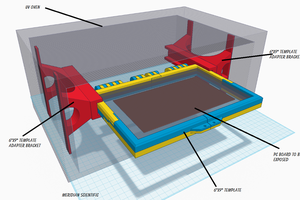

The project has its roots in the SMD soldering station by Martin Kumm

(http://www.martin-kumm.de/wiki/doku.php?id=Projects:SMD_Solderstation)

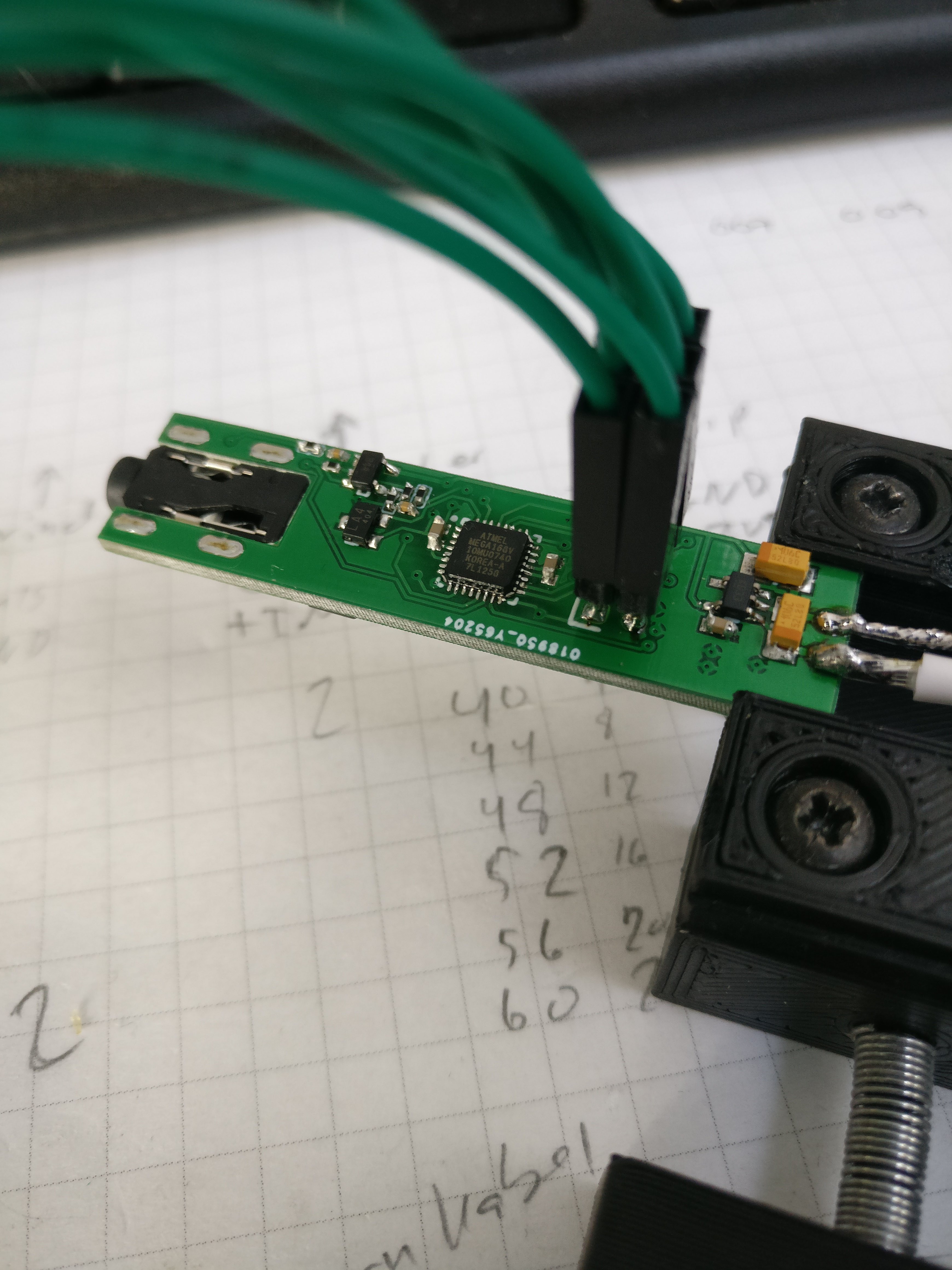

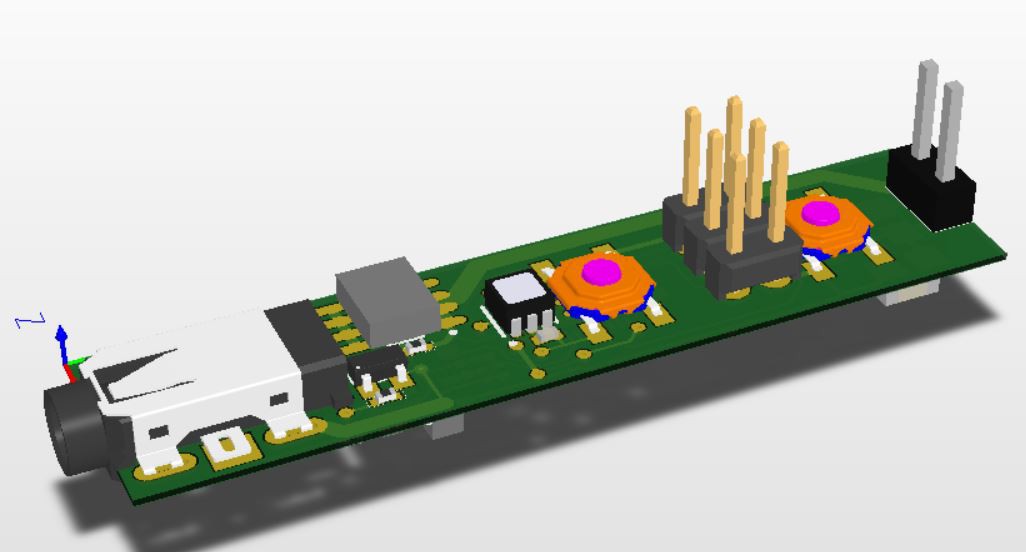

Some years ago I got a tray full of ATMEGA168's and since then I've always wonderes why people made shields for Arduinos. i mean, Just put the controller on the PCB when you're designing anyway. And since I got a bunch of them I might as well.

I figured that I didn't need a display for my soldering station. Why would I? I usually use the same temperature and only when soldering on large ground planes would I need some extra 'oompf'. For tasks like that I would usually take a bigger soldering iron anyway.

