Hey, we're back!

We took a year off so we could sort some things out, get better gear, and try again to make a fantastic piece of hardware for Defcon 27.!

Who are we?

We're the team that built the Ides of Defcon, a hackable, wearable, game badge for DC25, that you could fight as a Roman Gladiator with, attacking your friends for points and glory. #badgelife !

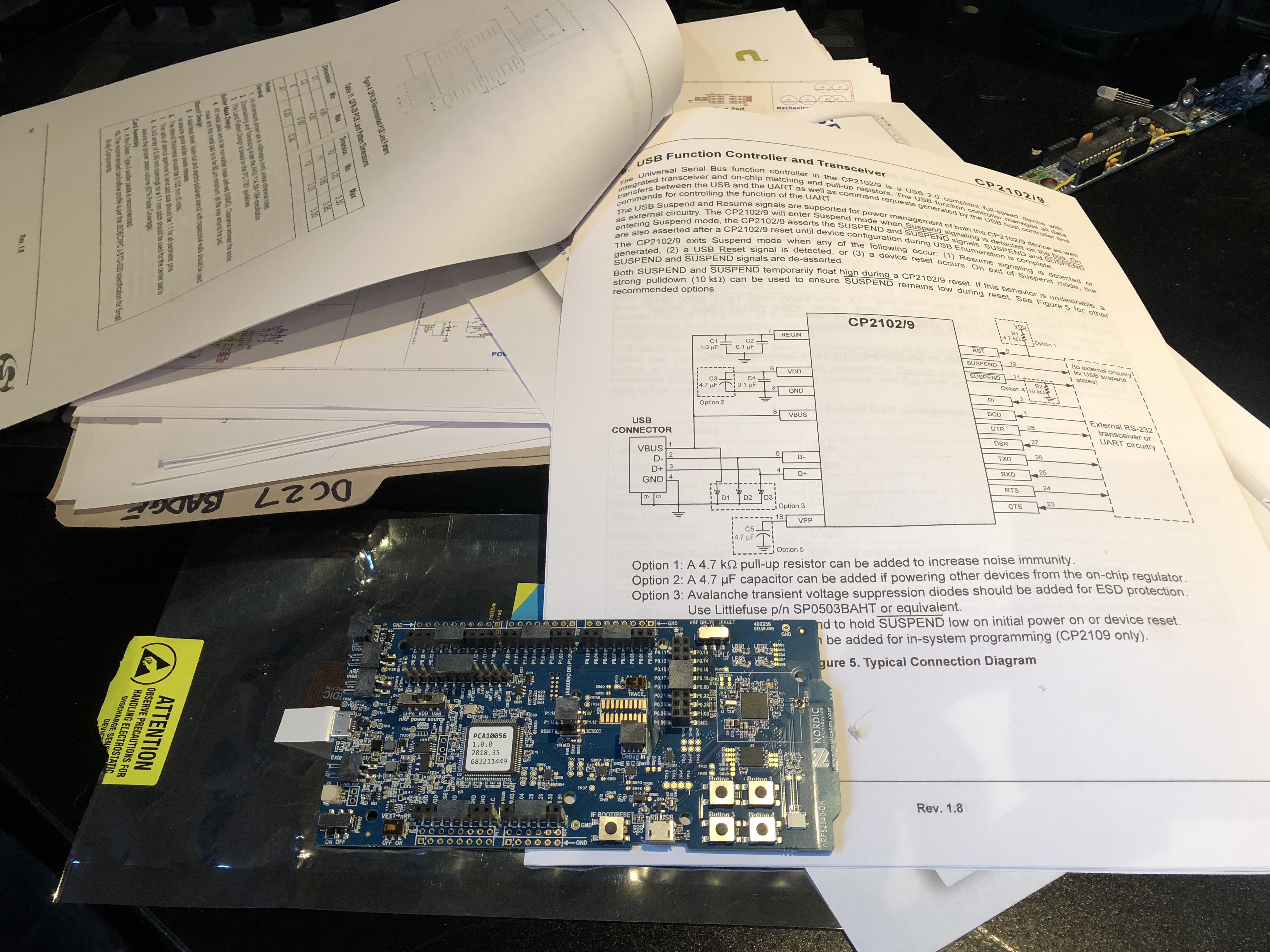

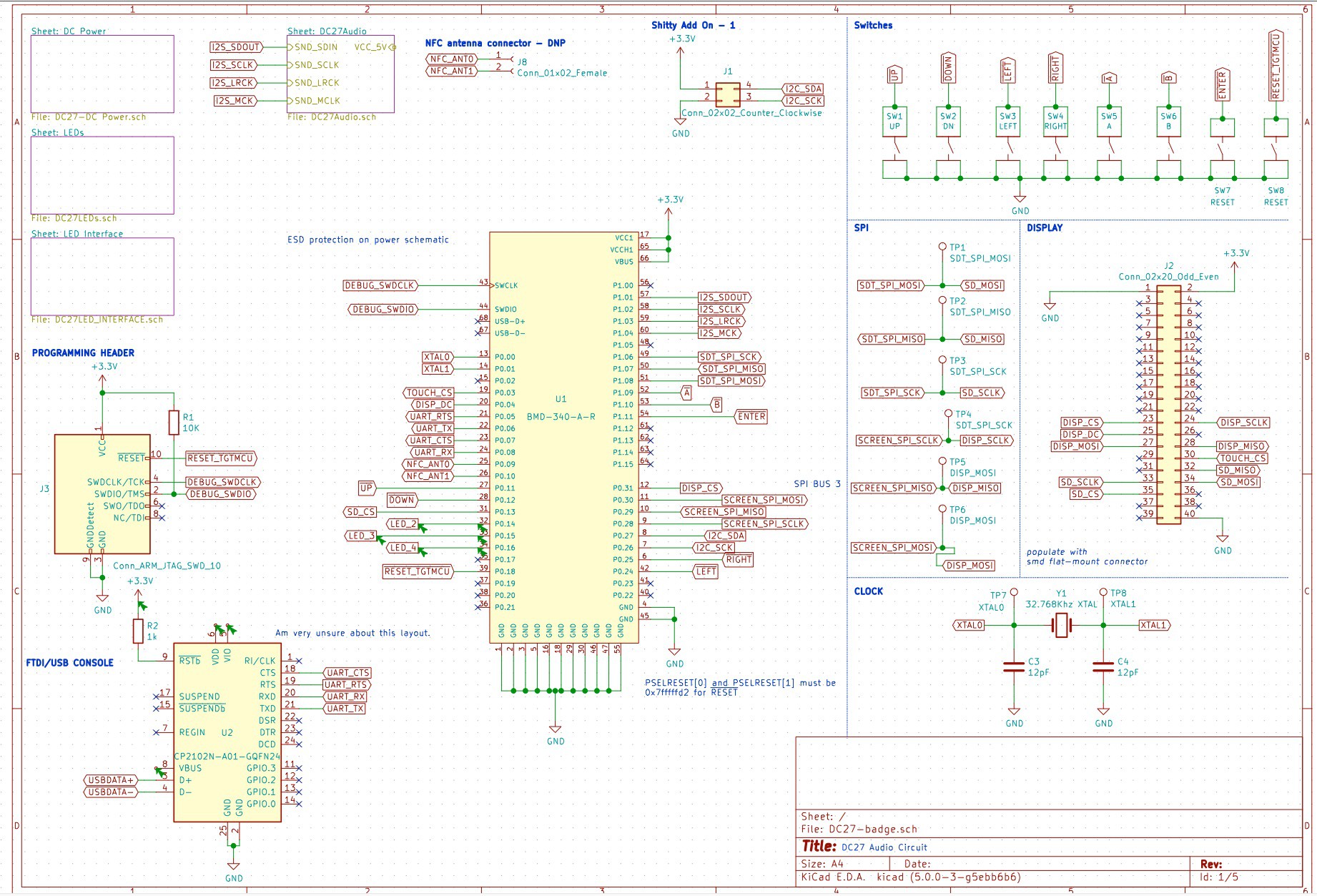

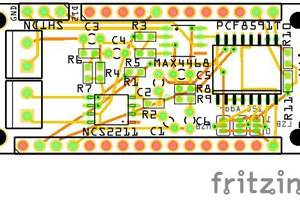

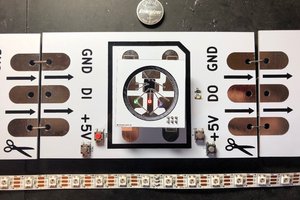

We're at it again, building a new badge for DC27. Our badges are rechargable, filled with audio and video wizardry, and for use for you to learn microcontroller engineering and to generally hack on. It's the best thing that you can get your hands on when you've graduated from the world of just-make-it-blink and Arduino.

We're are we at?

