-

Tearing down the house

03/05/2017 at 02:23 • 0 commentsandNote: I've changed the project description. The Stratasys is actually only 22 years old, not 30. This discovery comes later.

I'd already looked over the Stratasys parts when I pulled them from the original housing and I'd estimated I could likely fit the parts inside the fridge after removing some of the excess housing material.

The way the mechanics of the FDM 1650 had been built was as an aluminium plate box containing the vertical axis/bed with an existing pick & place machine on top holding the print head.

The pick & place machine was an Asymtek Automove 302.

![]()

That's it's rear panel sitting on top of it. It was already off when I got to it, and the wires connecting to it had already been cut.

On it's own, that wouldn't have been too bad. There's no smarts inside it. The sum total of the electronics within consists of two stepper motors and an endstop board.

That wasn't the only problem though. In addition, I'm in the UK. This was made in the USA. Not only are all the parts and fittings imperial, they're American imperial. And half the screws are either missing, sheared off or have heads that are totally chewed up. It was easier to dismantle the housing than open the service panel.

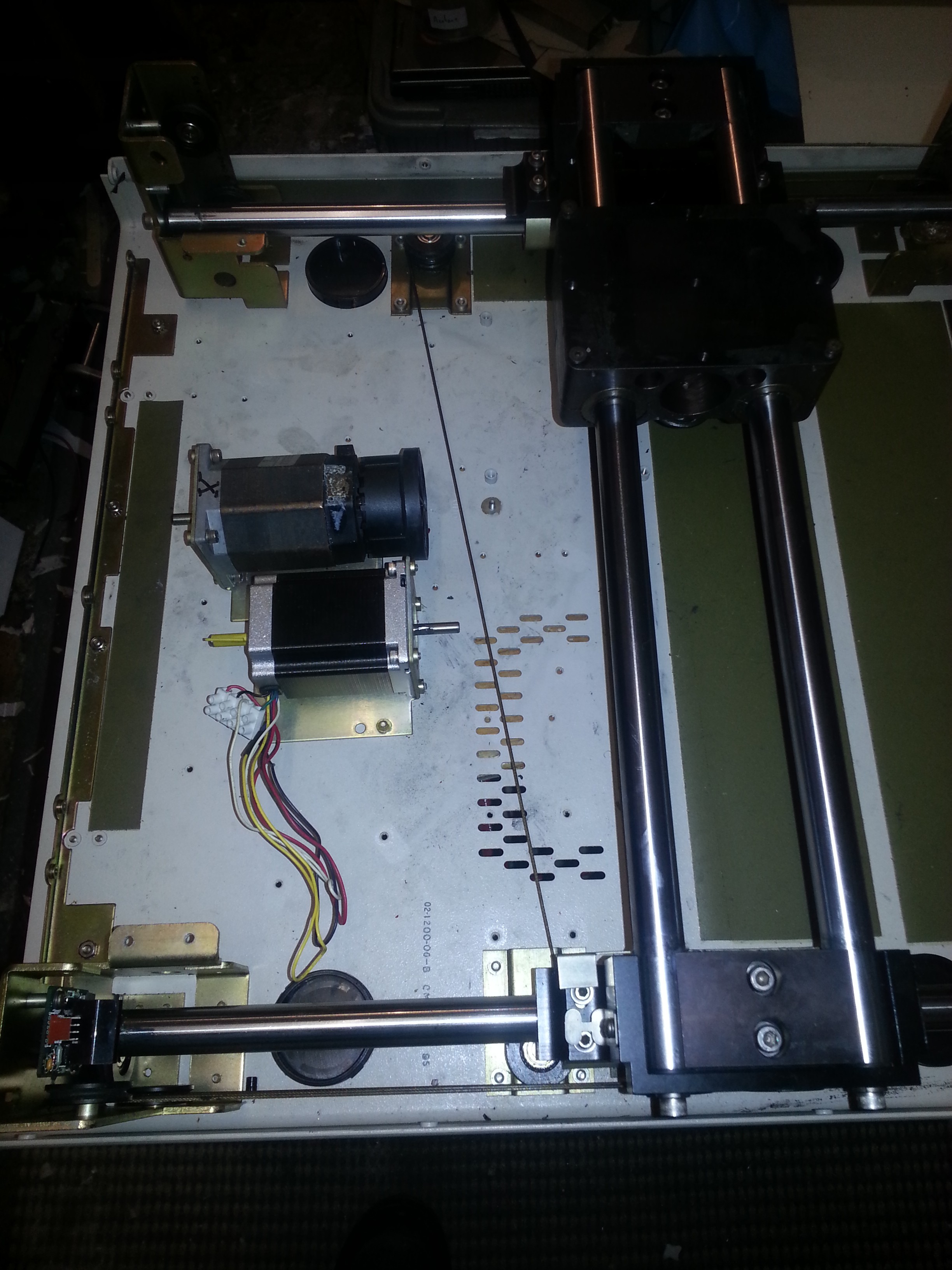

![]() Okay, that actually looks pretty good!

Okay, that actually looks pretty good!The whole thing is run with a clever web of plastic-coated steel cables and threaded capstans. The rails are really chunky at 19mm..? No, 3/4" thick exactly. And exactly 19" long.

Perhaps I could just transfer it all to a nice thick aluminium plate with a hole in the middle. Can I move the position of the motors though? Let's have a closer look at the cable.

Oh.

(I'll put the picture here when I find where I saved it)

I knew the plastic on the cable was a bit cracked, but it actually worse than I thought. It's flaked off completely in a lot of places and the cable has actually started to unwind in one portion. And this has been running over the aluminium capstans, which has left them pretty chewed up.

So the cable needs replacing. That's tricky, since it needs to be just the right length & thickness as well as plastic coated. But it's doable if I can find the right supplier. So I'll unhook it to measure it. That means I can check the pulleys too.

(I'll put the picture here when I find where I saved it)

Oh.

That's about a 2mm groove the cable's worn in the pulley over the years. It's hard to tell if the muck either side is pulverised plastic or hardened grease.

