Yarn Winder - Cone Winder, new Video on youtube (6.2.23)

I keep having problems with the yarn that I wound with the yarn winders I bought. As long as I operate the lock by hand, this is usually not a problem. It's different when knitting with the motor.

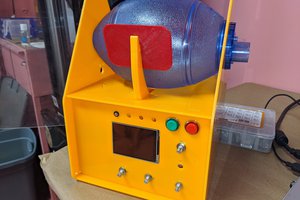

So I built my own yarn winder. Since my design differs from the other yarn winders, I made a video as inspiration for everyone who also wants to build their own yarn winder.

The project is still in progress. However, everything essential is done. There were no more problems with unwinding. The yarn I used measures between 15,000 meters to 30,000 meters per kilogram.

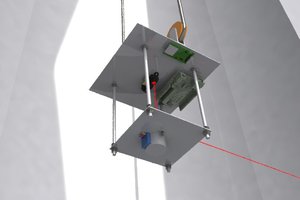

The yarn can be wound on cones or cylinders. Anyone who is good at mathematics can certainly create the most beautiful winding patterns. The XY axes move like the TBot (see the video below).

Video TBot

New Video on youtube (29.12.21)

The Video shows the setup, how I write a simple Jacquard technique in part 1. The second part shows how the machine knits and the swatch.

I will upload the new software version in the next few days on Github. I've revised the code and the GUI. I have also improved the error messages.

Passap E6000 is a computer-controlled knitting machine. It has two needle beds. Each individual needle on the front needle bed can be controlled via a console. The needles on the rear needle bed are controlled mechanically. I have always dreamed of being able to control the rear needles via the computer as well. I knew it was somehow possible but had no idea how. The essential idea came from Hackerspace Bamberg (https://www.hackerspace-bamberg.de/Passap_pfaff_e6000, https://github.com/knitty/firmware/tree/master/software/Knitty ). The hackers have exchanged all parts from the back-needle bed with those of a front needle bed. For the new rear needle bed, a second front lock has been rebuilt.

