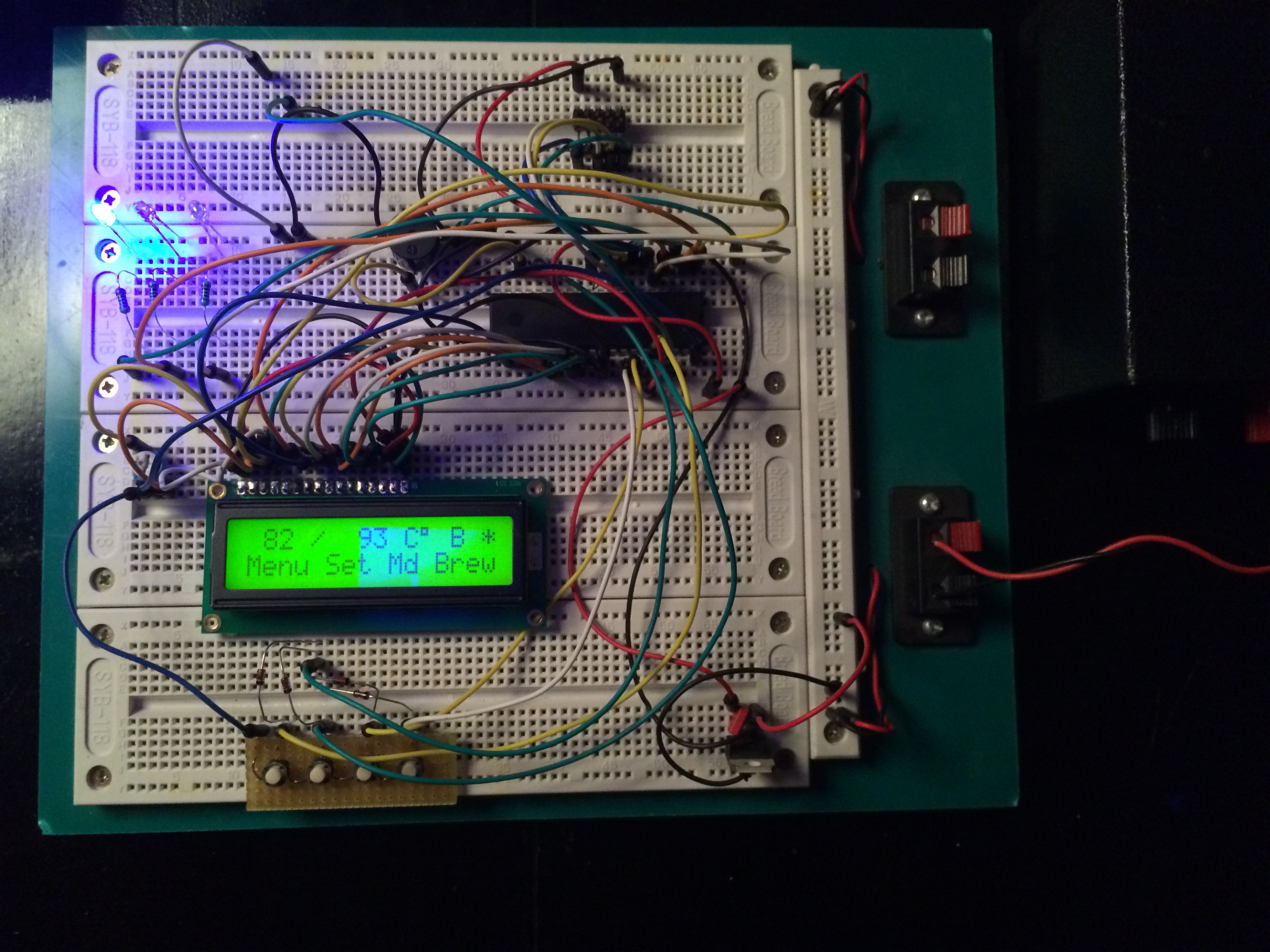

The final version of the firmware has the following features:

- Configurable brew and steam temperature

- Configurable grinder timer

- Audible beep when temperature for selected mode is reached

- Auto-flush when switching from steam to brew

- Grinder-only mode with heater disabled

- Config stored in EEPROM

- Auto descaling mode

(Let me know if anyone are interested in the firmware source and I will upload it.)

Tobias Rathje

Tobias Rathje

Fabien-Chouteau

Fabien-Chouteau

Wassim Chegham

Wassim Chegham

Jakub Laník

Jakub Laník

thetazzbot

thetazzbot