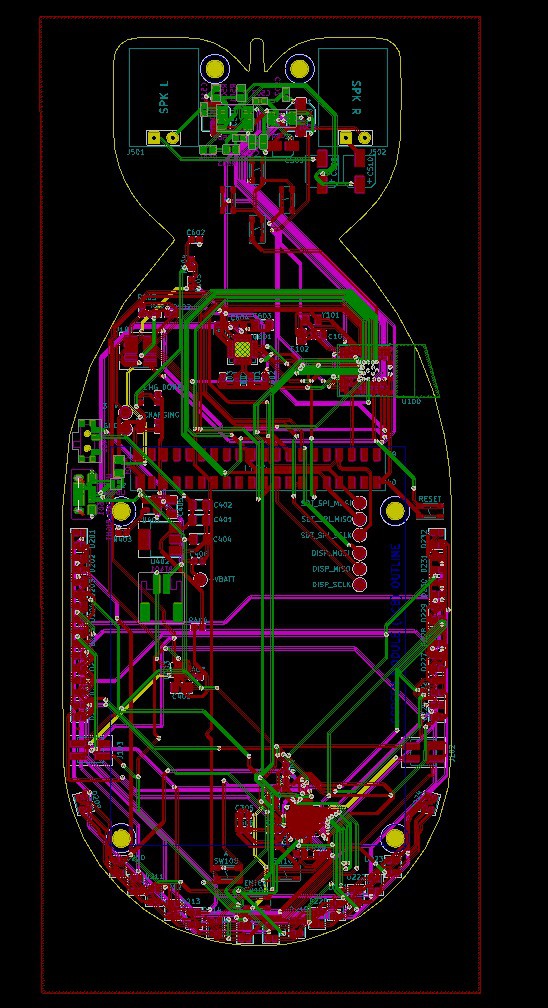

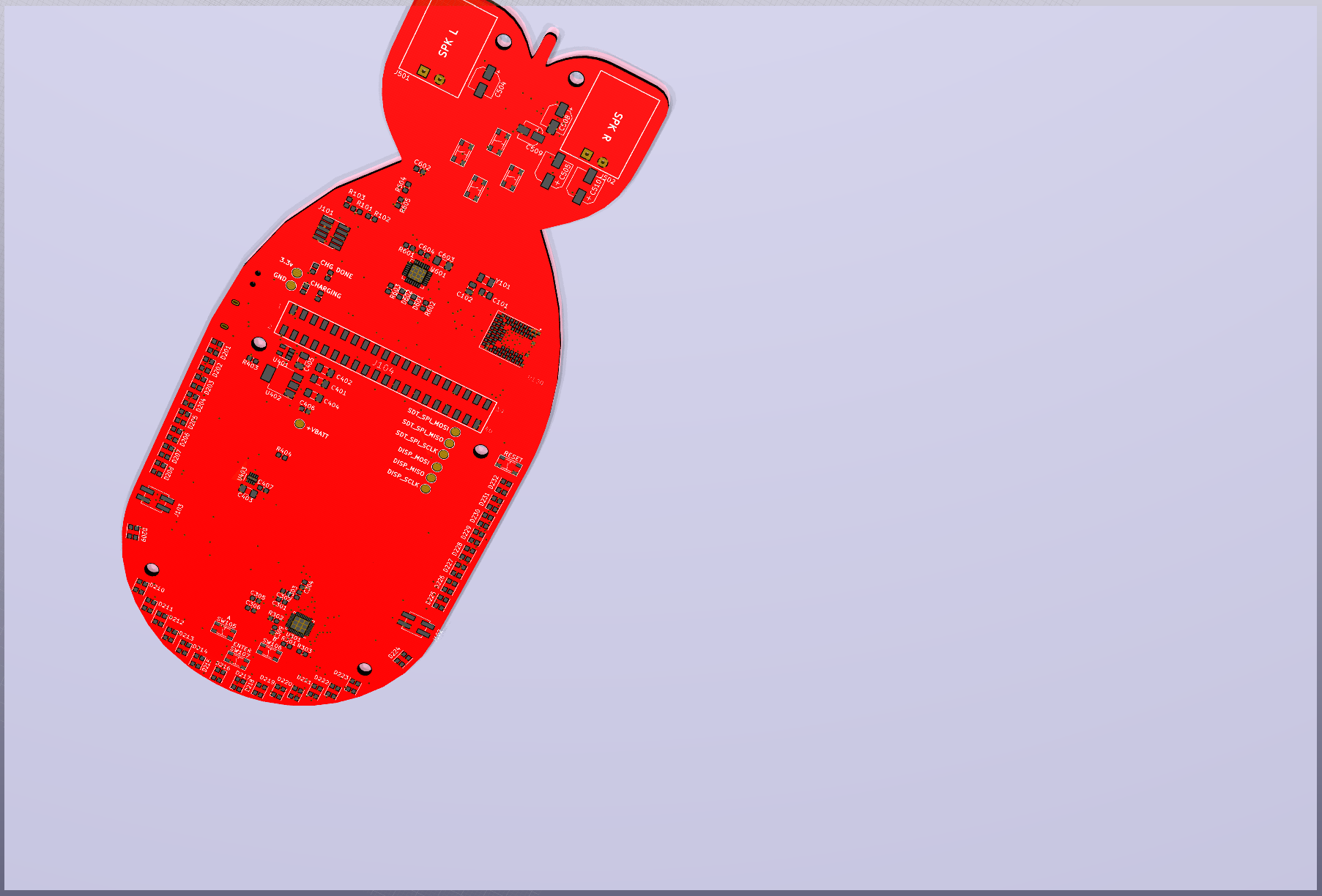

We've been working on the badge design for about a year now. The schematic, PCB layout, and BOM are complete, and in production.

