With V2 in the works, this will be blank for now. I plan to update this section with some Open Rocket calcs and other fun stuff.

3DPMRS - 3D Printed Modular Rocket System

Collaborative rocket design.

Collaborative rocket design.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

With V2 in the works, this will be blank for now. I plan to update this section with some Open Rocket calcs and other fun stuff.

While working on the drawings for V2, I came across FreeCAD. It hit me. If the end goal here is to have an open sourced rocket system, why am I using proprietary software? As much as I love SolidWorks, and as comfortable as I am with it... I'm moving to FreeCAD. I'll push to get some design files up in the next few days. I've been busy with work and some side projects, but I haven't given up!

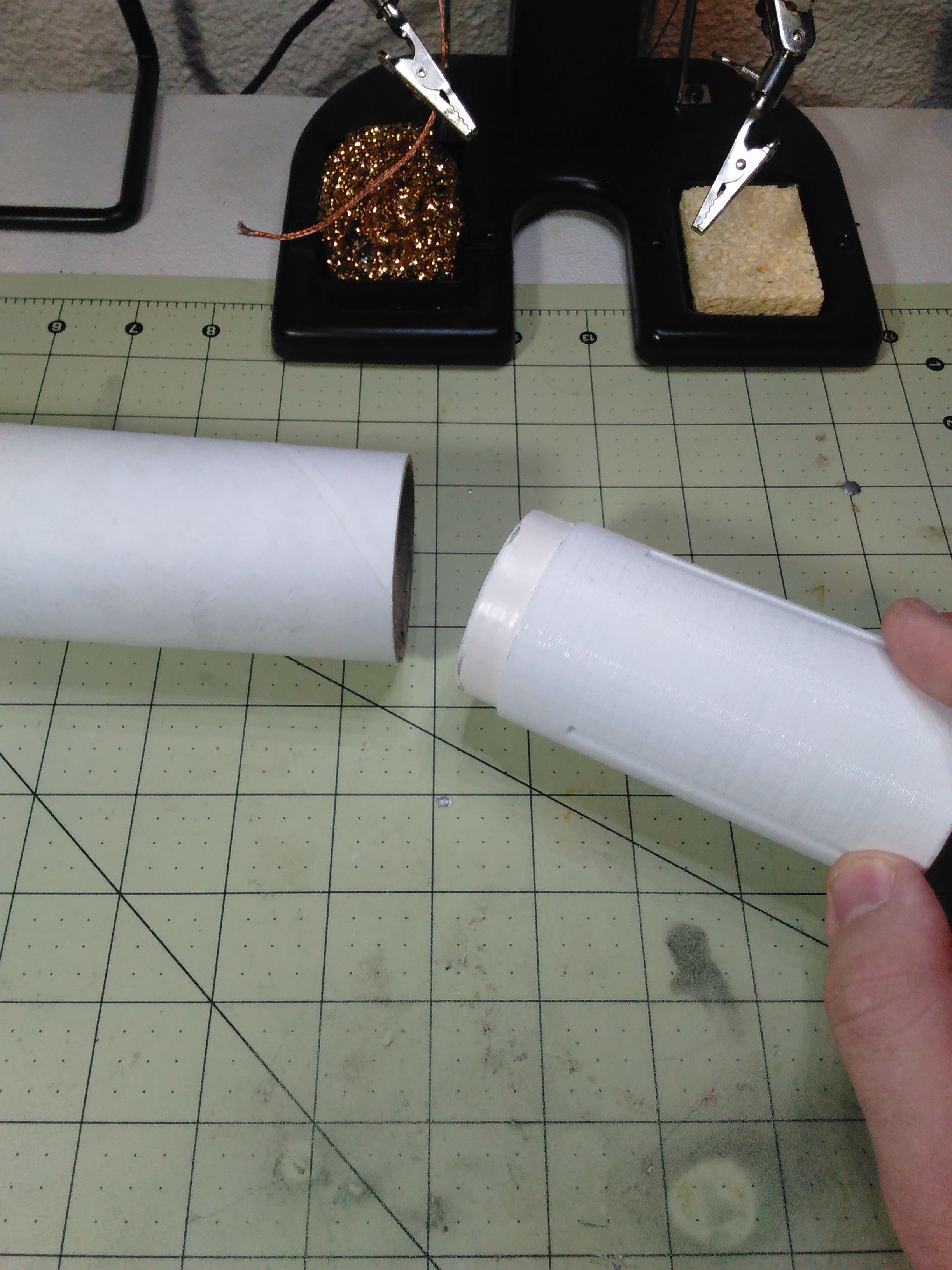

I just got my tubes and motors in this week. I'm also about 60% of the way done getting my printer back up and running. Between the new heat bed/platform, hot end and upgrading to the Simplify3D software my print quality should improve quite a bit.

