Having mulled for a while over whether I should get a laser or a router, I opted for the latter because it seemed like a more versatile (and cheaper) option. It arrived about a month ago, and this was my first real project with it:

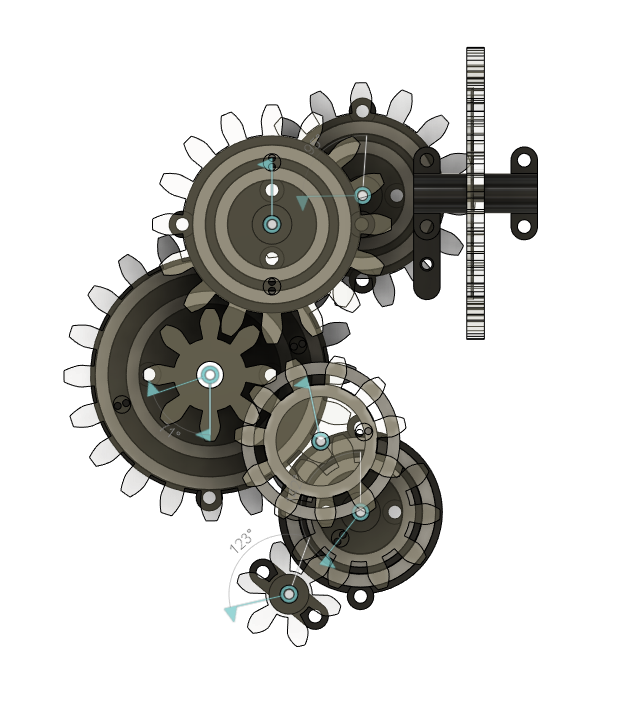

One of the goals was to do things I wouldn't have been able to do with the tools I had previously, so that led me down a circular and curvy path. While I initially was planning something very simple, maybe a few acrylic plates with electronics spread across them, I figured that adding a bit of rotational motion wouldn't hurt anyone. That quickly turned into a myriad of gears across two floors, with DIY slip rings to provide power to the LEDs attached to the gears, and a piezo element picking up the vibrations for amplification.

The biggest issue I had was to get the lead screw aligned through the structure. The lack of concentricity, due to a dodgy 3D printed coupler, caused the lead screw to grind along the edges of the holes on each level as it rotated, and also made the gears butt against each other with more force than necessary. Unsure whether a proper coupler would solve this, and I also didn't feel like waiting for said proper coupler to arrive, I shoehorned in another motor on the top of the structure both to provide more torque, but more importantly, fix the alignment of the lead screw. Thankfully that worked, and the project was finished.

It's rare for me to leave so many aspects of a build up to chance, but I was willing to push my luck a little bit in the design phase. Having learned a few hard lessons, I'm sure my next project involving gears and motors will be a breeze. Below is a video of the construction process:

Adam Jensen

Adam Jensen

Josh Cole

Josh Cole

Martijn

Martijn

Greg Kennedy

Greg Kennedy