How to make an energy independent electric vehicle with a Kite Turbine.

Updated Instructions 28/4/2022

- Put a Kite Turbine in your car

- Park up (best on a windy hill)

- Fly the Kite Turbine

- Use it to charge the EV battery

Well sort of, yes.

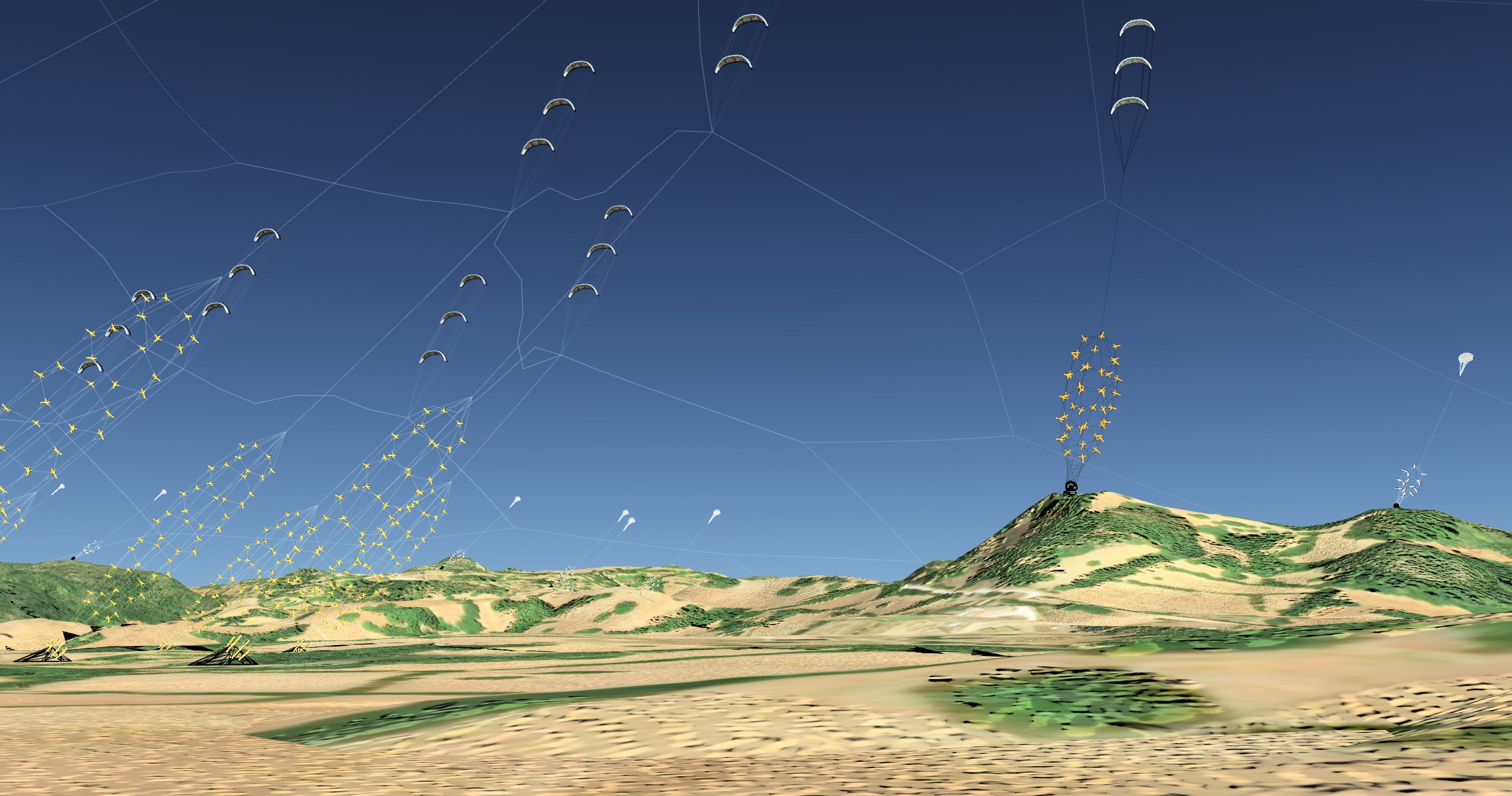

We've flown a bunch of missions and made lots of power, done some car charging and made lots of tea in the field. Lovely. But as you'd expect with wind power, and especially with freaky flying wind power, it's a lot more complicated than that.