Some of the pulleys are okay, but about a third of them will need replacing, which means making new ones. And the bearings they're mounted on are wobbly, so the bearings all need replacing too.

That motor with the "X" drawn on it is the original one. The other got replaced some time ago because the plastics had gotten so brittle the connector shattered. The remaining one has rust marks on it and also has brittle plastics. So the motor needs changing as well if I want this to be reliable.![]()

So with the cable removed, I decided to check the linear bearings. The X axis and the two sides of the Y axis.

One Y axis rail runs fine, the other sounds like it's full of sand and has some axial play. The X runs, but runs rough. So the bearings are all on their last legs.

No, it's ALL on it's last legs.

Ugh.

It's time for a change of plan.

I could, in theory, replace/remanufacture all the parts and rebuild the mechanics as they were originally. But to find the imperially sized parts will put the cost up, especially those large linear bearings. It'd cost less to build it from scratch. And if I'm doing that I can build something better.

So, what about the vertical axis? Is that usable at least?

Well, it's more usable.

Quarter and 1/8" anodised aluminium plate, four leadscrews with 1/8" pitch synchronisned belt drive from one stepper giving a 1/2000" resolution per full step. That would be very good layer resolution.

This was the one that used to blow the driver boards though. The stepper drew too much current. And looking at the weird way they arranged the linear guide makes it obvious why. It's not a linear bearing. It's a rail on either side and a fat tensioning screw that clamps onto them. So the less play you want, the harder the motor will have to push.

(I'll put the picture here when I find where I saved it)

So at very least a proper linear bearing needs to go there. Which means changing the rails out for a metric ones, which means modifying the mounts. And this would be to enable me to keep using the 22yo ballscrews. Which need to come out anyway because the supporting bearings are caked in molten plastic.

I'm not going to "grandfathers axe" this. About all that's here that's actually useful for a precise and reliable 3D printer is a single stepper motor, some aluminium plate and maybe some toothed pulleys.

The Stratasys guts I salvaged are only good for inspiration and scrap metal.

I even checked the heaters. There's four of them, all 900Watt. This thing used 3600Watts just for heating the build chamber.

One of the fans though did have a manufacturing date of 1995. So at least that corrects the age of the original machine.![]()

So next up: designing a stratasys-inspired 3D printer from scratch.

