Project Goals:

. Interesting for at least most of the grandchildren

. Quick enough to be completed during our summer week together

. Not too expensive, since 9 * (expensive) = prohibitive and I need one for myself, too

. Simultaneous control to allow racing - necessary to get the interest of some

Simply building a line-following robot would probably interest between three and five of the nine grandchildren. Adding the ability to control them with a phone or tablet and then to RACE them against each other will probably get the rest involved.

So, what sort of control from the tablets and phones? First I considered Bluetooth, but I fear that the multiple robots being controlled by multiple phones over Bluetooth would interfere with each other. Since simultaneous control is a MAJOR goal, that is OUT.

I settled on trying short UDP datagrams that set the state of the robot, with the processor on the robot taking it from there. Any WiFi network could support more robots than could fit into a room, so this seemed a good target.

Digression: UDP - User Datagram Protocol is the text message of the TCP/IP world. No "phone call" , no connection, just squirt out a limited size transport-layer datagram with no promise of delivery. The minimal requirements and overhead are just right for this application.

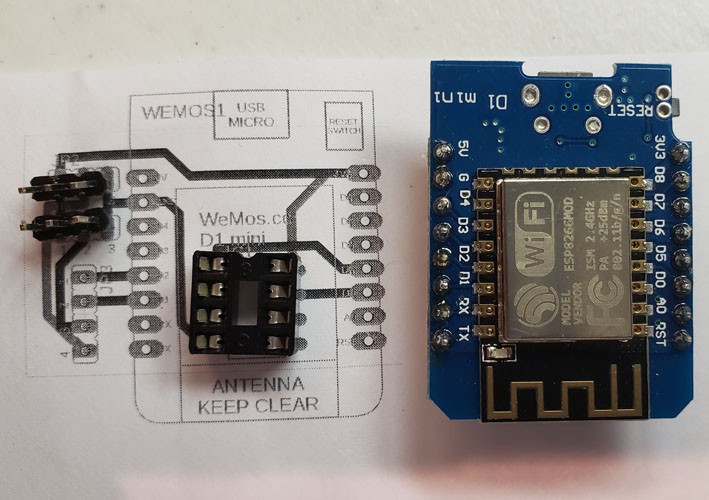

Next I needed to decide on the hardware to be carried on the robot. To me the choice was obvious - some version of the ESP8266. It has all the capability I need in an inexpensive package. I can't use the smallest versions but some ESP8266 Mini NodeMCU version has all the power plus easy implementation that I could ask. I found a three-pack at Amazon for $13 with amazing one day shipping and I found many on eBay for less with not so amazing one month shipping.

Link to single example on Amazon

I purchased samples and started developing.

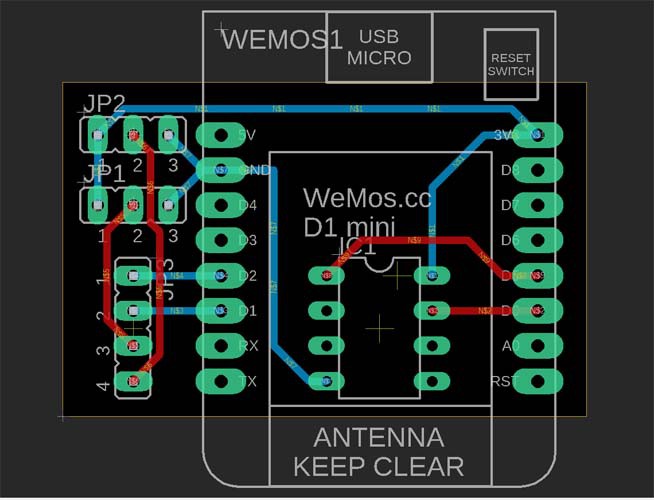

There are various versions of the mini NodeMCU but they all share an onboard 3.3 volt regulator, a USB<->serial conversion circuit, and the various other support circuitry so that they work right out of the box. The ESP8266-12 that they have onboard needs some pins tied high and others tied low before it will load software. It also needs a special "program" lead held high while reset is toggled. The NodeMCU package takes care of all of this for you. The version I use here is best documented at Wemos Electronics.

I use the Arduino IDE for ESP8266 development, so I just started my version 1.8.7 and selected the NodeMCU 1.0 as my target board. That let me look at the Examples and I found (under File>Examples>ESP8266WiFi) a "sketch" called Udp. I nabbed a little code from there and went into "software blacksmithing" mode. I heated it up and pounded on it a bit to beat it into my first test application.

All that application needed to do was:

1) connect to the WiFi network

2) get an IP address

3) display the IP address on the debug terminal

4) loop while

5) listening for UDP packets and displaying them

6) interpreting properly formatted packets and displaying the result

The result of this is called ESPlineUDP.ino and is the first program. Since this was only testing communication with the NodeMCU, I needed only to connect one to a USB port on my PC and proceed.

To send test UDP packets, I used a Linux system and the script sendudp.sh. That script is also in the program section, but is so short that it follows here:

cat bin/sendudp.sh <-- Linux command to display the script

#!/bin/bash -x

IP=192.168.95.107

# test sending UDP packet (only in bash)

echo -n "996,025" >/dev/udp/$IP/4949

sleep 3

echo -n "096,955" >/dev/udp/$IP/4949

sleep 3

echo -n "000,000"...

Read more »

jed

jed

Stephen Holdaway

Stephen Holdaway

Sandeep Patil

Sandeep Patil

Enrico Gueli

Enrico Gueli