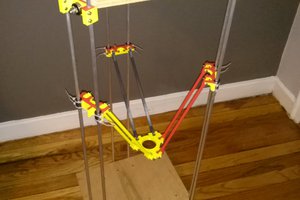

This was a build first design later kind of project.

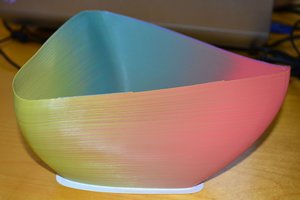

All design details will be made available - My goal is 100% open source and open hardware.

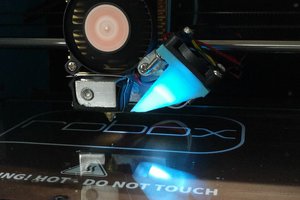

The Firmware for the moment is Marlin although I have also tried Repetier (both GPL licensed)

The design is similar to the Kossel http://reprap.org/wiki/Kossel

and the RepRap Rostock http://reprap.org/wiki/Rostock

Both are GPL licensed designs

oneohm

oneohm

AndyMac

AndyMac

Rob Ward

Rob Ward

Daren Schwenke

Daren Schwenke