-

Part 3: Body Built & Servo Problems

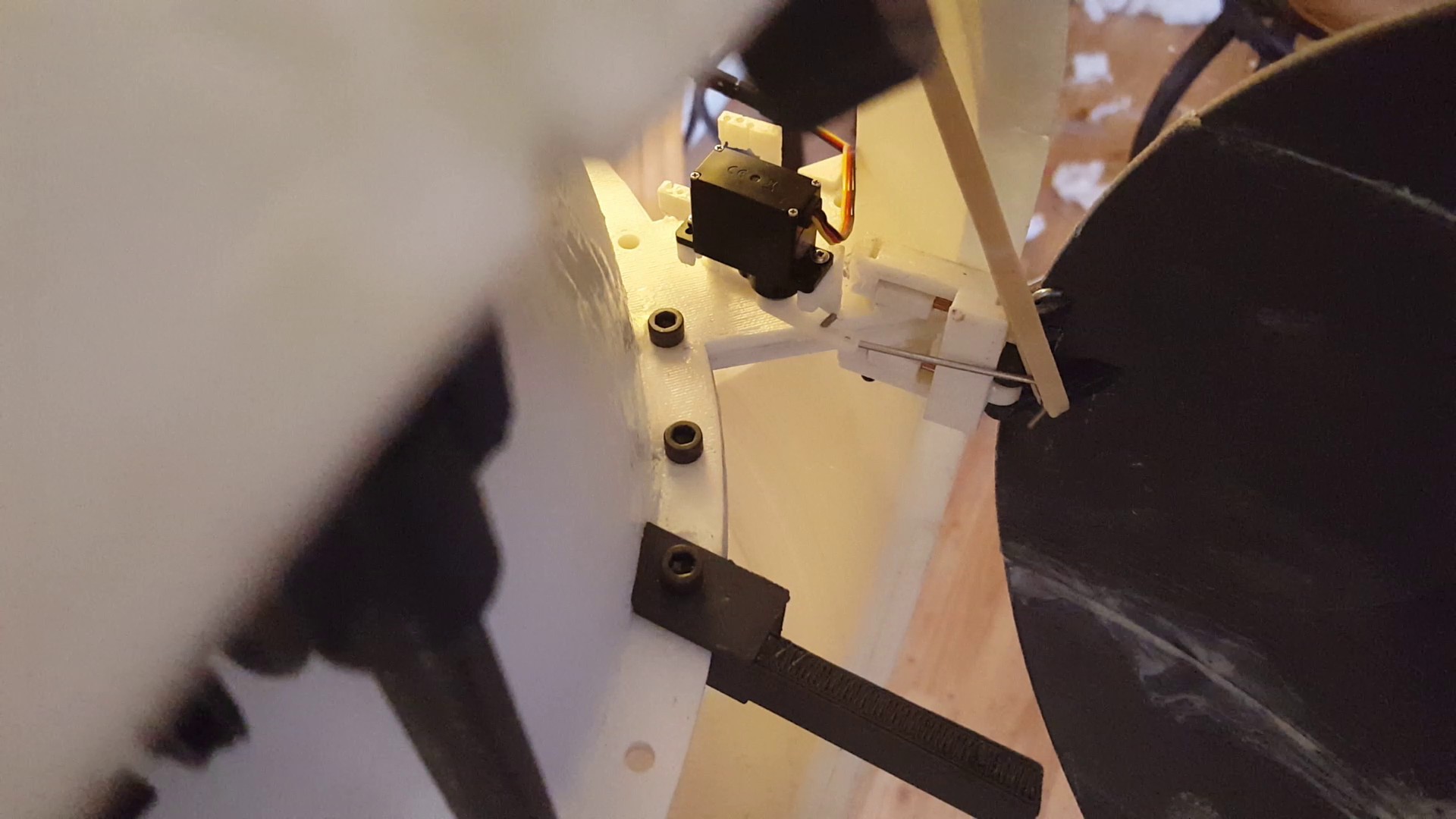

11/23/2015 at 10:02 • 0 commentsSo after 10 days of 24/7 3D printing 53 different parts on my Lulzbot Mini I have solvent welded together BB8s upper frame.

![]()

The frame is rock solid. Standing on the outer shell it supports my weight no problem. It its probably a lot stronger and heavier than it needs to be. It weighed in at 4.5 lbs. So the full weight of the frame will be 9lbs. Or about 1/4 the max thrust we will get from our motors.

