My Smart FishRoom/Animal Room

how i'm building my fishroom (aquariums), and what i do to automate it and make it smart.

how i'm building my fishroom (aquariums), and what i do to automate it and make it smart.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

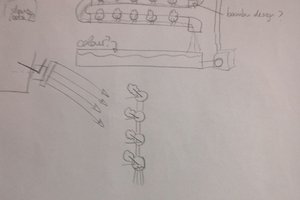

Following the work presented in the previous post, i routed the chanels for the top planks :

I routed with a 12mm double flute router bit with 5mm passes approximately, with time between passes to let the tool cool down (a makita compact palm router, that i bought for my CNC).

I generated quite an amount of dust and shavings, but hopefully, i have my home made 3D printed cyclone (link is to hackaday.io project) to help me cope with that :)

At this point, it's a matter of sanding a bit, then applying oil.

I used 8 layers of oil (the oil dries quickly, so i took me a day or two at max), with sanding by hand with 500 grit sandpaper between each layer.

It turned really smooth, and i'm very happy with the result.

The platters have simply been oiled 2-3 times, with little to no sanding in between (they'll be covered by a mat, then by the aquariums, i just wanted to waterproof them a bit)

So next time, we'll install the frame of the second level on top of the first level, secure it, then put the platters in place.

The first level of the rack has regular feet : vertical beams attached to the main surface.

But for the second layer, i need to be able to secure those feet to the first one. To do this, i decided to simply add a cross beam at the bottom of the foot assembly : instead of havint an inverted U shape, it is now a square shape (with a square hole in the middle):

As you can see, i kept the general shape of the previous layer, but added this bottom cross beam.

It will allow me to drill it, and secure it to the bottom layer with screws, thus making it really stiff.

You can see the two beams that will help me make the surface of this level, and obviously, i need to add 3 perpendicular beams (one on the top of each foot assembly) to have everything at the same level.

But for that, i secured the feet to the beams with screws, to have it beeing in the right position :

At this point, i measured the distance between the beams, and cut pieces to fill this part.

I turned it over to screw those beams from below :

On the picture above, you can see the second level from below. As it's built, it doesn't stay square by default, as only one long screw secures each corner of the rectangle, so it could easily end up not beeing square.

To correct that, i added metal L brackets at the junction of the long beams and each foot. I painted them brown, but perhaps a lighter brown would have been better.

This not only keep the top square on the X/Y plane, but helps keeping the feet perpendicular on the Z axis.

It's not on the picrue below, but the cross beams are secured with 2 5x70mm wood screws from below.

Next step is carving a groove in the top of the wood to be able to drop a 15mm thick plywood plank in each of the large rectangles, as for the first level; then rounding the edges with the router and thus oiling the wood.

I bought the lumber for the second level of the aquarium rack.

Again, it's raw tiger wood. This time, i worked the wood better :

Last time, i used the electric planner then the orbital sander : it is really ineficient. The belt sander is incredibly faster, and in my case, gave a comparable surface finish. Obviously, with fine grain on the orbital sander, you can go smoother. However, it has little to no effect on the final piece once oiled.

Indeed, when oiling the wood, it will raise the grain, and you will have to sand anyway between passes. In the end, this time, i skipped the orbital sander completely, but used 500 grit sandpaper, by hand between each layer of oil. It was a faster process, and i got a way smoother result (however last time i used only 3-4 layers of oil, this time i did use 8 layers).

You can see on the picture above the wood after sanding, before any oiling.

All in all, this went much faster, but the wood was neither straight nor square, i would really love to have access to a planer. However, i did without it, and ended up with a pretty close result to what i had designed. However, the assembly required a bit more work to compensate for 1-2 missing/extra millimeters here or there.

In the next log, we'll see how i made the foots for the second level of the aquarium rack.

With most aquariums, you need a filter to remove muck, and also to extract toxins from the water. I used to make filters out of PVC tubing, but i decided to design a filter that would be fully 3D printable, and modular. I may create a separated project for it later, but here's a video explaining it :

Compared to other DiY filters, this one takes longer to physically create, since you have to wait for the printing. However the printer works alone :)

Assembly is fast (a few minutes), and the filter can be altered, expanded, modified, etc...

If you want it larger, simply print more chambers and install them!

See you next!

In the last post, i presented the waste water management. This time i improved it :

Cheap plastic ball valves for the win :)

In the previous post, i described how i built the water output for the room.