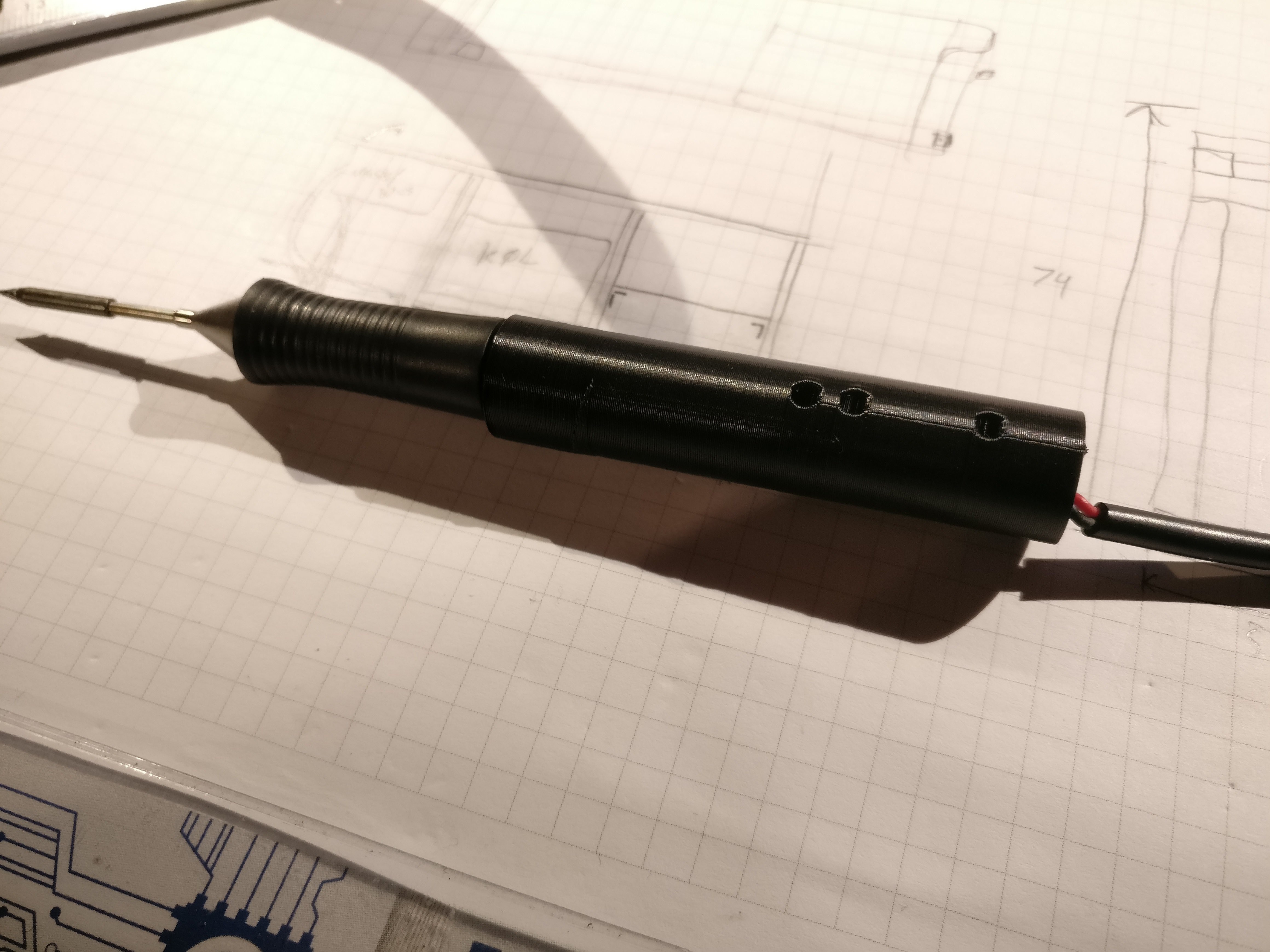

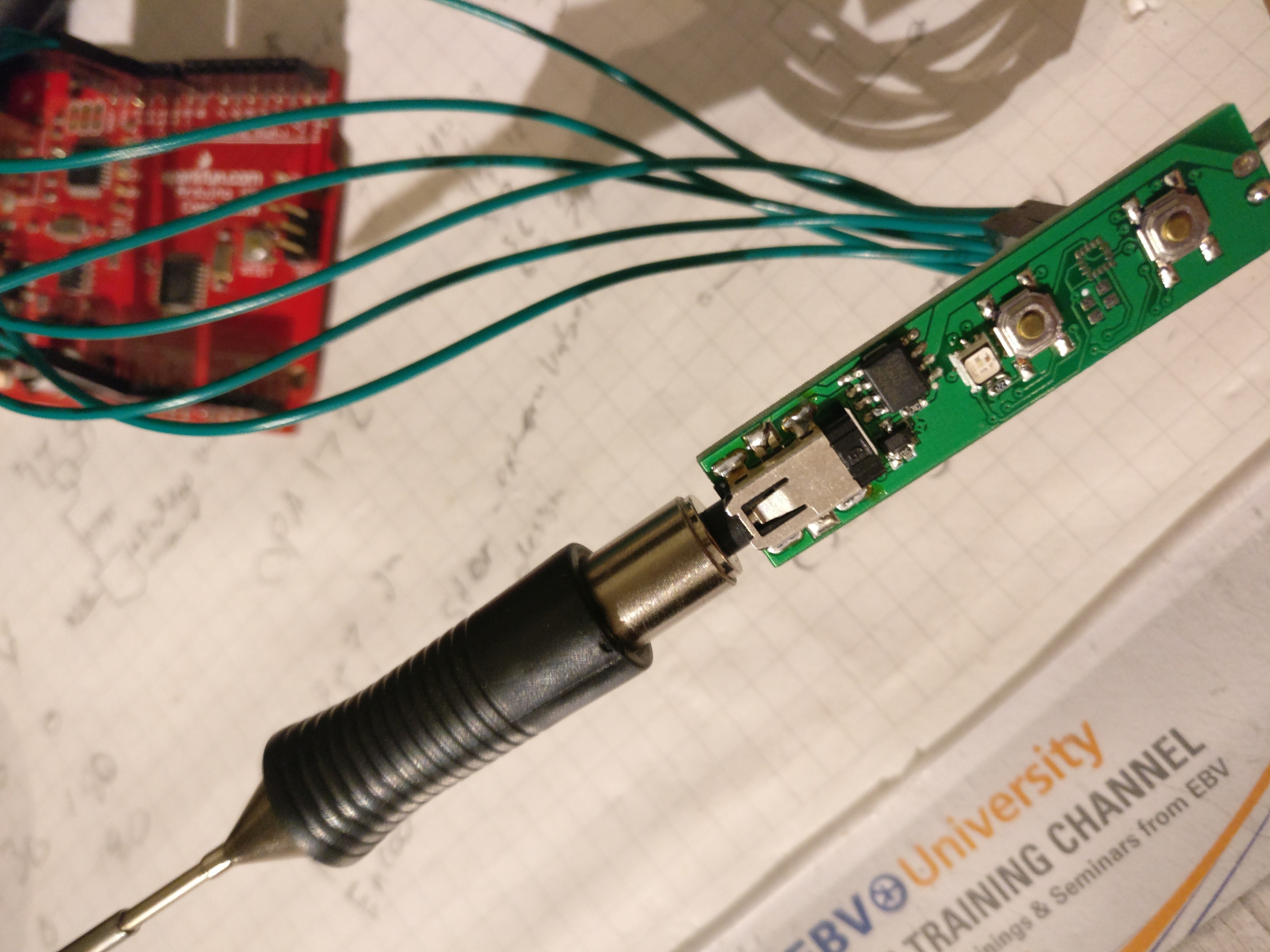

