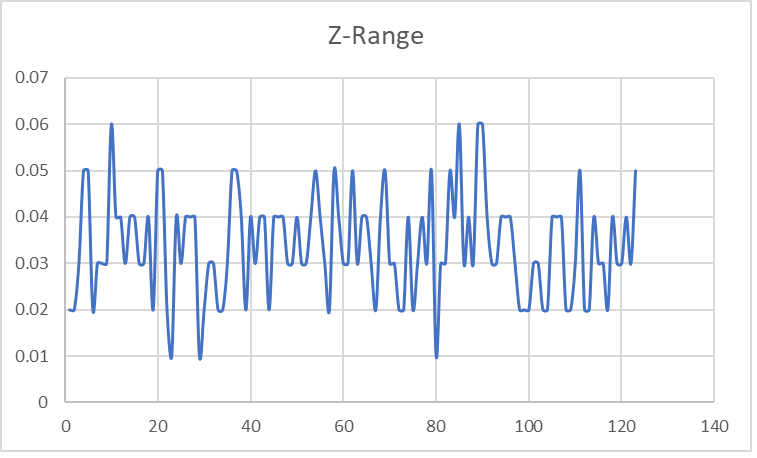

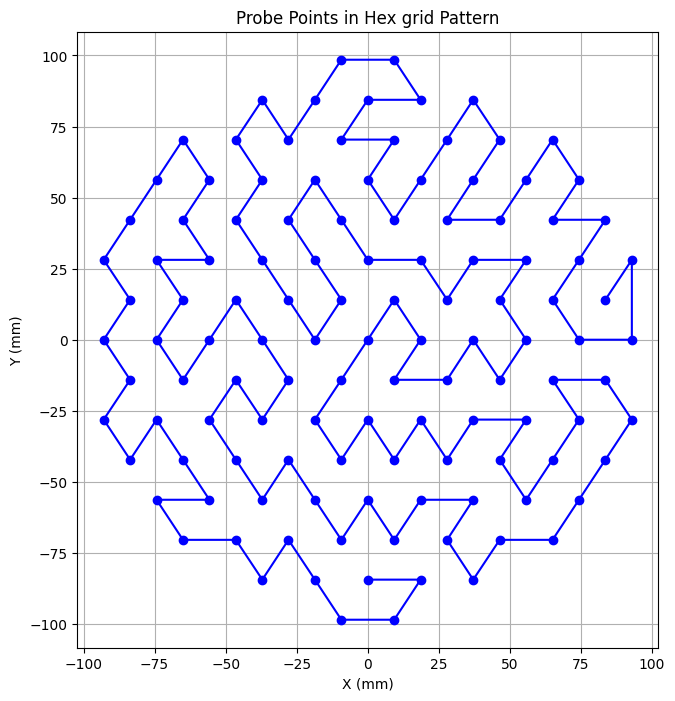

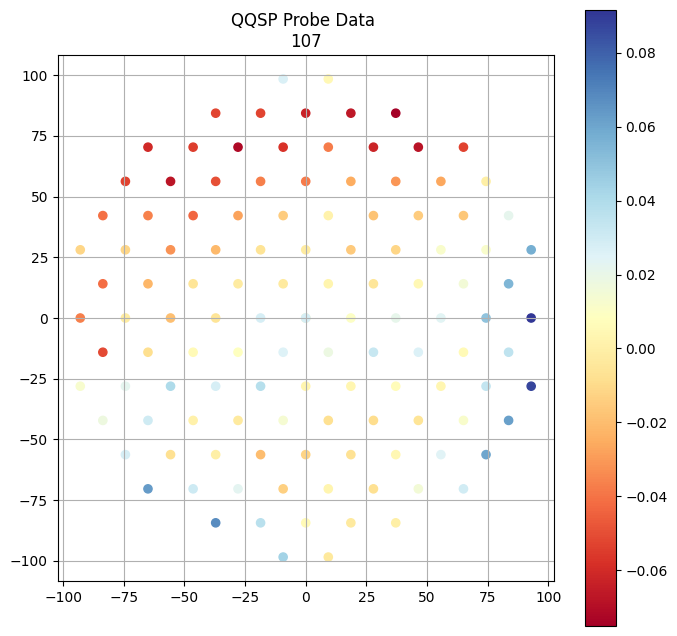

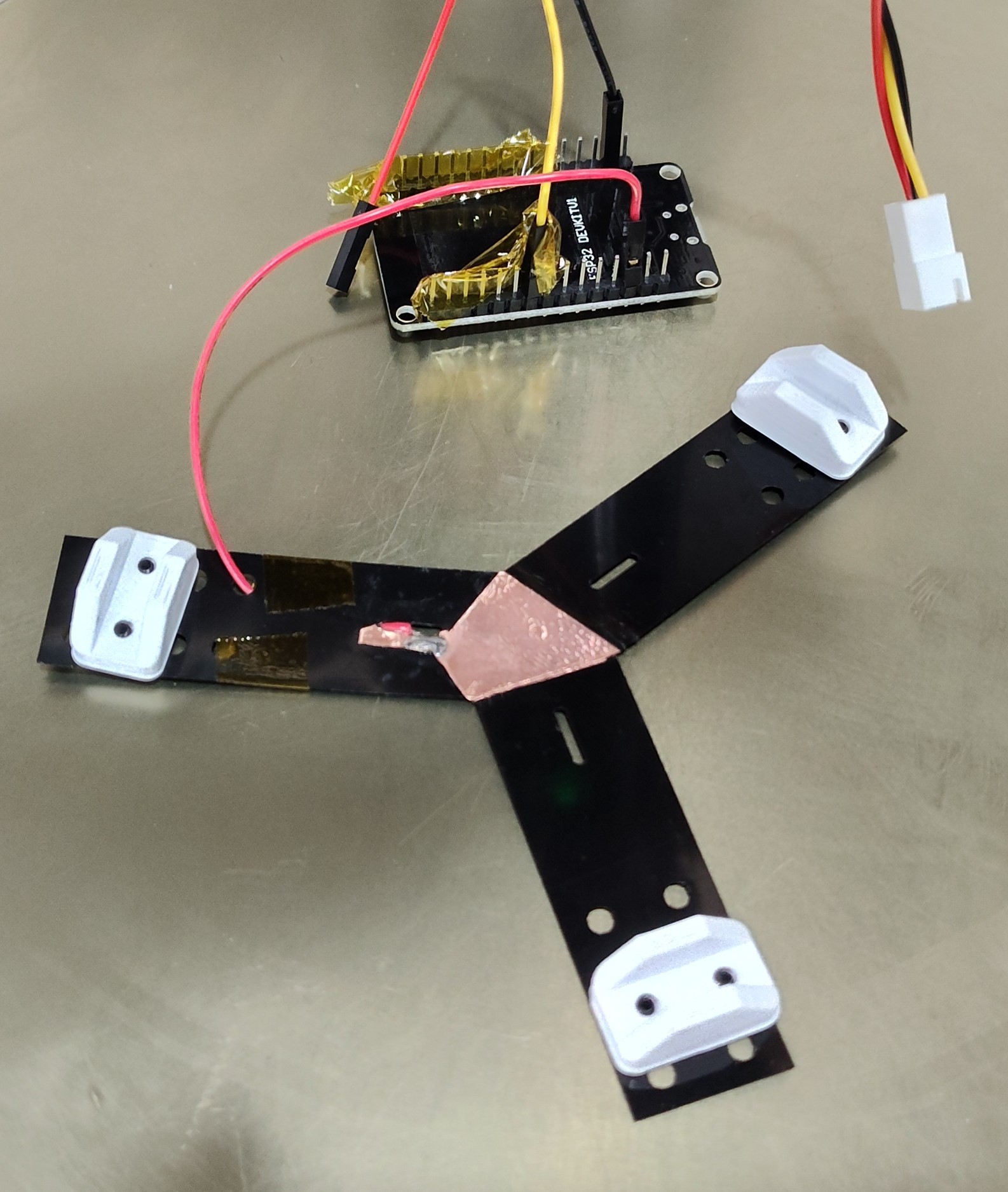

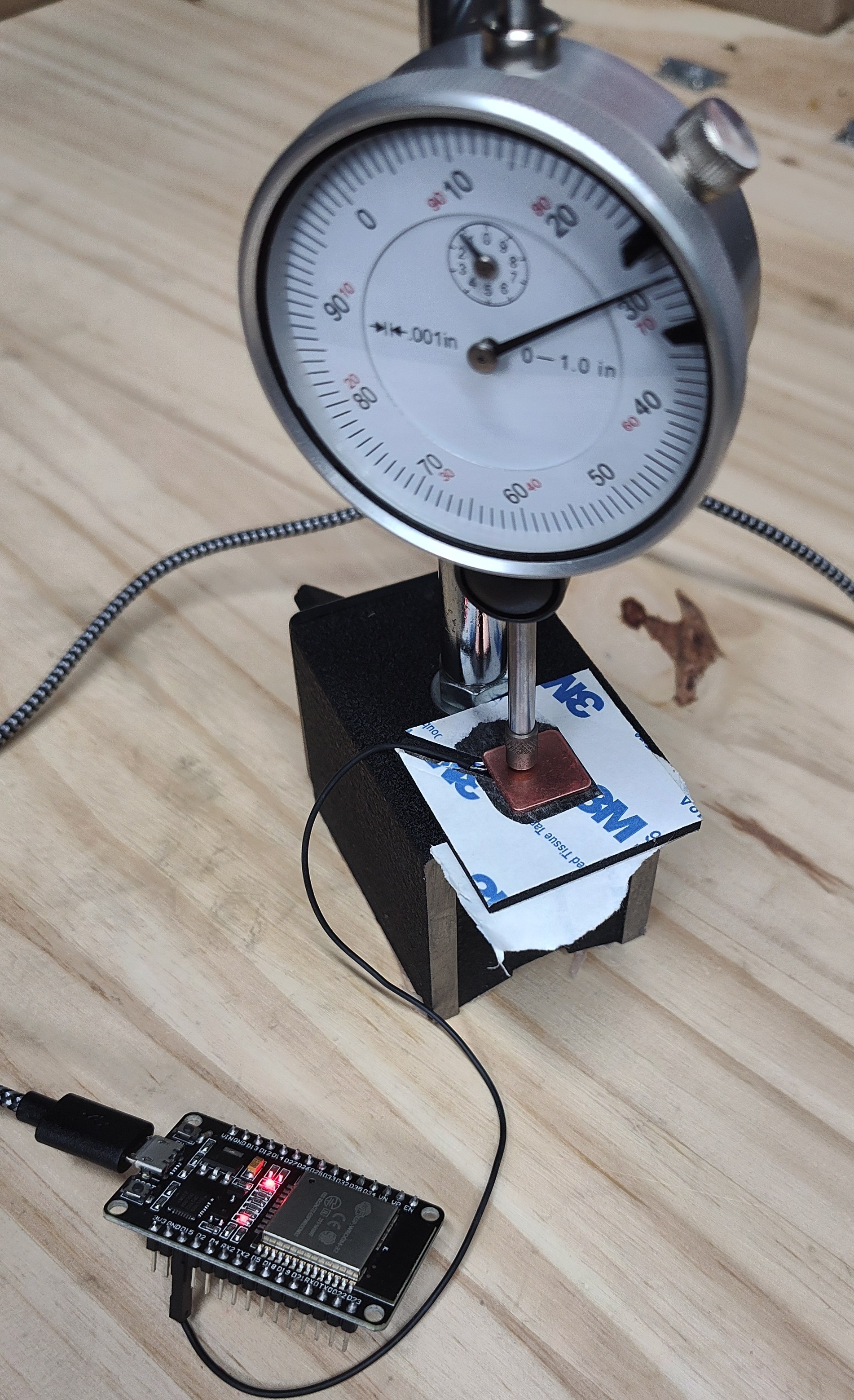

The delta calibration guide for klipper recommends a 0.025 mm consistency or better for automated probing. Testing of this probe location bias on my FLSUN QQ-S Pro with the stock magnetically attached probe showed the bias was at least an order of magnitude higher. A concept was developed to retain a 15mm x 15mm copper pad under the nozzle. As the nozzle lowers the pad will first contact and become parallel with the bed prior to the nozzle touching the pad. The design was refined to use a 40mm x 40mm foam pad and 2nd copper shim to basically make a 5mm thick sheet of paper.

Delta Printer - Capacitive Nozzle Probe

Test accuracy and consistency improvements of a capacitive bed probe triggered by contact with nozzle.

mulcmu

mulcmu

Shawn Gorman

Shawn Gorman

DeepSOIC

DeepSOIC

Mark Rehorst

Mark Rehorst

Daniel Westhof

Daniel Westhof