Part of the SupplyFrame Design Lab residency #0x02

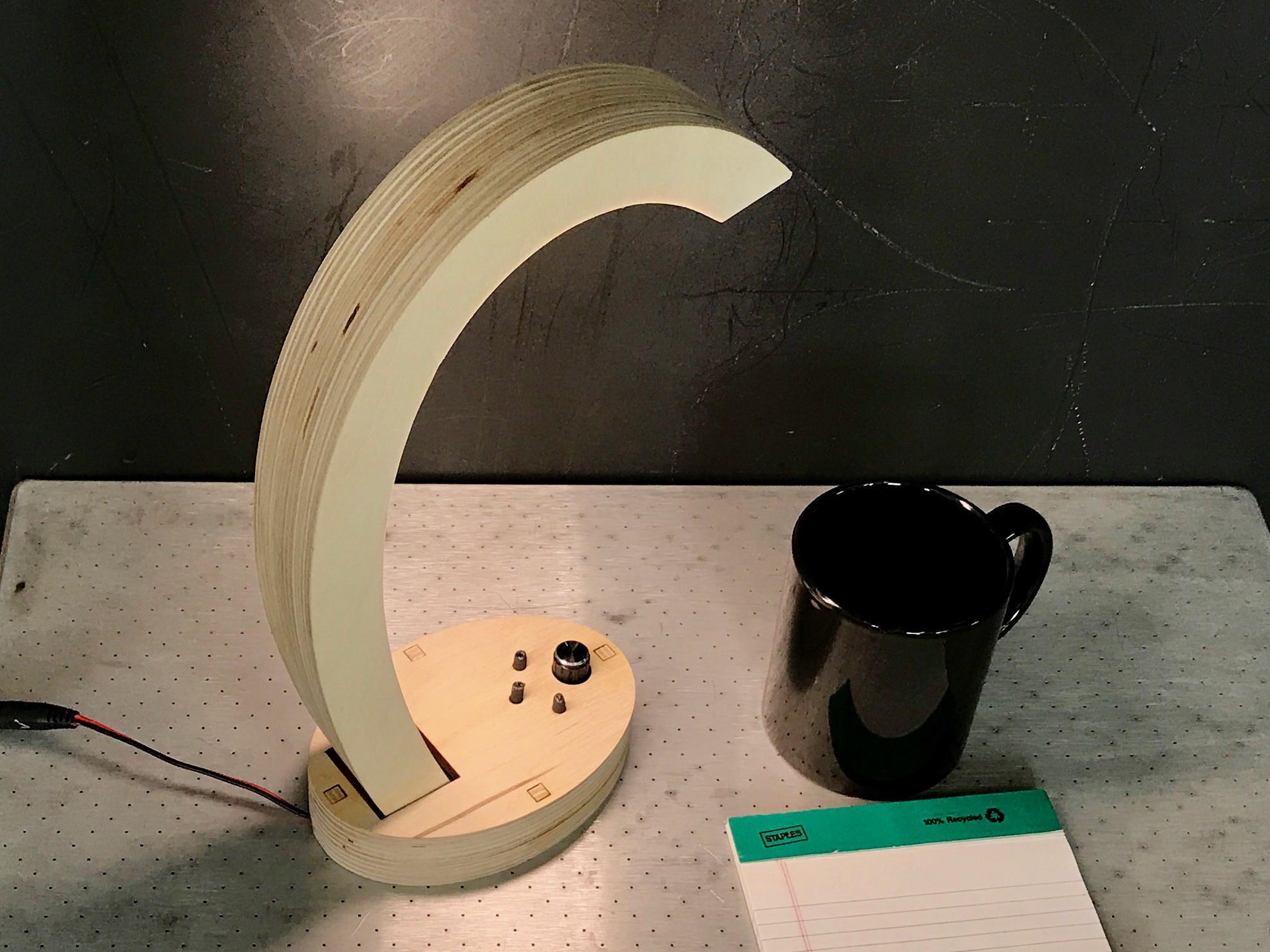

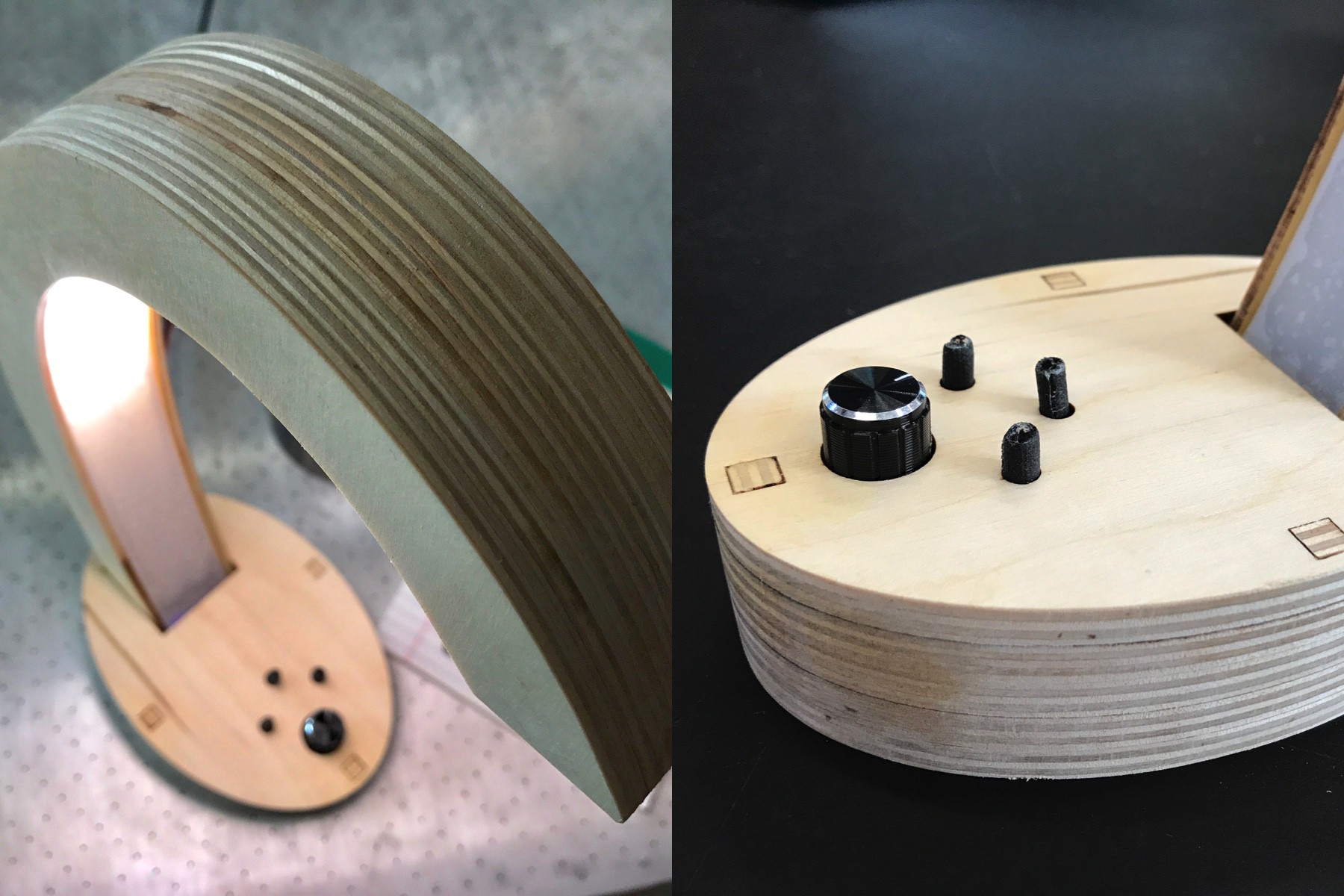

Inspirations:

