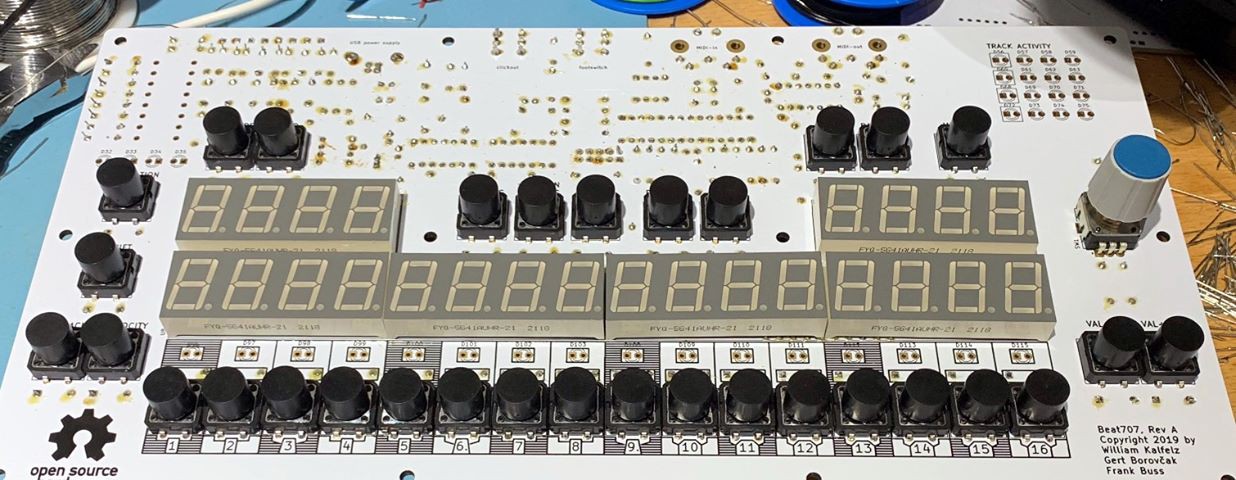

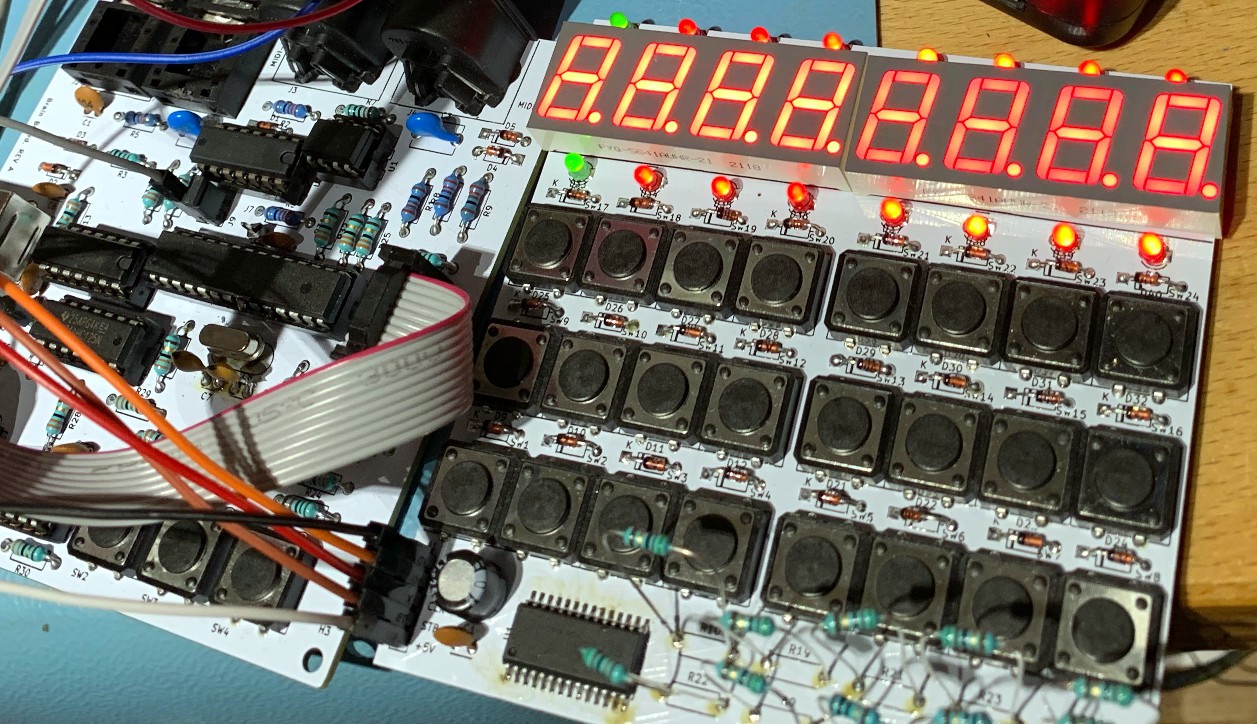

In 2017 William Kalfelz started