_______________________________________________________________________________________________________________

Juni 2021 New Version

_______________________________________________________________________________________________________________

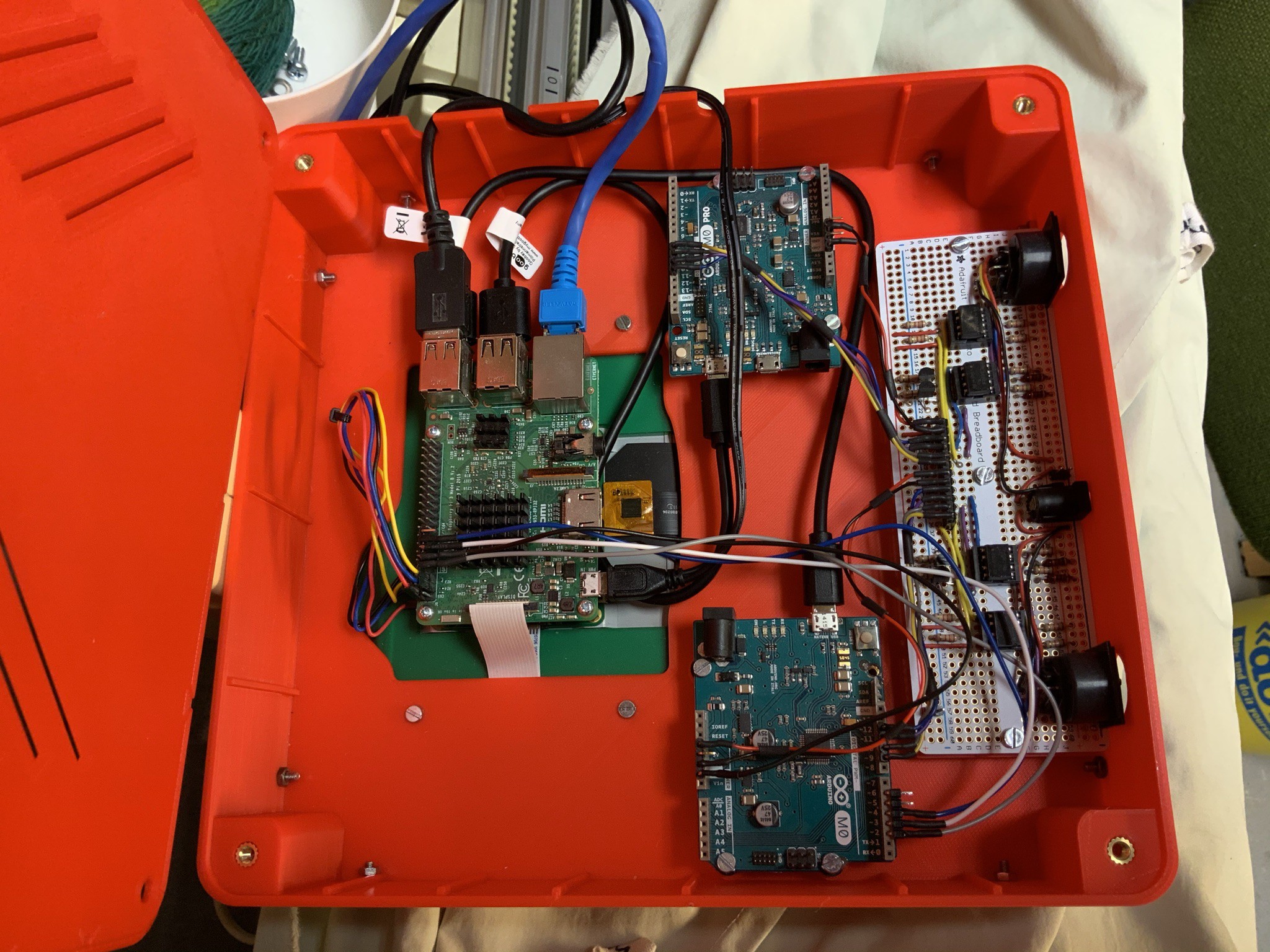

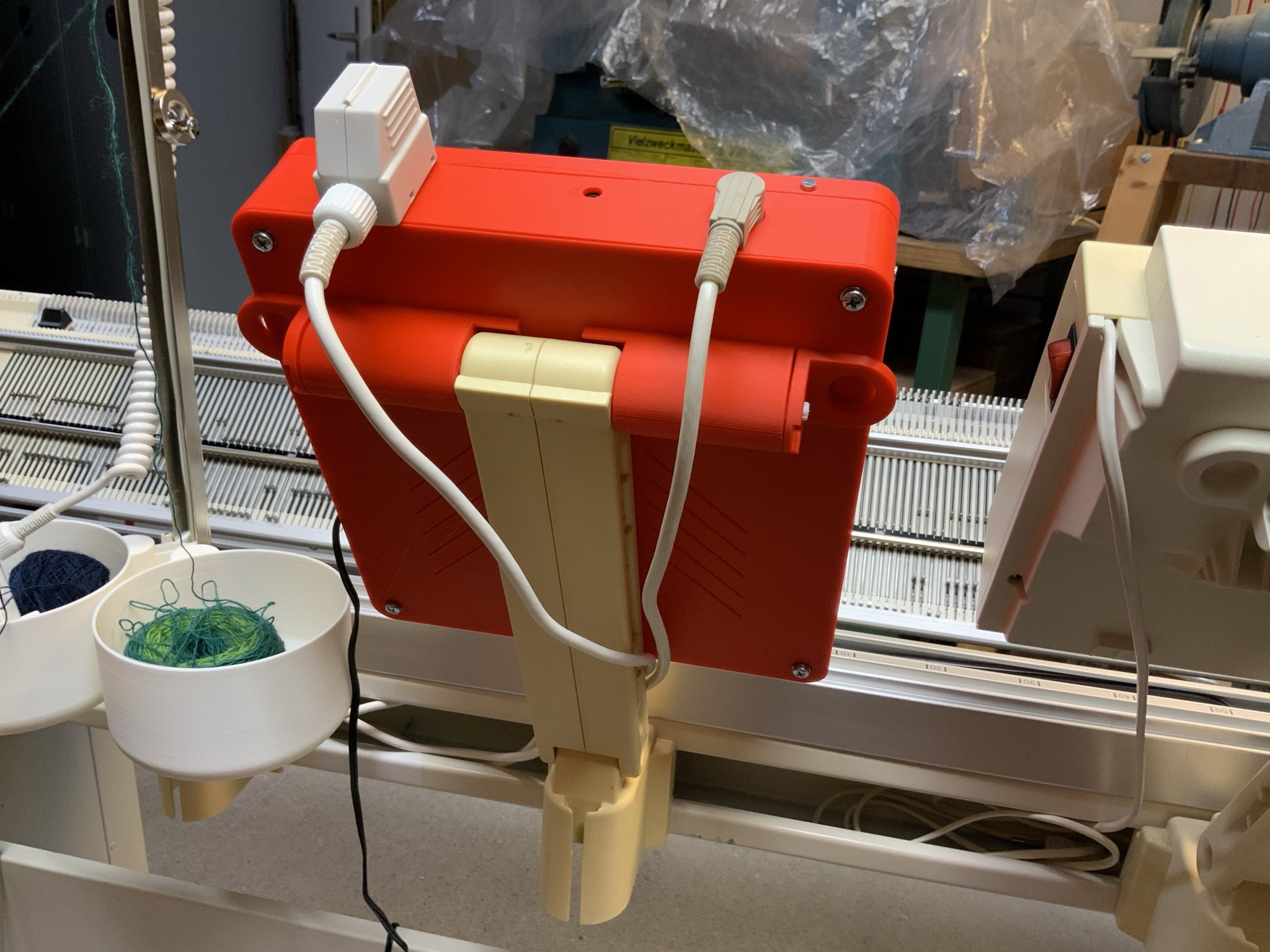

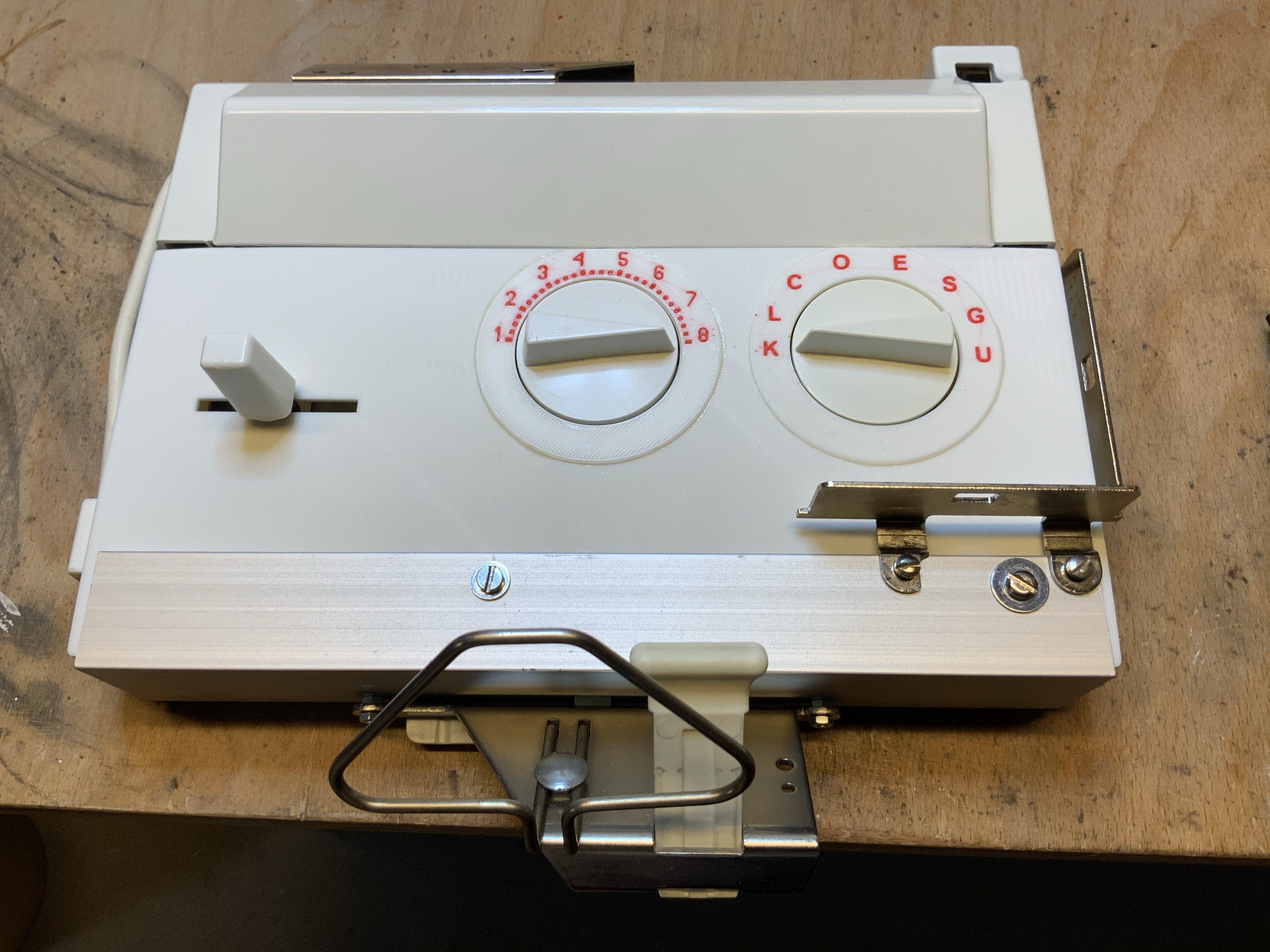

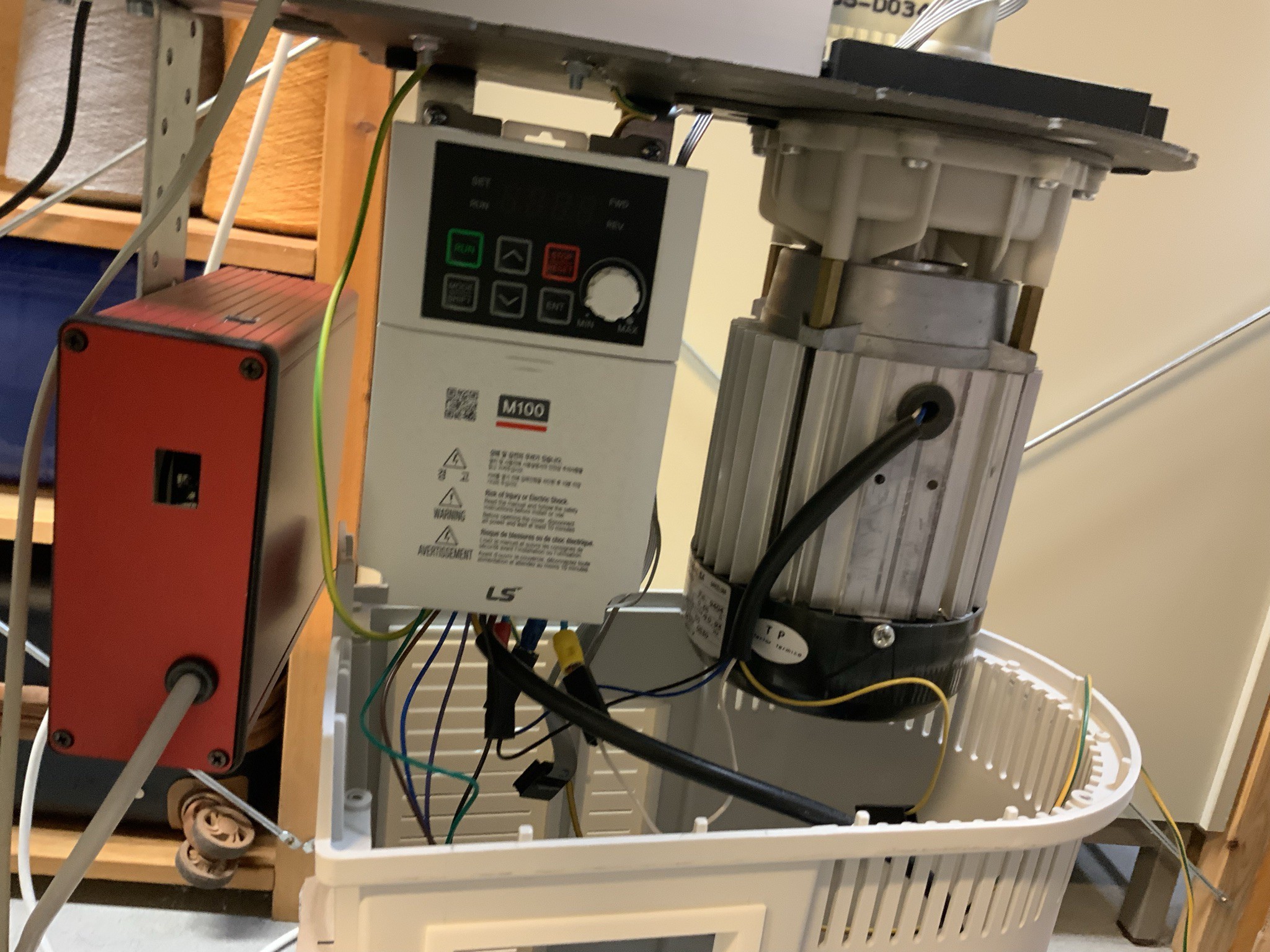

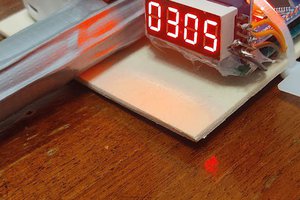

Video and photos of the console, the motor controller unit and interface.

If you would like to find out more, just ask.

Same mounting as the original console

Back of the console

Rear lock

Motor, window for the frequency converter. On the left: Motor interface. Black cable on the top of the red enclosure is the USB connection to the console.