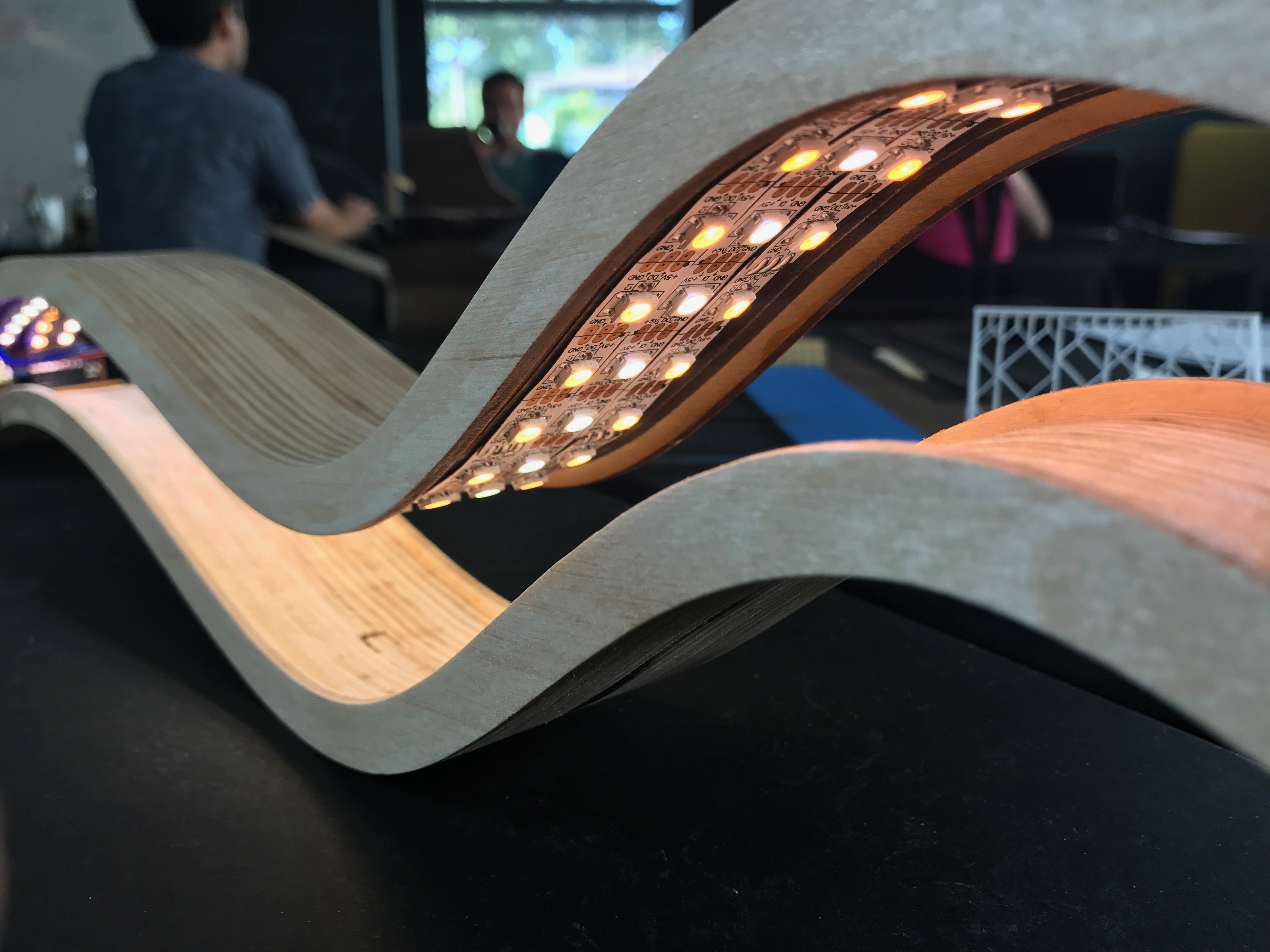

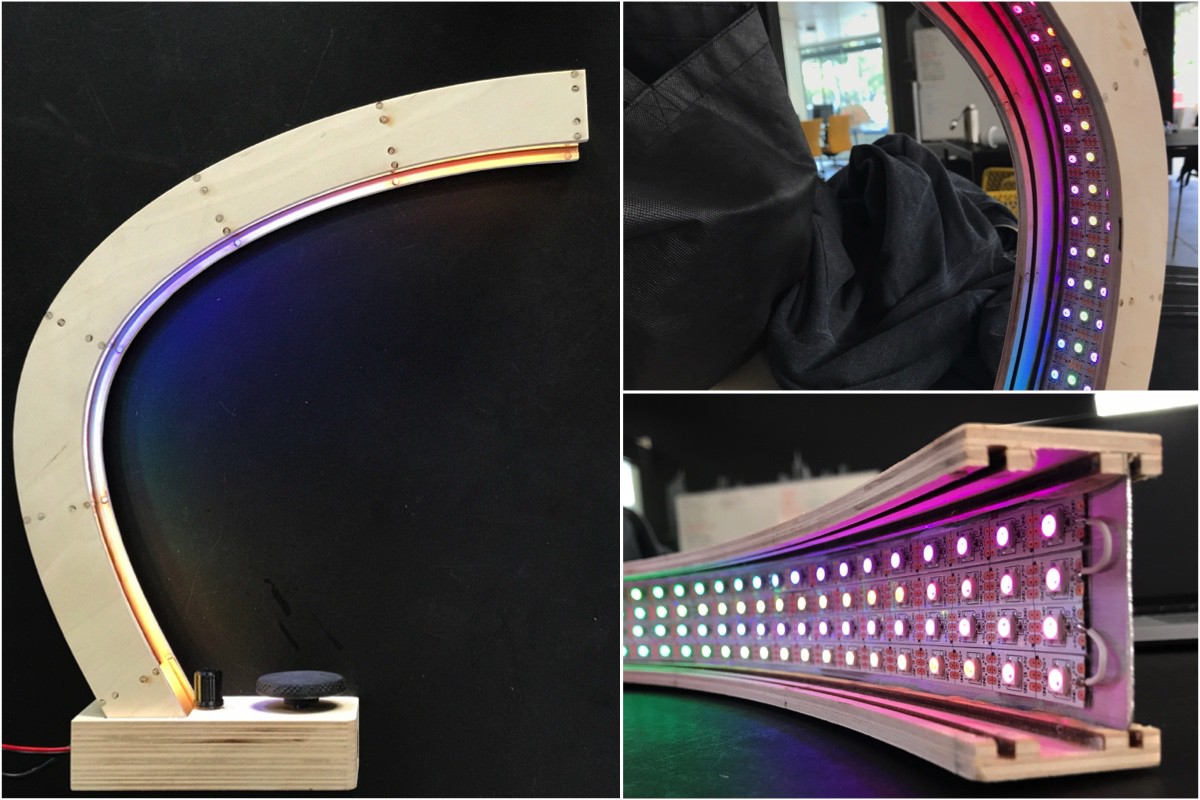

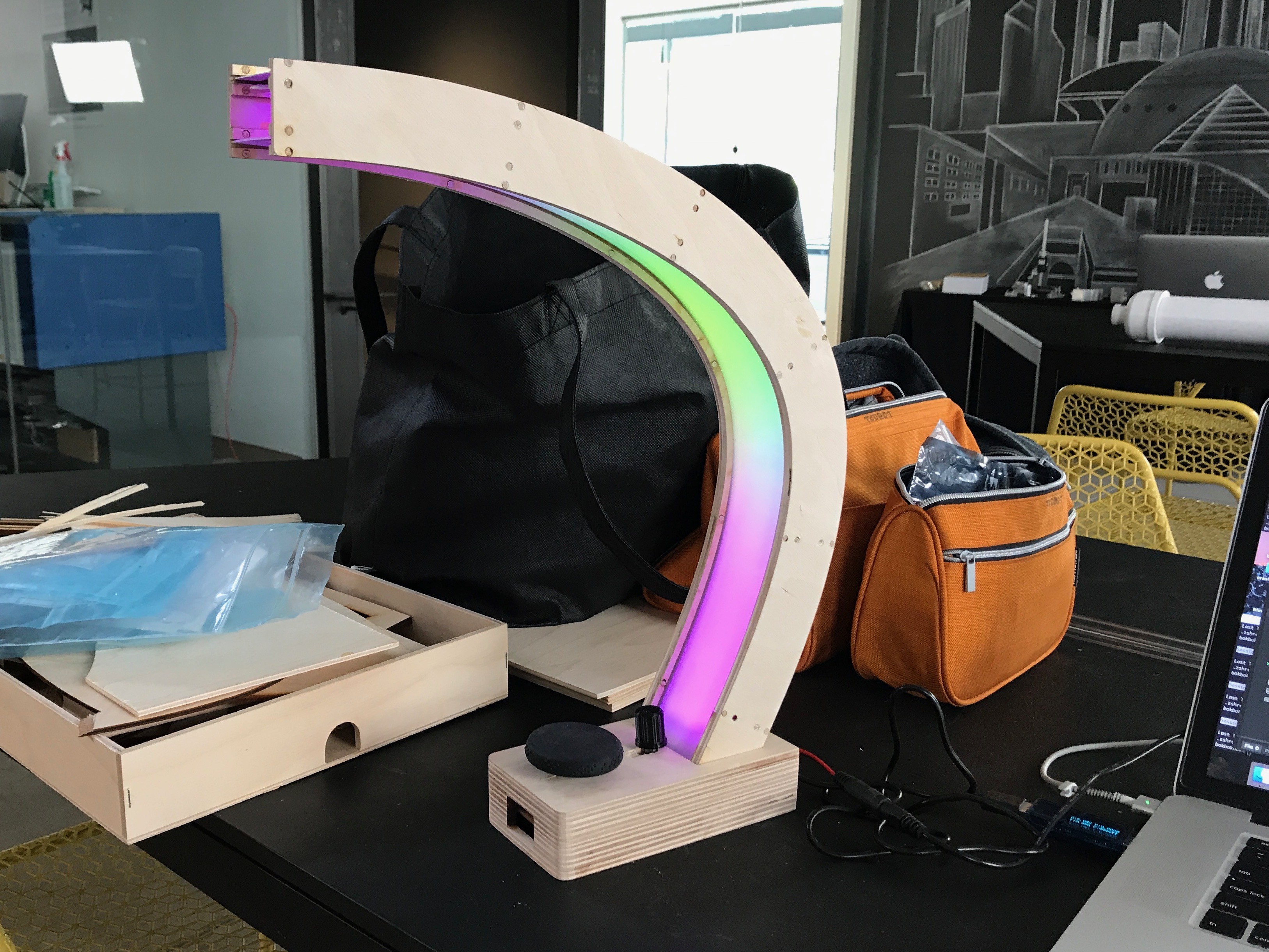

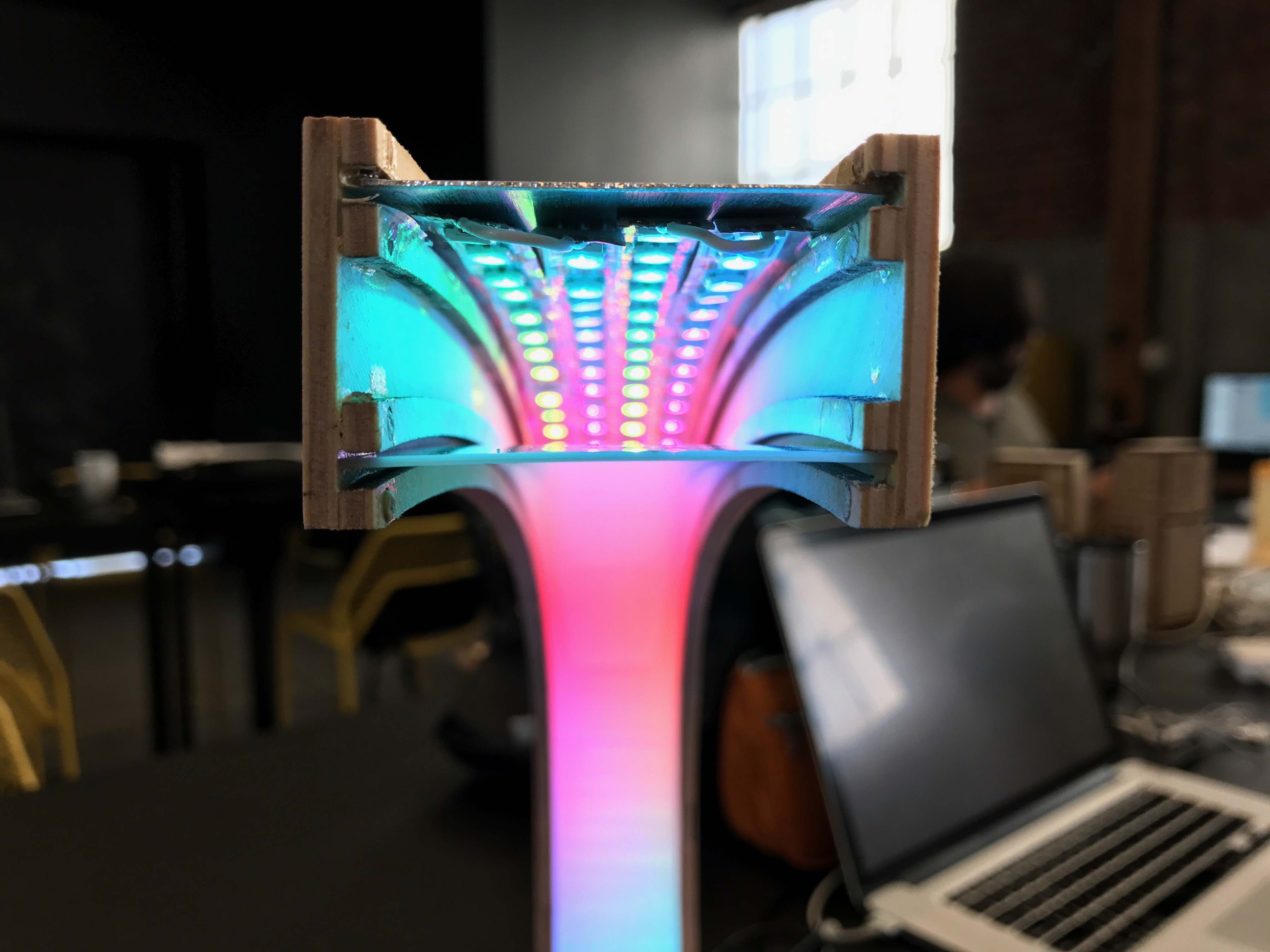

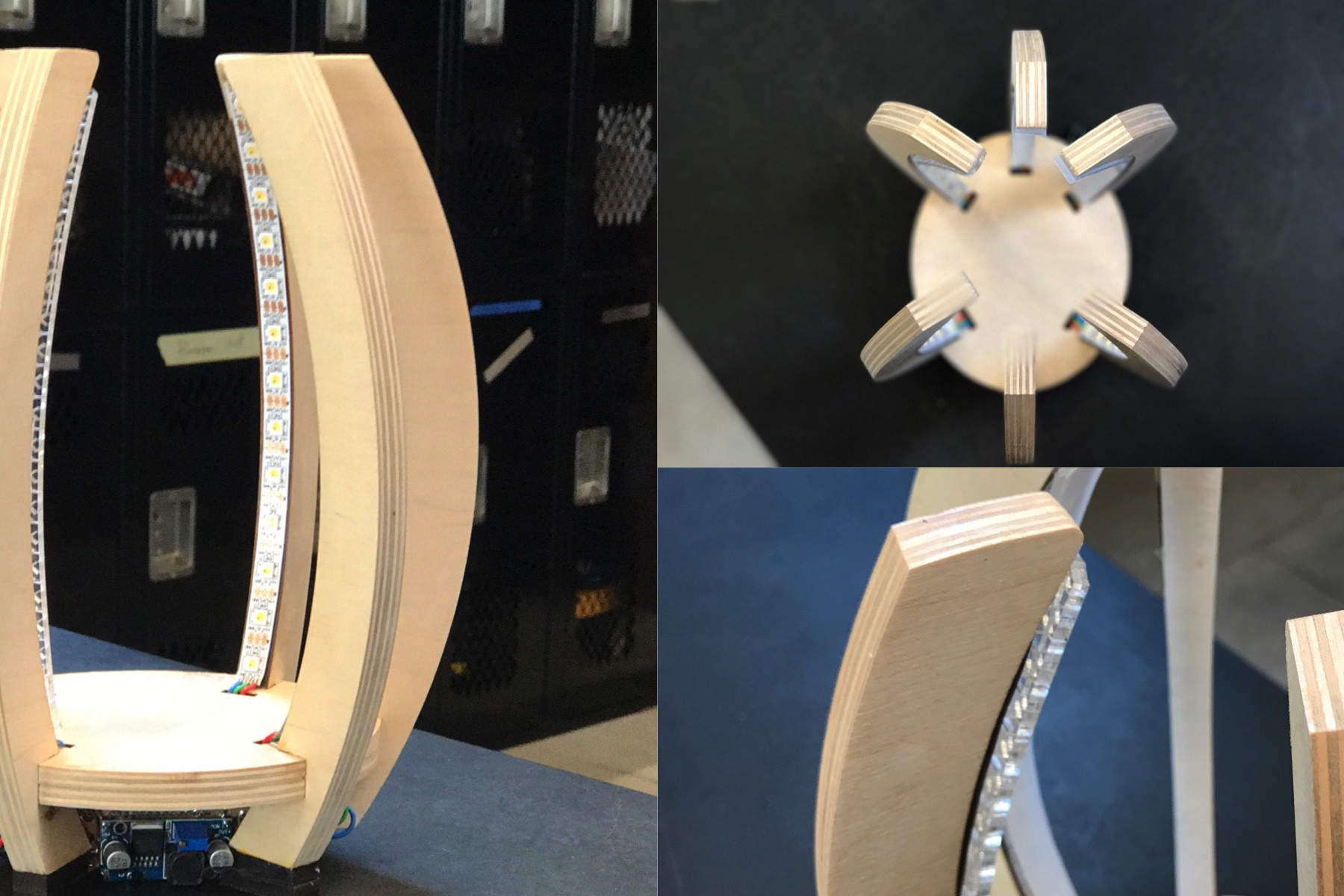