![]()

I setup one door and one motor lifter to see how well they worked. The supplied drum that came with the winching servos for the lifter was to wide to lift the motor all the way so I printed a spindle with about half the diameter and now it gets up no problem. The door has a bit of trouble with it bending down under its weight so it gets caught and doesn't close properly. There are a few ways to remedy this. Right now I am using a rubber band to offset the sag, but I could also use a bearing on the outside of the slide to keep it more upright. The shafts for the slide and hinges are also undersized so more accurate shafts should reduce the slop. The last possibility is printing the doors hinge pieces so its natural state is to sit to high up. This way its sag set it into the right position.

![]()

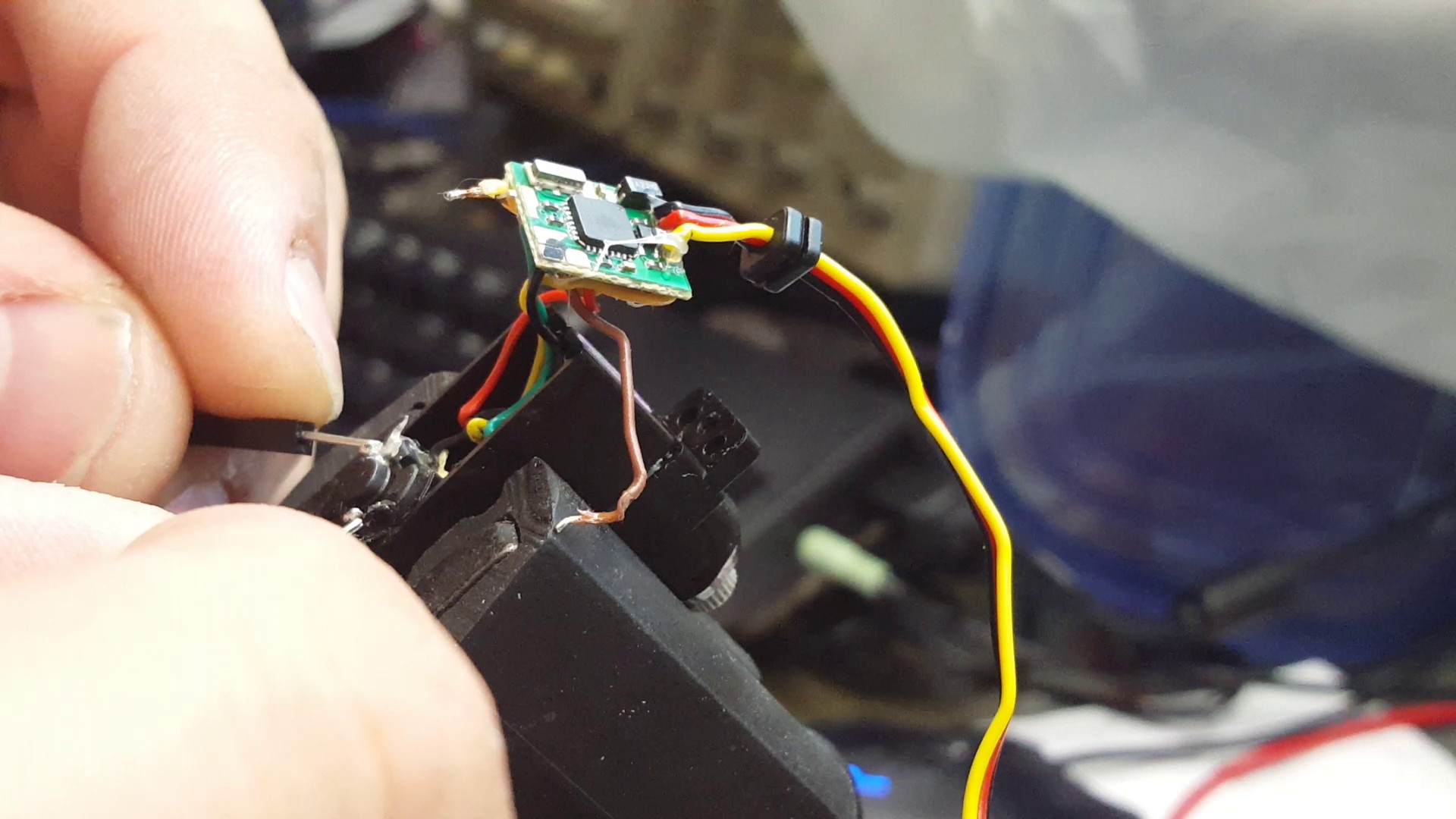

Because of the sagging I had a problem with one of the servo motors. The servo motor that ran the door was stalling when it got caught closing and one of the driver FETs got damaged.

