Why would you do this?

We have been keeping bees for a few years in two different Texas locations -- Gulf Coast and Central. Like many beekeepers, especially beginners as we are, we have had a high amount of hive losses. Some of these losses have been very easy to identify. For example in the Gulf Coast the invasion by tropical fire ants (Solenopsis geminata) has been devastating to many desirable species -- and they definitely do kill new bee hives. Other causes of colony collapse in our hives have been hard for us to diagnose. And even harder to catch early enough to help the hive recover.

We looked at other bee hive monitoring projects and they all provided interesting data, like the number of bees entering and leaving. But we do not know how to translate this to the ongoing health of the colony. Forager bee count data can be strongly influenced by things like climate, temperature, rain, cloud cover, amount of pollen providers, etc. What we hope is that we can initially use hive weight changes to provide a more direct indication of what is going on with the overall colony.

All of this leads to a number of questions that we hope to answer with the data from this project. Some of these questions will be explained in the project log.

____________

How will we do it?

Our hope is that we can create a consistent method of data collection so that it can be shared with other bee enthusiasts and compiled for analysis across many environmental conditions and locations.

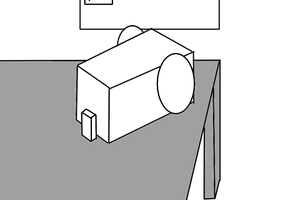

On the hardware side our prototype monitors are progressing. We are using as much Consumer Off The Shelf (COTS) items as we can. For the scales we have selected some that have seamless stainless steel tops that roll over the edges to prevent water drip lines. They also have closed bottoms. The key feature is they have a detachable head that contains all their electronics and batteries. Having the power external to the scale platform is vital. You do not want to have to move an active hive to replace batteries.

The original scale head is cut off and replaced with our hardware system. This system consists of input conditioning for the scales and other sensors, the Microcontroller Unit (MCU), the power system, and an external WiFi antenna.

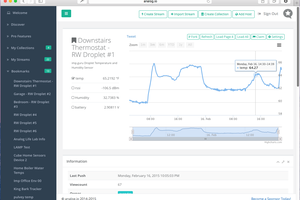

These monitors then send MQTT data packets as clients over their WiFi connection to the local network. In a remote location we have a Raspberry Pi that acts as an MQTT broker and general server. This server also contains an Ifluxdb database instance for data logging. Grafana also runs on the server to display the data.

We have also set up a free test account with Adafruit.io (Many thanks Adafruit for doing this for the community!). This will allow us to mirror the data to Adafruit and have remote access to it without having to configure routers, write firewall rules, etc. Once complete we can share the data in the public cloud(s).

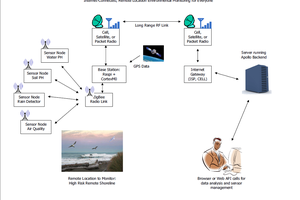

Future enhancements may be to use a LoRa gateway to enable the hives to be monitored further than WiFi can conveniently reach. We are also considering a mesh WiFi approach using an ESP8266 intermediate repeater, but this is less desirable due to the "bowtie" effect and requirement for additional solar/battery power system.

____________

What is your approach?

To date we have been making progress on the prototype systems. We have a simple mechanical arrangement to keep the hives on the scale platforms, protect the scale, and keep the whole arrangement solid and level. We have tested a number of sensors, displays, modules, and ESP8266 development boards. This has led us to our current configuration. We are now integrating everything and beginning work on the mechanics of enclosures, weather resistance, etc. We are building and testing the implementation as we go. There are many items left to program, build, test, and correct before a robust, reliable system is working. That process is what we expect to detail in the project log.

sparks.ron

sparks.ron

Luke Beno

Luke Beno

minifig404

minifig404

x3n0x

x3n0x

Hi, Excellent project. Bees needs attention otherwise there will be no bees and that will affect our food supply too. I started designing a similar project 5 years ago (with a similar concept) but then other obligations took me of the project and merely abandon it

What is the status of the this project today? I am also interesting on the environmental matter of the project . Sensing environment in hush conditions is not an easy thing and we have problems too on that field in our environmental M10CUBE project.

https://hackaday.io/project/171770-m10cube/log/185946-m10sensor-build-and-working

Now redesigning with Raspberry silicon R2040. Our new design will measure pollutant gases as well.

I believe LoRa is a candidate for the communications since it is low power and that is needed to save batteries and power it from a small PV.

Our thinking back then was to have only one LoRa transmitter for long range communications and a local mess network (Zigbee, Matter, etc) to send to the local LoRa station

Anyway I would like to join and help as my free time permits so both our projects can benefit