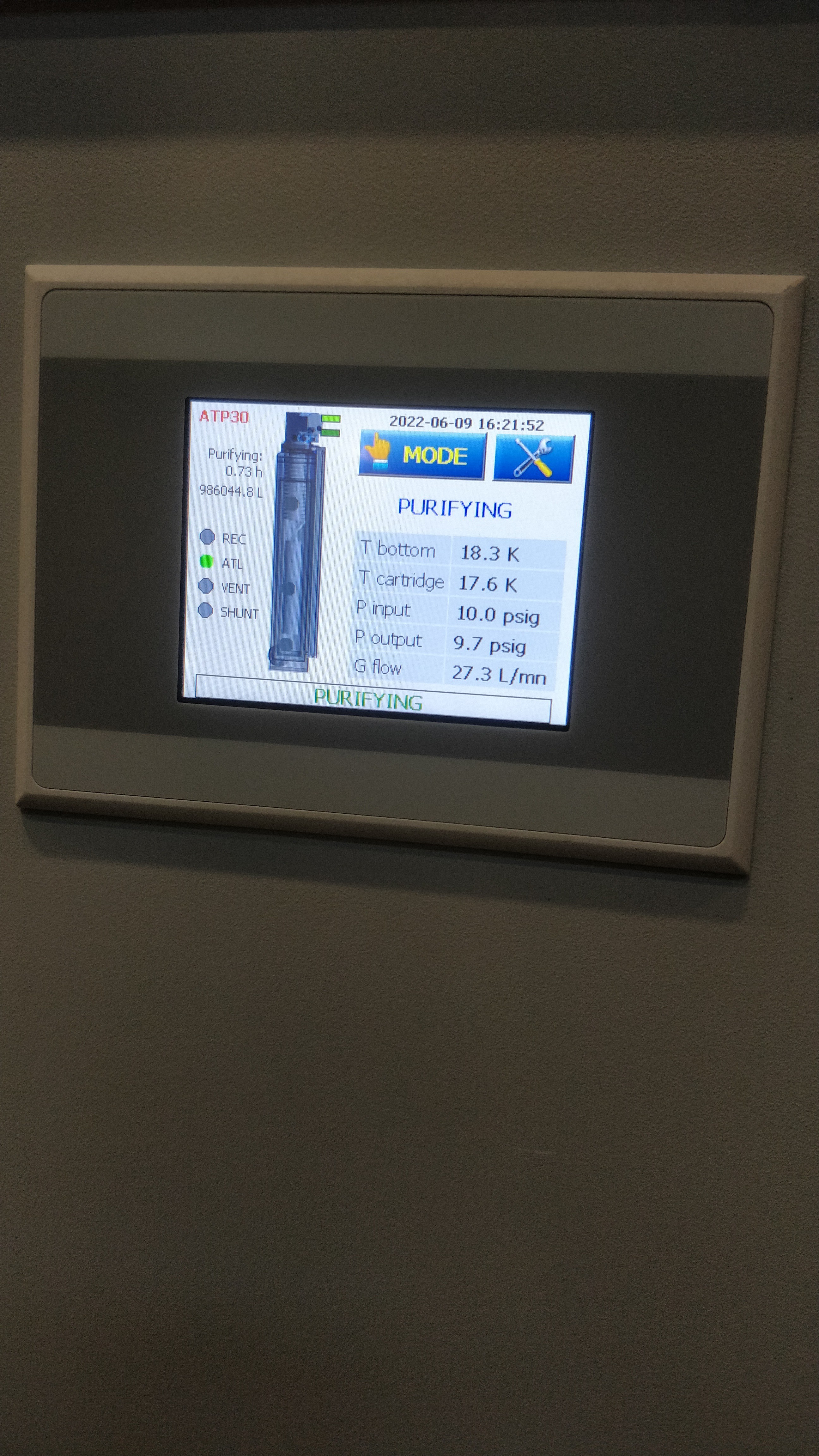

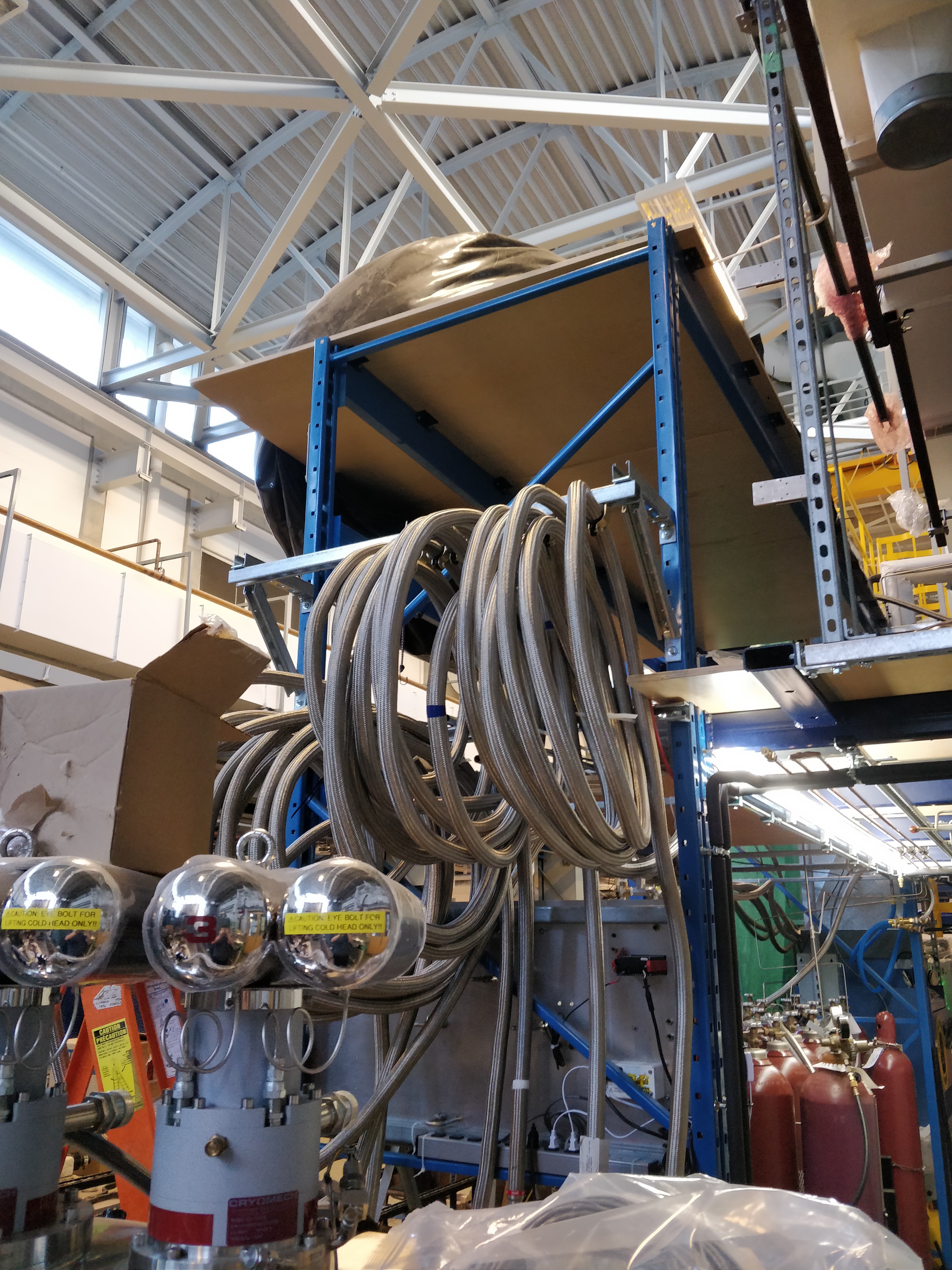

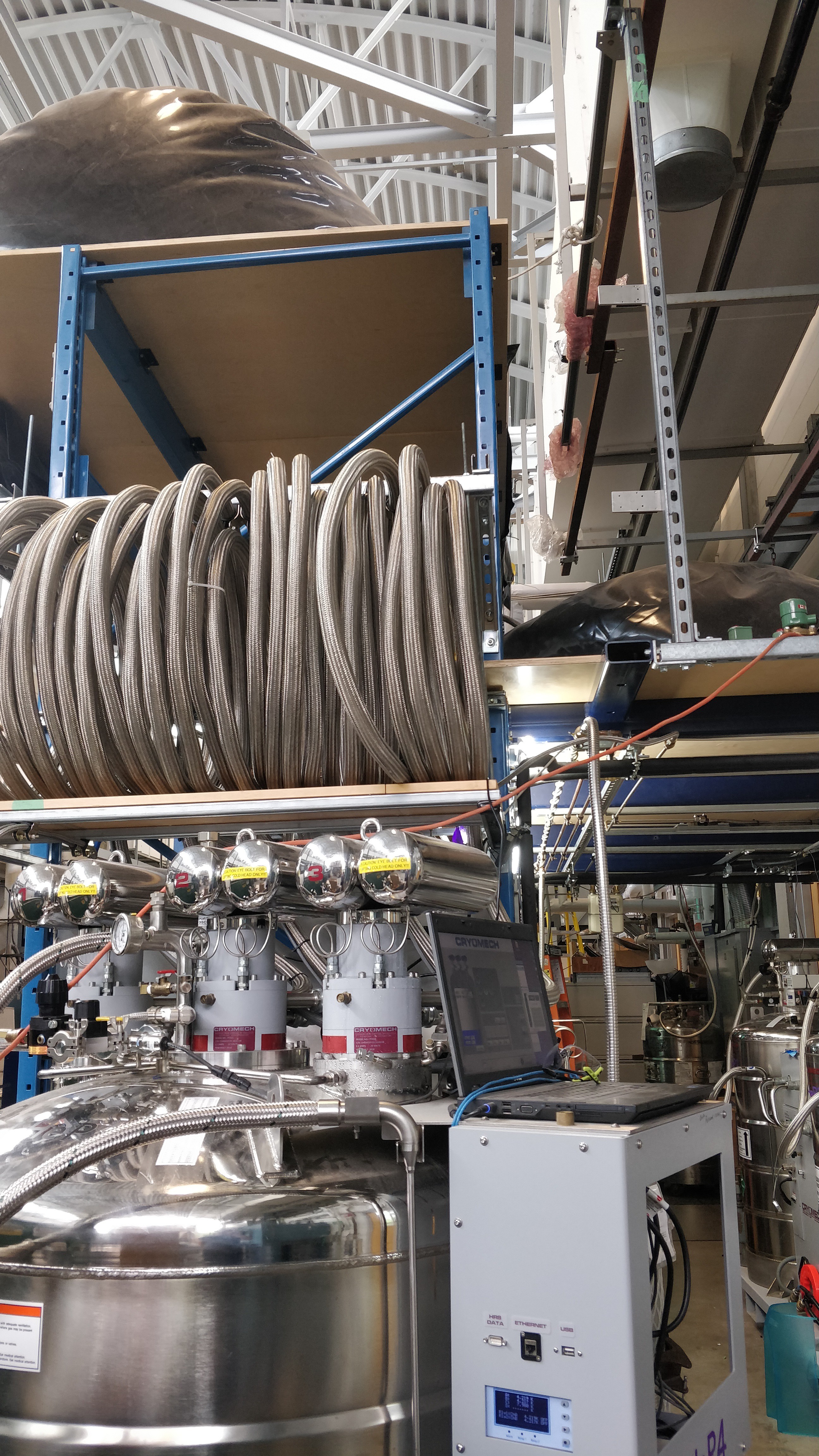

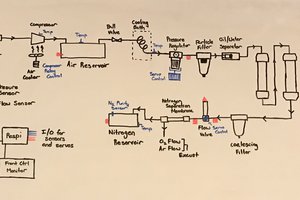

I manage and maintain a helium recovery system for a lab. We have a closed cycle helium recovery system. I give labs liquid helium and they use it and it comes back to the system as gas.

We use liquid helium because of its cold temperatures. Regularly at 4.2k. We recycle helium because its fairly expensive to get and its not a very renewable resource. a big part of my job is to babysit the machines and make sure they are working properly.

Meow

Meow

This took place between 2020-2021 It took a few months to set up and fully finish. It took a while to run the electrical, set up plumbing for water and run the helium gas lines.

This took place between 2020-2021 It took a few months to set up and fully finish. It took a while to run the electrical, set up plumbing for water and run the helium gas lines.

Dave Ehnebuske

Dave Ehnebuske

Rory

Rory

Leo Mahdessian

Leo Mahdessian

Audrey Robinel

Audrey Robinel