![]()

I intend to replace the servo boards with OpenServo boards. This way I can control them via I2C and get feedback on position and power usage to see if they have stalled. I will use the existing boards for the winching servos which are full size but I will have to design a board for the doors microservo to fit it in.

![]()

That's all for this post. I get more plastic this wednesday so I can start printing the lower frame. So stay tuned in for that.

-

New Propeller Test, More CAD, Door Hinge test

11/06/2015 at 22:21 • 0 commentsThis time around I have some more CAD for the BB8. Testing of the new motors with the folding propellers. And the resolution of some 3D printing problems as well as a working cover hinge. Enjoy.

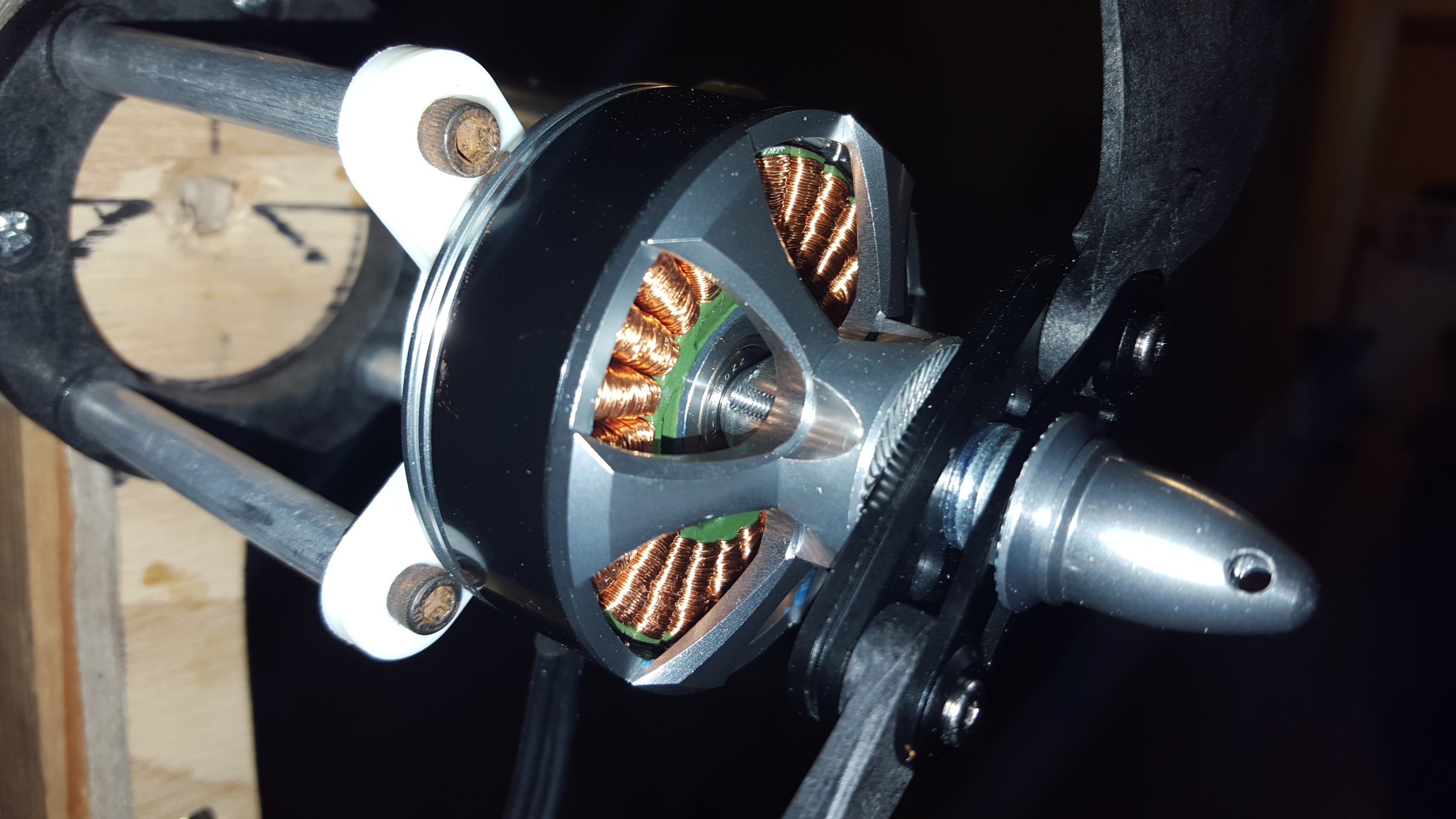

![]()

Above you can see the new MN5212 KV420 Motors I got in all there glory along with the 17 inch folding propeller blades from DJI. The motors have 24 poles so they should be fairly easy to drive to the positions I need them in to fold the propellers after a flight. You can see in the propeller hubs I'm using M6 washers to keep the hub from being crushed by the prop holder. These hubs are meant to be screwed on at 2 points but there hole spacing is 18MM and the motors is 12MM. I will have to machine or 3D print an adapter plate.![]()

The setup for measuring the motor stats is fairly simple. I was going to measure RPM but the hall effect sensor kept getting blown off the motor. Two multimeters measure the voltage and current comming from the battery. The Fluke 87 is measuring the voltage across a 1.5 mOhm shunt resistor made on a PCB from a fixed width/length trace and measured using a known restive load at measured voltage. This gives a little over 1 mV per amp. The thrust is measured with a scale.

![]()

Below I have a comparison of the chart from the manufacturer and the measurements I made. I'm comparing against the 17 inch propeller cause that's what I got.

I maxed out my thrust at 4.3 kG or about the same as their 85% thrust test. I suspect this is because of the voltage sag of my battery down 3.5v from its unloaded value. If you divide there test Wattage measurements vs current you get a steady 24 volts which I did not have. Going up to a 7S battery or potentially a higher capacity / C rating battery is should allow me to reach their maximum figures.

My goal weights for BB8 are as follows. For just the flight system plus the frame and doors I want to end up at 20 lbs. That would put my needed thrust to weight ratio at about 1:2 running in the 55% to 60% throttle range. We have decent efficiency there of about 6.5 g/W.

However for the flight system plus the rolling drive system and the head I'm aiming for 30lb's. That puts me in a 1:1.5 thrust to weight ratio, 75% full throttle. We loose about 20% efficiency at 5.5 g/W in that area.

Hopefully with a decent battery we can get a 5-10 minute flight time. No way we get much above that.

