Part List:

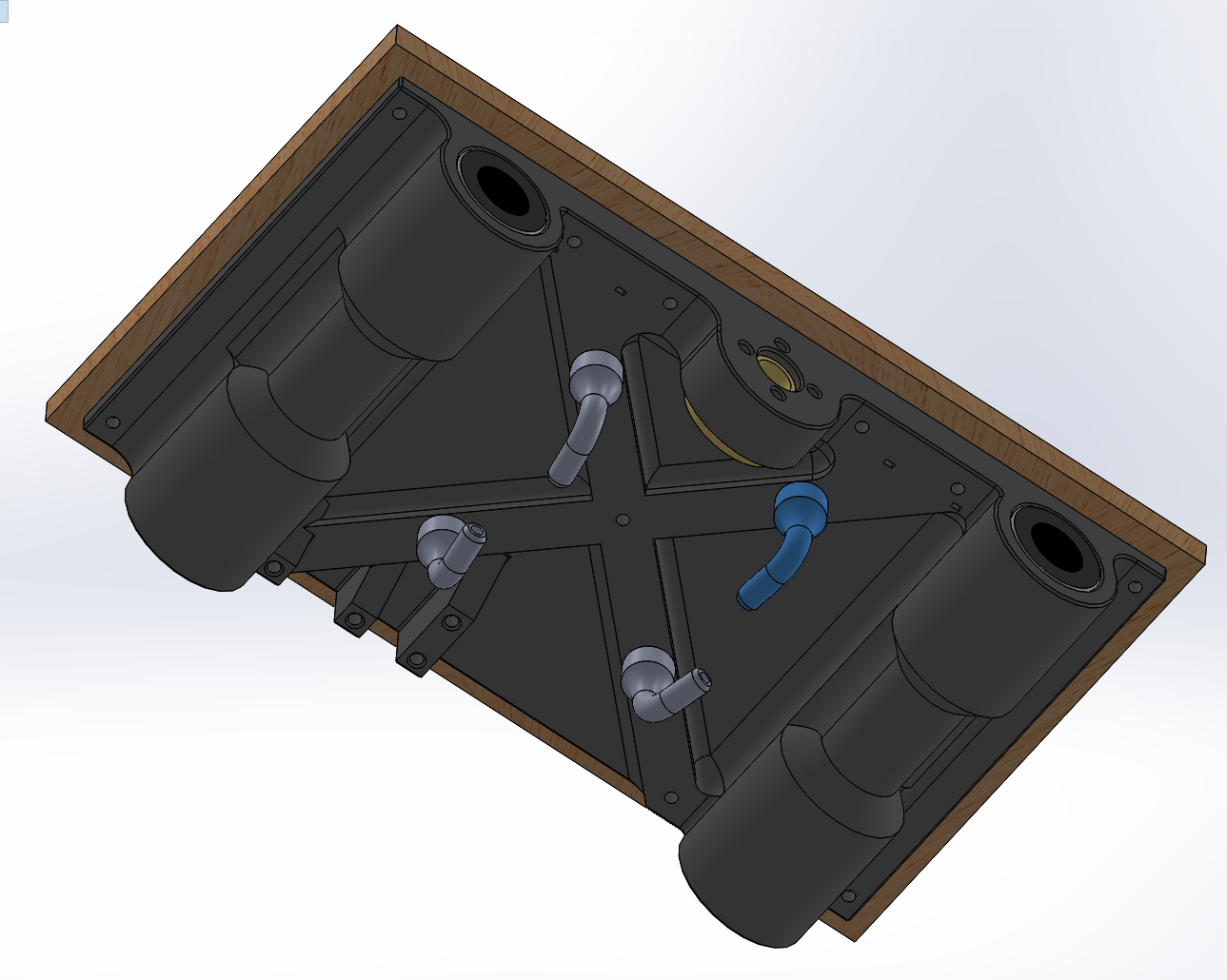

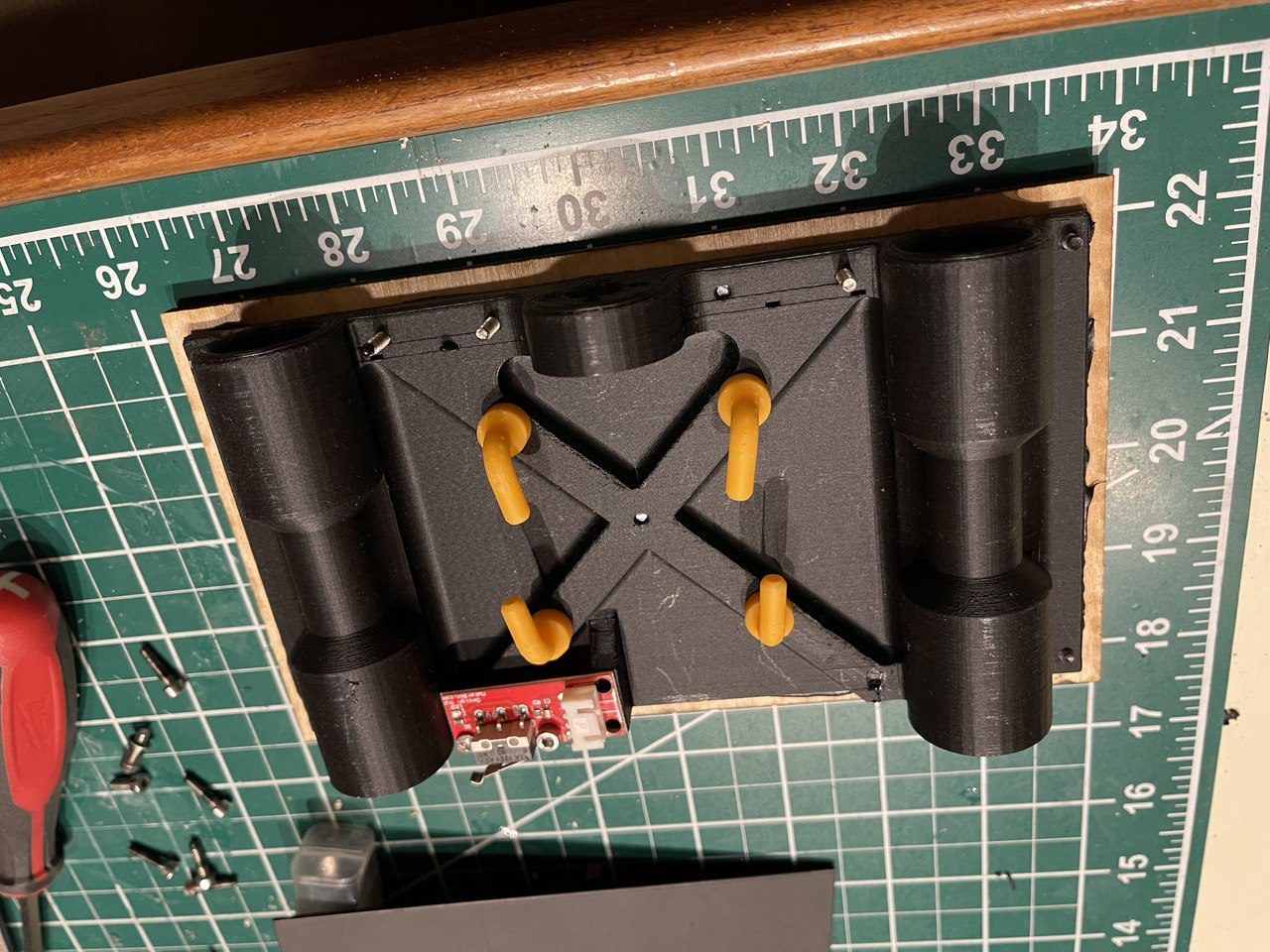

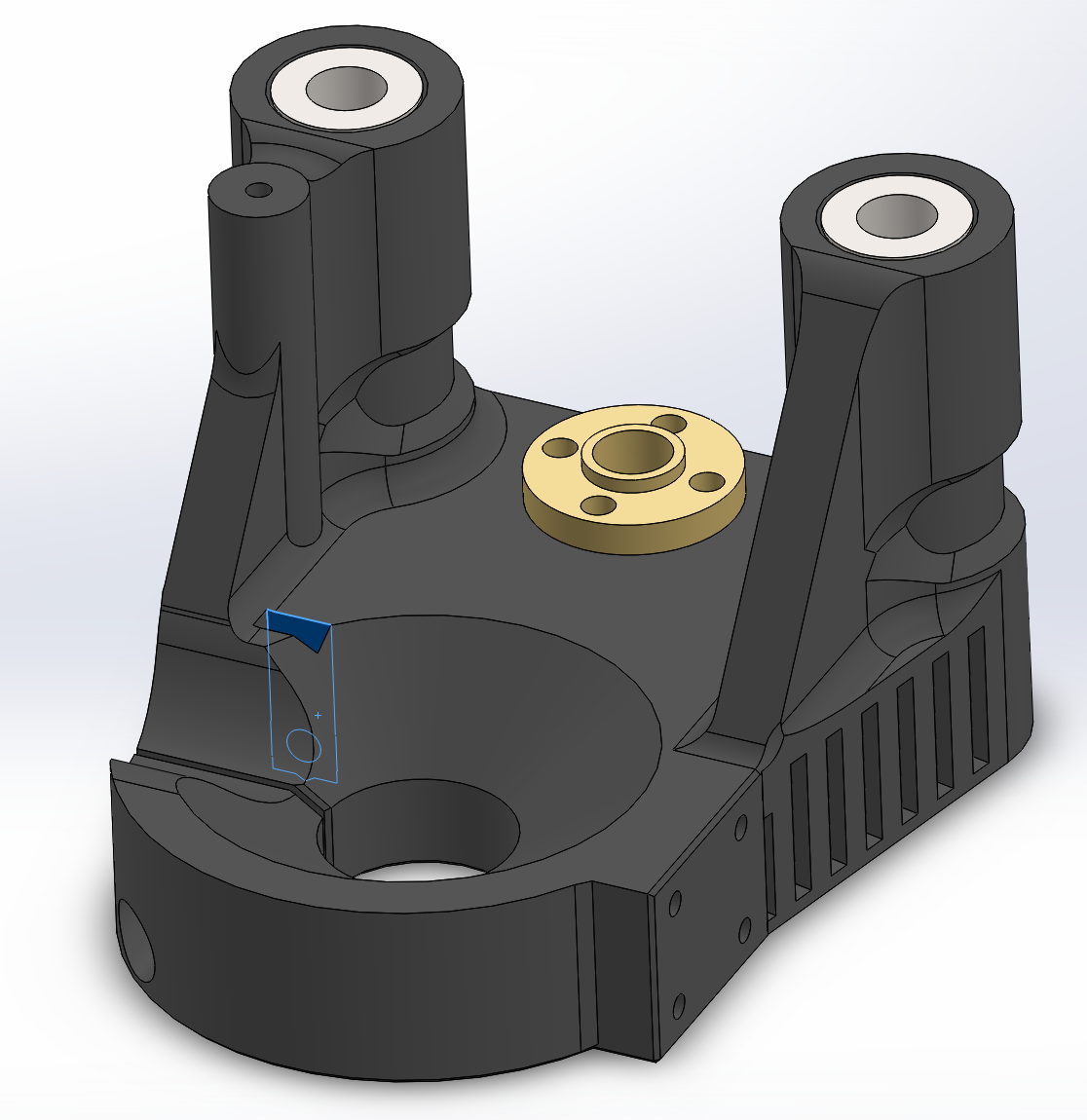

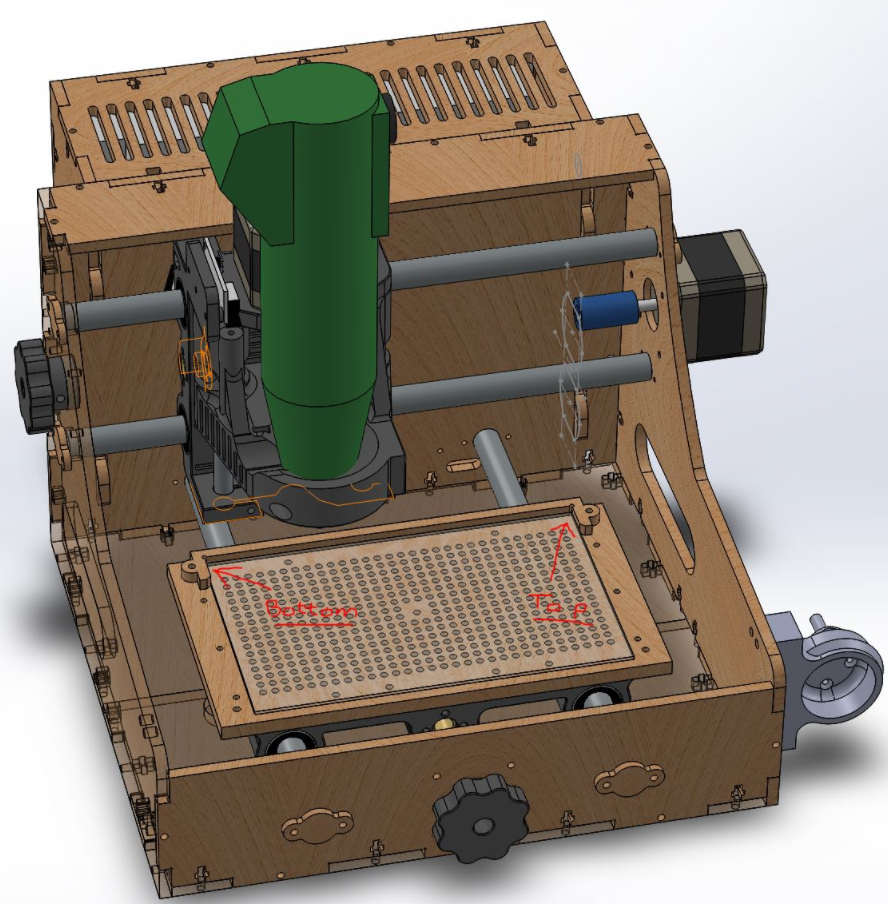