-

Tearing down the house

03/05/2017 at 02:21 • 0 commentsandNote: I've changed the project description. The Stratasys is actually only 22 years old, not 30. This discovery comes later.

I'd already looked over the Stratasys parts when I pulled them from the original housing and I'd estimated I could likely fit the parts inside the fridge after removing some of the excess housing material.

The way the mechanics of the FDM 1650 had been built was as an aluminium plate box containing the vertical axis/bed with an existing pick & place machine on top holding the print head.

The pick & place machine was an Asymtek Automove 302.

![]()

That's it's rear panel sitting on top of it. It was already off when I got to it, and the wires connecting to it had already been cut.

On it's own, that wouldn't have been too bad. There's no smarts inside it. The sum total of the electronics within consists of two stepper motors and an endstop board.

That wasn't the only problem though. In addition, I'm in the UK. This was made in the USA. Not only are all the parts and fittings imperial, they're American imperial. And half the screws are either missing, sheared off or have heads that are totally chewed up. It was easier to dismantle the housing than open the service panel.

![]() Okay, that actually looks pretty good!

Okay, that actually looks pretty good!The whole thing is run with a clever web of plastic-coated steel cables and threaded capstans. The rails are really chunky at 19mm..? No, 3/4" thick exactly. And exactly 19" long.

Perhaps I could just transfer it all to a nice thick aluminium plate with a hole in the middle. Can I move the position of the motors though? Let's have a closer look at the cable.

Oh.

(I'll put the picture here when I find where I saved it)

I knew the plastic on the cable was a bit cracked, but it actually worse than I thought. It's flaked off completely in a lot of places and the cable has actually started to unwind in one portion. And this has been running over the aluminium capstans, which has left them pretty chewed up.

So the cable needs replacing. That's tricky, since it needs to be just the right length & thickness as well as plastic coated. But it's doable if I can find the right supplier. So I'll unhook it to measure it. That means I can check the pulleys too.

(I'll put the picture here when I find where I saved it)

Oh.

That's about a 2mm groove the cable's worn in the pulley over the years. It's hard to tell if the muck either side is pulverised plastic or hardened grease.

Some of the pulleys are okay, but about a third of them will need replacing, which means making new ones. And the bearings they're mounted on are wobbly, so the bearings all need replacing too.

That motor with the "X" drawn on it is the original one. The other got replaced some time ago because the plastics had gotten so brittle the connector shattered. The remaining one has rust marks on it and also has brittle plastics. So the motor needs changing as well if I want this to be reliable.![]()

So with the cable removed, I decided to check the linear bearings. The X axis and the two sides of the Y axis.

One Y axis rail runs fine, the other sounds like it's full of sand and has some axial play. The X runs, but runs rough. So the bearings are all on their last legs.

No, it's ALL on it's last legs.

Ugh.

It's time for a change of plan.

I could, in theory, replace/remanufacture all the parts and rebuild the mechanics as they were originally. But to find the imperially sized parts will put the cost up, especially those large linear bearings. It'd cost less to build it from scratch. And if I'm doing that I can build something better.

So, what about the vertical axis? Is that usable at least?

Well, it's more usable.

Quarter and 1/8" anodised aluminium plate, four leadscrews with 1/8" pitch synchronisned belt drive from one stepper giving a 1/2000" resolution per full step. That would be very good layer resolution.

This was the one that used to blow the driver boards though. The stepper drew too much current. And looking at the weird way they arranged the linear guide makes it obvious why. It's not a linear bearing. It's a rail on either side and a fat tensioning screw that clamps onto them. So the less play you want, the harder the motor will have to push.

(I'll put the picture here when I find where I saved it)

So at very least a proper linear bearing needs to go there. Which means changing the rails out for a metric ones, which means modifying the mounts. And this would be to enable me to keep using the 22yo ballscrews. Which need to come out anyway because the supporting bearings are caked in molten plastic.

I'm not going to "grandfathers axe" this. About all that's here that's actually useful for a precise and reliable 3D printer is a single stepper motor, some aluminium plate and maybe some toothed pulleys.

The Stratasys guts I salvaged are only good for inspiration and scrap metal.