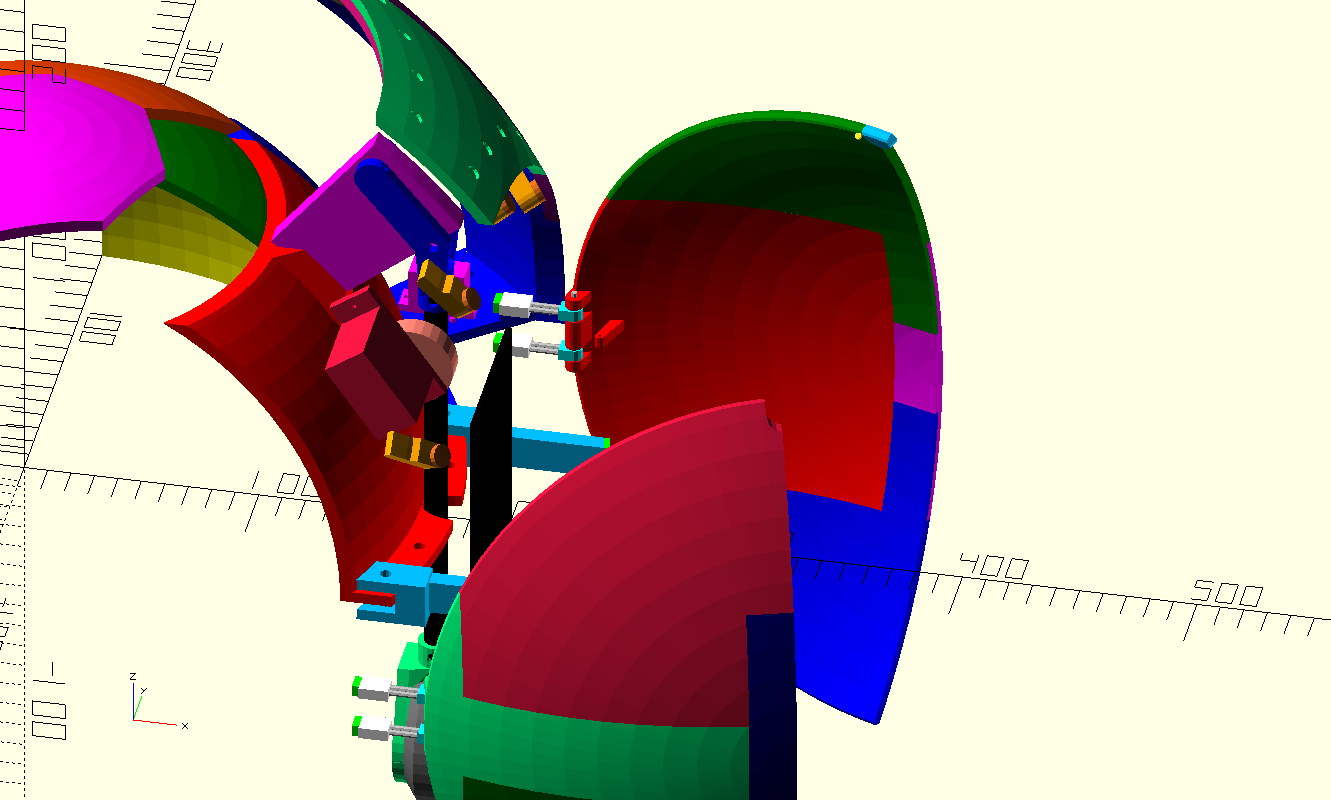

![]()