You can buy one at https://troupeit.com/badge !

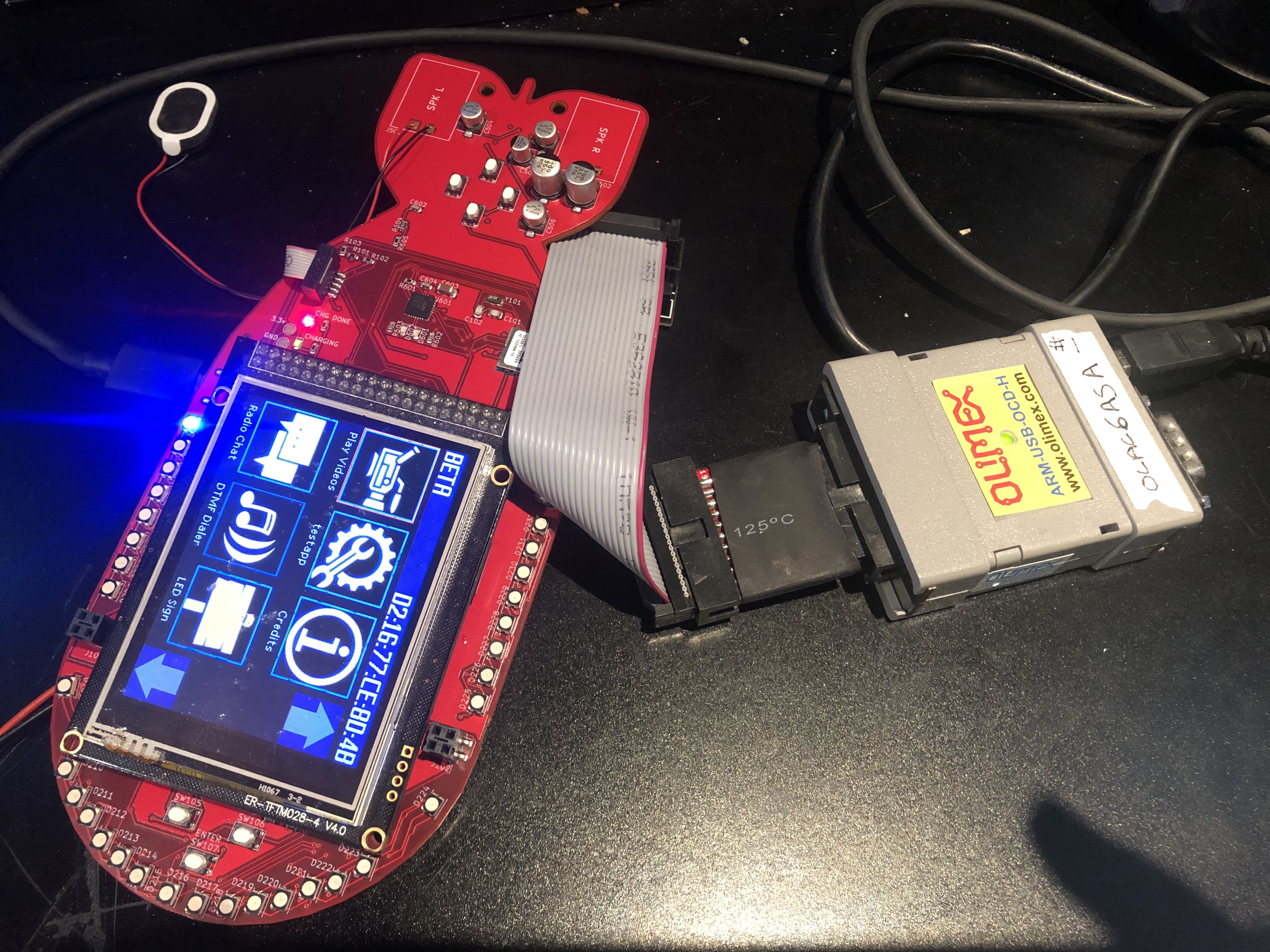

Prototype #1 is back from Macrofab, and we're setting up for Prototype #2 this week. Nearly all functions are functional, and we've just got some minor revisions to sort through. We've selected speakers for our board, tested our code and are getting ready for production.

The Kickstarter is going great too - We've only got $10,000 to go and have booked $15,000 in sales so far!

John Adams

John Adams

Benchoff

Benchoff

bobgreenwade

bobgreenwade

blinkingthing

blinkingthing

Jonathan Brodsky

Jonathan Brodsky

missed the campaign.. I'm so yaaark.. Huh..

Fingers crossed to finally put my big hands on the next badge :)