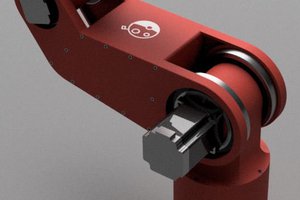

I was inspired watching kids at an ADHD camp interact around a toy of fighting spinning tops. Older kids were involved and engaged with the younger ones. They chatted freely about the tops and the games. I realized I could do the same, maybe better with something more sophisticated and focused, perhaps involving ideas from education and ADHD research. I finally had a chance to use my engineering skills to help kids. From this, Skoobot was born.

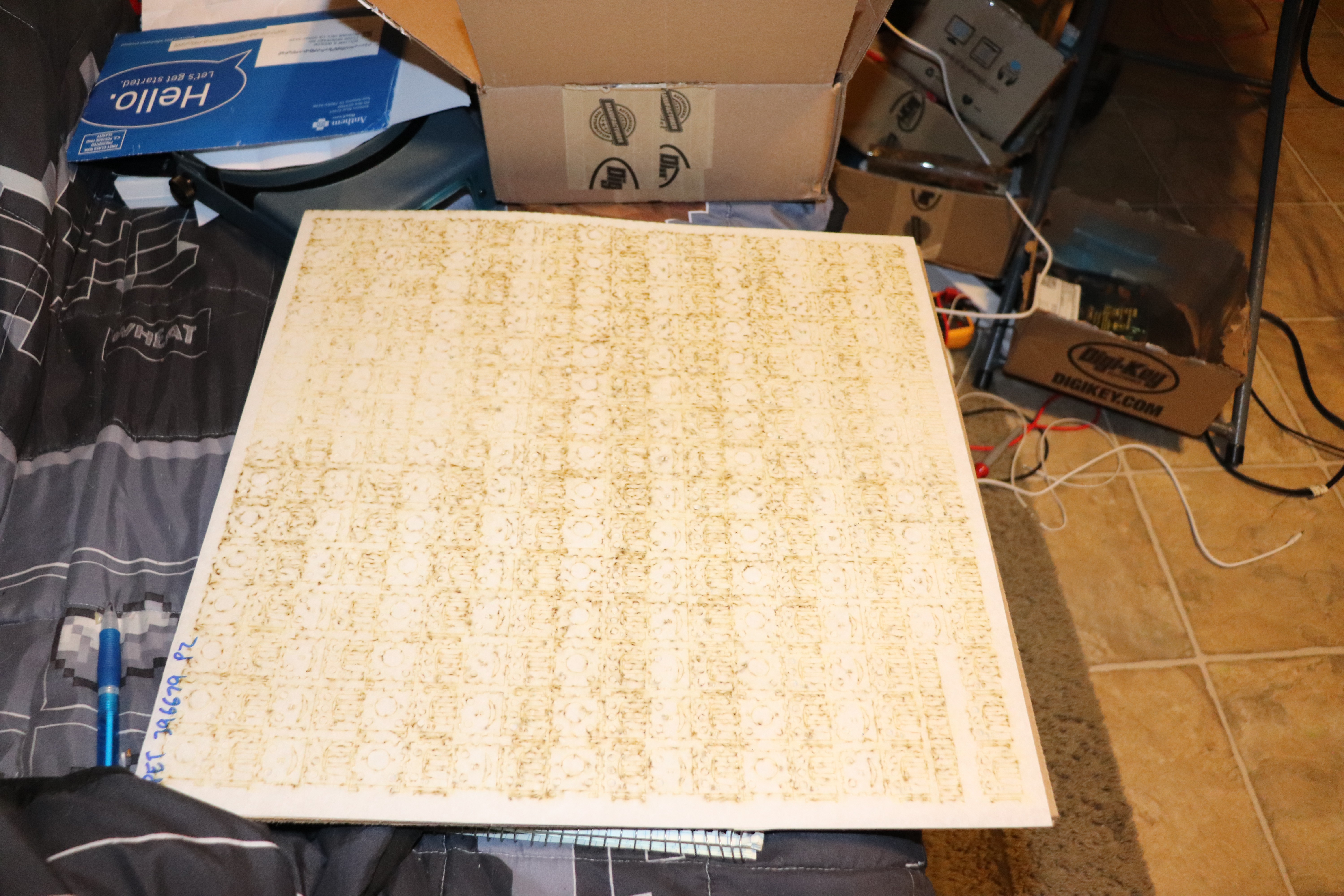

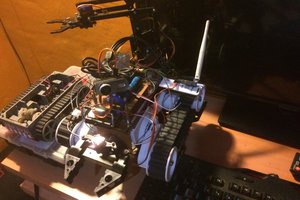

Skoobot is a fun, tiny little robot. It has a microphone, and a powerful enough processor to handle the math needed for audio, like spoken word recognition. With the buzzer, and the robot’s movement, this creates enough feedback to interact with children in a meaningful way. Once the children are drawn in by the cuteness and novelty, they are directed towards a cooperative game, using spoken commands, with each child taking a turn. The game could be to solve a maze, or to help the robots communicate with a beep-based language. The cooperative game will be optimized for fun and social learning. But first, I need to prove out the basic hardware and software of the robot, and the manufacturability. This is partly because the EdTech business is long term. Coming in to the field and leaving right after is not an option because Educators need to know I will be there tomorrow.

To this end, I decided to roll out Skoobot in phases. The first is the the software hacker phase, where I build a community and get as much help as possible proofing the robot and building the software. The next phase is the Arduino phase, were the software is made less complex, where more people can try out Skoobot and have fun with it. These first two phases should create a stream of revenue. This gives me the runway I need to build the dream of making Skoobot a true Edtech product.