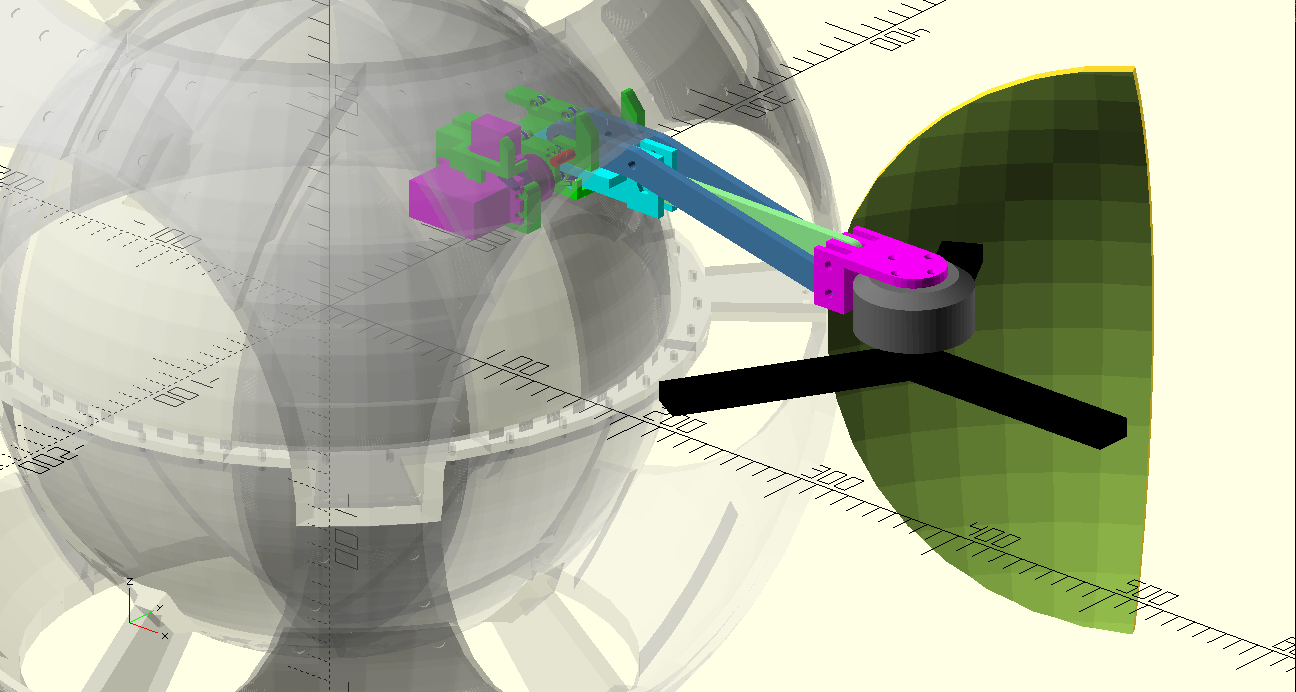

Here is a shot of the latest OpenSCAD design file. You can see I designed in the hinging mechanism and motor mount. I've roughed in the servos but I don't want to design the mounts till I have them to measure. The door hinging mechanism has been added as well as braces along the edges and middle to help it close properly along with rounding of the back edge of the door.

![]()