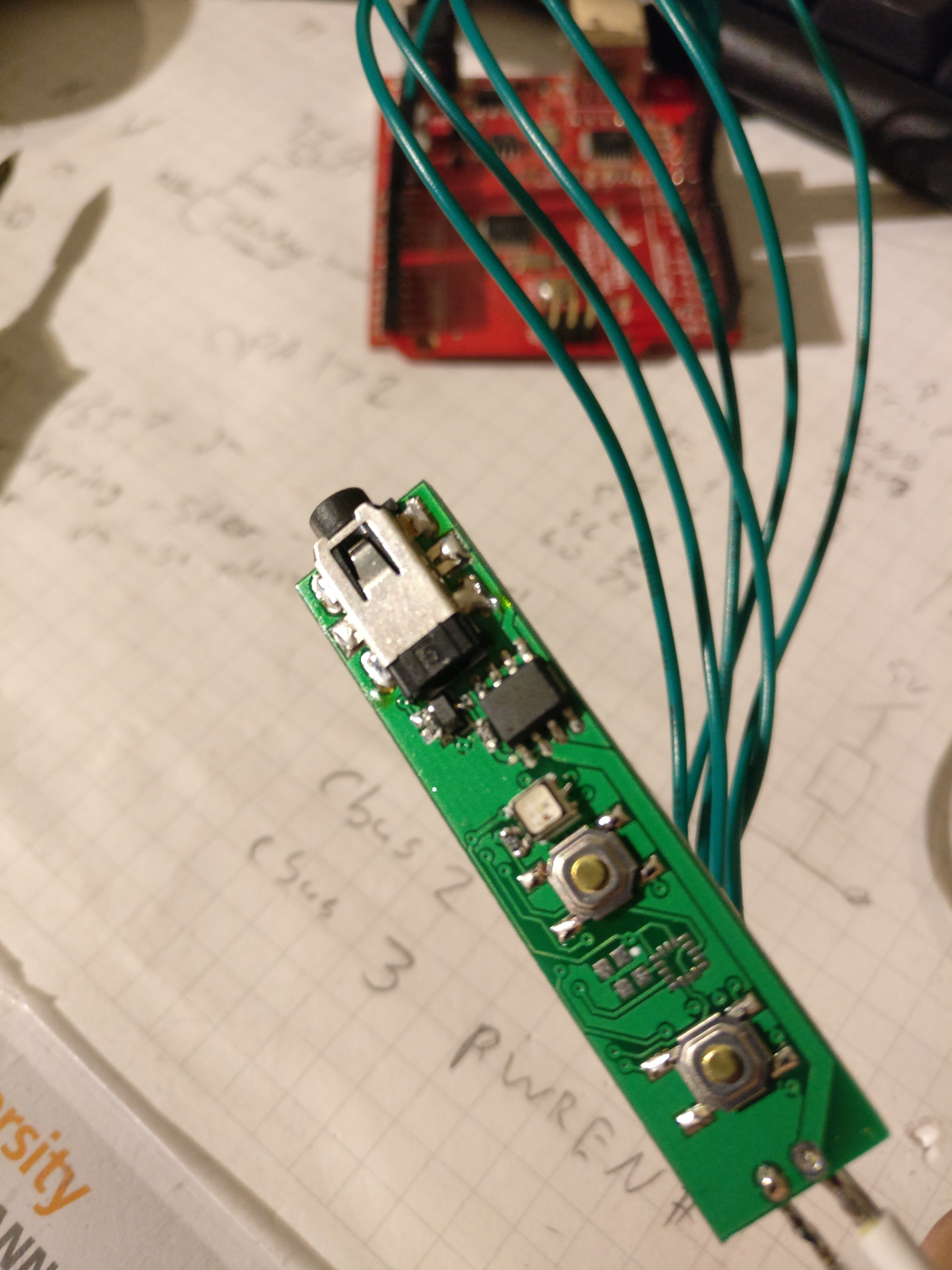