I started testing ideas on kite power in 2010, because kites can provide a lot of power with little material.

Harnessing kite power and converting it to electrical energy - can't be too hard ! And it's a really good thing to achieve because it could be scalable.

Most Airborne Wind Energy Engineers start out like this, and also from being Kite Surfers.

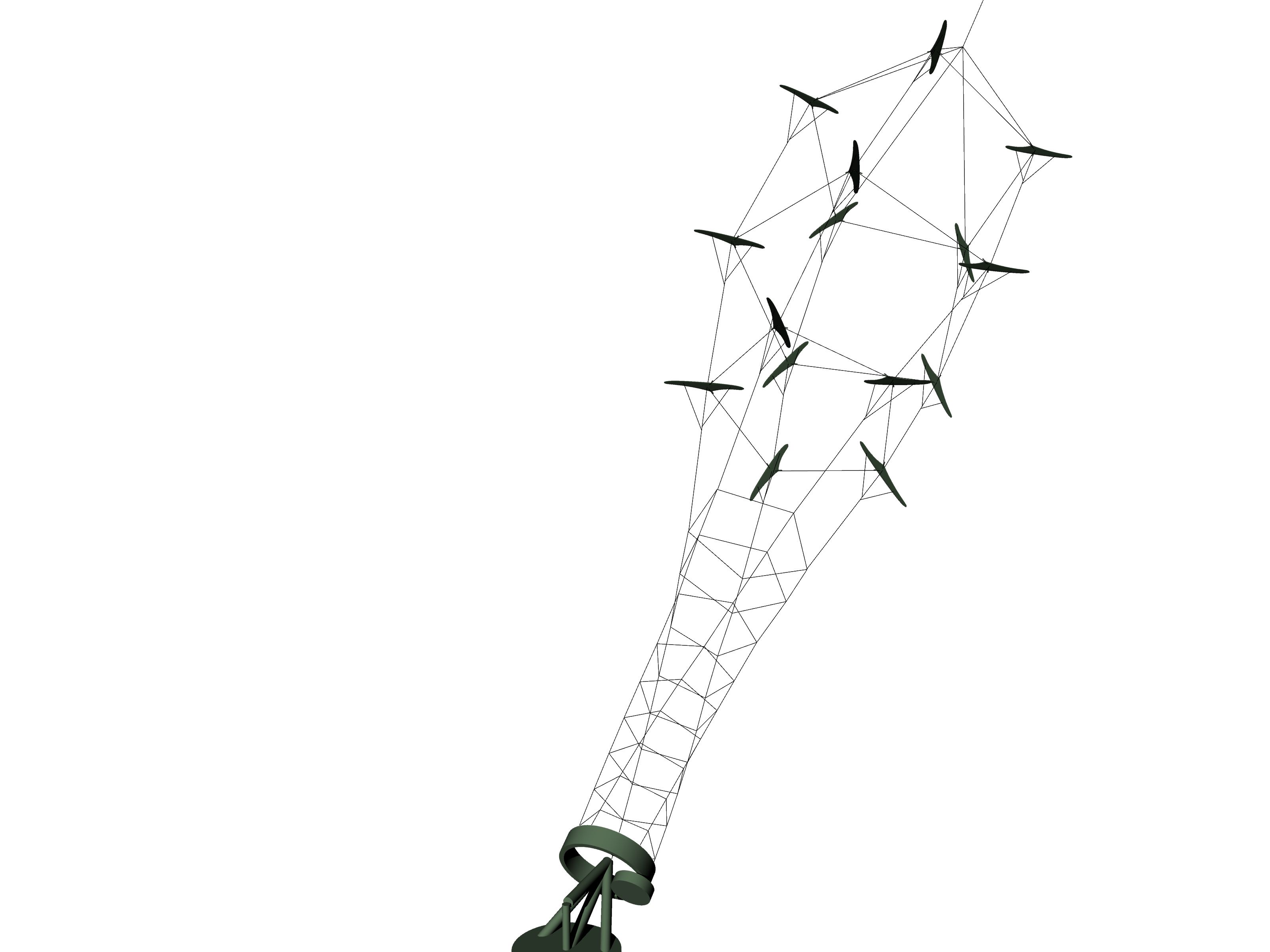

After a lot of experimenting, My favourite method is the Kite Turbine.