- 8 x LM12UU

- 4 x LM8UU

- 2 x 12mm x 260mm hardened linear rod

- 2 x 12mm x 240mm hardened linear rod

- 2 x 8mm x 110mm hardened linear rod

- 3 x 8mm to 5mm aluminium coupler

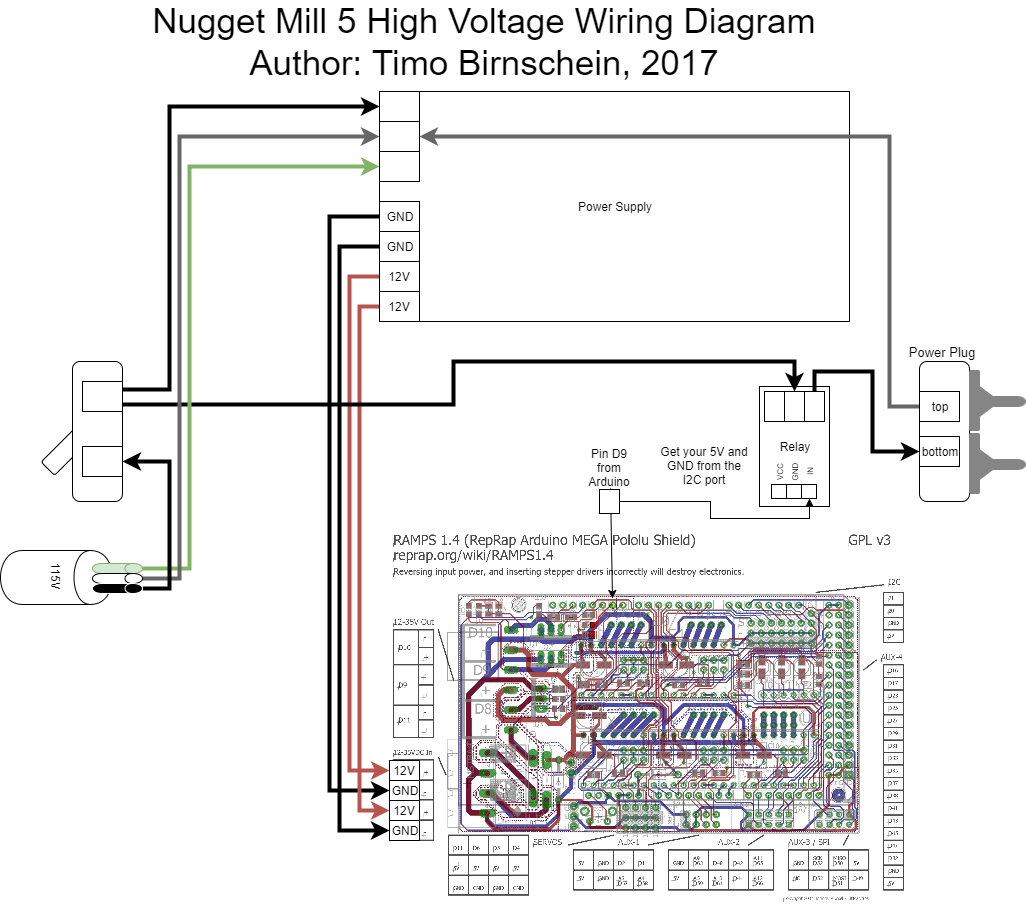

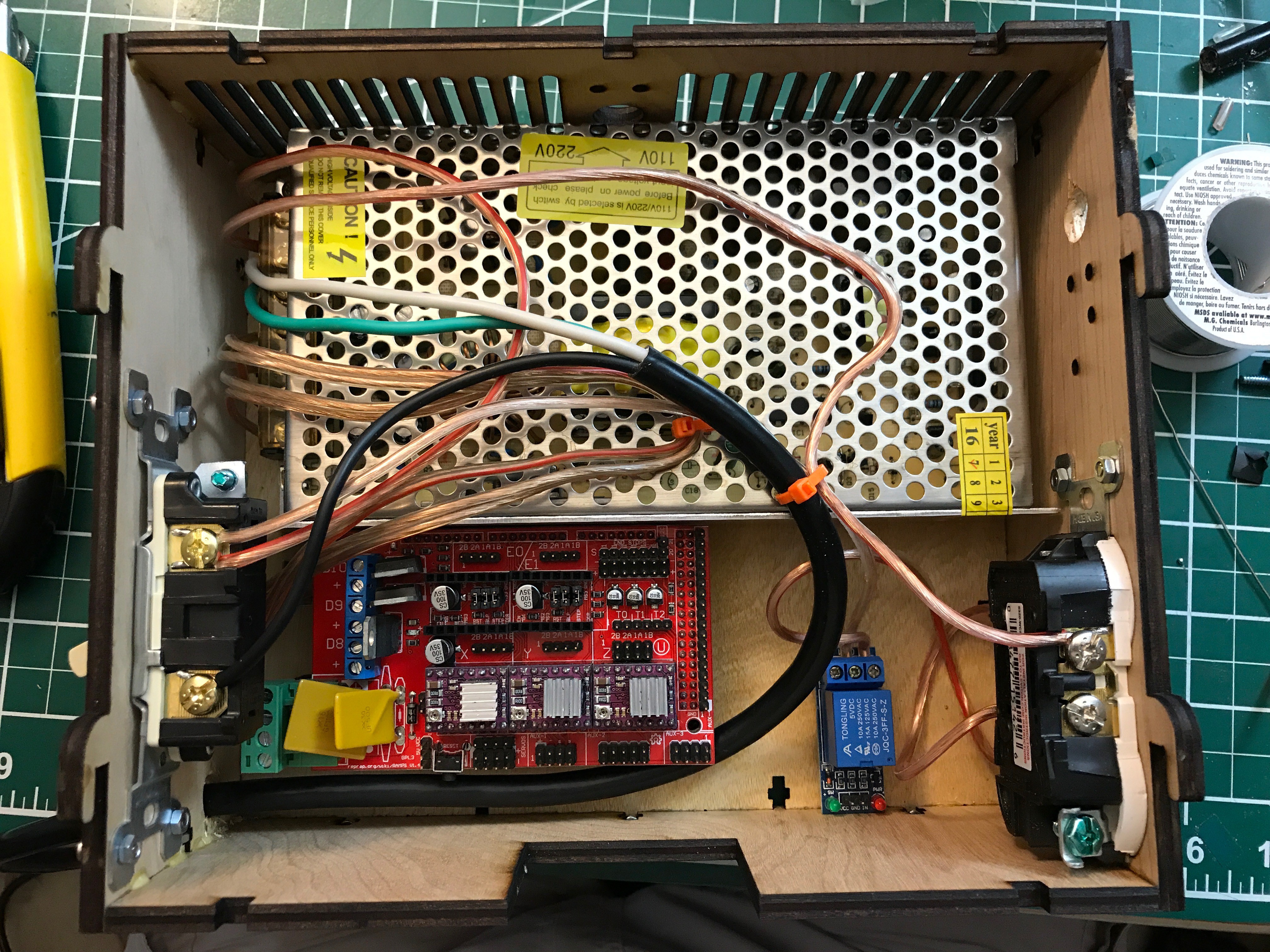

- 1 x DC 12V 10A 120W power supply

