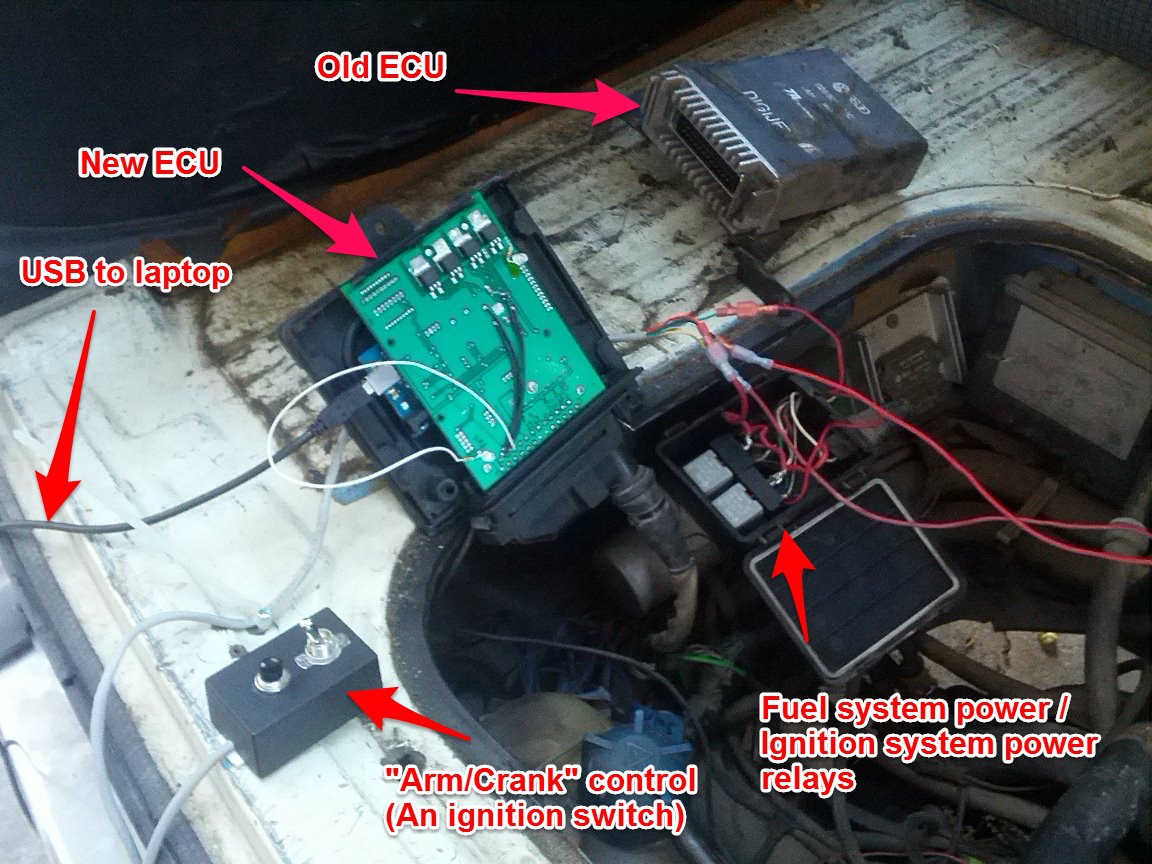

Current status: Igniton EMI from 1986 distributor causes driveability issues. Currently upgrading to coil-on-plug to mitigate EMI.