It's simple, continuous rotary output, scalable yet workable on a small scale, mechanically autonomous (apart from launch & Land & as long as it's all balanced)

You can see the launching process sped up in this video

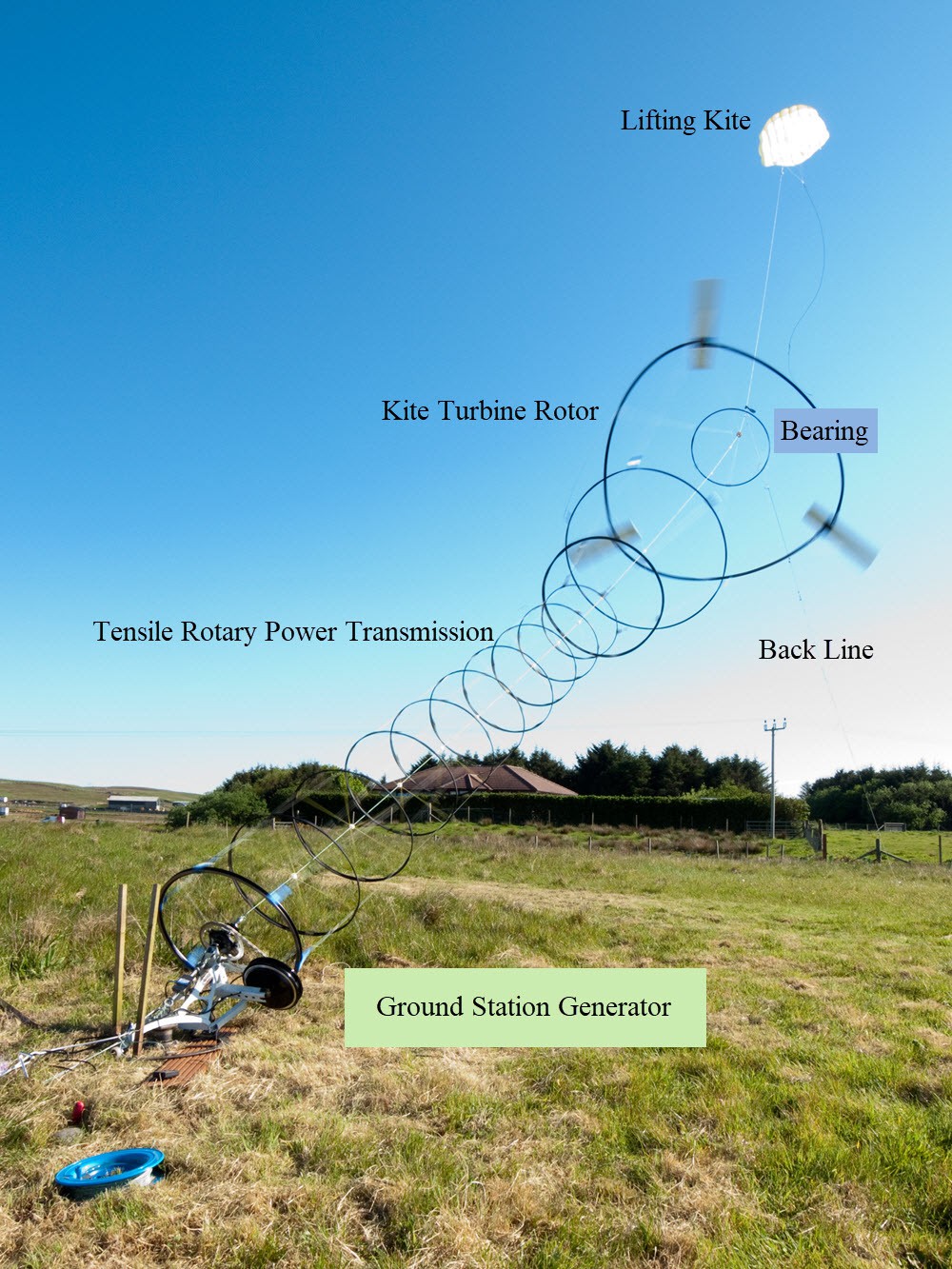

First of all the lifting kite is launched. It's job is to guide the turbine downwind, and give initial line tension to hoist the turbine.

The turbine is then released into the air using the back-line to hold it down.

