Introduction

Ultrasonic welding is a highly effective and widely used technique for joining materials together. It utilizes high-frequency ultrasonic vibrations to create strong and reliable bonds between different types of materials. This article provides an overview of ultrasonic welding, explaining its principles, applications, and benefits.

Principles of Ultrasonic Welding

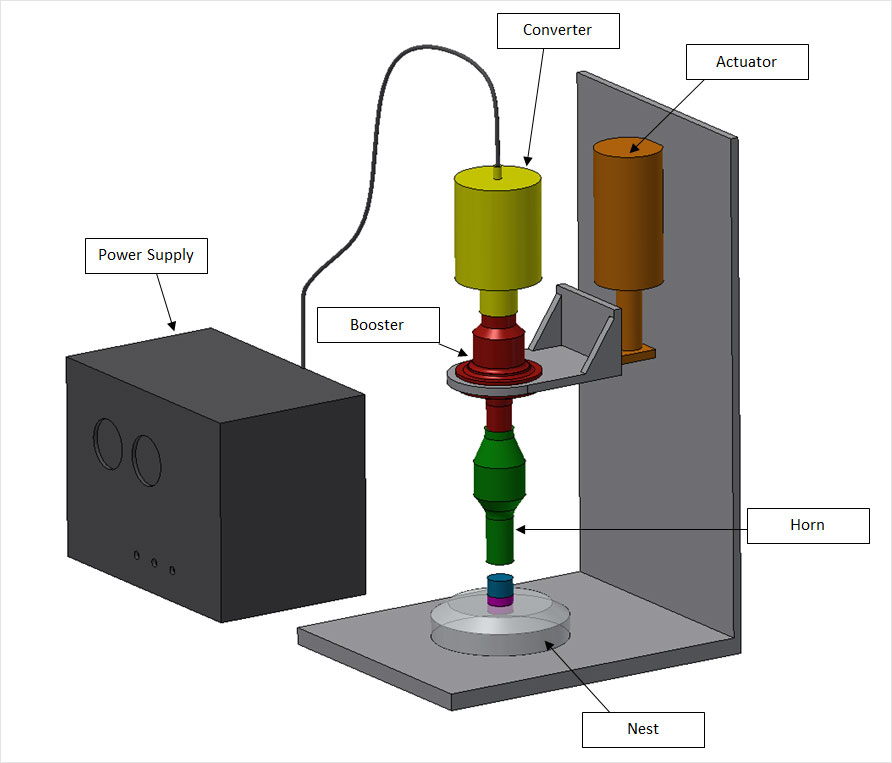

Ultrasonic welding operates on the principle of mechanical vibration. The process involves applying high-frequency (typically 20 kHz to 70 kHz) ultrasonic vibrations to the materials being joined. These vibrations generate heat through friction at the interface of the materials, causing localized melting and subsequent fusion. The ultrasonic vibrations are transferred to the materials using a specialized tool called a sonotrode, which applies pressure and vibration to the joint area.

Applications of Ultrasonic Welding

Ultrasonic welding finds applications in various industries, including automotive, electronics, medical, packaging, and textiles. It is commonly used for joining plastics, as well as dissimilar materials such as metal and plastic. Some specific applications include:

- Assembly of electronic components

- Sealing and welding of plastic containers

- Bonding of automotive parts

- Joining of medical devices

- Textile lamination

Benefits of Ultrasonic Welding

Ultrasonic welding offers several advantages over traditional joining methods:

- Speed and Efficiency: Ultrasonic welding is a rapid process, with weld cycles typically ranging from milliseconds to seconds, depending on the size and complexity of the joint.

- Strength and Durability: The resulting welds are strong, hermetic, and resistant to vibration, making them suitable for demanding applications.

- No Consumables: Unlike adhesive bonding or thermal methods, ultrasonic welding does not require additional materials such as adhesives, solvents, or fasteners, reducing production costs.

- Automation Potential: Ultrasonic welding can be easily integrated into automated assembly lines, allowing for high-volume production and consistent weld quality.

- Environmentally Friendly: As a solid-state joining process, ultrasonic welding does not generate smoke, fumes, or hazardous byproducts, making it environmentally friendly.

Conclusion

Ultrasonic welding is a powerful and versatile technique for joining materials. Its ability to create strong and reliable bonds quickly and efficiently has made it a preferred choice in various industries. With its numerous benefits, including speed, strength, and automation potential, ultrasonic welding continues to revolutionize manufacturing processes and contribute to advancements in product development.

Related Article:

Sam

Sam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.