with some cheap 7-segment / button boards from eBay and an ATMega to implement a MIDI sequencer. See this video:

Later Gert Borovčak built a version as well and helped improving the firmware with William. He even manually desoldered the 7-segment elements and buttons of the eBay board and soldered a custom version on perf board, see this video of a short demo performance:

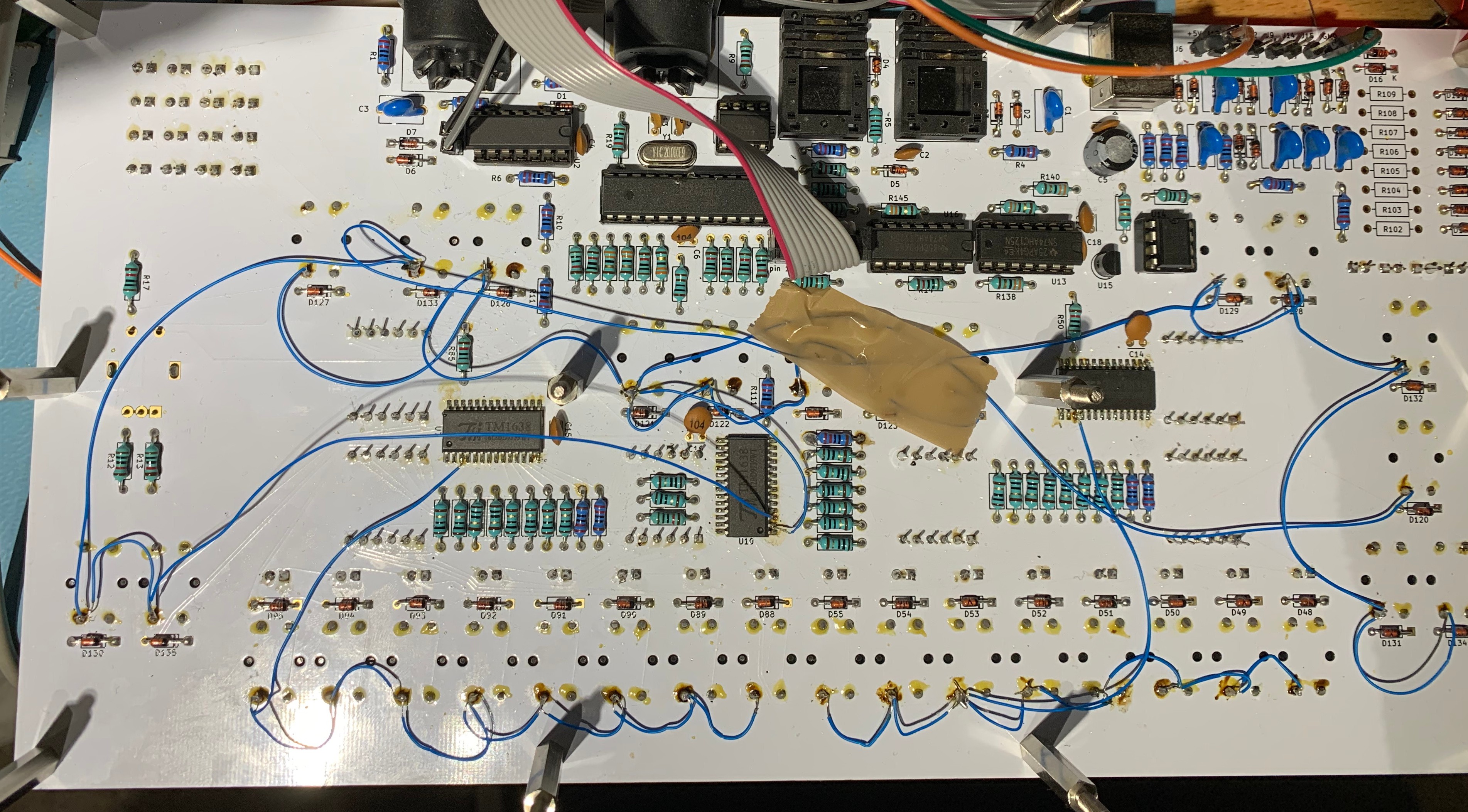

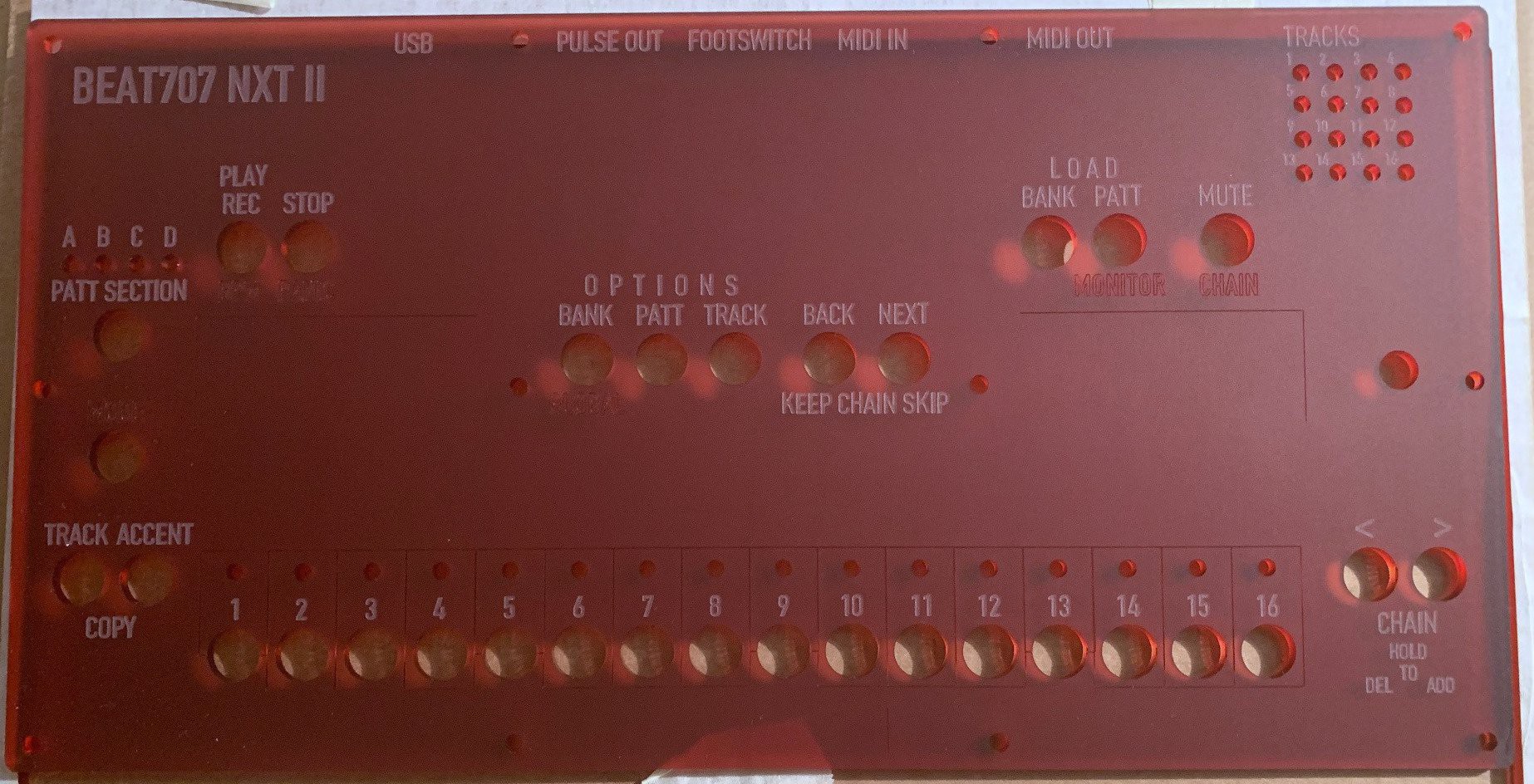