The brake is released on the ground station so that rotation can start and regen can begin.

The wise among you might now be thinking... That's bizarre - torque - sent along a string - but surely it would just twist?

And yes - without the kite line tension and the extra rings between the lines- it would twist and has twisted. The power transmission here is rotary, yes- that's novel, but it works. We use normal Dyneema(R) rope tethers.

But How? This is where researching Tensile Rotary Power Transmission (TRPT) will help.

I'd recommend Oliver Tulloch's PhD and the Airborne Wind Energy Forum

Basically, TRPT works with 2 ratios, the geometry ratio (ring separation / ring diameter) and the force ratio (Axial tension / torque) . For a given geometry ratio you can safely apply a certain force ratio by adjusting the torque demand at the generator. Balance these and it works. More pull axially means a more torsionally rigid shaft = higher energy transfer capacity.

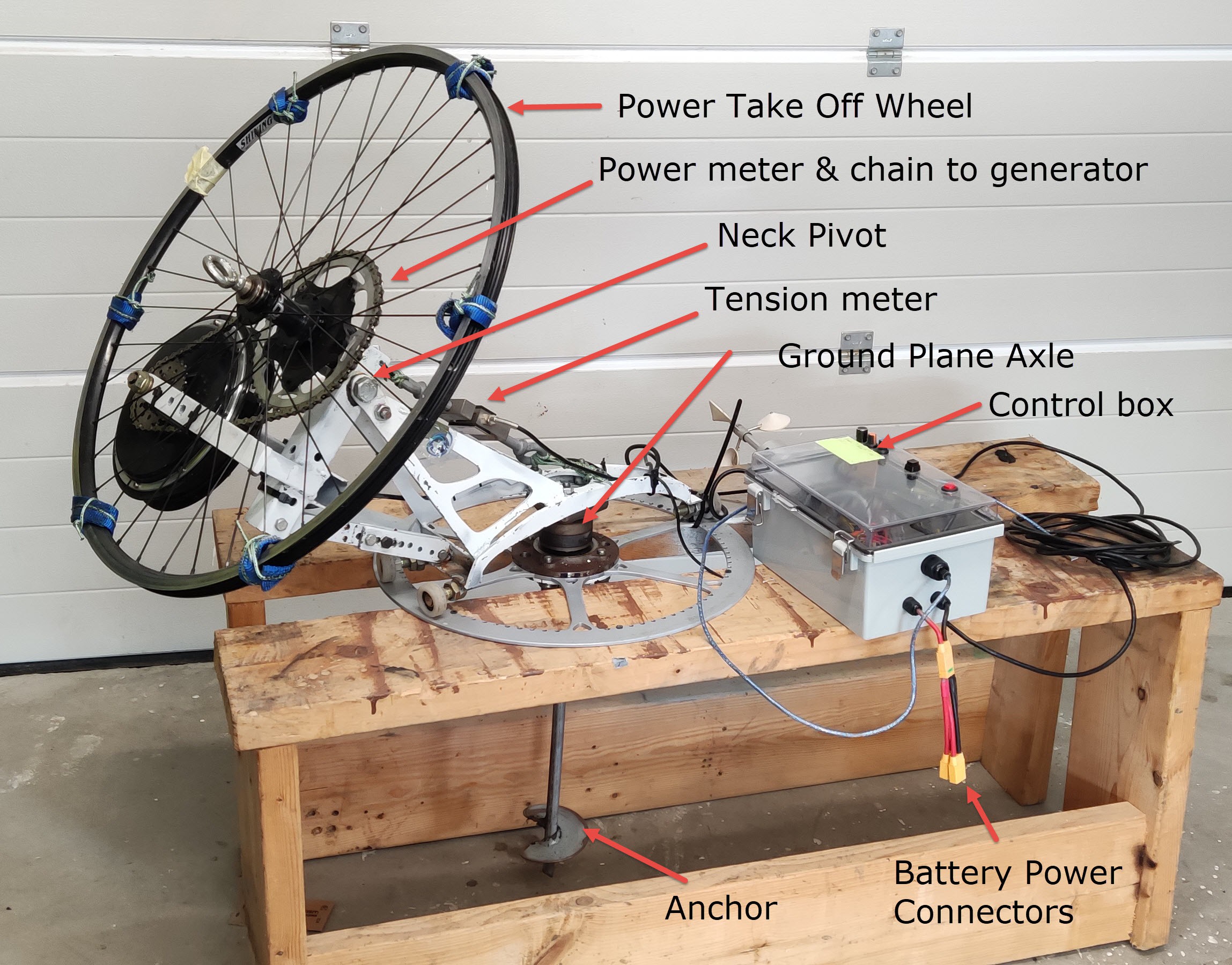

Now we have that tensile shaft power down on the ground we can plug it into a Power Take Off Wheel on an anchored ground generation station.