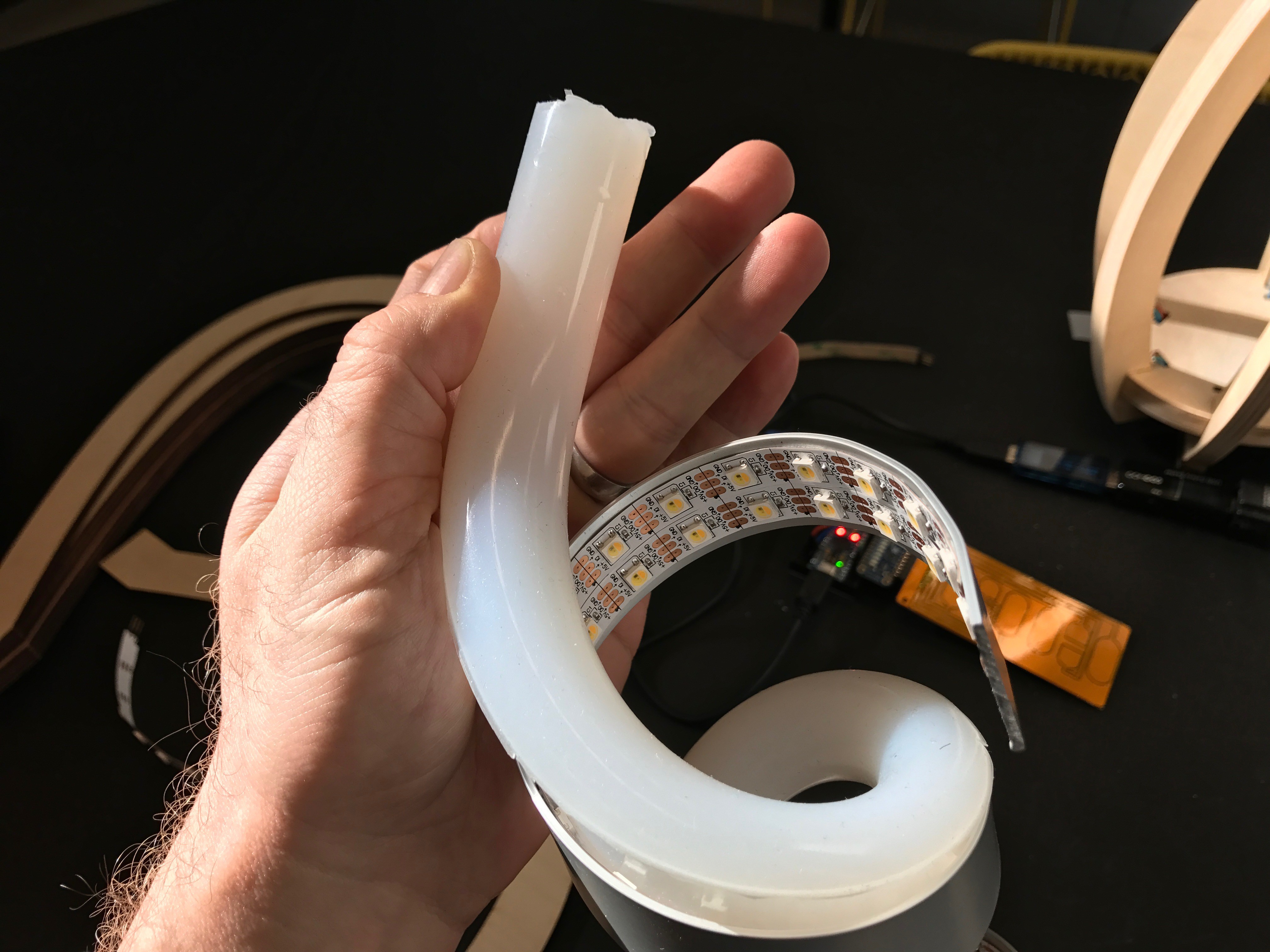

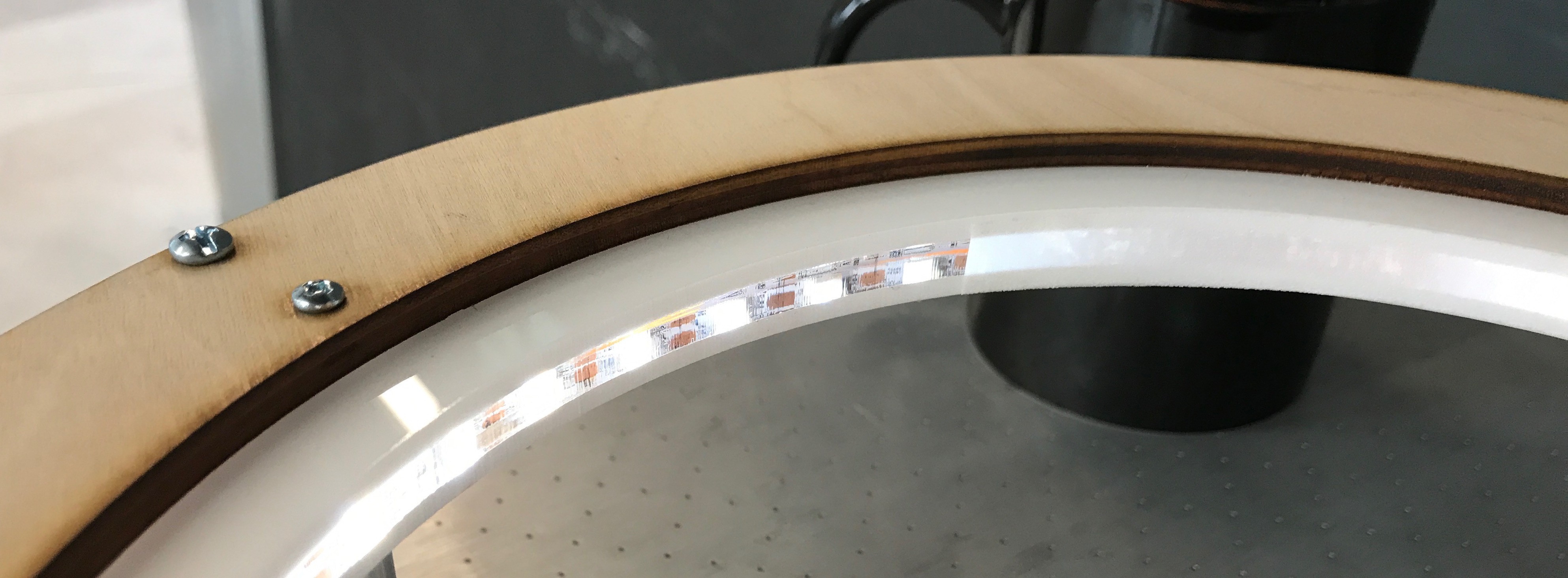

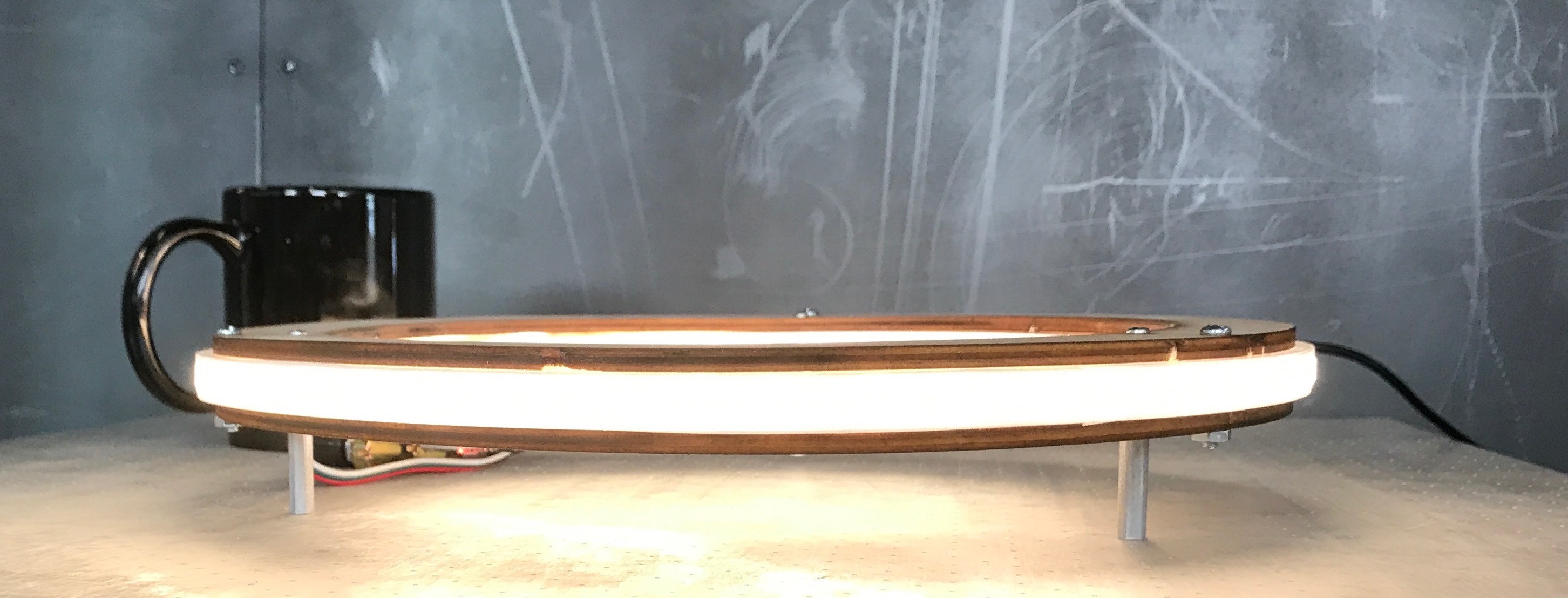

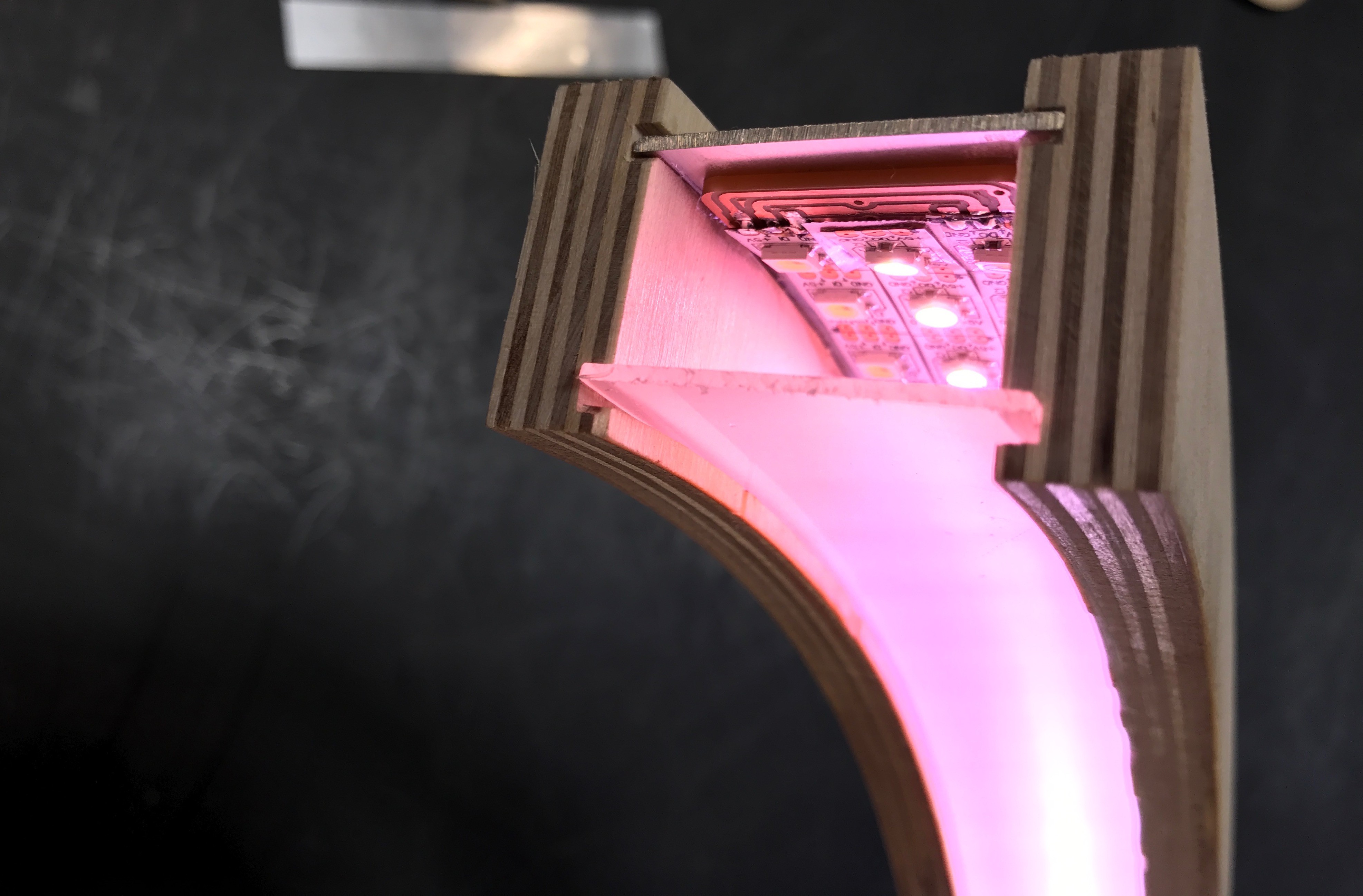

