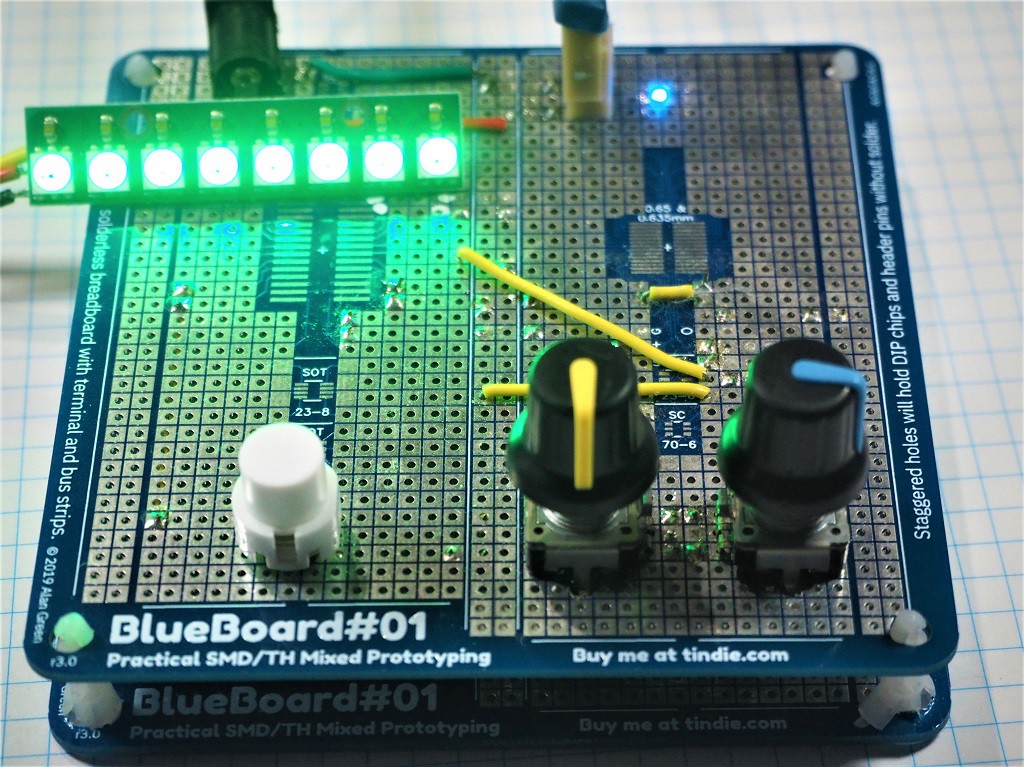

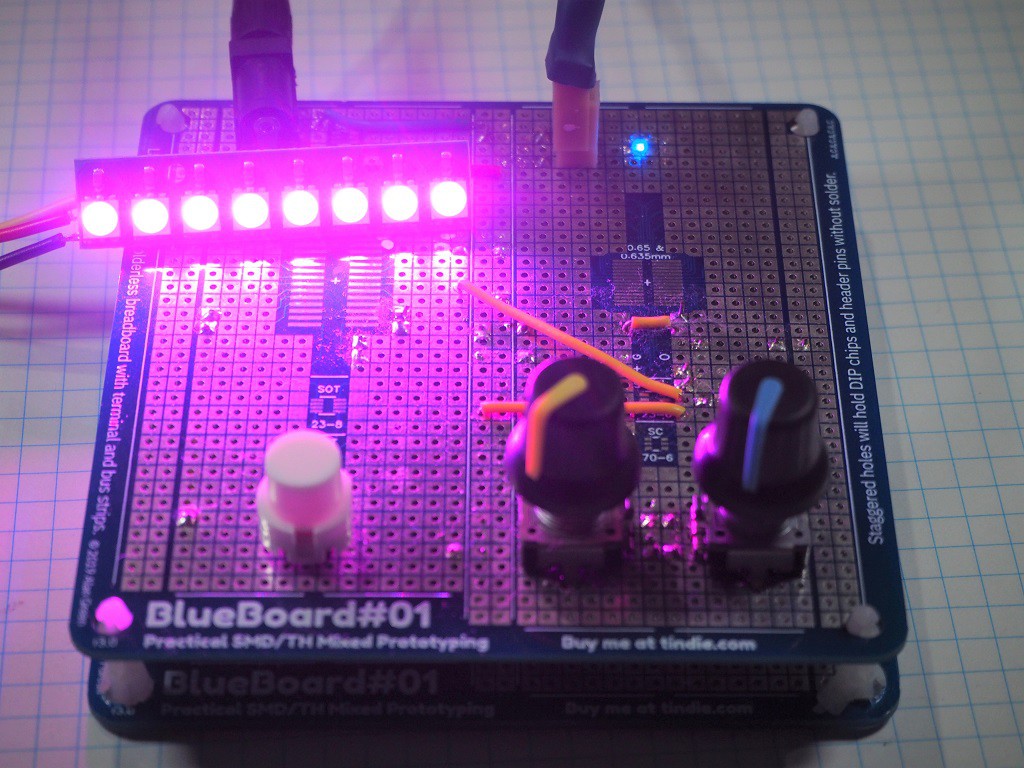

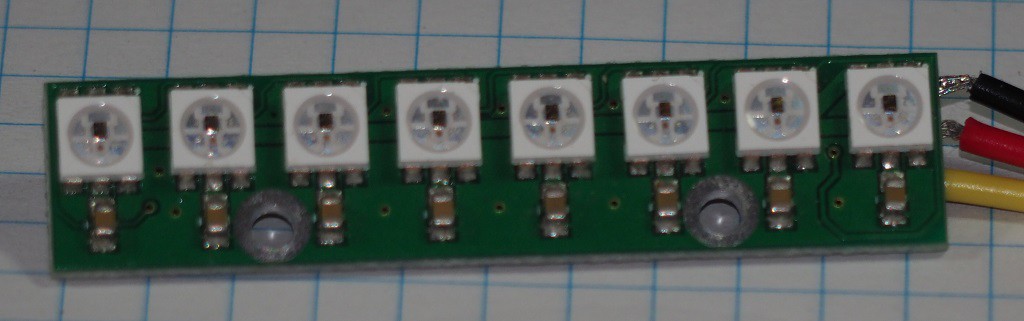

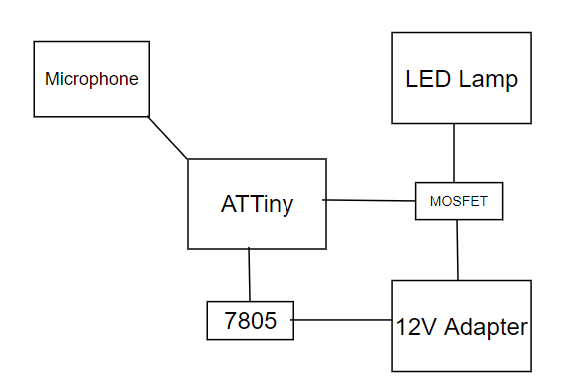

This project uses BlueBoard#01, and other components I had in cupboard. I'm pretty pleased with the result - it works, it's useful and it's acceptably tidy.