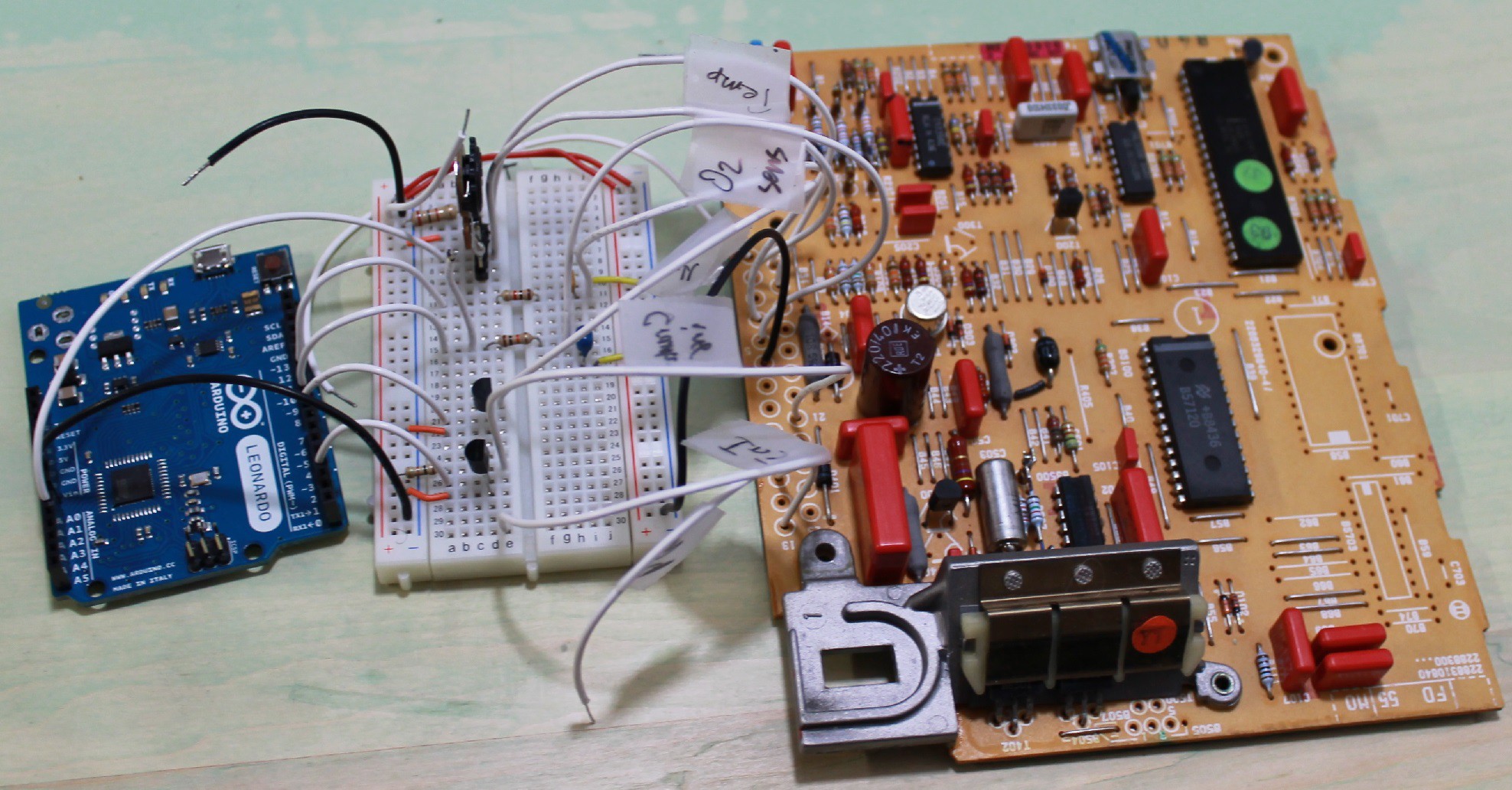

Firmware Build tools:

- Visual Studio Community 2013 (free) with Visual Micro.

Interface to the Firmware:

- The Arduino serial monitor

Engines supported:

- 1984 VW vanagon gasoline "digijet" (in development)

Control Inputs:

- Stock 1986 distributor for hall-effect signal without mechanical ignition timing

Control outputs

- Injectors : Batch-fire (same as 1984 stock)

- Ignition: ECU controls timing of single coil (with distributor)

- Currently developing: Coil-on-plug system

Auto-tuning

- Adjusts engine map while running (this is unusual among aftermarket ECUs)

- Both global and local (on the map) fuel adjustments happen simultaneously.

- Map changes not permanent unless saved.

- O2 sensor type: narrow-band (1984 stock) O2

Mike Thielvoldt

Mike Thielvoldt

Frédéric Druppel

Frédéric Druppel

Rory

Rory

Casual Cyborg

Casual Cyborg

Hugh Brown (Saint Aardvark the Carpeted)

Hugh Brown (Saint Aardvark the Carpeted)

Great Project. I was dreaming up the same approach yesterday evening for my vintage 1984 Westfalia, then proceeded to check for any previous work. Voilà ! Your project.

Have you progressed with coil-on-plug ?