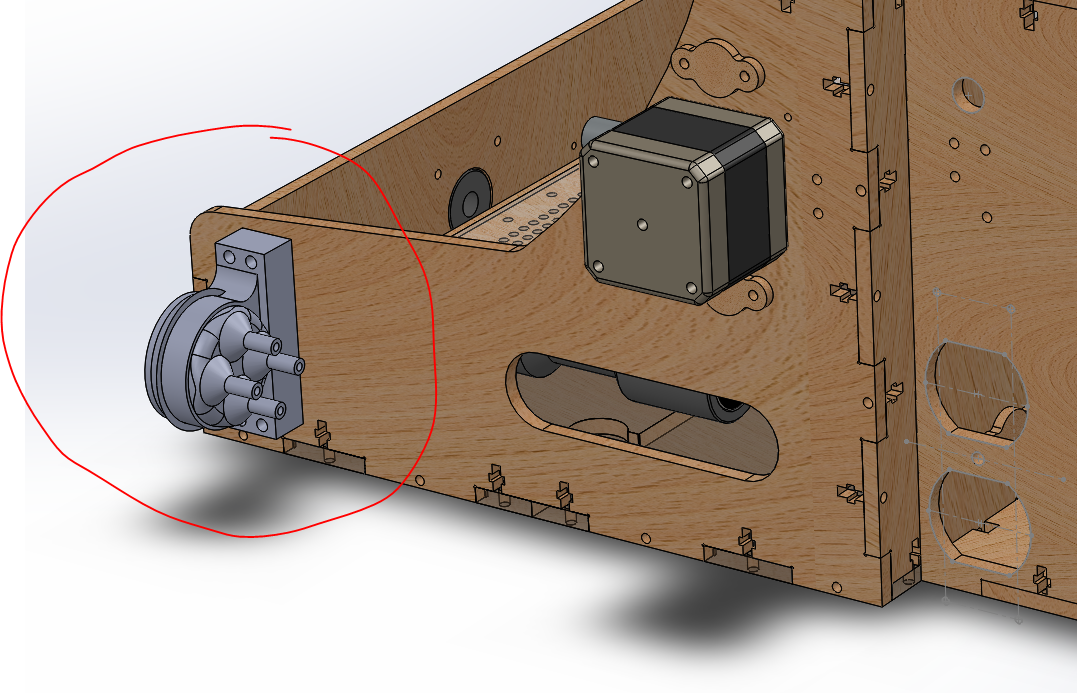

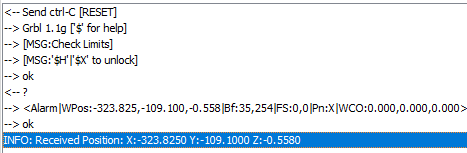

- 1 x Ramps 1.4 kit with stepper motors and Adruino Mega Controller and end stops