Today i made a small video (sorry for the audio quality at the start of the video), showing how i use this newly installed system to make my water changes easy :

Previously, we saw how water comes into the fishroom. So we have a water source to make top-ups, to compensate evaporation. However, for water changes, we have to throw away dirty water. In this post we'll focus on adding a conveniant way to throw water away.

This is simply done using 40mm PCV piping. The idea is to have an horizontal pipe (with a slope), to get water from near the aquariums, to the outside.

To get water IN the pipe, we need an access. For that purpose, i added four T PVC pieces on this pipe, with the openings vertical. Each T recieves a 20cm pipe. We thus have a few upward pipes, opened at the top.

This is then a matter of introducing a smaller diameter flexible tubing, and doing a siphon from the aquariums. We have an exit near each aquarium, so that we don't need long tubing to siphon, as shown on the picture below:

The previous circuit joins a second pipe that gets the water near a hole to the outside.

Here is what it looks like (dry fit, not in the good orientation) :

So, once everything was good, i glued the circuit in 2 parts, and one joint is just friction fit, to keep things adjustable.

I tried it, changed aproximately 100 L of water with no leaks, and without a sweat :)

This makes it so much easier to do the water changes, i will now be able to maintain pristine water quality!

I tend to consider that for a security system (such as a blade guard on a circular saw) to properly work, it must be easy and conveniant to use. Otherwise, users bypass it, or don't use it at all. I applied the same philosophy here : for me to do my water changes, they have to be easily done, so that it's not a chore.

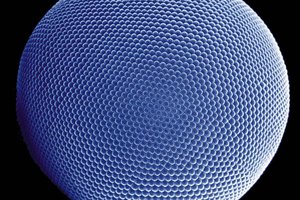

All of those systems are meant to house my fishs and shrimps. It has other no relation to this very post, but i can, so here are two 4K pictures of my Neocaridina Davidi Sakura red shrimps, with a berried (she has eggs under her belly) female :

And now two females, with the one in the background beeing the berried one :

Here is a very young (2 weeks top) baby shrimp in the same tank (aproximately the same scale on the picture):

it is this hard :

This is a 4mm wood drillbit, and it got like that when i was drilling the wood...

For sure, it wasn't a high quality drill bit (quite the contrary) and the tip was a bit dull (hence the force i applied). However, it never happened to me prior to this, even with bent drill bits...

On the other end, metal drill bits drill perfectly trough this hardwood, with clean, nice edges.

However, i had no problem drilling with a quality 4mm wood drillbit (quite a long one, because i had long screws), but i had to be more careful (slower, cleaning the bit more often).

I made a little VLOG on youtube to update you on my progress :

Sorry for my english, i'm a native french speaker and didn't practice english for a few years :(

This project uses nice wood, so i went for a natural finish. First step was sanding :

As you can see, sanding dulls the figures of the wood, but it's not a problem, it will come back once some finish is applied.

Indeed, here is the same piece, with one fresh coat of transparant oil :

At this stage, the oil raises the grain of the wood. I thus sand it with fine grit sandpaper, with the oil still wet. This is a very light sanding, and it helps removing the risen wood grain, but doing it with the oil wet causes the wood dust to fill any cracks on the surface, giving a very soft touch.

With this oil, you're supposed to use a clean rag to remove any excess. In this case, i did apply just the right amount to save on product (that's my last bottle of transparant oil, and there's none at the store, so i wanted to be sure to be able to finish the pieces).

After a few hours (it's 27°C in here, tropical place, so no winter ;) ), it has dried, so i can sand lightly with fine grit sandpaper, then apply a second coat. Rince and repeat for as many coats as wanted; recommanded is at least 3.

Indeed the second and third coat revels the figures of the wood even more; but i stopped there to conserve oil.

Since this oil doesn't release nasty chemicals in the air, i'll be able to add more coats later on, on the assembled rack in the fishroom (anything releasing dangerous chemicals is banned from the fishroom : shrimps are very sensitive, or at least supposed to be. I'm taking no chances here.).

On the picture above, you can see the oiled beams (still wet, you can see that it's milky before drying), as well as the oil can i used.

it is Syntilor Oil (natural finish) for furnitures and work surface. It has an A+ for emission rating, meaning very few emissions. It's easy to apply, gives a good finish and tools clean with water, so no need to use smelly chemicals to clean your brush.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Jan

Jan

Xo Ne Un

Xo Ne Un

Roberto Vicente Romero

Roberto Vicente Romero

Kenji Larsen

Kenji Larsen

Beautiful tanks! How did you do the lighting? Do you add CO2?