frequency converter

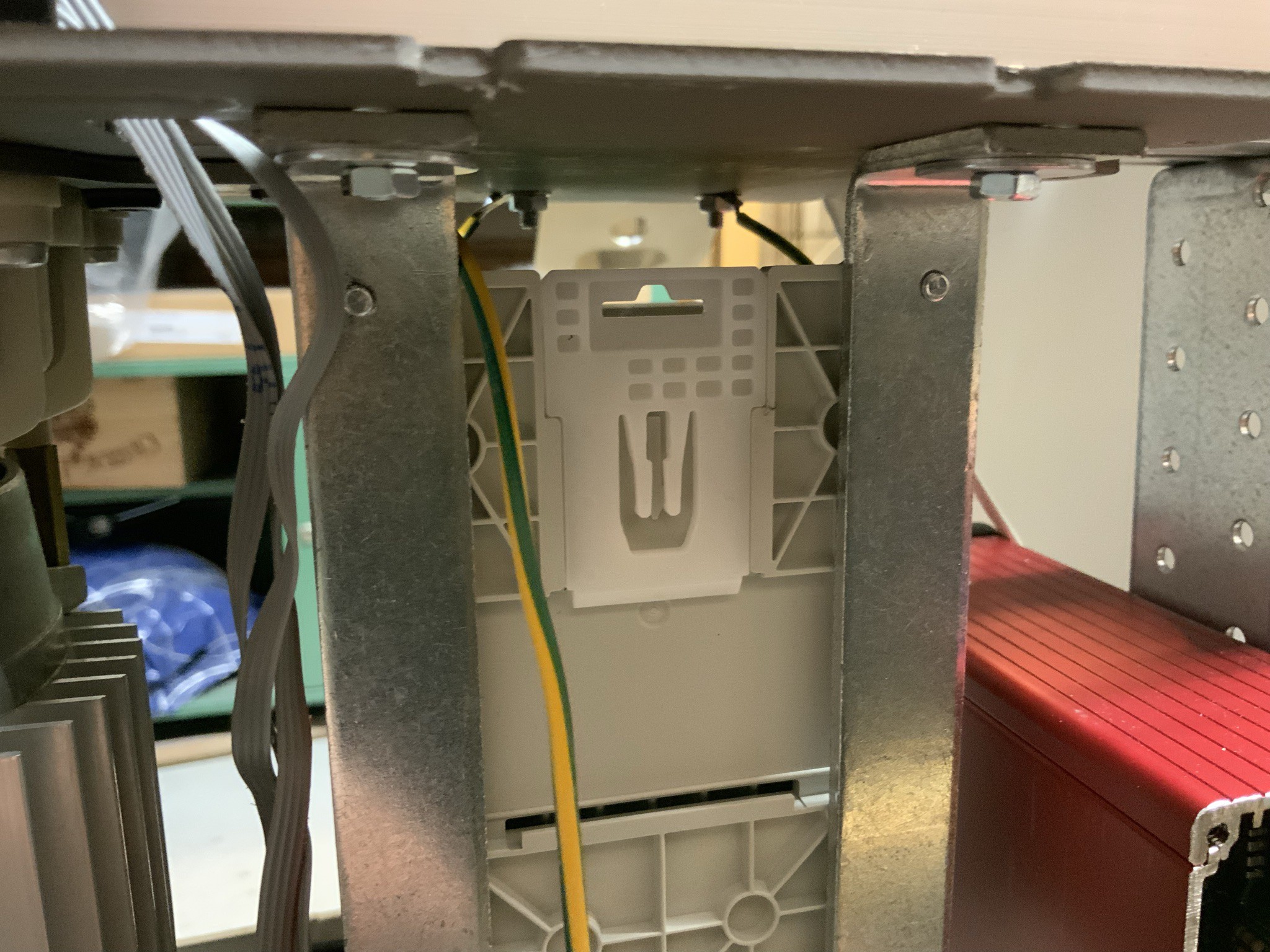

Mounting frequency converter

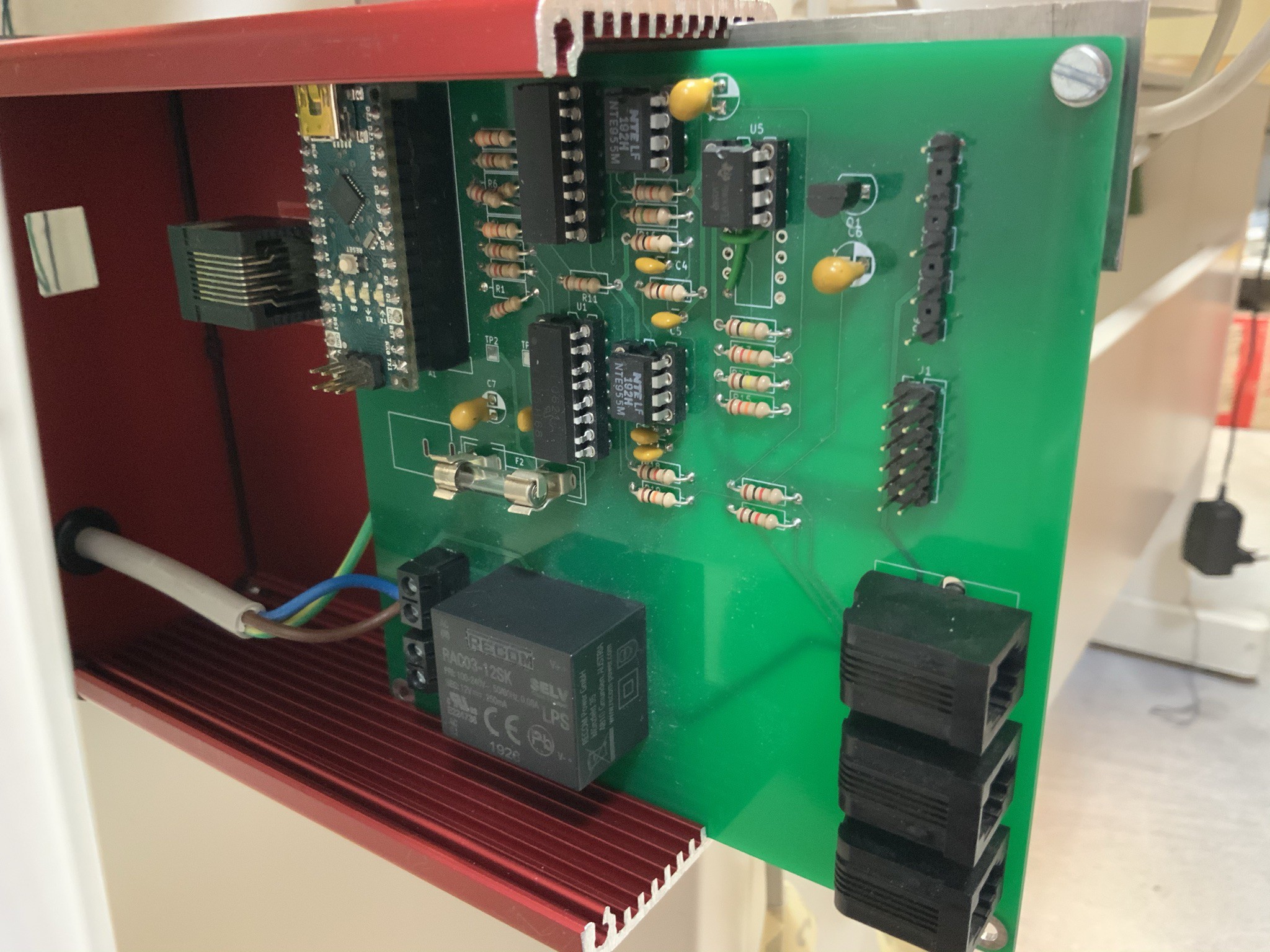

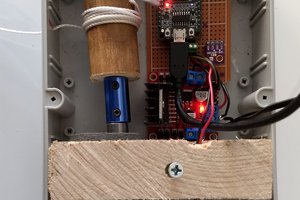

Motor interface. Owen made the design of the board according to the previous interface, thank you Owen, the interface looks now much nicer. The Arduino is now on this interface.

___________________________________________________________________________________________

Passap Electra 4600 rebuilt (2020)

____________________________________________________________________________________________

In the video below (2020) you can see the knitting machine and the motor Electra 4600 in action. More detailed information will follow over the next few weeks.

What is new?

The electronics of the Passap Electra 4600 motor have been replaced by a frequency converter, an interface and a controller. More project details will follow over the next few weeks. The latest version of the software will be published on Github. I hope this information will help you to realize your own project.

Electra 4600 connected to the frequency converter

I actually wanted to integrate the Electra 4600 engine in my project. Unfortunately the Electra 4600 engine had malfunctions. The control circuit board was damaged. We couldn't find out if more was broken. For example, the linear voltage regulator (REG 1) got very hot.

Since the board is very expensive, My husband came up with the idea to control the motor via a frequency converter. As tests showed the motor works wonderfully with the frequency converter.

... Read more » Irene Wolf

Irene Wolf

Laio Athos Nevar Fonseca

Laio Athos Nevar Fonseca

Tsjakka

Tsjakka

Daren Schwenke

Daren Schwenke

Giulio Pons

Giulio Pons

Hello Irene, I am new to this board and have a selfish interest in joining. My wife owns a Passap E-6000 and we occasionally encounter problems with the electronic components. The current problem is with the optical sensor in the front lock. We encountered error codes 200 and 207. It's most likely there is some issue with the optical sensor. Getting anyone to consider making board level repairs seems to be impossible. I think there would actually be many people interested in having repairs of this type made, so they could get their machines running again. I live in Toronto, Canada. I'm not sure where you're located, but can you provide any contacts that I could reach out to to help in this situation? Any advice would be most welcome! Thank you, David