- 1 x 8mm x 260mm T8x8 trapezoidal threaded rod with brass nut

- 1 x 8mm x 240mm T8x8 trapezoidal threaded rod with brass nut

- 1 x 8mm x 80mm T8x2 trapezoidal threaded rod with brass nut

- 1 x 5V relay module for automatic spindle control

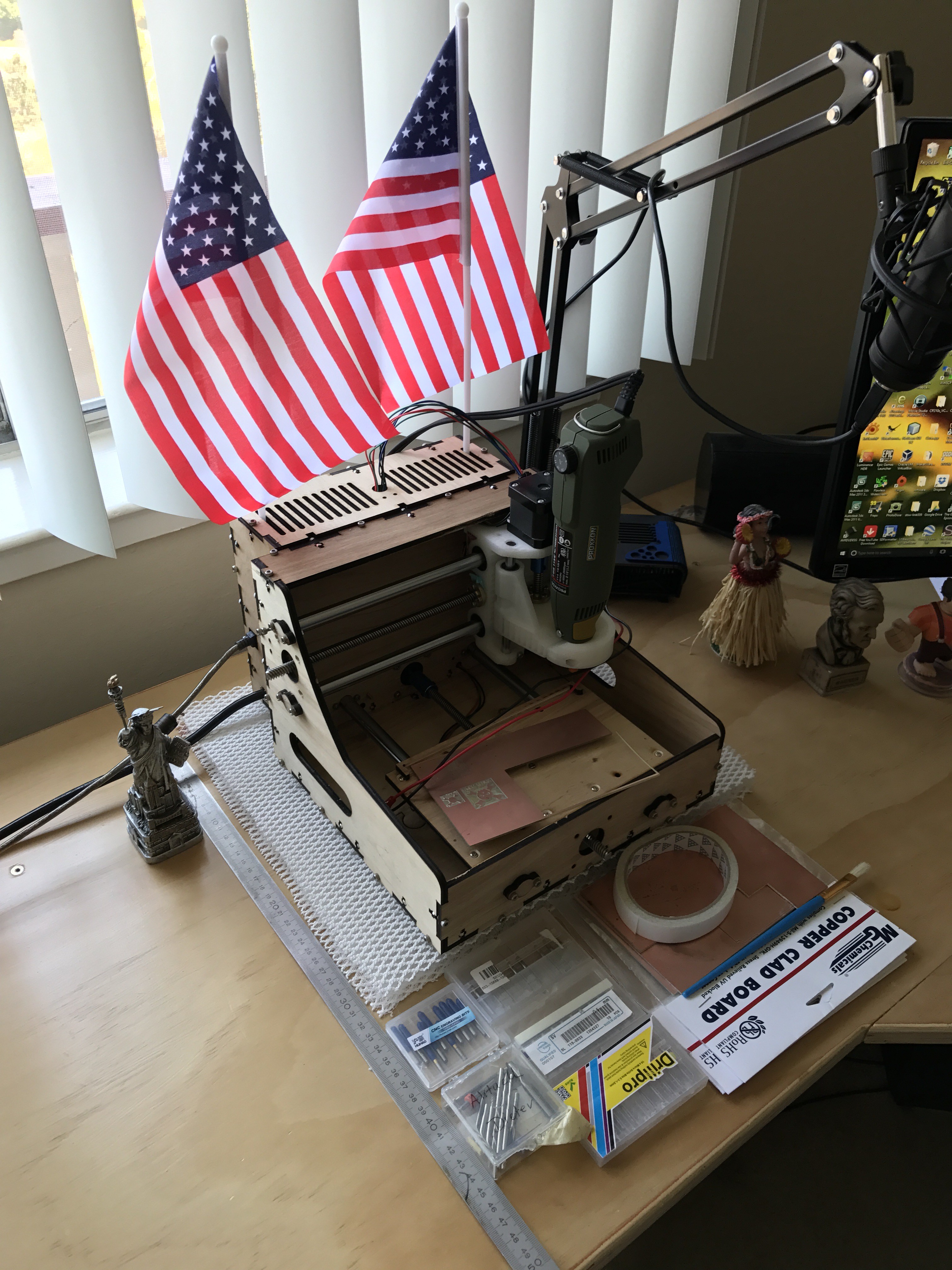

- 1 x sheet of 5mm plywood from home depot and a circular saw to cut it to 200mm x 300mm sheets (I suggest going with something more expensive than I did)

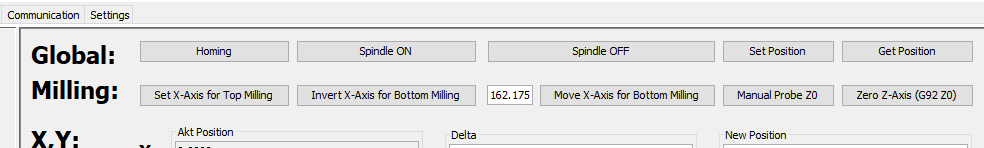

- 1 x Proxxon FBS 115/E because the original dremel is not precise enough!