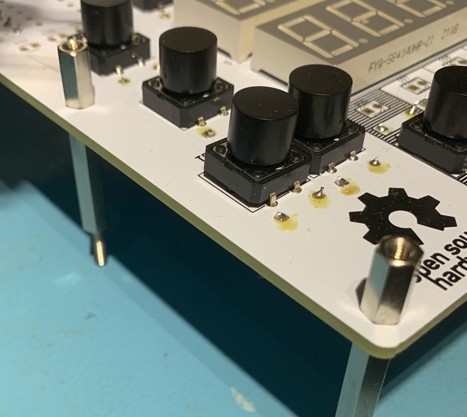

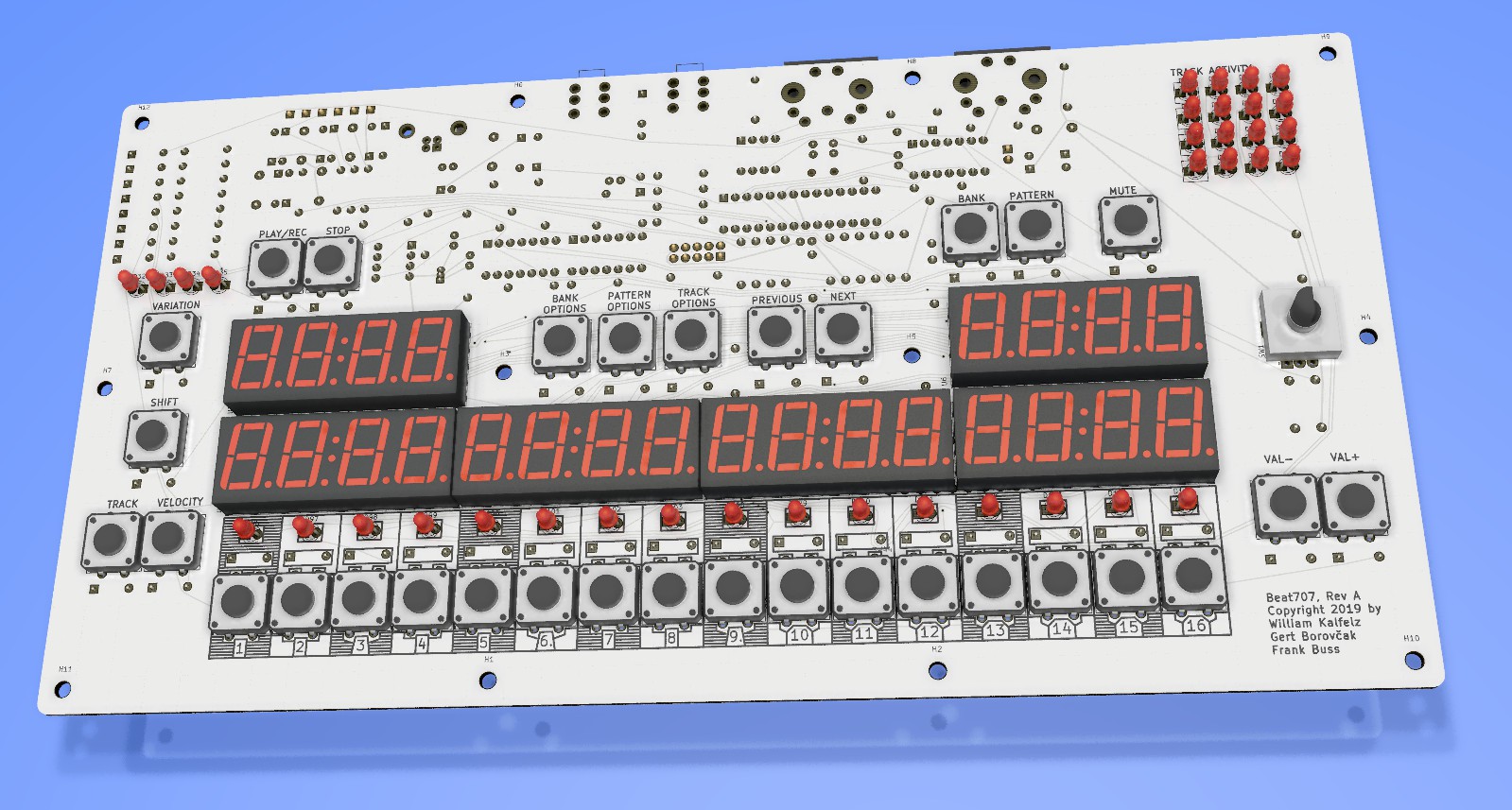