Notice that there are 2 sticks at the back of this ground station generator... Without them it get's wobbly.

This was a ground station and turbine combo I was preparing for the scouts (More about that at the bottom of this chat.

The ground station has to have a really good anchor. You never want to see a 20kg lump of edgy steel flung past your head by an angry kite.

For ground station designs go here ground stations

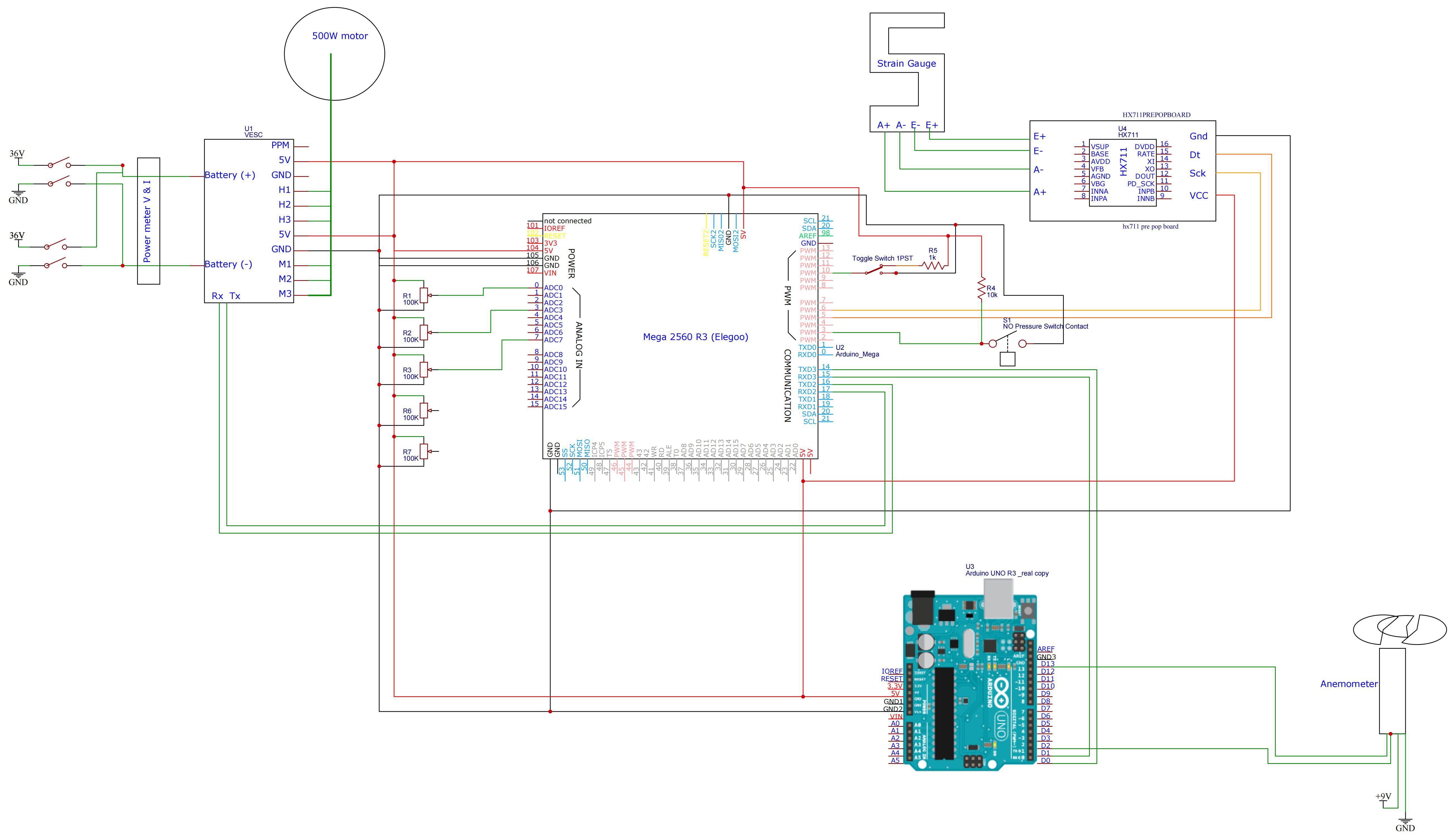

The ground station motor/generator controller code can be found here DaisyKiteTurbineControl