- 1 x Proxxon 28940 steel collet set for high precision milling

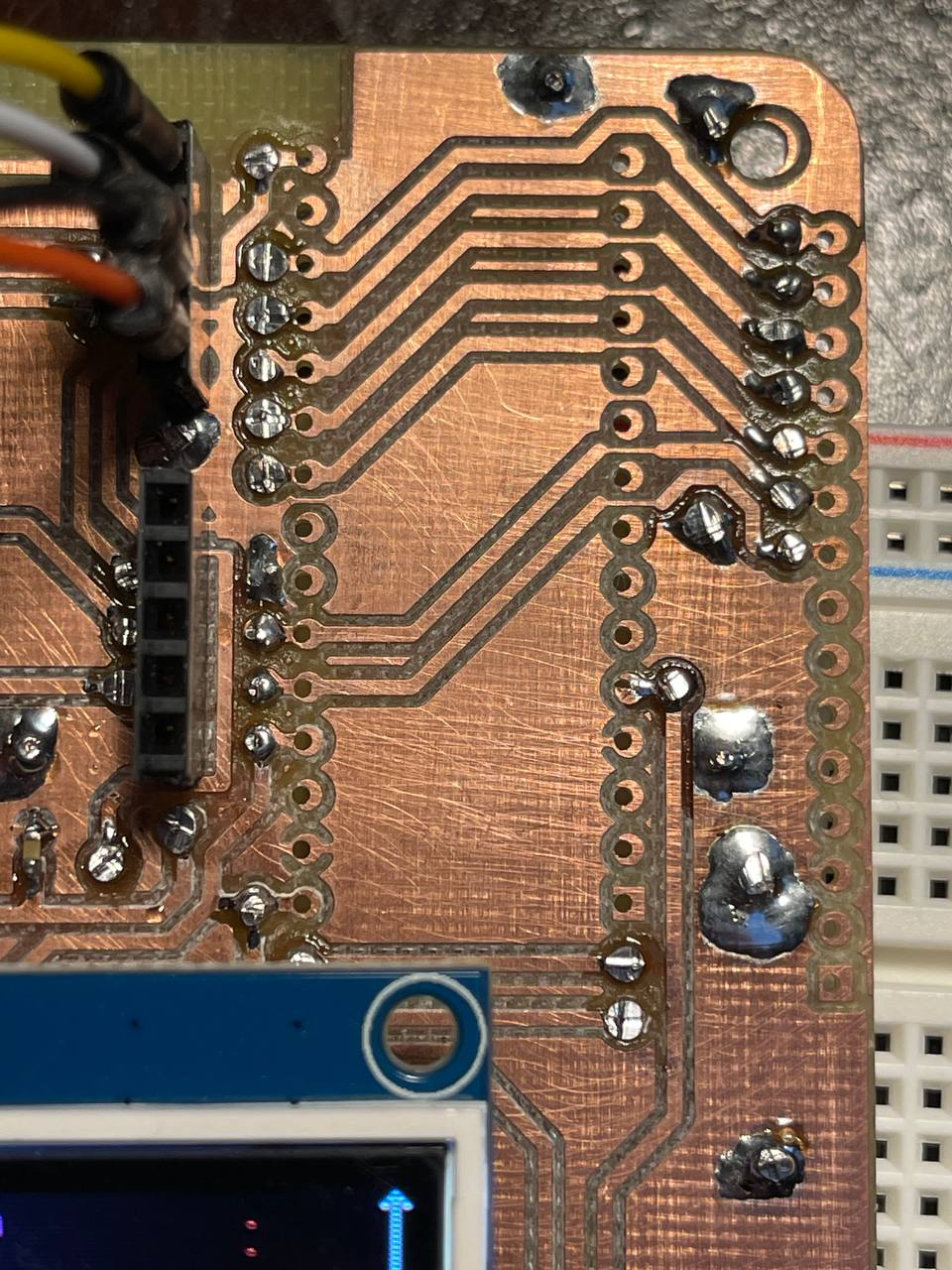

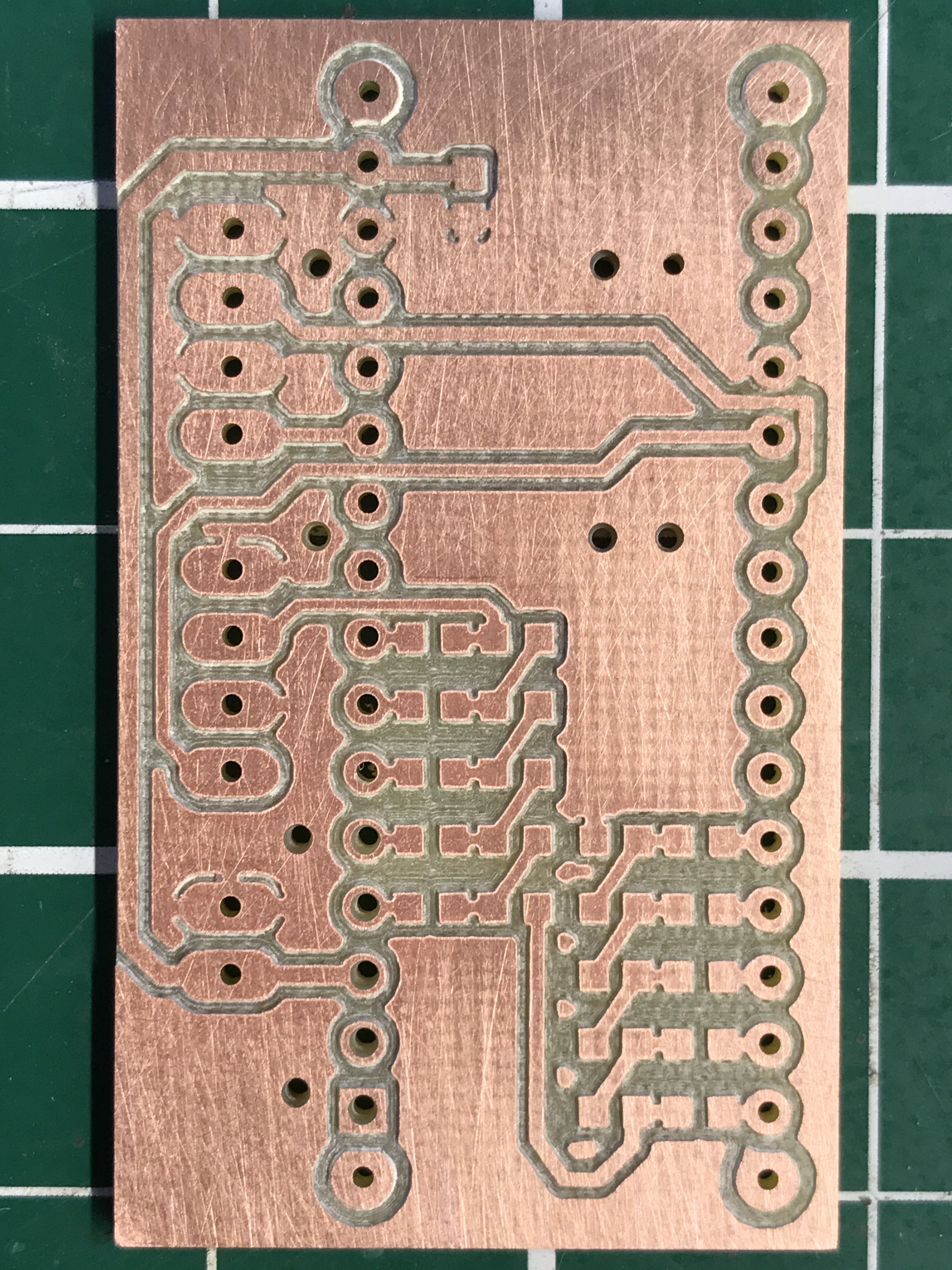

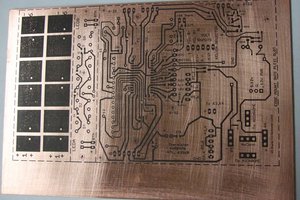

- 1 x 30 degree 0.2mm PCB engraving bits with titanium coating

- 1 x 1mm PCB milling bits with carbide coating

