Main things to keep in mind while designing this 3D printer:

- be able to print high peformance engineering plastics

- it's gotta have a heated chamber(upto max. 150 degree celsius)

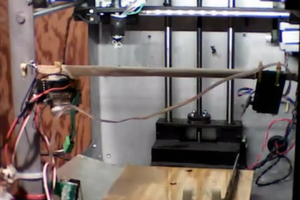

- it has to be a dual extruder

- it has to be direct drive

- it has to be safe to use

- accurate, reliable, ergonomic, aesthetic and affordable.

Main design features considered:

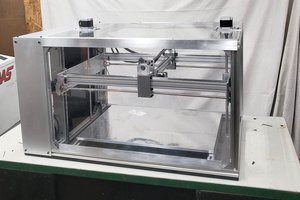

- core-xy mechanism- for keeping the kinematics simple, and reduction of moving mass and to keep the motors outside the heated build chamber

- heated build chamber - up-to 150 degree Celsius. this is required for printing in peek or ultem

- heated bed - this is a common feature in all 3d printers and shall remain as it is

- linear rails for x and y axis - MGN15 guide rails and blocks for achieving high positional accuracy, speeds and load bearing capacity.

- smooth rods and ball-screws for z axis - 16mm smooth rods and LMK16LUU bearings because they are easy to work with , and ball screws because of their efficiency (it can be substituted with lead-screws as well , should not be a problem)

- nema23 motors with ~20kgcm torque, so that there is never a step loss.

- insulation of all mechanics and electronics from the heated build chamber, because i cannot expect the belts and bearings to work at 150 degrees. thinking of using glass wool for this.

- 4040 aluminum extrusion frame - because it is easy to work with and is very rigid.

- Duet wifi as controller - because it is 32-bit, and highly recommended by current users, and because it has Trinamic drivers with 2.6Amp capacity.

- 7" PanelDue touch screen interface

- all machine parts are milled aluminum for material uniformity . so that there are no uneven thermal expansion issues.

- It has to be build at lowest possible cost, but without compromising on quality, hence making it affordable.

- water-cooled hot end - with chamber at 150 degrees Celsius i cannot think of air cooling at all.

- pause on filament runout

Other surprising features: (going against the tide)

- no automatic bed leveling - because i absolutely hate software compensation for bad hardware. i just believe that the hardware had to be just right, and if its not then fix it, not compensate in software.

- minimum software compensations - no skew correction.

Features i need but do-not know how to implement: (these are advanced features and are not needed to run the machine)

- power panic

- laser filament monitoring

jon.knutton

jon.knutton

Shane Hooper

Shane Hooper

Matteo Borri

Matteo Borri

anthony.webb

anthony.webb

how is this going did you ever build it?