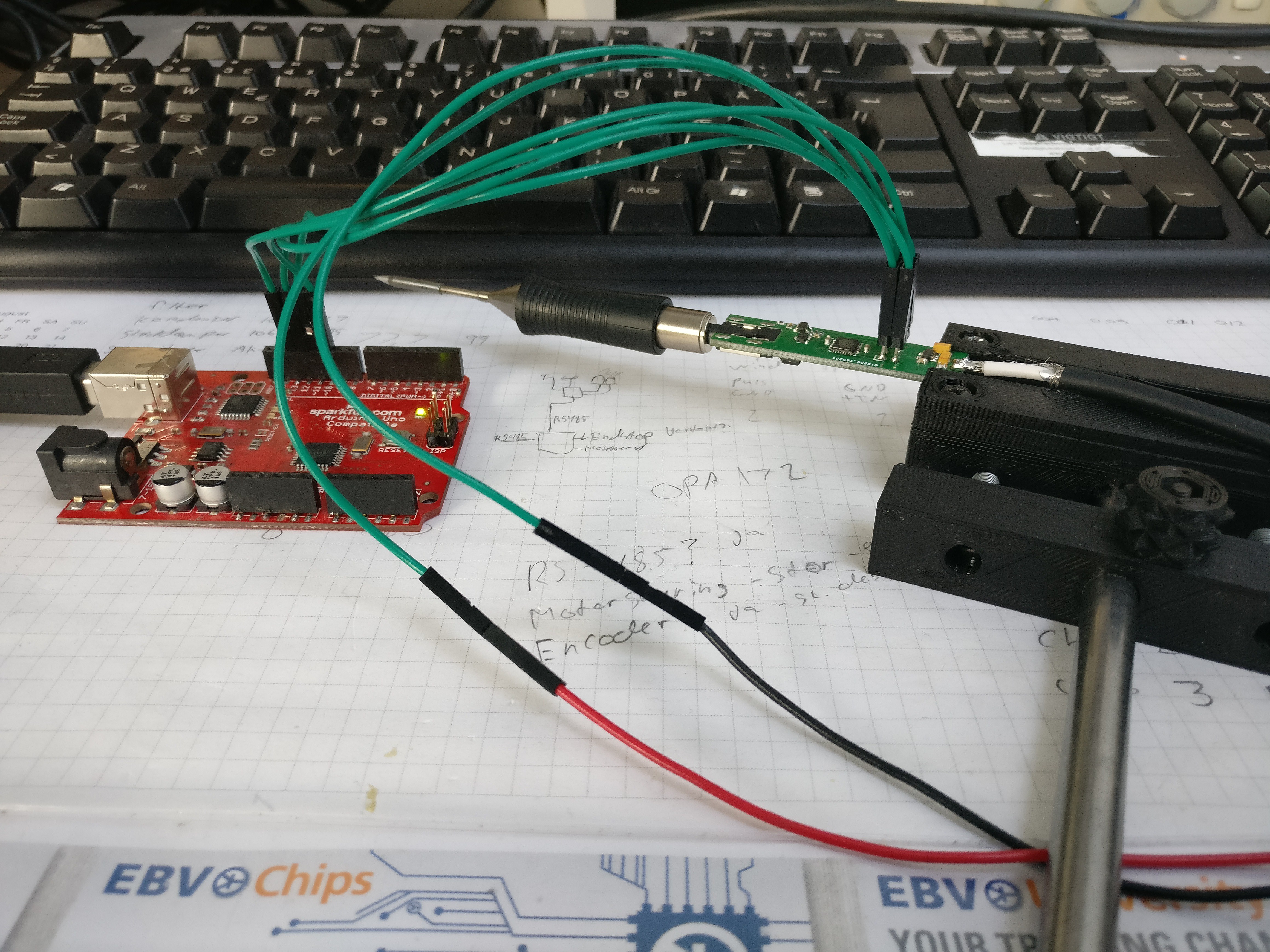

Thus the minimal soldering station was born. no display but with a USB interface for computer control.