- 1 x Varying drill bits between 0.3mm to 1.2mm

- 1 x Wall mount toggle switch as 15A on/off switch

- 1 x Wall mount wall power plug for spindle

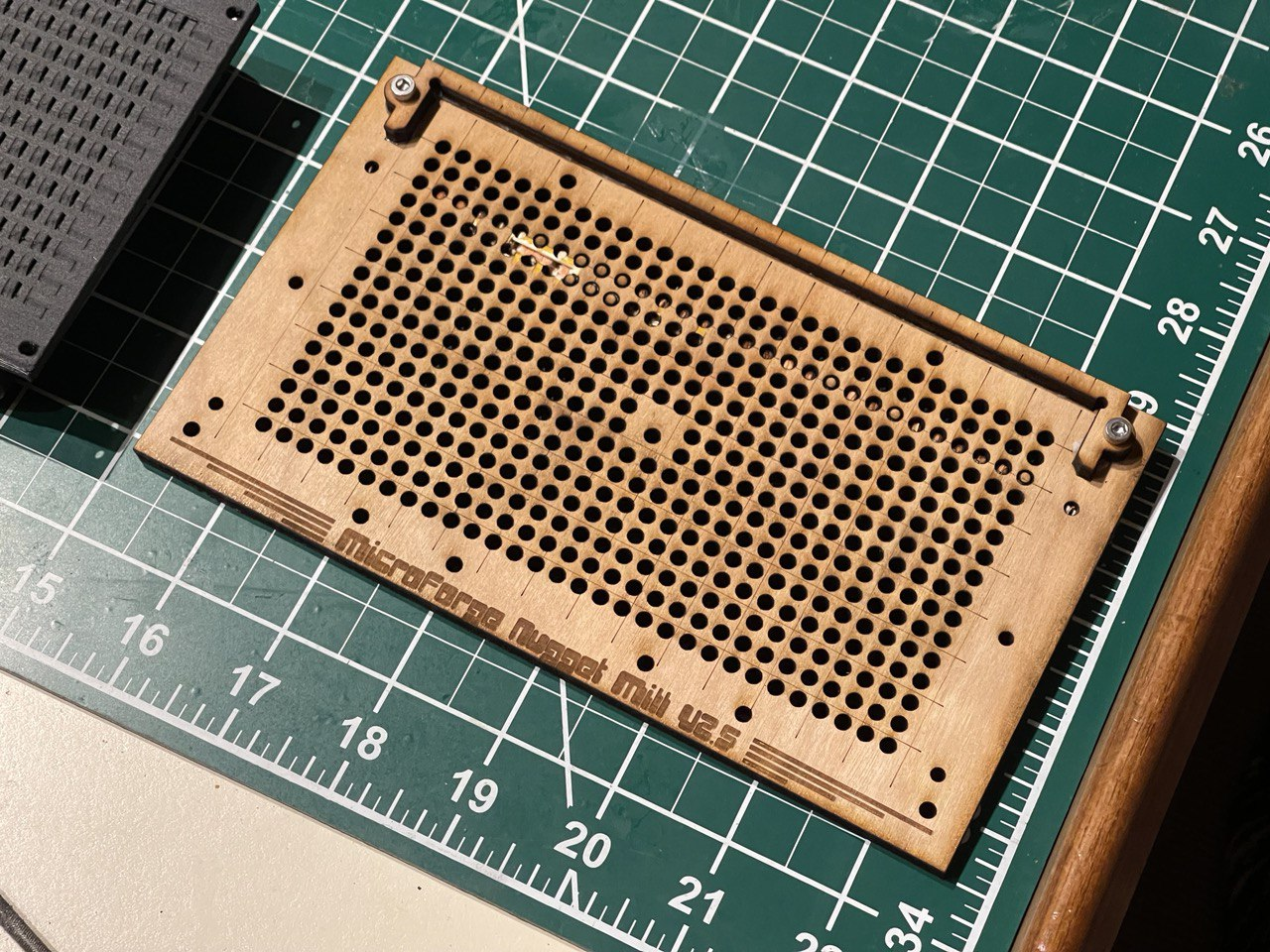

It would be good to have access to a laser cutter to make this. Otherwise just order the parts including material from your local laser cutting shop.