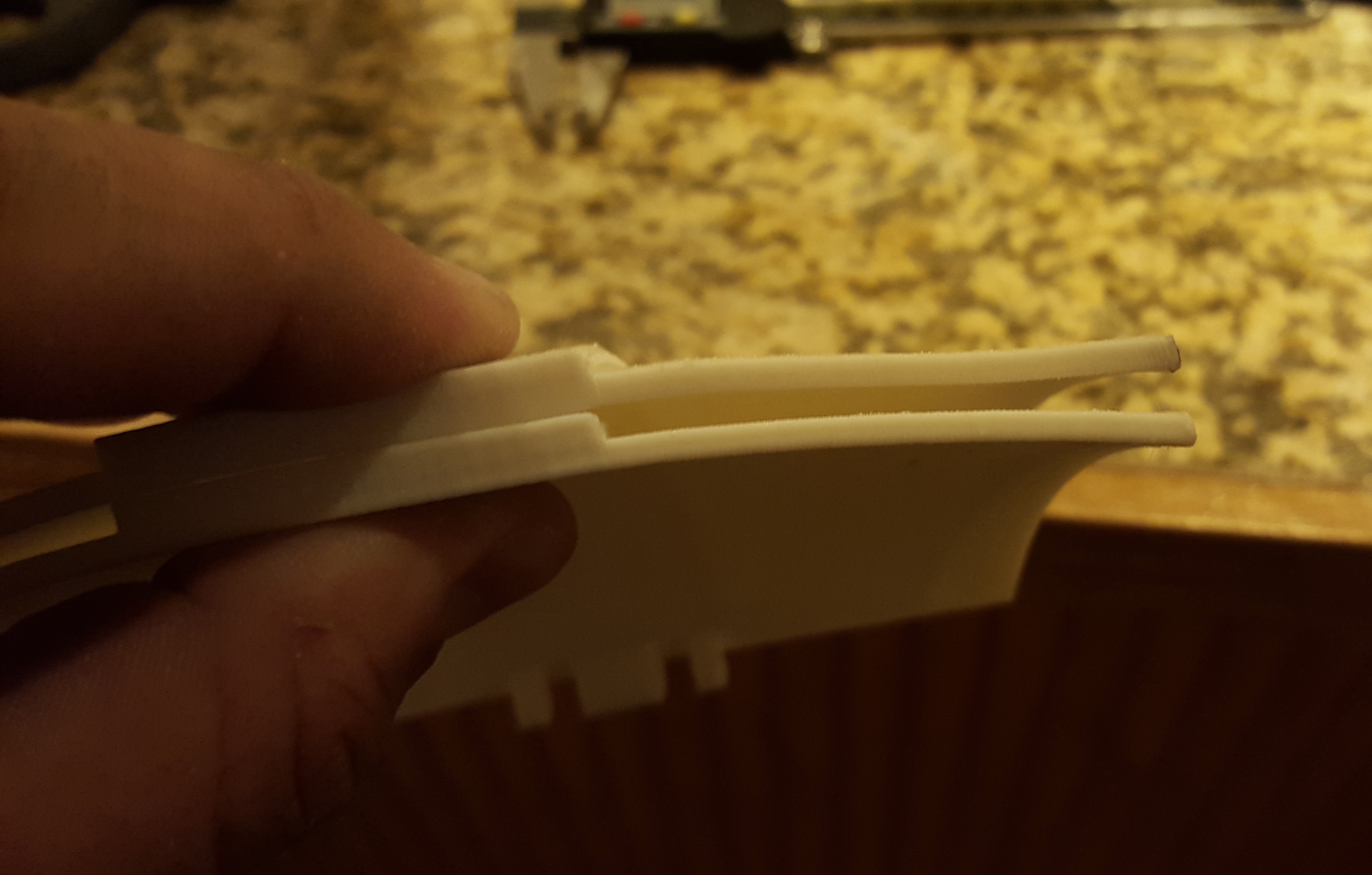

Here you can see the hinge mechanism. Its simply a slide combined with a hinge. A servo arm pushes it out past the edge where it can rotate out to 70 degrees open. Braces along the edge of the door and from the middle of the door will help it close flush. I also needed to round the back edge of the door so it doesn't get caught on the edge of the body closing.

My initial prints of the door suffered some problems. You can see in the top print below I experienced warping toward the bottom of the print. After some research and testing it was determined this was because my heated bed at 110 C was to close to the ABS Glass Transition Temperature and was causing this distortion. Lowering the bet temperature to 90 C fixed it as you see in the lower print.![]()

![]()

To facilitate printing with the lower temperature I built a headed build chamber for my LulzBot Mini. This also had the added benefit of reducing cracking and helping bed adhesion as the whole part shrunk less overall during the print.

That's all for this week. I should have some fun updates in 2 weeks. Half of the frame should be printed by then and I will have the servos so I can build and test the door mechanism and the motor lifter. Also I should have done some design work on the custom ESC to properly fold the propellers.

-

First Propeller Tests and CAD

10/28/2015 at 09:16 • 0 commentsFirst I would like to give a shoutout to James Bruton. His R6 and BB8 droids are really what inspired me to start this project. Seeing what he can make with just 3D printed parts is amazing. If you haven't seen his channel you have to check it out here:

http://www.youtube.com/user/jamesbruton

I completed the first tests of some propellers to see what I will need to get BB8 to fly as well as determine the weight of the frame.

My initial CAD resulted in the above design. To get the propeller out far enough it combined a lever with a slide. The circles on BB8's sides open up for it to extend and then close behind it with cutouts that fold down for the bars to stick through. The propeller was a 10x5", the biggest that fits through the circle in BB8. I selected a 3 blade for maximum thrust. The motor was also configured in a pusher configuration so the air-stream would be disrupted less. I was really starting to like this design but then an initial thrust test with the propellers killed my dreams.![]()

