What

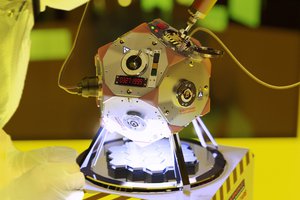

Assistive Technology (AT) buttons are a way for someone with a limited range of motion to control his or her environment at the same level as anyone else. Most AT buttons available are quite expensive, and are engineered to be used in high reliability situations. As a result there are a lot of home DIY projects to make cheaper buttons, but they often lack long term suitability and are thus more stop-gaps than replacements.

Why

Clunke exists to fill the gap between low cost switches (e.g. taping wires together) and high cost switches (existing commercial solutions) with a material price point of $10 and sturdy design suitable for daily use.

Who

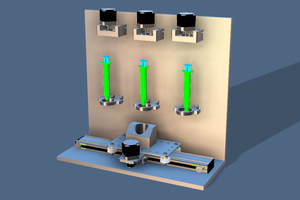

This button's initial model was created as part of a team-based senior design course. We worked with a local organization, UCP and TASC of Huntsville, to design and construct an AT keyboard and AT button.

The senior design class ended with a second button design made, but not user tested. I now maintain the project and am working toward a third design revision and user testing.

How

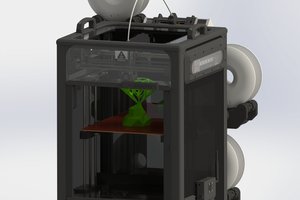

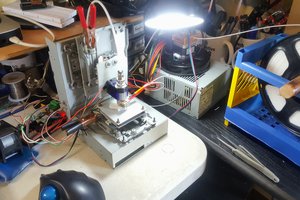

The current button design requires a hobby level 3D printer and mechanical keyboard switches. See instructions below for build details.

Christopher

Christopher

Dewet

Dewet

Michal Wojciechowski

Michal Wojciechowski

AccidentalRebel

AccidentalRebel

Obviously doesn't have the high reliability your going for, but still fun in the same vein.https://www.youmagine.com/designs/awesome-button-for-dash-button