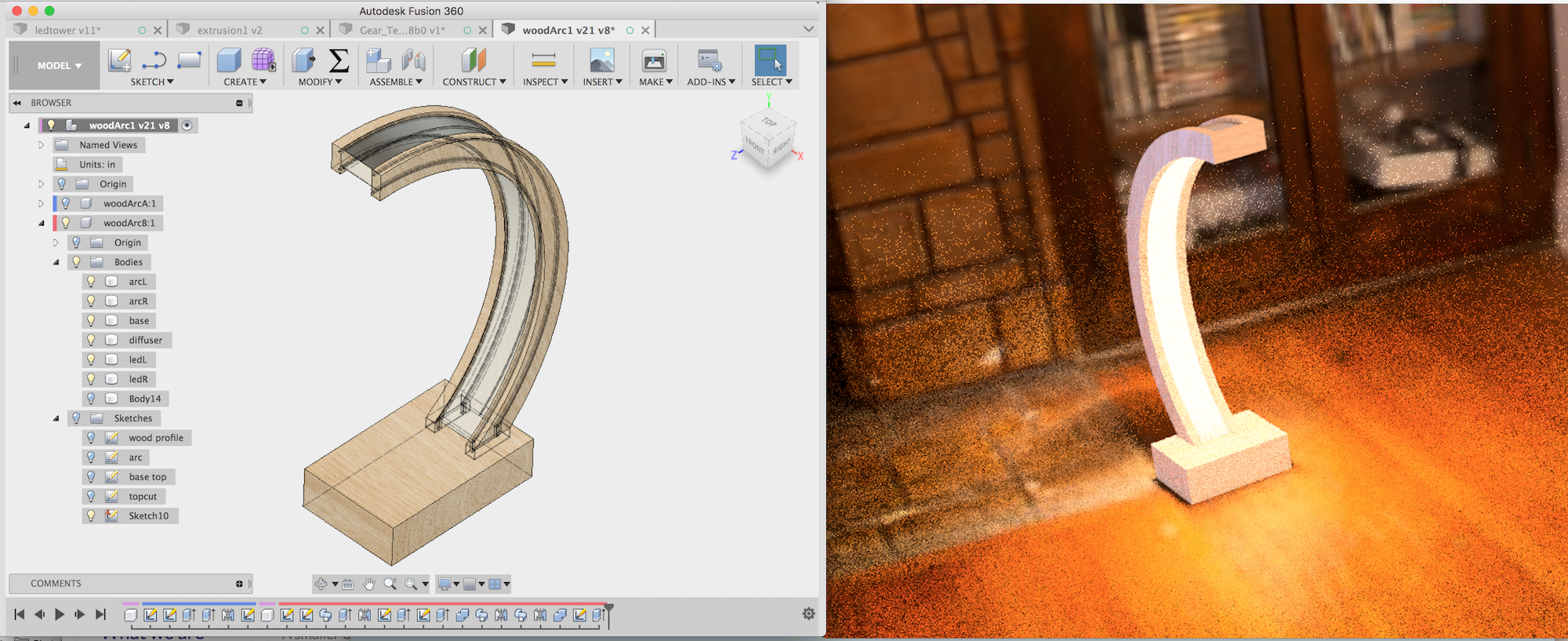

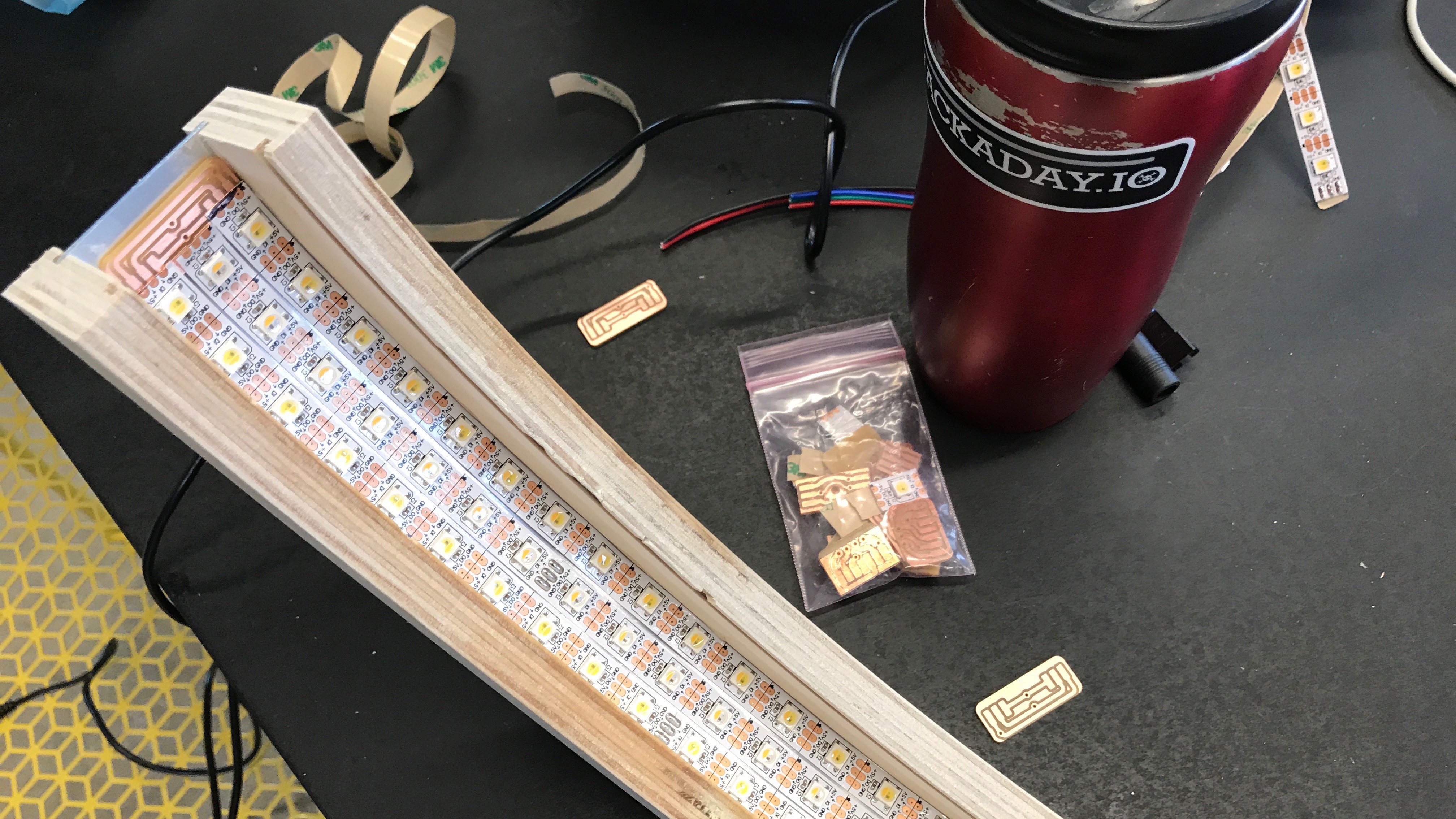

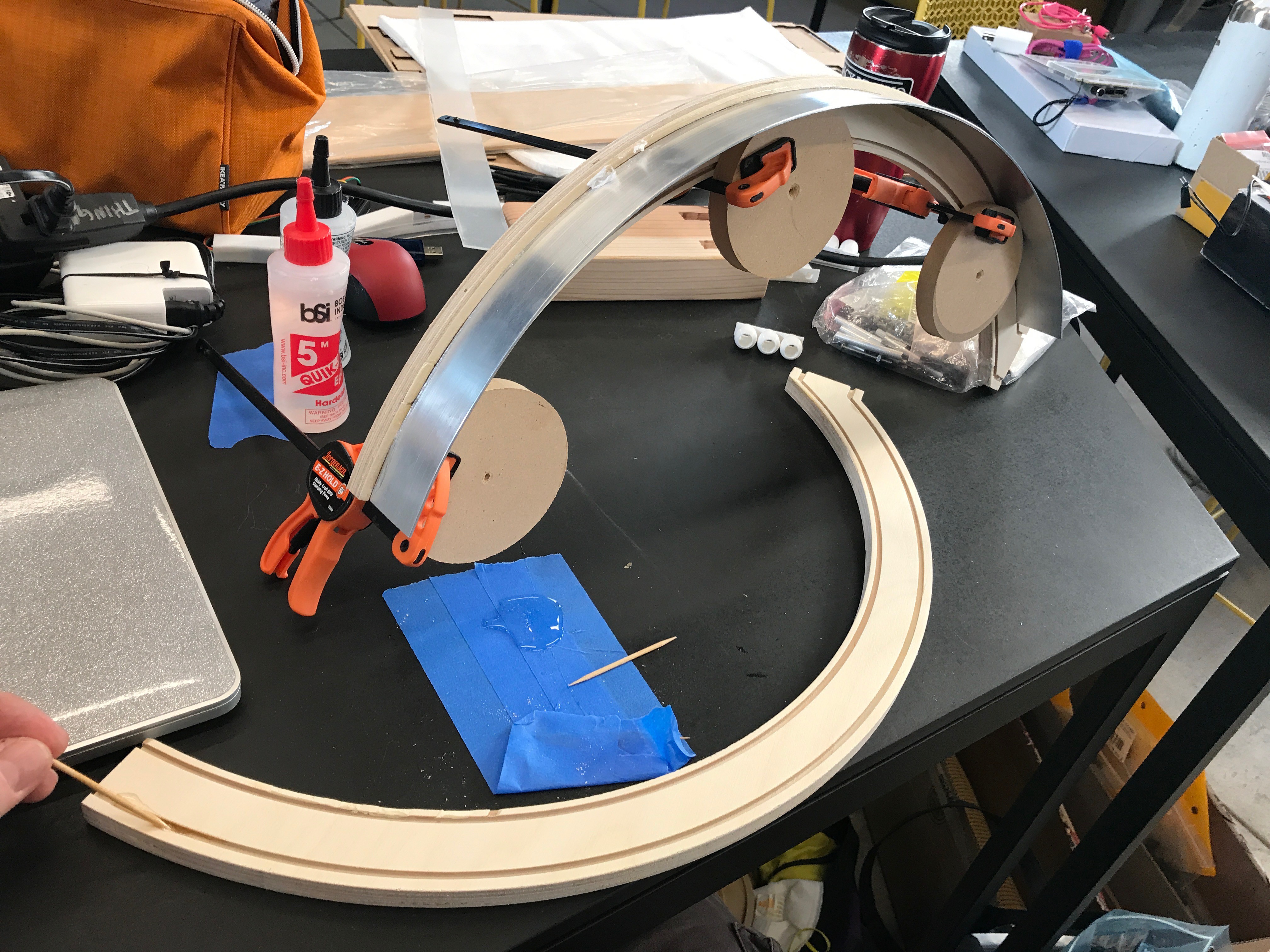

- The look and feel of subsurface scattering of light

- The evolving glittery but calming nature of caustics