I even checked the heaters. There's four of them, all 900Watt. This thing used 3600Watts just for heating the build chamber.

One of the fans though did have a manufacturing date of 1995. So at least that corrects the age of the original machine.

So next up: designing a stratasys-inspired 3D printer from scratch.

-

Part 1: Fridge teardown

02/10/2017 at 03:36 • 0 commentsThe original Stratasys FDM 1650 that the London Hackspace was donated was apparently built by one of the now directors of the company when they first joined the company. Which is an amusing way of saying; it was really old.

It was also really big. Think of the tumble-driers you use as a laundrette, but could only produce prints the same size as a modern kit printer. Though admittedly, at fine resolution.

The mechanical elements were the best bit of it. The bed used four ballscrews with a vertical resolution of 1/2000" at full step. The XY was handled by an Asymtek Automove 302, which I gather was an early high-spec pick-&-place head. But we'll get to that on the next log entry.

These great parts were in an oversized environmental enclosure, and I liked the idea of bringing it down to the size of household whitegoods. In the UK at least, that's 600mm wide and the same for kitchen cabinets. I also already use a large commercial display fridge as a heated cabinet for keeping my resins at their ideal storage temperature. A fridge is basically just an insulated box and commercial ones tend to lack weird internal mouldings. From the main guts of the Stratasys, I figured I could fit them inside a fridge with a 600mm outside width.

After a couple of weeks I managed to find one of close-enough size on ebay that was also within collection distance.

![]()

Once I peel off those decals, it'll look really cool with items printing inside in a nice warm environment.

First though, let's pull out the refrigeration unit.

I didn't have to worry about releasing the gas into the air because this fridge was sold as non-functional and in need of regassing. But just the same, it didn't look like it'd be hard to remove in one piece.

![]()

After removing the rear panel; issue one. That's expanded polystyrene, not the urethane foam I was expecting. Also, it's held in place with duct-tape, apparently from the factory.

The polystyrene is a problem. ABS best prints with an ambient temperature of 70-90°c. While polystyrene melts at 240°c, it's very flammable. And during long-duration prints it's possible something could go wrong enough to get a single point of ignition & send the whole thing up. The insulation will need to be swapped out for something more durable.

The panel came right out and there's the chiller. I'm a bit surprised it's only connected to the compressor by one pipe. I thought it would have to circulate back, but obviously some sort of push-pull system is possible. Anyway, 5 screws on the compressors mounting-plate and some aluminium hooks bending back and it all comes loose. Let's quickly take the door off so I can tip it forward without damaging it..![]()

Hmmm, the plastic studs are actually plastic rivets holding the liner to the frame. They're also packed with plastic strips for a complete thermal break. Worth remembering for reassembly.![]()

It took a lot of prying and wiggling but I managed to get the liner out. And yes, it's polystyrene on all sides. Imperial thicknesses too by the looks of it, but I think standard 30mm Celotex will replace it fineand drastically improve the insulating ability.![]()

Aside from some rust under it at the bottom and a few small dents, the shell should do fine. I may need to make some alterations to the liner though. At very least, the ventilated back piece will need swapping out. The existing shelf-mounts may be fine for holding the printer guts.

Let's get those decals off the door quickly and call it a night.

Magnetic seals, clamped to the door frame with more of the thermal-break strip. It's pretty gross and splitting in a few places. Plus of all the plastics, it's the one I'm the most concerned about. The working temps I find for replacement seals lists their maximum in the 50°c range. I may want to replace it with over-door seal, but it probably won't seal as well, or be magnetic, meaning I'd need a different sealing mechanism.![]()

![]() Oh.

Oh.There's no extra layer sandwiched to the front like I thought. The decals are painted on the INSIDE of the glasing unit. That's... going to be tricky to remove. Also the rubber sealing compound is very soft and I'm already worried it might melt at the temperatures needed.

That's going to need some thought. I may need to make an entire custom door. I'll fix the insulation first though.

StrataFridge FDM printer

The mechanical guts of a 22yo Stratasys, reengineered & mounted in a stylish drinks fridge.

Sci

Sci

Okay, that actually looks pretty good!

Okay, that actually looks pretty good!