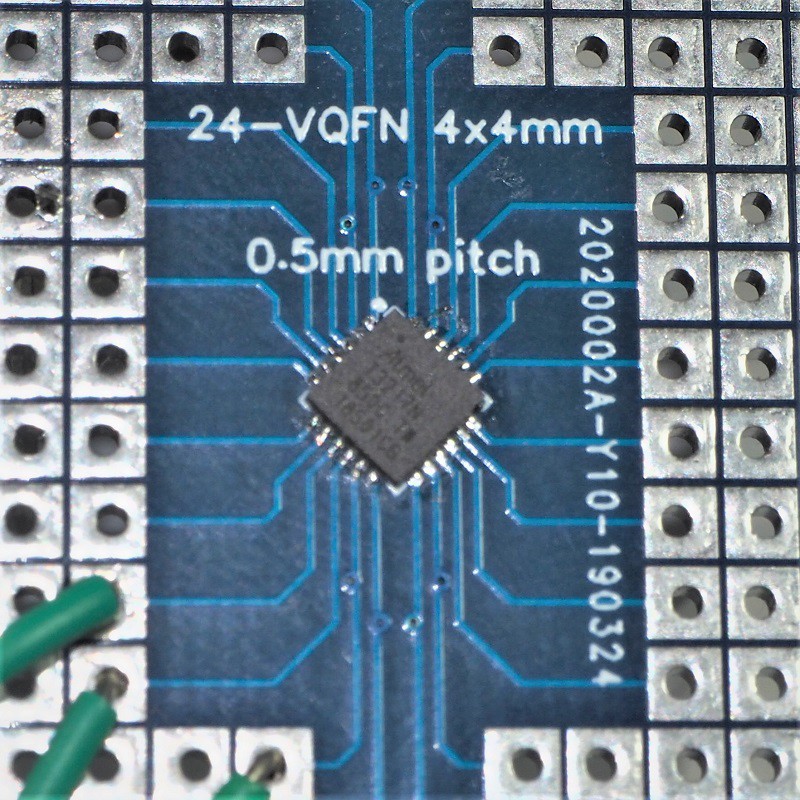

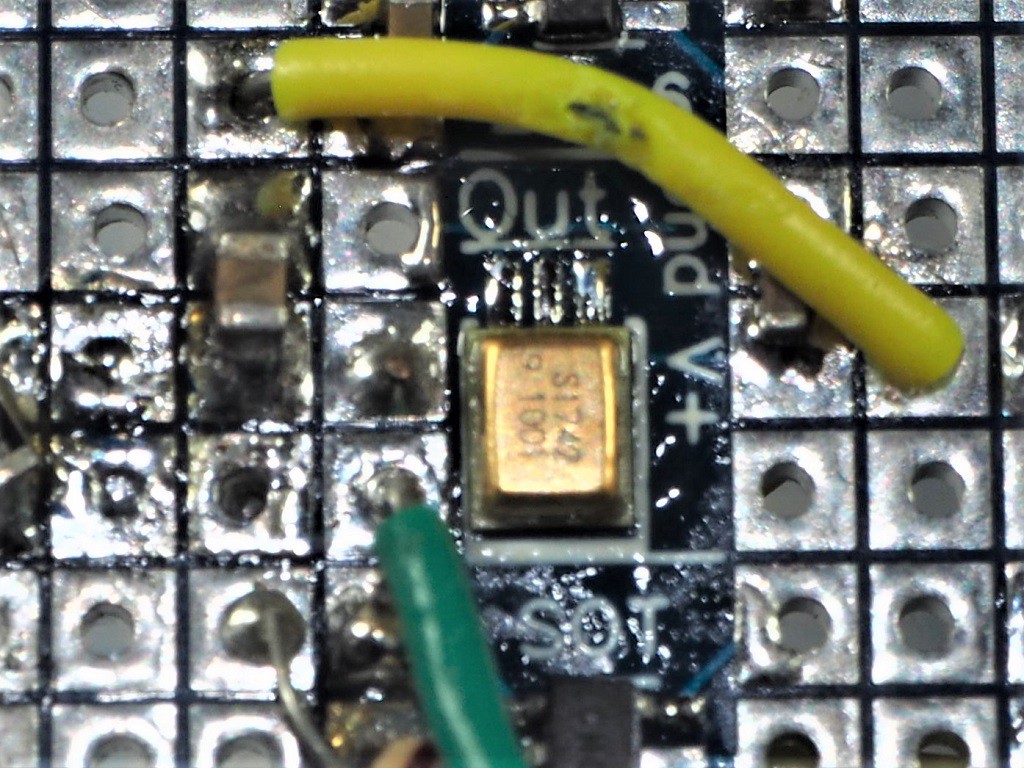

This was the final prototype of BlueBoard#01 before it went into production. The differences are:

- It uses HASL (solder) instead of ENIG (gold) plating.

- The placement and size of the mounting holes changed.

This project serves as an example of how to use BlueBoard#01 for one off projects.

Alan Green

Alan Green

Matthias Kampa

Matthias Kampa

Crypto [Neo]

Crypto [Neo]

Jon Kunkee

Jon Kunkee

mulcmu

mulcmu