When running, the IRC bot is on Freenode. Flooding is prevented by executing commands once a second, and tallying votes between executions. The IRC bot is a mod of an open source Java bot.

Basic commands are:

* N: move Y+1mm

* S: move Y-1mm

* E: move X+1mm

* W: move X-1mm

* U: pick Up a piece.

* D: Drop a piece.

* L: turn nozzle +1 deg (ccw)

* R: turn nozzle -1 deg (cw)

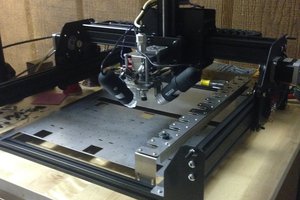

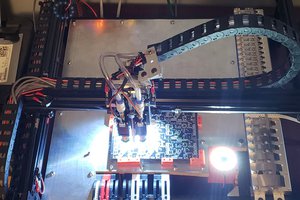

The original machine was a corexy gantry I designed with ~80cm working area and about 2cm of Z travel. It had an Arduino clone running Makelangelo-firmware from the Makelangelo robot project. The camera was a Logitech webcam, stripped of it's plastic shell and mounted on the gantry head.

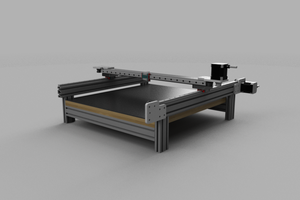

The new version is an Inventables X-Carve with a Raspberry Pi B and a PiCam. It has at least 75cm travel XY and ~4cm Z travel.

Dan Royer

Dan Royer

anthony.webb

anthony.webb

ProtoVoltaics

ProtoVoltaics

John

John

what a nice project it is i read all the articles about it and realize that it is similar to those which i added in my blog here you can see on https://bestjigsawguide.com/best-jigsaw-blades/