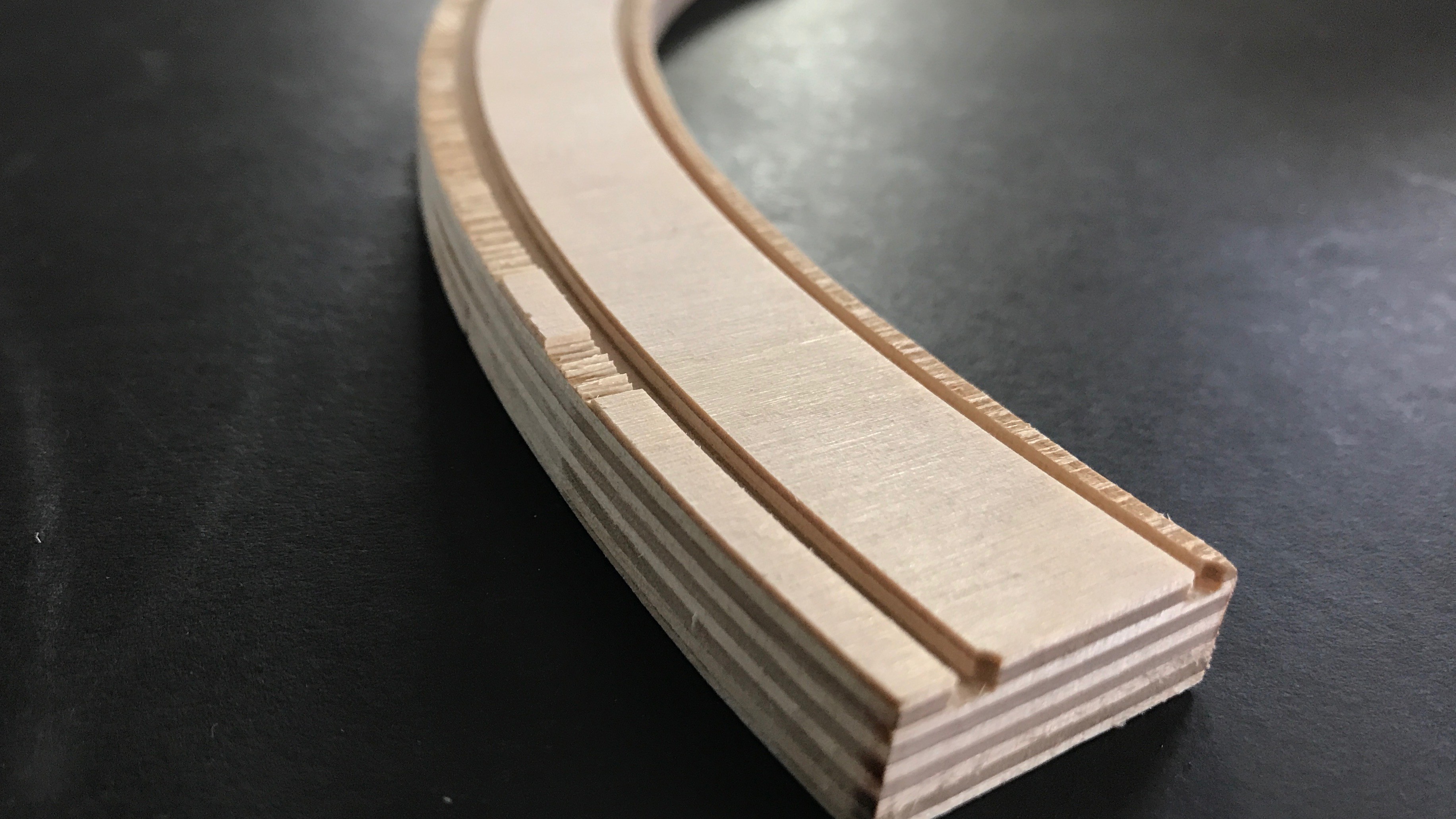

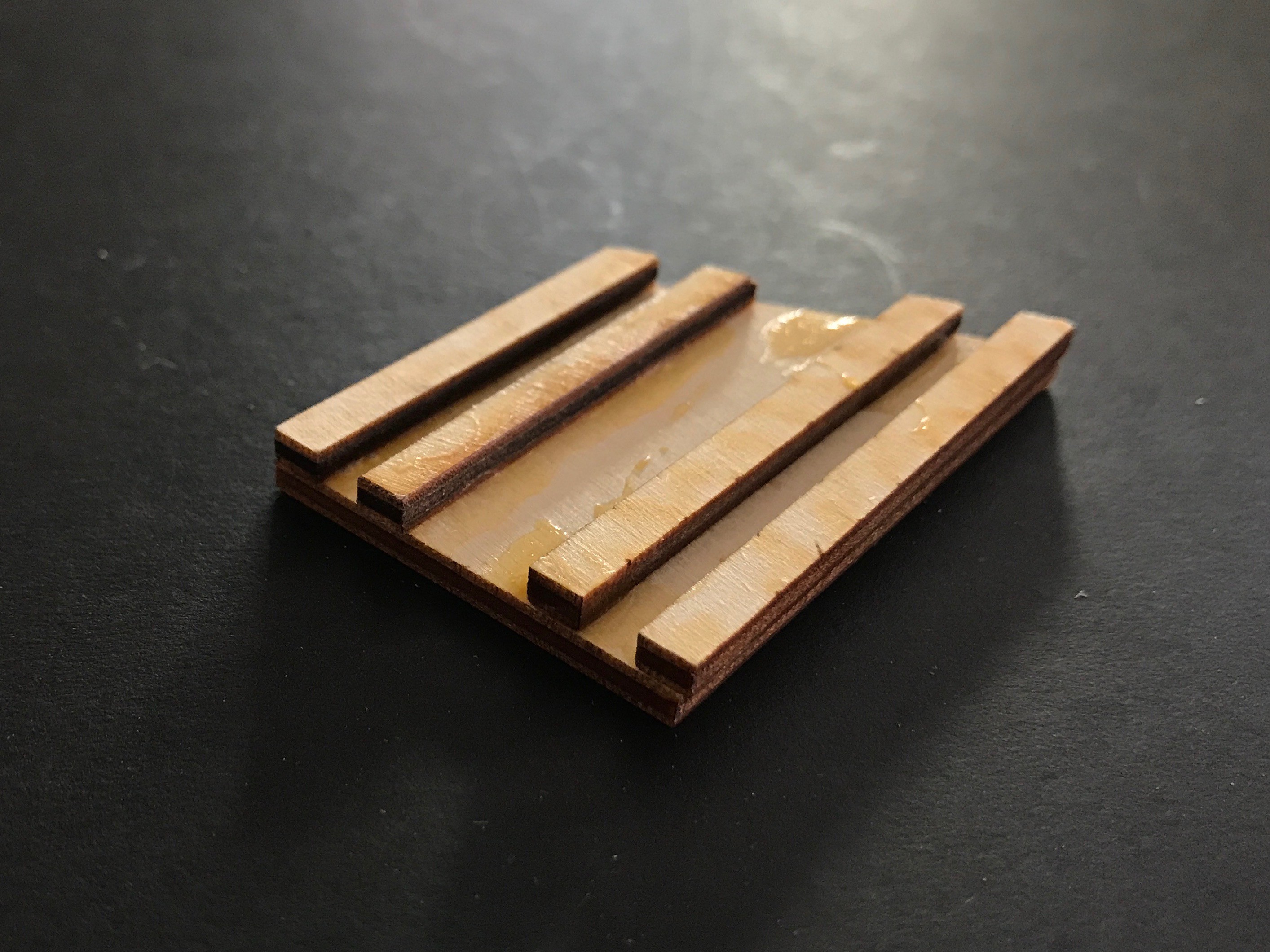

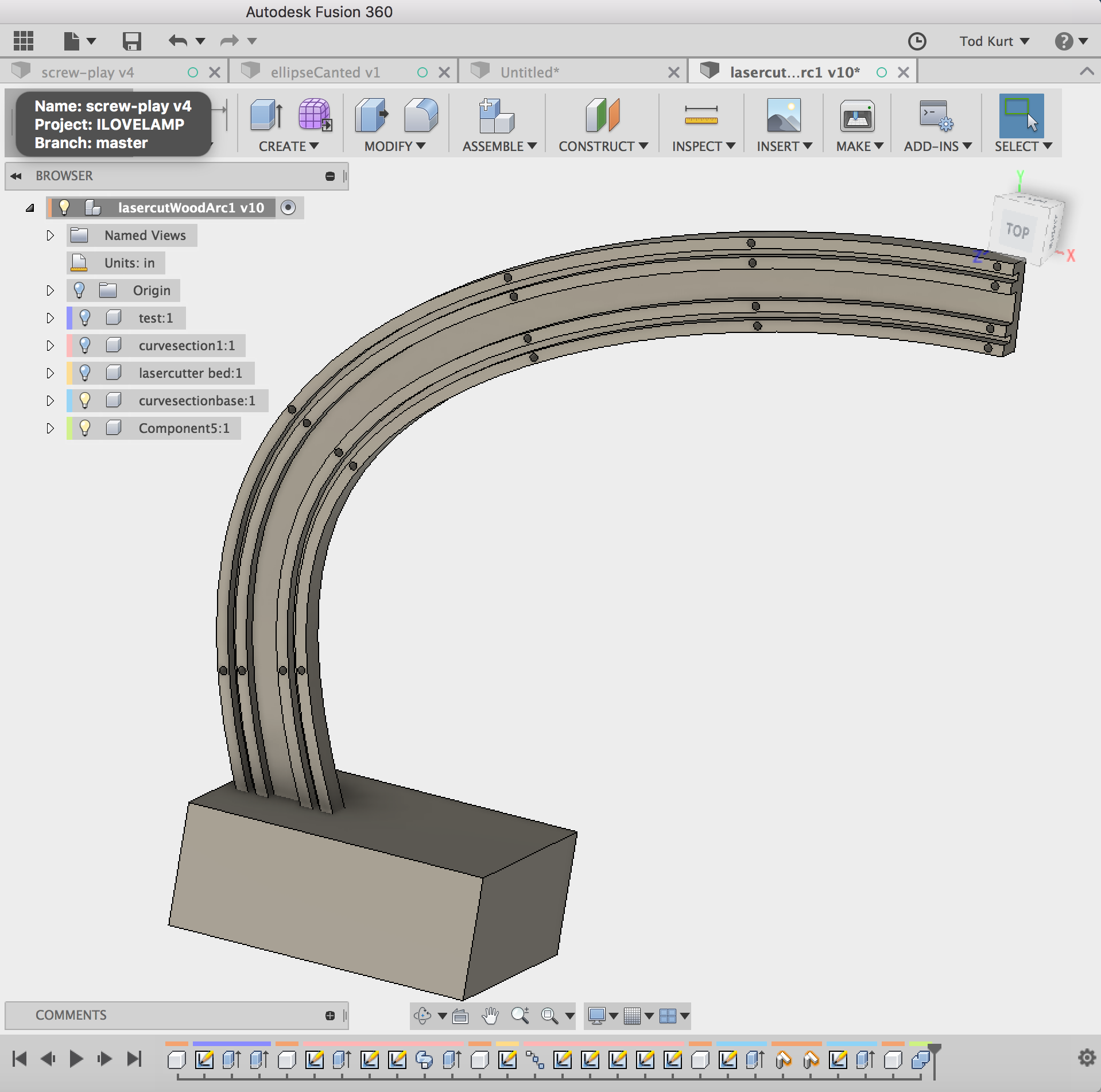

- The clean geometric lines of Art Deco