I'm planning on working with the Proto-Pasta CF infused PLA from here on out. From what I've read I'll be able to go with thinner walls while retaining strength. This should assist in a not insignificant change in weight, at least I hope it does.

I'm also working with some AeroTech G80s, which will be a huge improvement over the F15's from Estes I was limited to.

Along with all these other changes, I'm building a new launch setup. With a 6' 80/20 rod, I'll be able to move to launch buttons and have much more time for the rocket to stabilize before it leaves the pad. Coupled with more power (...and better acceleration) and a lighter rocket my weather-cocking issues should be all but gone.

So, I went with slightly smaller fins and took a few inches off the nose to correct the over-stability issues. The winds were a bit high; 7mph or so sustained and gusting to roughly 15mph. This resulted in more weather-cocking (though not quite as bad as last time), and ultimately the loss of the air frame. We searched some, but it went in the woods relatively close to a nearby archery range. We decided to just chock it up as a loss. I've already got V2 in the works, so look more updates soon!

Well, I found a pretty good deal on some Aerotech G80-13T motors. I know, the 13 second delay isn't ideal, but I can work around that. I've also got some BT-60 body tubes on order. Besides being lighter, the drop in diameter will help cut weight by allowing for slimmer printed parts.

Plus, I've got a new hot end for my printer ordered... the next few weeks should be pretty interesting!