The test's with the small propeller that just fits in the side slot was somewhat disappointing. It only produced 1.2 kG of thrust. Even with 4 its max thrust will be 4.8kG under even just the calculated frame weight of 5kG.

Tests with a full size 18" propeller resulted in 4 times the thrust. Using the bigger propeller would allow for a 13kG (30lb) droid assuming a thrust to weight ratio of 1.5. Leaving plenty of margin as the frame motors and battery add up to about 6.8kG (15lb) now.![]()

The real question is how do you fit an 18 inch propeller in a 12 inch hole. The answer is in fact quite simple a folding propeller however locating an appropriate one was a difficult task. After several hours of scouring the internet I found the DJI E1200's propellers. 17x6" Propeller blades that fold, just what I was looking for. So I have a set of those on order.

But a final question still remained how to fold them up so they can go back into BB8's body. The first ideas that came to mind where over-complicated. Servos on the sides of the motors that have levers to push the blade. I settled on the idea of using the doors to fold the propellers.

No not pushing it with the doors but rather rotating the motor to push the blades on the doors. This will still be a tricky task as no existing ESC has this capability to drive a brushless motor like a stepper motor. I will have to design it from scratch.

Brushless motors generally have multiple poles and a three phase input. It will take some testing to be sure but I believe it is possible by putting varying voltages on the 3 wires to position the blades at any angle. I will also need some optics to properly detect the blade position so it can move appropriately to get its propellers in the correct place to fold. This part of the system will still require some thought. Will I need a single board computer with a camera running computer vision algorithms, or can I get away with a simple optical sensor on the motor arm to detect the initial blade positions by rotating them past it.

I'm off to quite an exciting start and only more fun to come.

3D Printed BB8 Quadcopter

A full scale BB8 Astromech droid with deployable quadcopter arms in the shell.

DrYerzinia

DrYerzinia