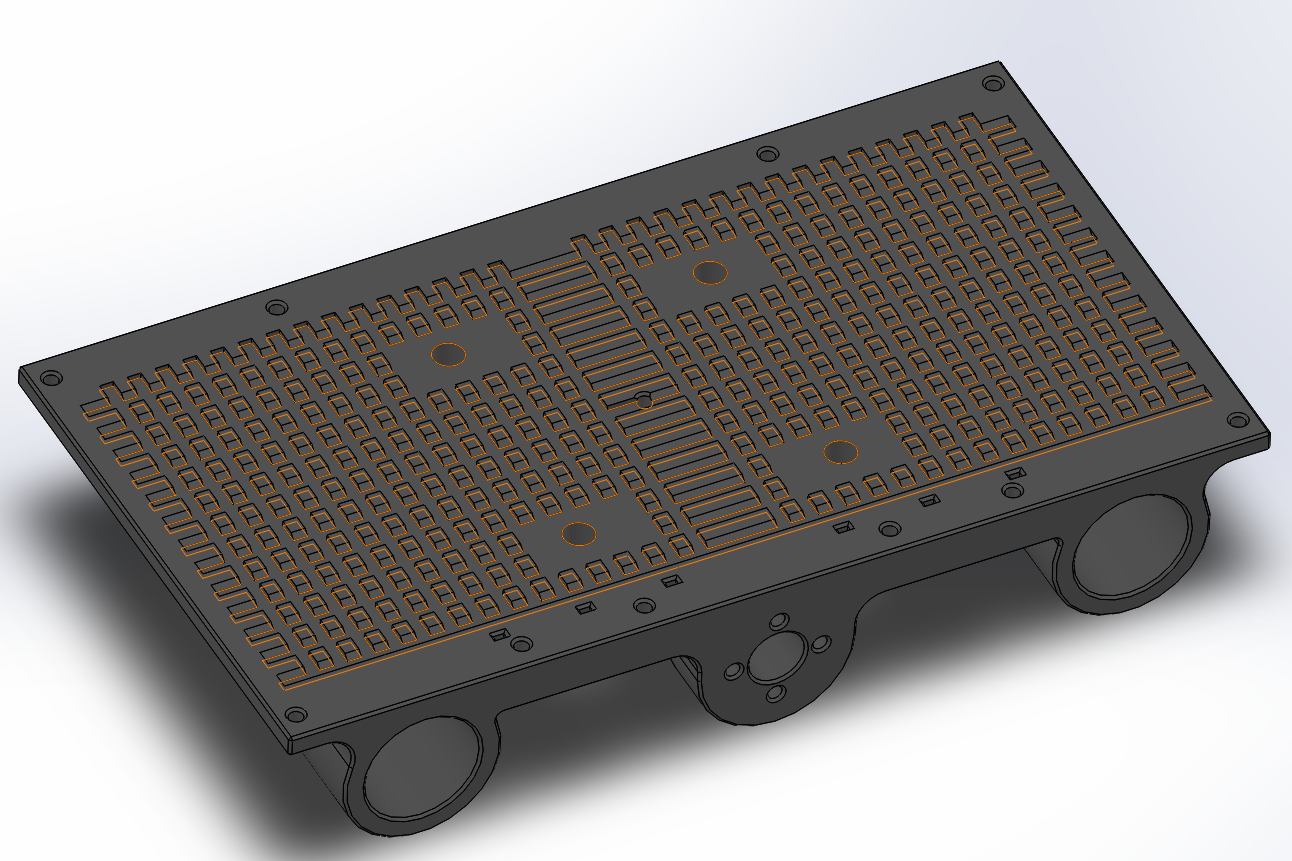

Print Instructions:

I use KisSlicer for printing my parts! I use it because it offers a VERY valuable function which calculates insets for holes. Properly calibrated, this gives me exactly 12mm when I design a 12mm hole! For all parts, this means that I can pressfit my linear bushings! Please keep that in mind before you kick of your 10h prints!

Timo Birnschein

Timo Birnschein

Sam Griffen

Sam Griffen

mosaicmerc

mosaicmerc

Mike Teachman

Mike Teachman

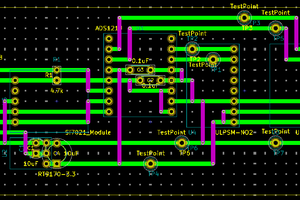

PCB designer

PCB designer

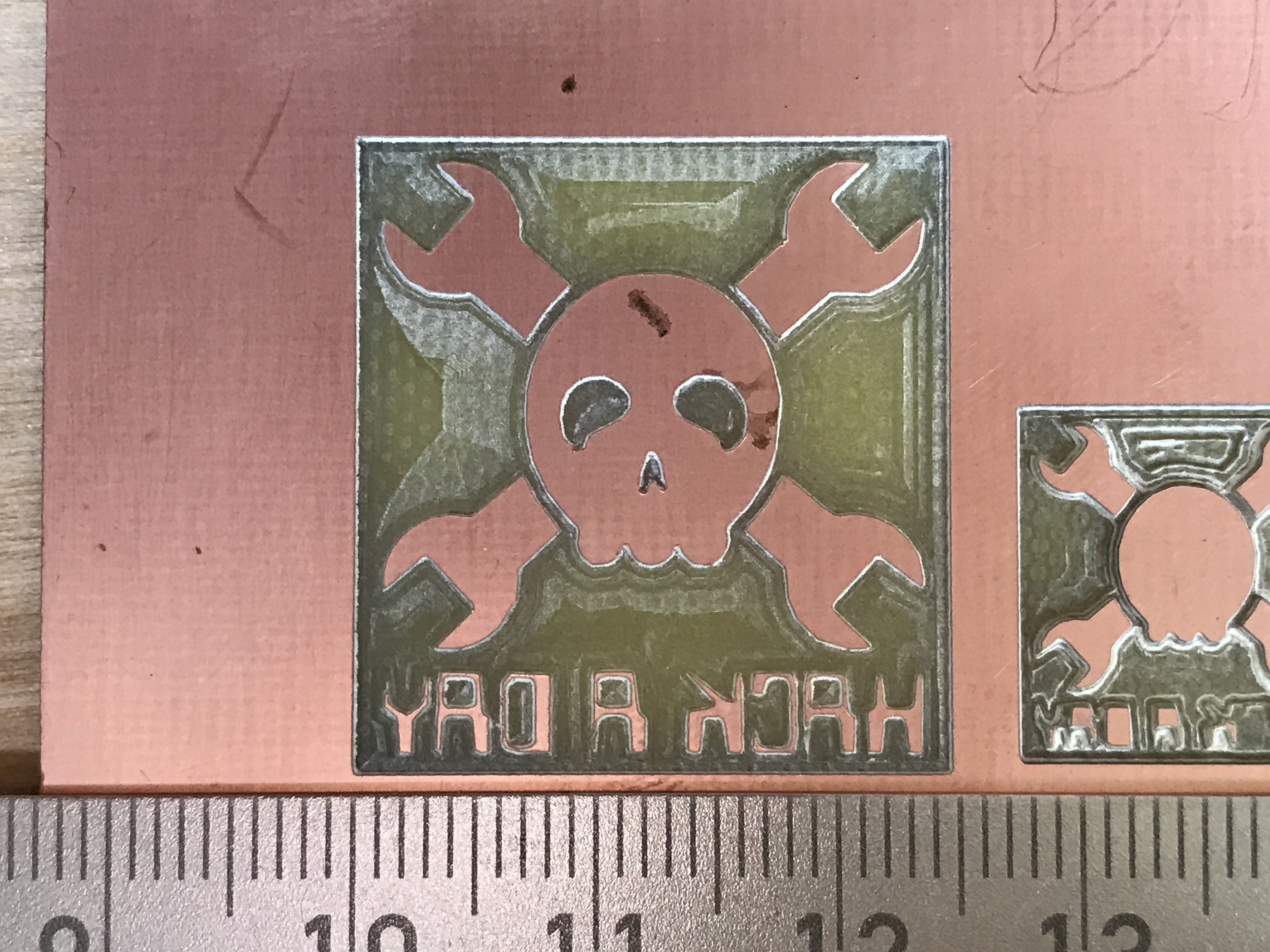

Hi Timo. Thanks for the skull/follow for #Minamil! It won't do 100x160mm, but I wonder -- since you've had this machine for a few years by now -- how much of what you do with this could be done in 55mm+ x 55mm+, or maybe 70mm x 70mm?