the outline of the project was almost clear:

- Support Weller RT tips

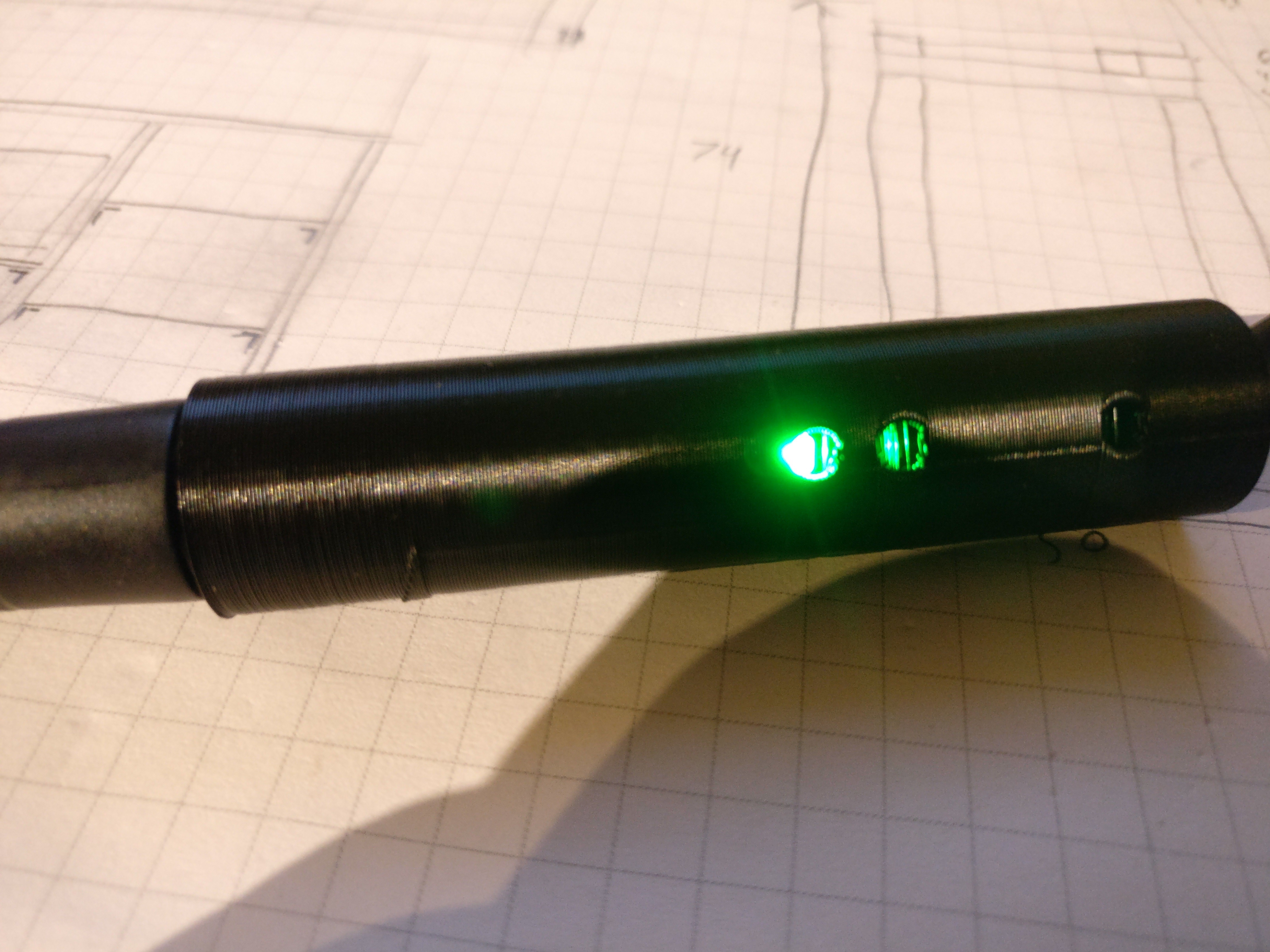

- Visual indication of heating and 'ready to solder'

- support cooldown switch

- store temperature in EEPROM

I sat down and drew a diagram.

HP (@banjohat)

HP (@banjohat)

core weaver

core weaver

fl@C@

fl@C@

Mangus Tiranus

Mangus Tiranus

sako0938

sako0938

Why did you invent soldering pen and what is the significance of that?