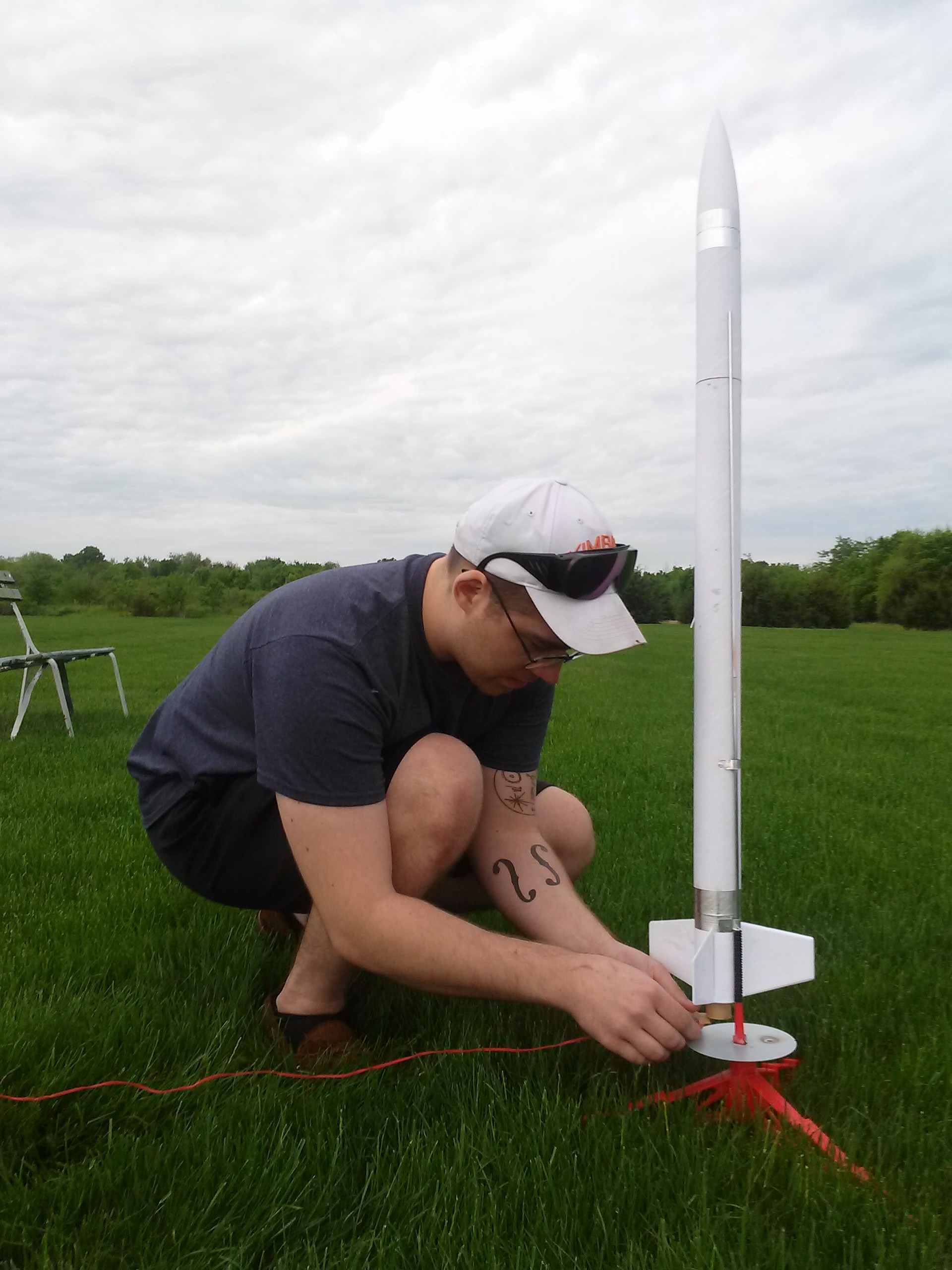

Well, it took off. And it flew. We also recovered it.

Despite the woefully inadequate launch platform, it cleared the rod without issue.

The issue appeared when the rocket weathercocked hard as the motor burnt out.

The issue appeared when the rocket weathercocked hard as the motor burnt out.

The chute didn't deploy until just before it hit.

The rocket was recovered with pretty minor damage. Just two broken fins and a little dirt on it.

In hindsight, the 3.1 cal reported for stability in open rocket should have been a red flag. My thinking was that any extra stability would help with the lack of power. This may have been acceptable with a dead calm day, but the 7mph or so winds proved to be too much. After a few adjustments I see no reason why we shouldn't see a successful flight on an F15-6 (although 4 would be a much better choice...).

We're almost ready to launch it. I'm hoping to get out just after sunset for a test flight. The issue is that it came out with a ready to launch weight of 23oz. According to open rocket it'll fly. If we manage to recover it, I'm ordering a few G78s from Aerotech. With a 10 second delay, open rocket is suggesting that we'll see apogee around 1500ft. More to come.

So far the build is going really smoothly. All the printed parts are fitting well and my printer has been behaving (for the most part). I'll be sure to update the build instructions with a full build when it's complete.

However, as I'm building it, weight is definitely something I've been stressing over. This has led me to look outside the Estes line for other options. I'm not sure I'd like to do this considering you can grab Estes motors at most craft stores and Wal-Marts for cheap. The issue is that the F15-6 only puts out a peak thrust of about 26 newtons. Whereas, with Aerotech, I can grab a 29mm motor for not too much more cash that easily triples that. That would almost negate the weight issues completely.

Seeing as I'm looking to 3D print motors, this is more of a diversion than a total setback. In the end, I still believe the entire rocket will be able to be sourced locally!

Finally starting to make some progress. I've gotten the motor housing/fin mount and fins printed. This issue is that all together (along with the lower body tube) I'm sitting at about 12oz. I've read that some have flown rockets around 24oz with the F15 motors from Estes, but I'm hesitant. It's going to be a very slow climb initially, which may require a longer launch rod or some fine tuning of CG/CP. I'm looking at reducing weight as well. Moving to a body tube made for rocketry will save some weight as these shipping tubes are anything but light. I can also switch to ABS over PETG for my 3D printed parts. I love the strength of PETG and it's ability to flex, but that comes at a weight penalty. I'm at 10% infill for the motor housing, I'm not sure going lower will make much of a difference. But, I'm printing in .6mm layers using a .9mm nozzle. Using 2 shells may be unnecessary as well as three solid layers on the top and bottom. How much weight this adds vs strength, I'm unsure. It may be worth it to play around with some settings to see if I can lose an ounce or two there.

I managed to launch something today. It wasn't a 3D printed rocket, or even a scratch built, but it was fun to knock out a kit my with girlfriend in a few hours and launch the same day.

I haven't been able to devote too much time to this project lately. However, I've just taken two weeks of leave, so I'm sure I'll be able to get some things done. I'm hoping to knock out (or at least start) on:

-Fiberglass body tube (just need to wrap and glass...)

-Larger 3D printed motor mount and nose cone

-Updated interchangeable motor cage to allow for a variety of motors

-Multi-stage?

-3D printed motor (or at least test the viability of a one time use motor...)

Hopefully I'll be back with updates soon!

Take the printed motor cage and ensure a snug fit with the 24" tube. If it's loose add some tape to the tab, if tight sand it down some.

