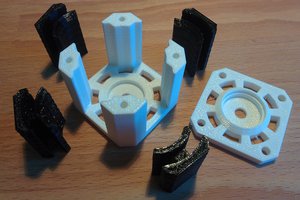

Printed in PLA from Filaments.ca, the brace from the tower to the vanes was easy enough to fix... but why just repair? I made it betterer.

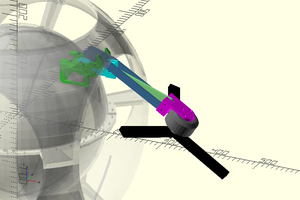

I also upgraded the stock BLDC to one about 20% more powerfuller (2212 2200kv) and put a triple blade (5x4) prop on it. The controller and radio were the suck, so they got upgraded too. The transmitter/receiver combo was the AX5S (still cheap, but better)

Let's just say that water is optional now.

I added a bit of steampunk flair to the brace design cause thats how I roll.

ken.do

ken.do

with some built in attachment thingy...

with some built in attachment thingy...

zakqwy

zakqwy

DrYerzinia

DrYerzinia