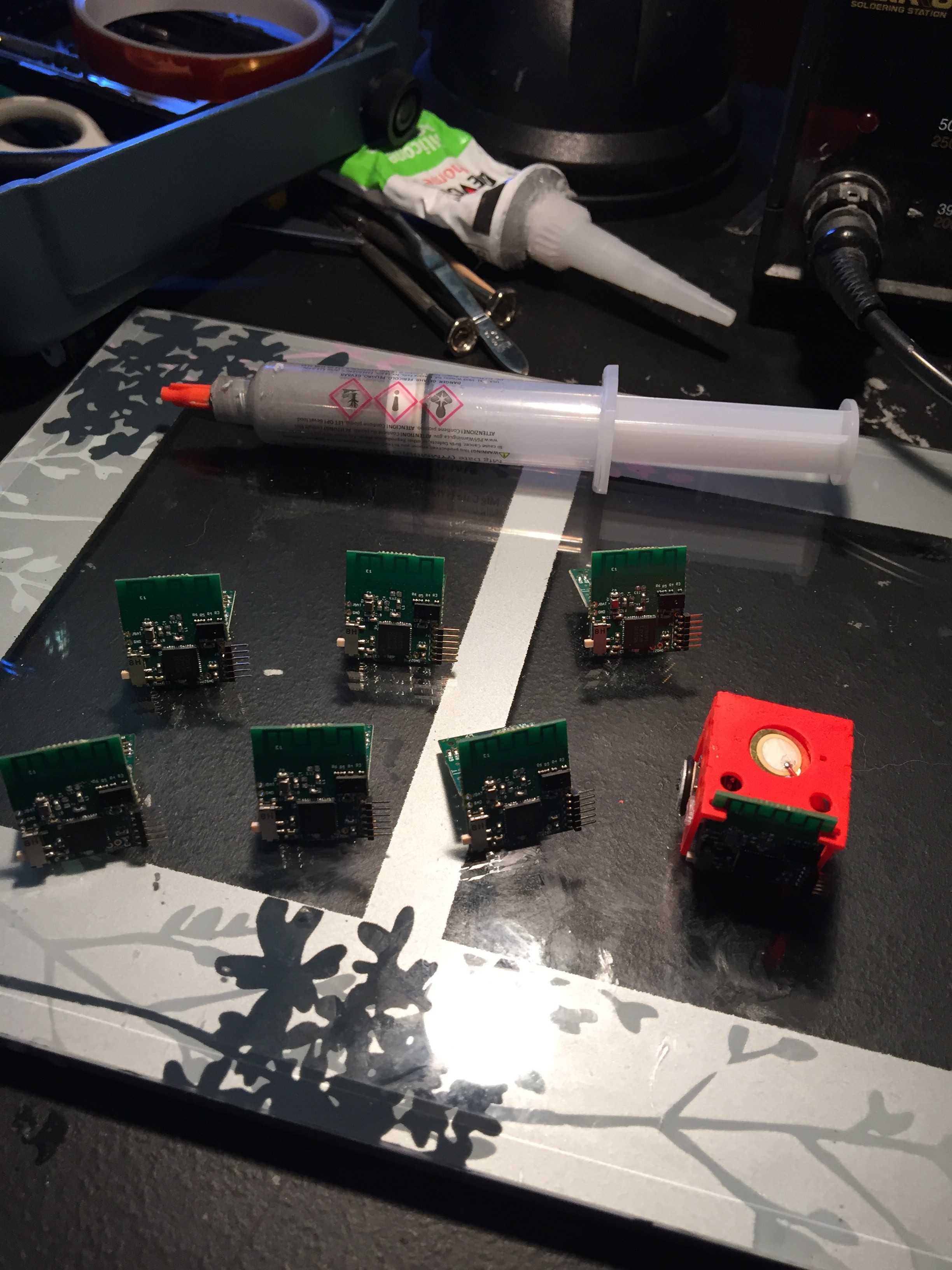

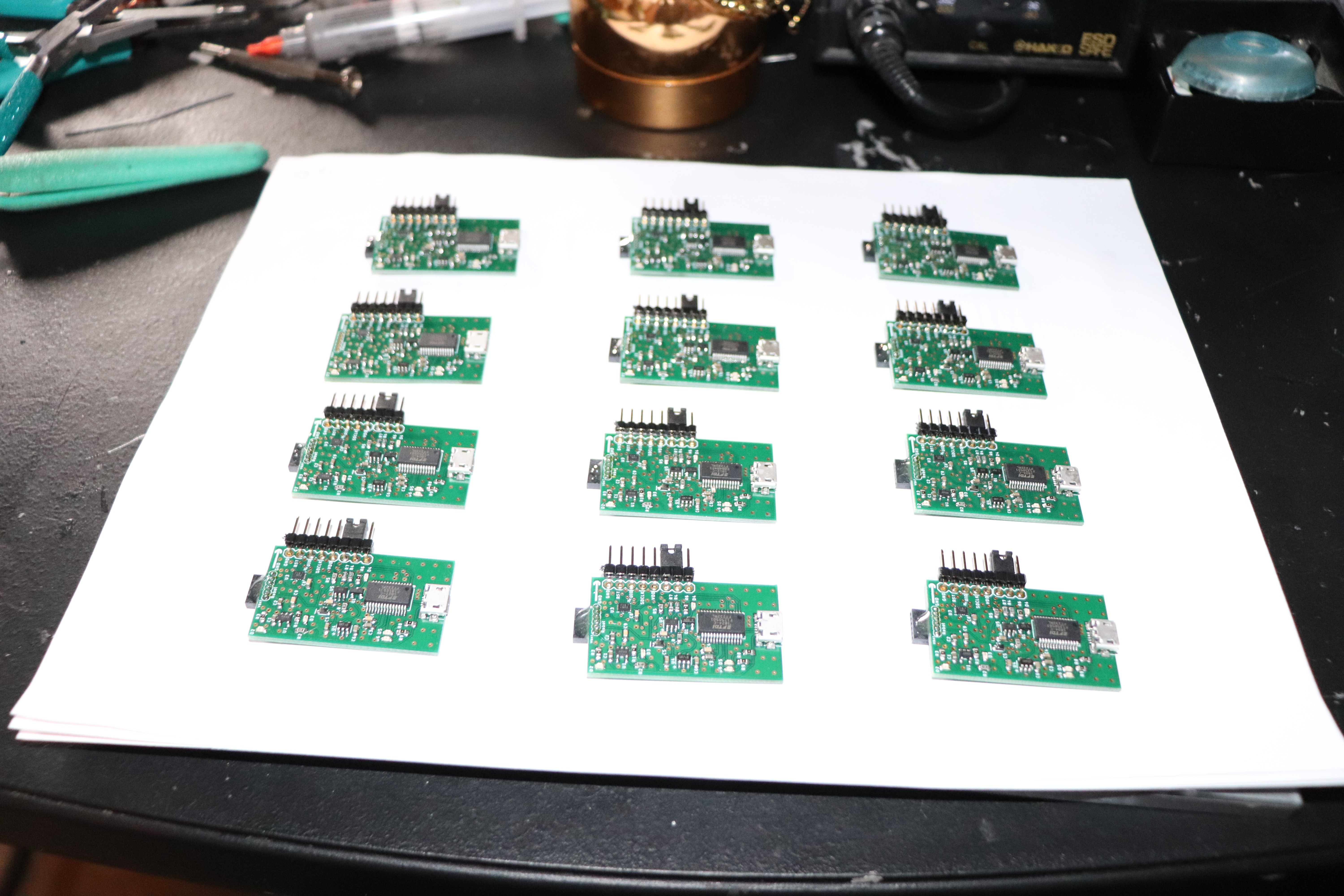

The delivered hardware is a robot and a companion board for programming. The companion board has these features:

1. It charges the robot's battery

2. It enables programming with the Arduino IDE, or C and other languages.

Bill Weiler

Bill Weiler

Dan Royer

Dan Royer

Erik Knutsson

Erik Knutsson

Kenny.Industries

Kenny.Industries

Rishaldy Prisly

Rishaldy Prisly

Just got mine today -- super easy to control from Windows!