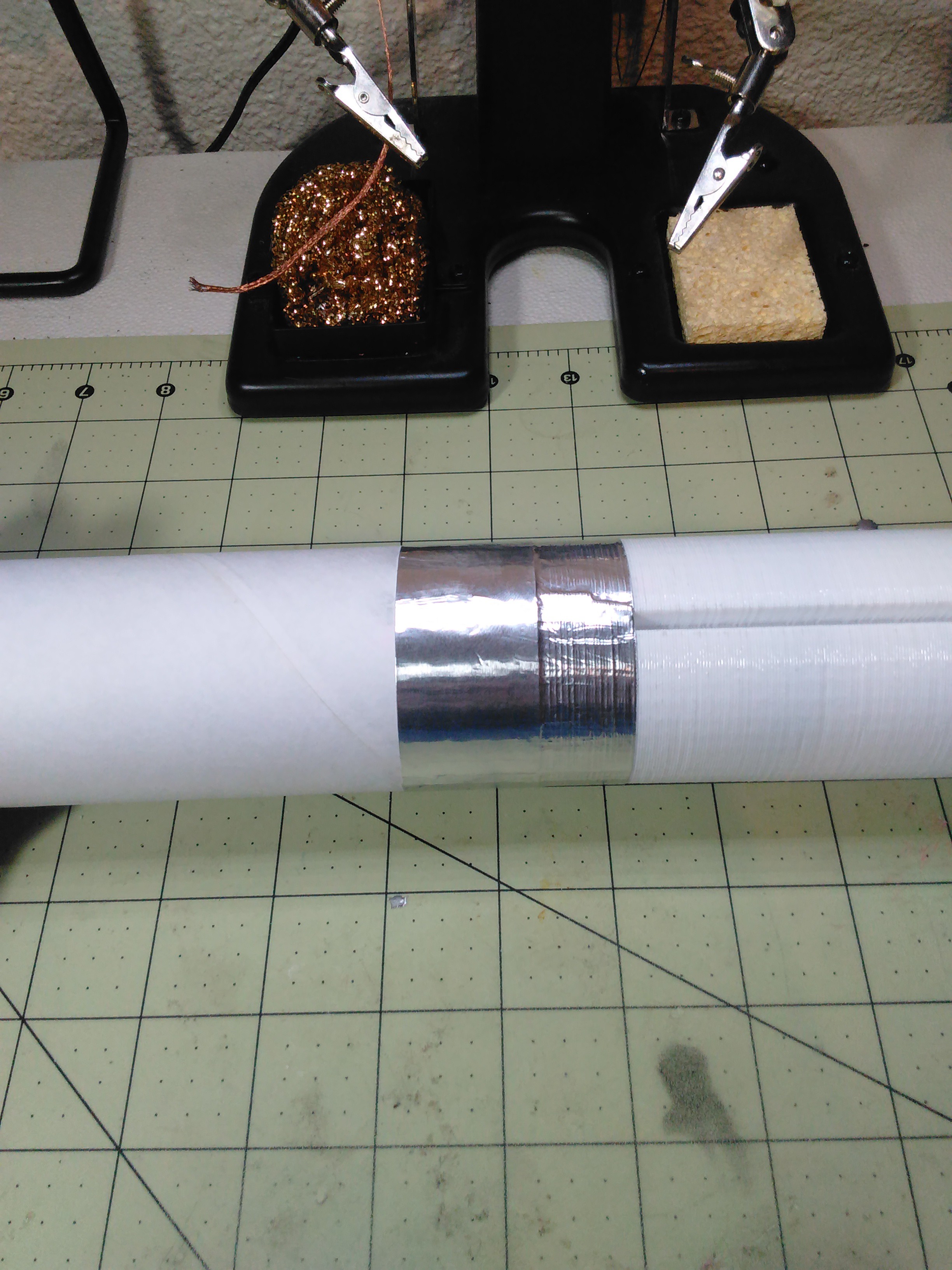

Once you've got the fit up to par, tape or glue the cage in place. I chose aluminum tape. It looks cool and can smooth over issues.

Now it's time to test fit the fins. If all is well glue them into place using CA. Ensure they're all facing the same direction; they have an asymmetrical airfoil to initiate a spin. This is for stability.

Create an account to leave a comment. Already have an account? Log In.

No real reason other than ease of build and novelty. With the base and fins being one entity, I can build the rocket pretty quick by just riveting the body tube to the motor mount.

Become a member to follow this project and never miss any updates

Steve

Steve

Will F.

Will F.

Glytch

Glytch

I'm curious, why 3D print vs wood fins?