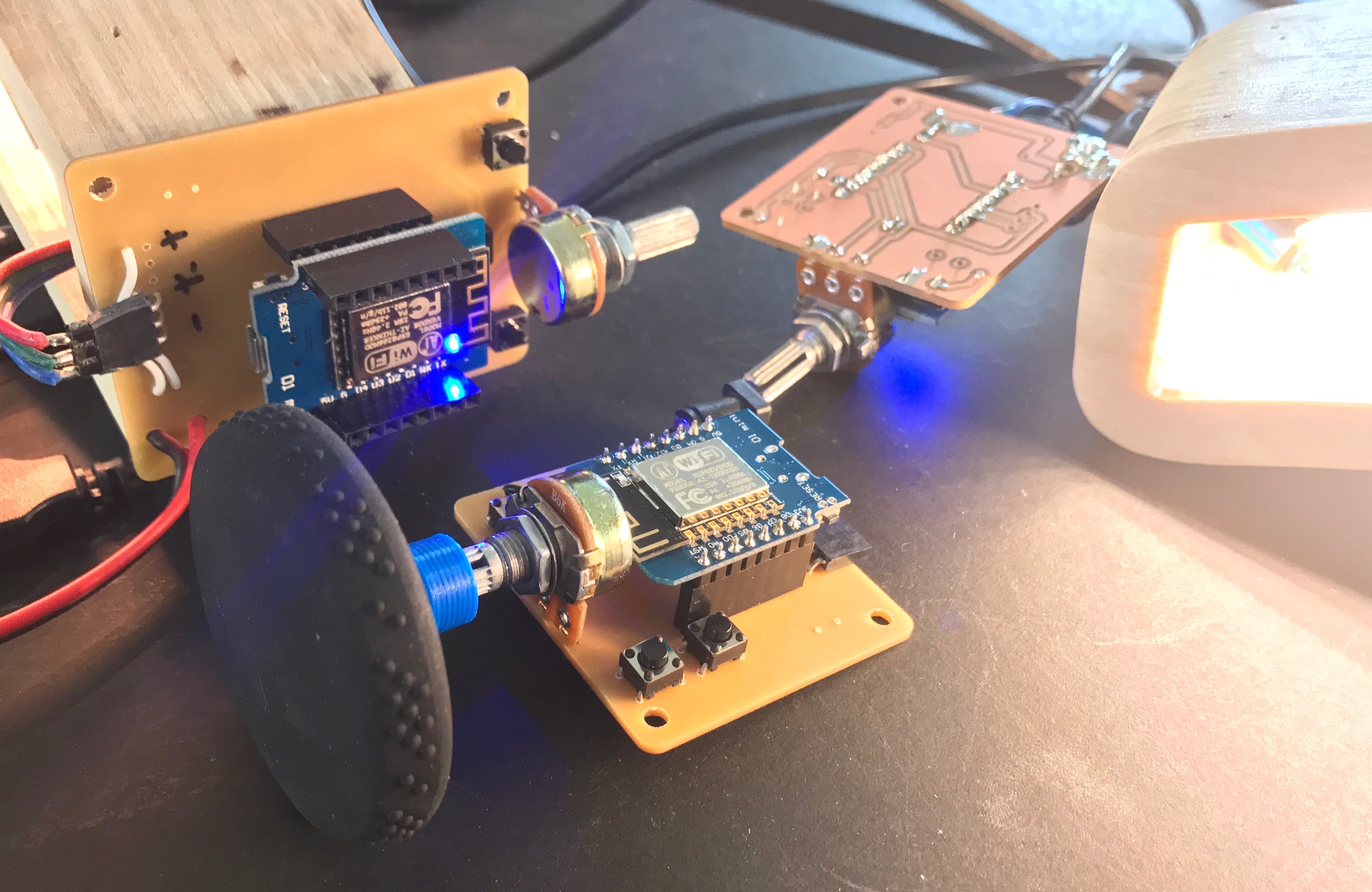

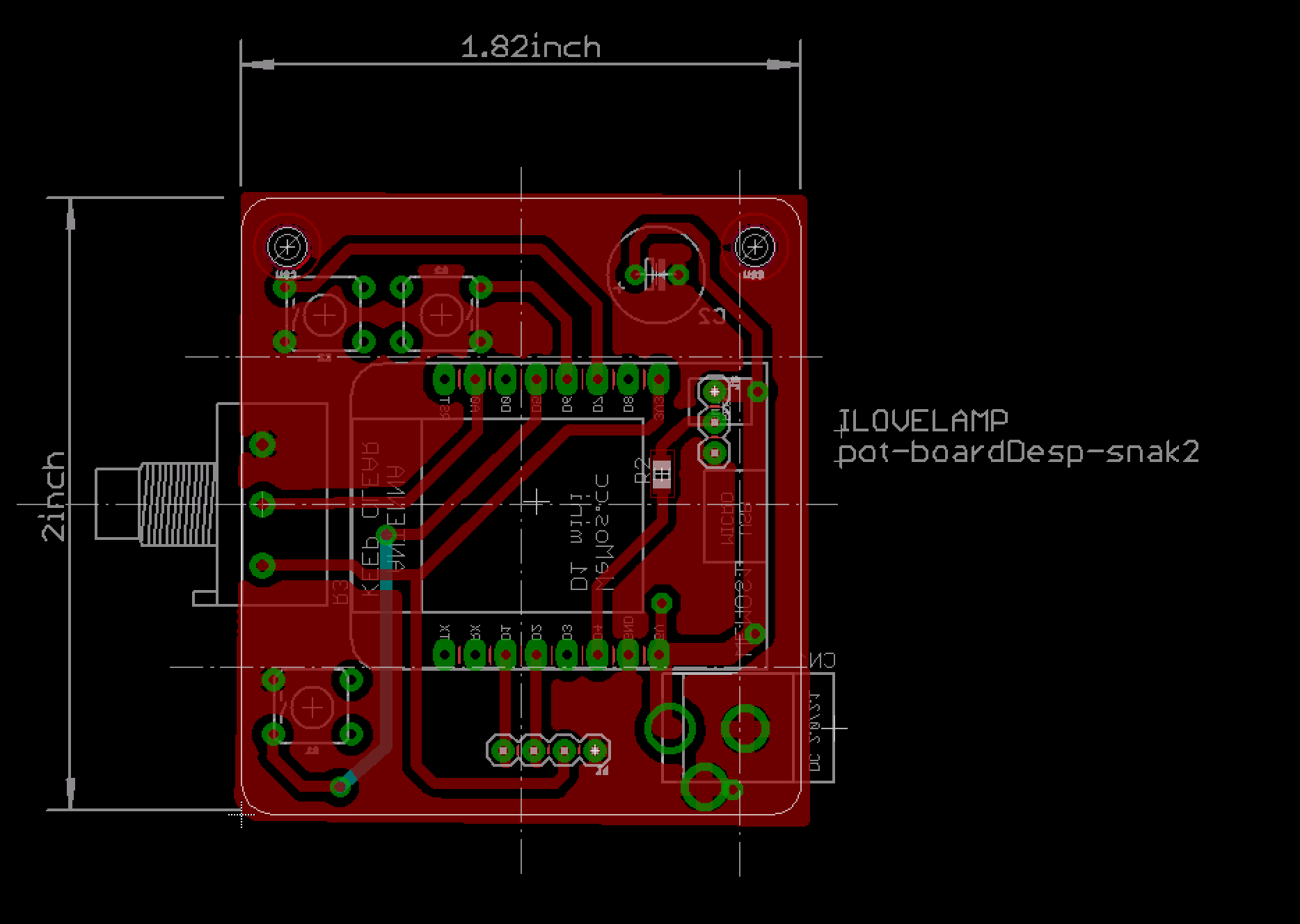

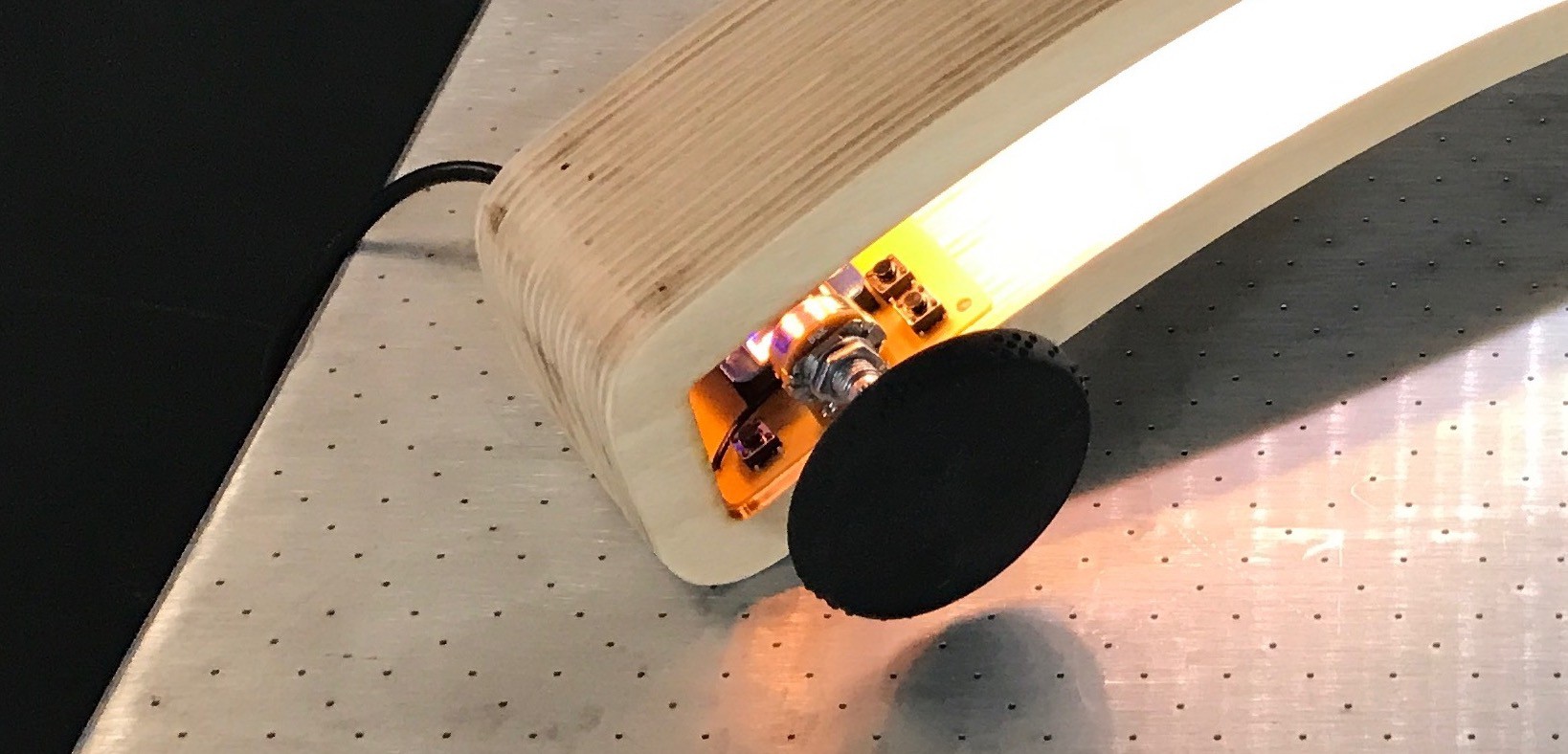

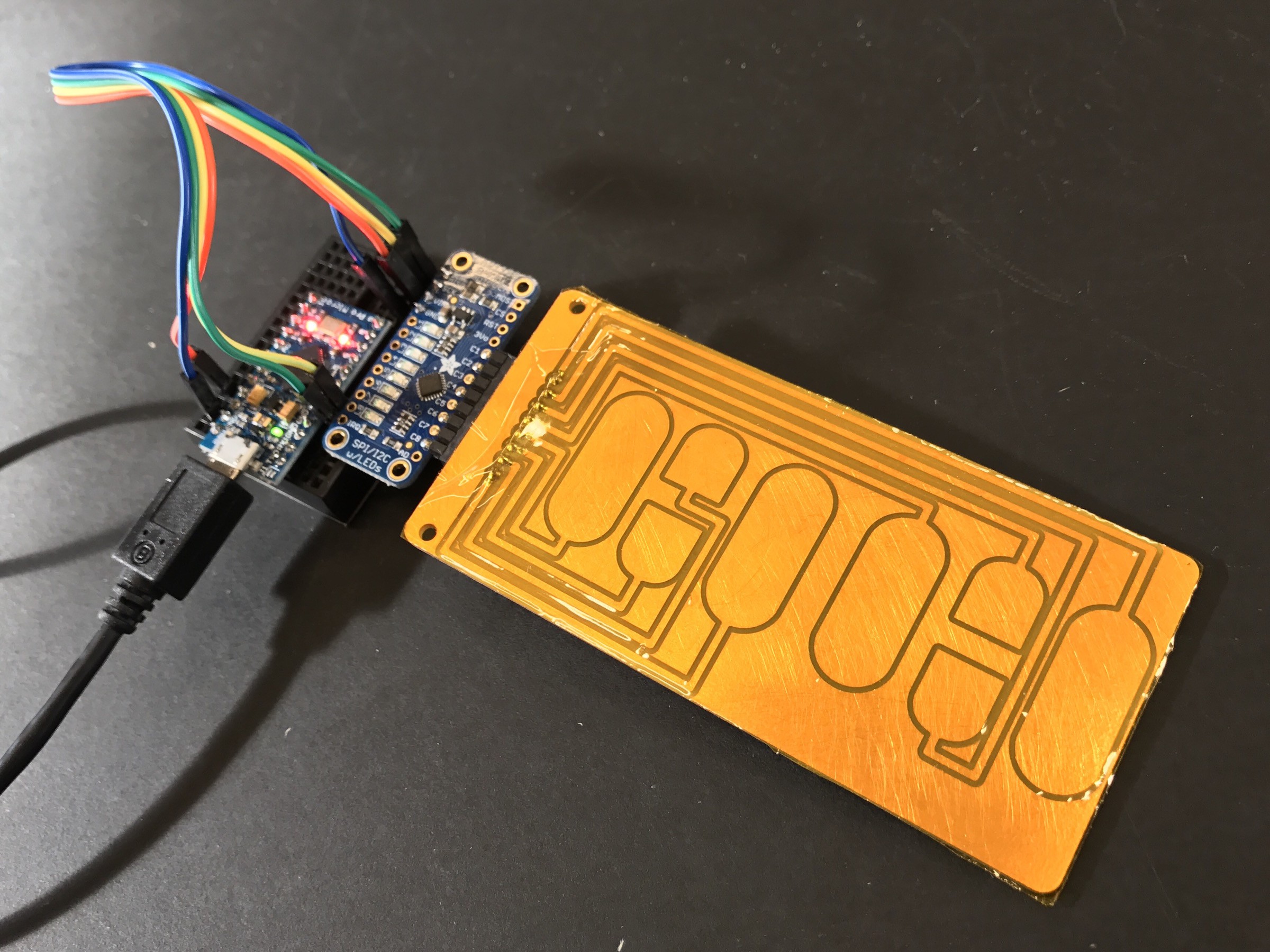

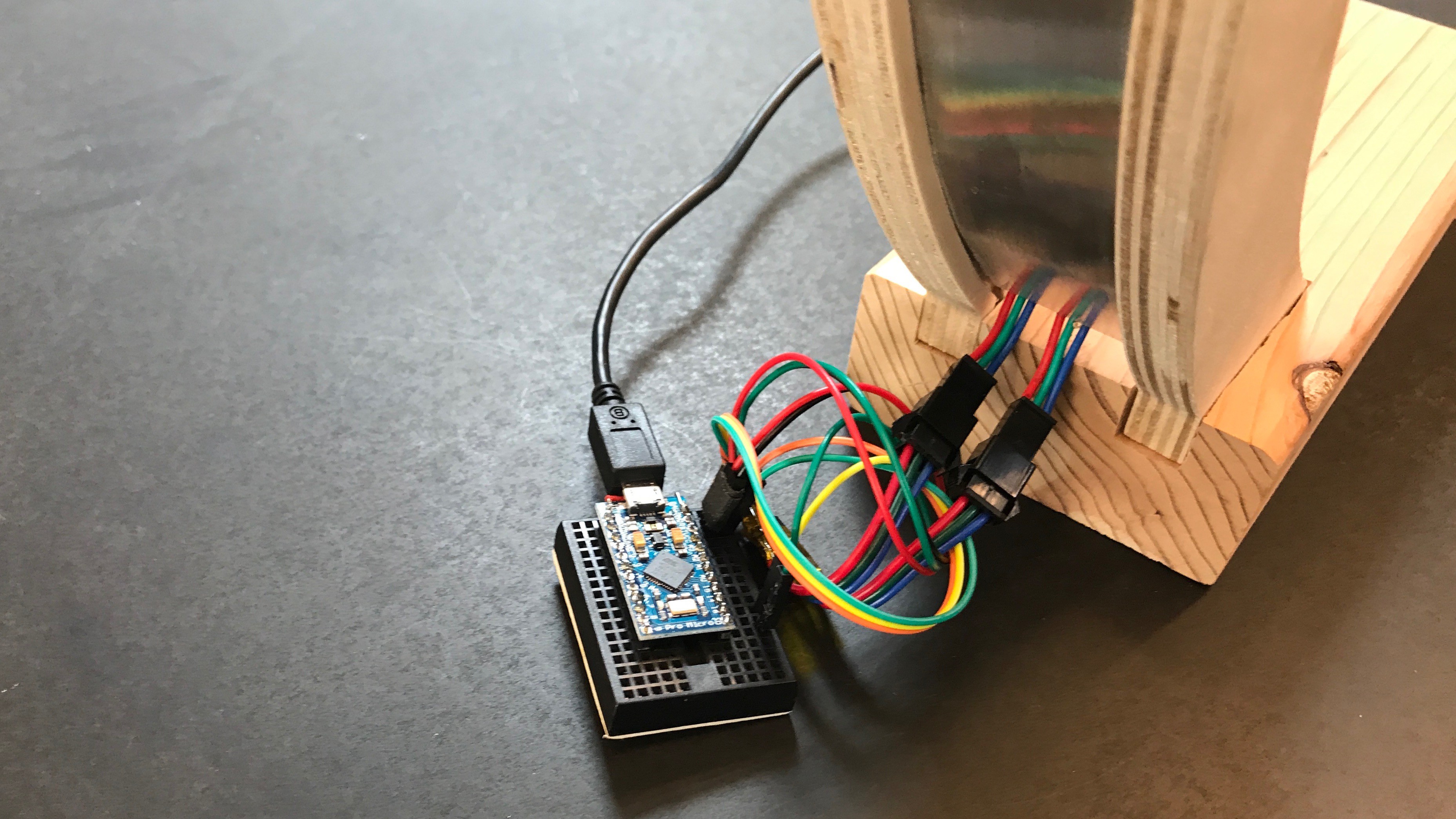

- The power and control of addressable multi-channel LEDs

Or.... "Welcome to the spaceship. We are happy to see you!"

todbot

todbot

Josh Cole

Josh Cole

Steve Pomeroy

Steve Pomeroy

Dirk-WIllem van Gulik

Dirk-WIllem van Gulik

Tom Dowad

Tom Dowad

It is a huge addition in the enhancement of room presence. All the designs are very nice. I would love to share it through my website also.