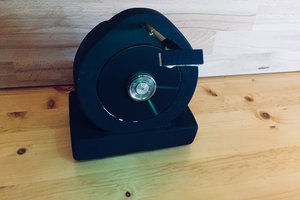

An analog clock with no hands (well not in the standard sense), rather the hands are virtual and created by the effect of UV light on photo luminescent material. Hence called an Analumi-Clock. (Analogue Luminescent Clock)

This is a revision of the Analumi-Clock. Why a revision.

Well the first version was more a case of having a working design rather than how it looked.

Therefore, the look was given more consideration in version 2, this is in addition to a number of other changes.

In the original version the housing was simply to conceal the electronics but left the display exposed which made it vulnerable and given the size and positioning of the housing compared to the display made it somewhat disjointed. This style also meant that it was only really suitable for shelf mounting were there is less chance of impeding the display.

The new enclosure started life as a floating shelf which seemed ideal in many ways. It could be mounted in a number of ways; shelf, wall or table and would support both the display and house the electronics. It's minimalist clean lines also fitted in well with a clock with no physical hands.

One of the changes in the electronics was in the servo driver board.

There is a requirement to switch off individual LED's to differentiate between the hour and minute hands.

The original servo driver board was chosen due to its lower cost and small size but was later found it would not allow independant switch off of a channel used to control an LED, the LED was always on, although intensity could be varied. This therefore required some means of switching off the required LED and was accomplished by adding a MOSFET pulldown circuit. This workaround still enables the cheaper board to be utilised.

However, changing to the board used in the Lumi-Clock simplifies build and control, enabling easier modification of hand configurations without recourse to additional boards.

The other change removes the Pinbetween.

The LED arm was modified to reduce its overall size and also to remove the Hall effect sensor from the front to improve the asthetics. The Hall effect sensor was moved to the motor board at the back and the disc flange modified to accomodate the ball magnet at this new location.

Different methods of photo luminescent display were evaluated both opaque film and translucent filament.

In this case opaque film has the following advantages, brighter and slower decaying light emission, improved resolution leading to better visibility under higher ambient lighting conditions for longer compared to a filament disc.

UV LED's are used to illuminate the luminous film but require some means of moving the film under the LED's to create the hands.

This is achieved by using a single stepper motor which can rotate clockwise and anti-clockwise.

Fitted to the stepper motor is a CD or similar disc and to this is fixed the luminous film.

A fixed arm is at the 6 o'clock position and to this 8 LED's are attached to form one column.

As the motor rotates the luminous film moves under the arm pausing momentarily whilst the required number of LED's for the appropriate hand are switched on.

Each hand is created in turn with the appropriate angluar offset resulting in both hands coming to rest at the required positions for the analogue time being displayed.

Control is provided by a Microbit in conjunction with a RTC, servo board and bespoke logic.

The LED arm, dial and motor support are 3D printed.

Bjorn Bosell

Bjorn Bosell

Zach Archer

Zach Archer

danjovic

danjovic

Mark Wilson

Mark Wilson