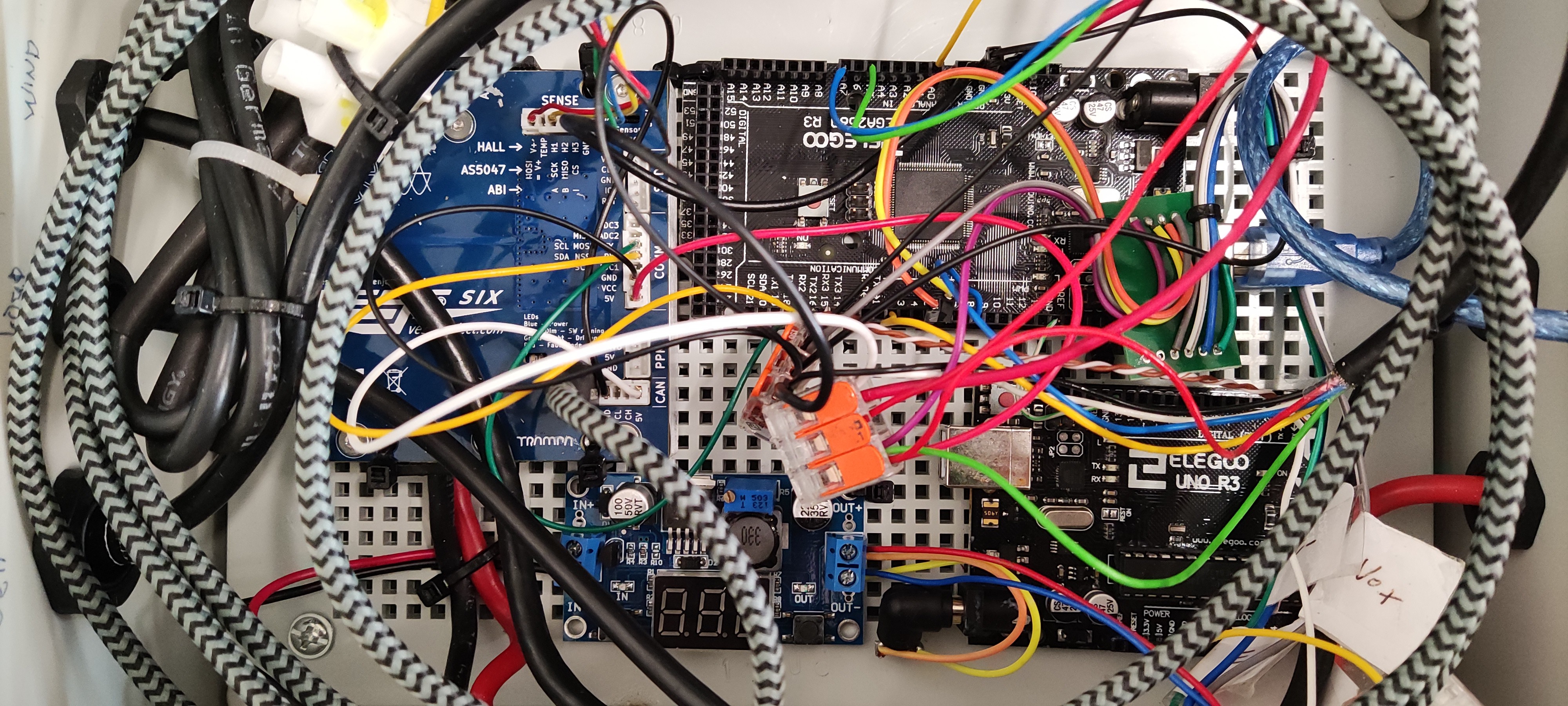

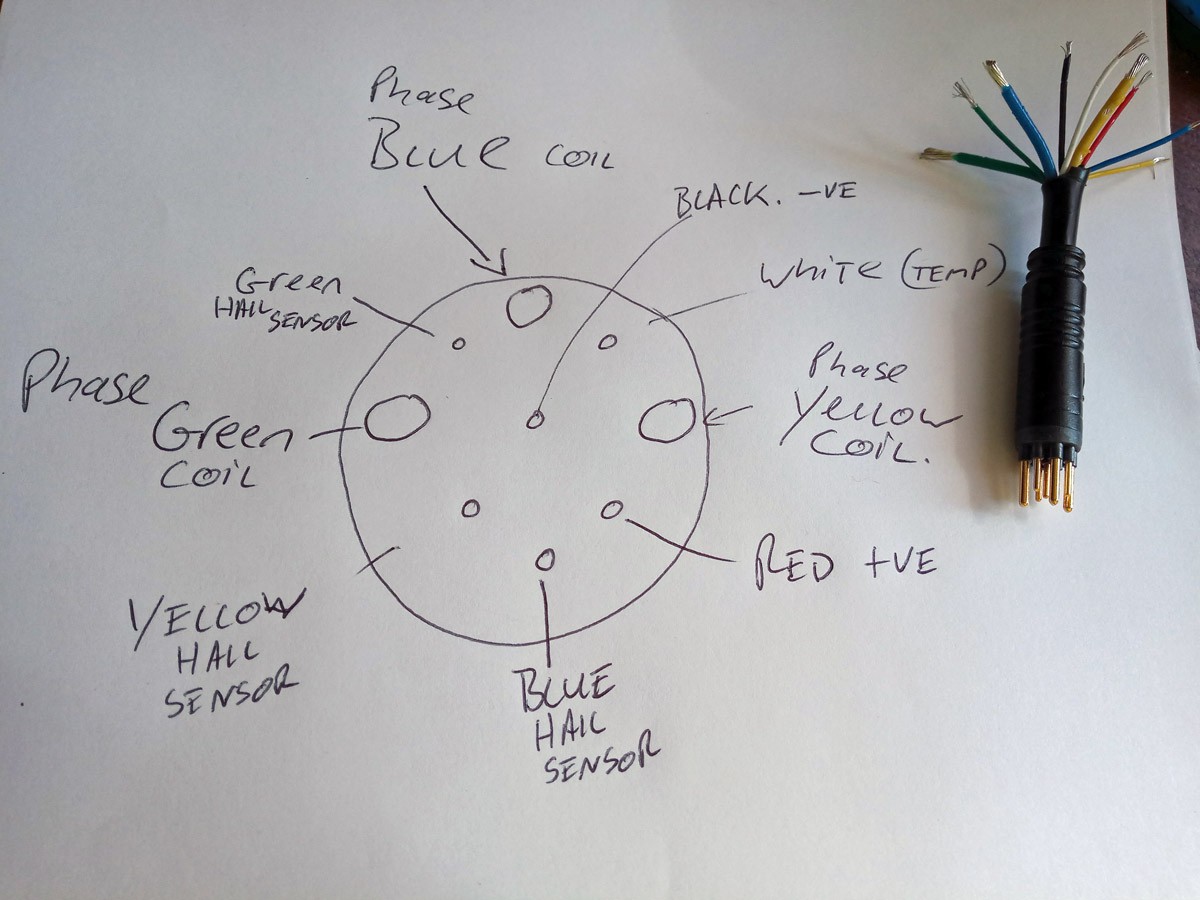

it controls this rats nest

With the software and knobs and sensors, You can govern the max regen and mix the levels of control from the tip speed ratio, the tension torque ratio and the speed trend. You can also hold a brake and boost forward for start up or unwinding a mistake.

OK, nearly there.

Make sure your sram crank power meter (converted to the chainring sprocket) is connected to the wee bike computer.

Get a few powerful 36V e-bike batteries and connect 2 of them with XT-90-s anti spark plugs to the power in leads. Connect the Mega 2560 (way too slow for next revision) to your pc to get a stream of data.

Run the turbine to charge the batteries... just like that.

With your spare batteries, Connect them very carefully to a ~5kW inverter. Very Carefully.

Then fish out an EVSE car charger capable of selecting a lower than normal charging...

Read more » Roddy "Rags" Read

Roddy "Rags" Read

Josh Starnes

Josh Starnes

Eric

Eric

Latest test results over 1 kW

https://youtu.be/UpIECYxP4xc