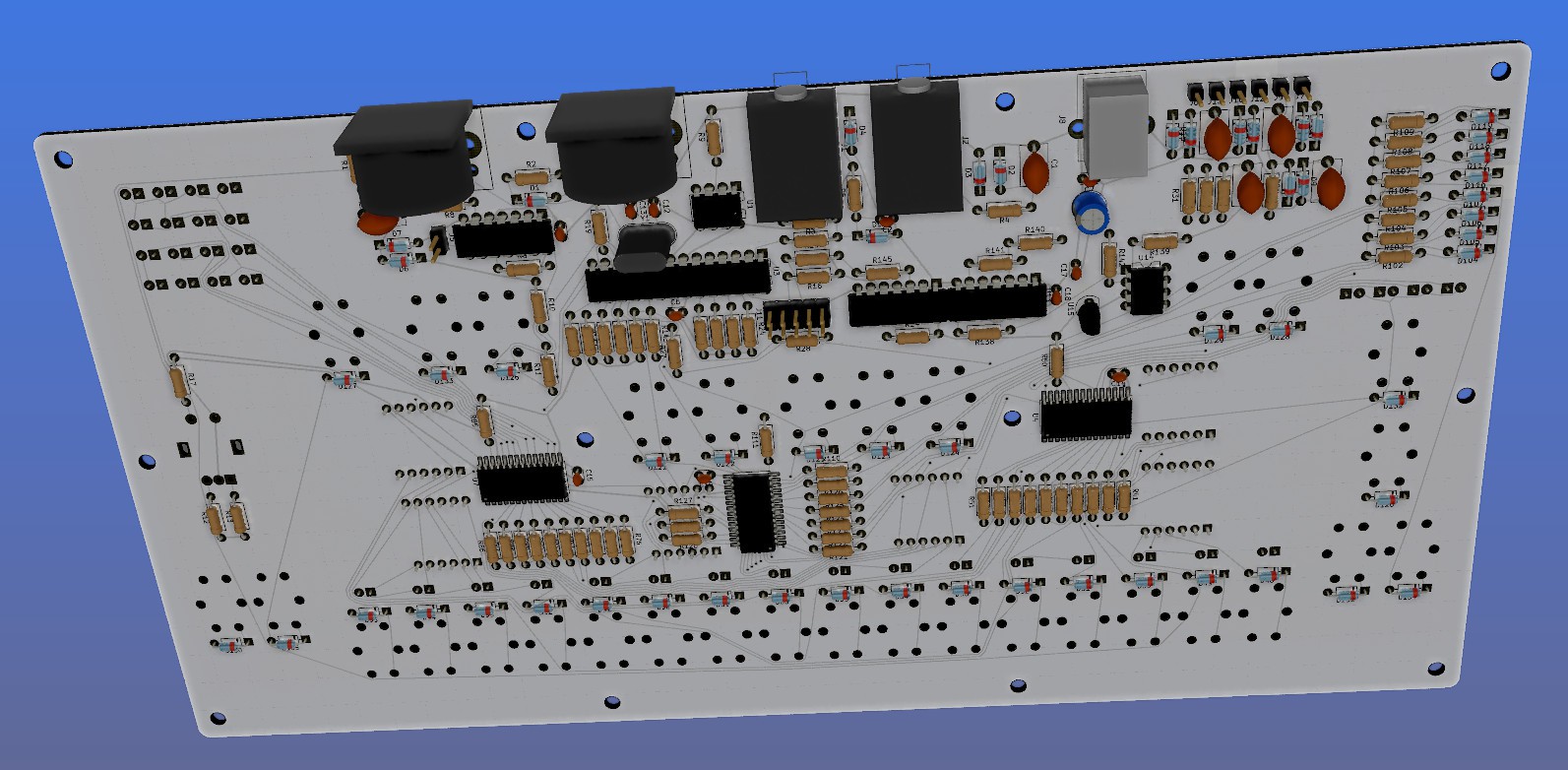

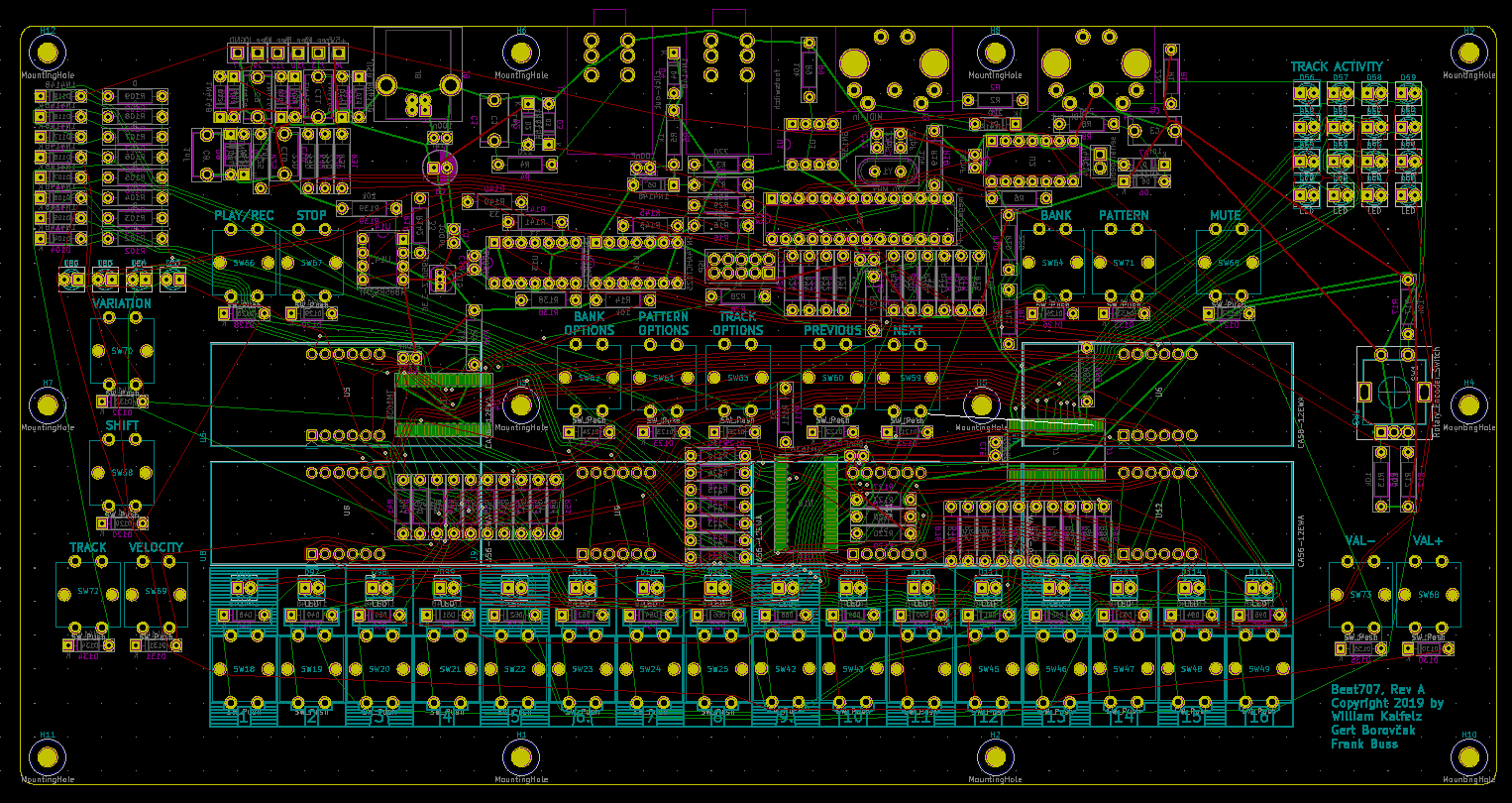

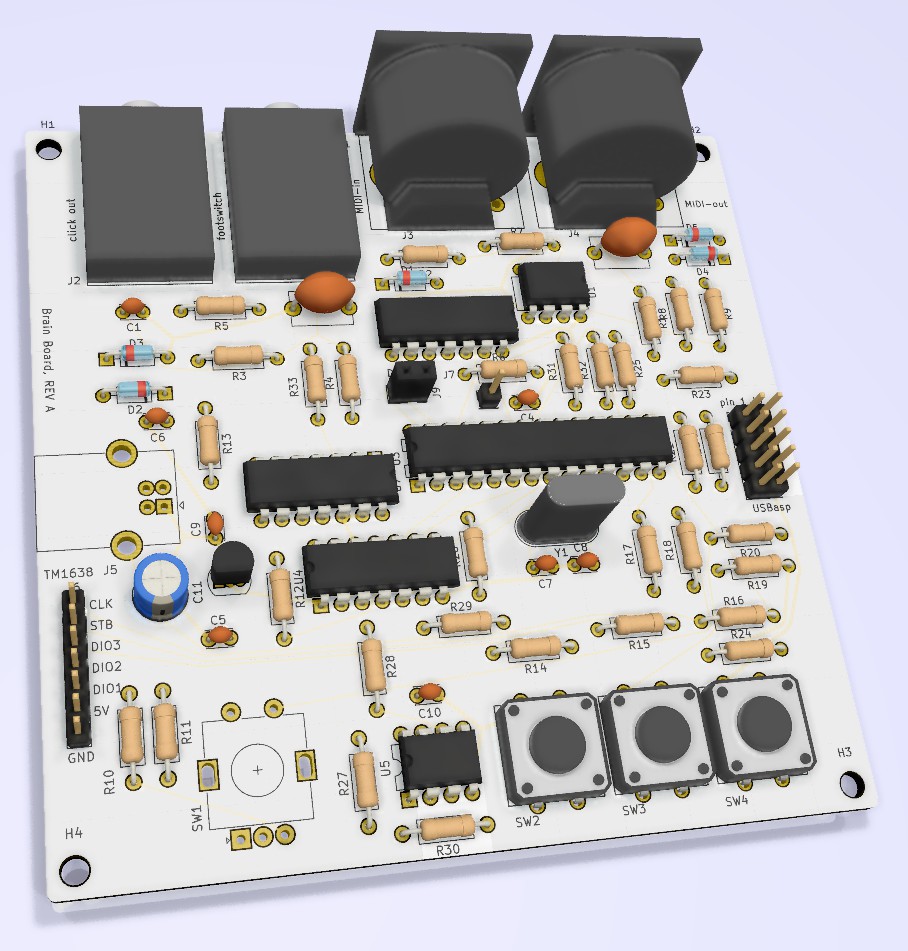

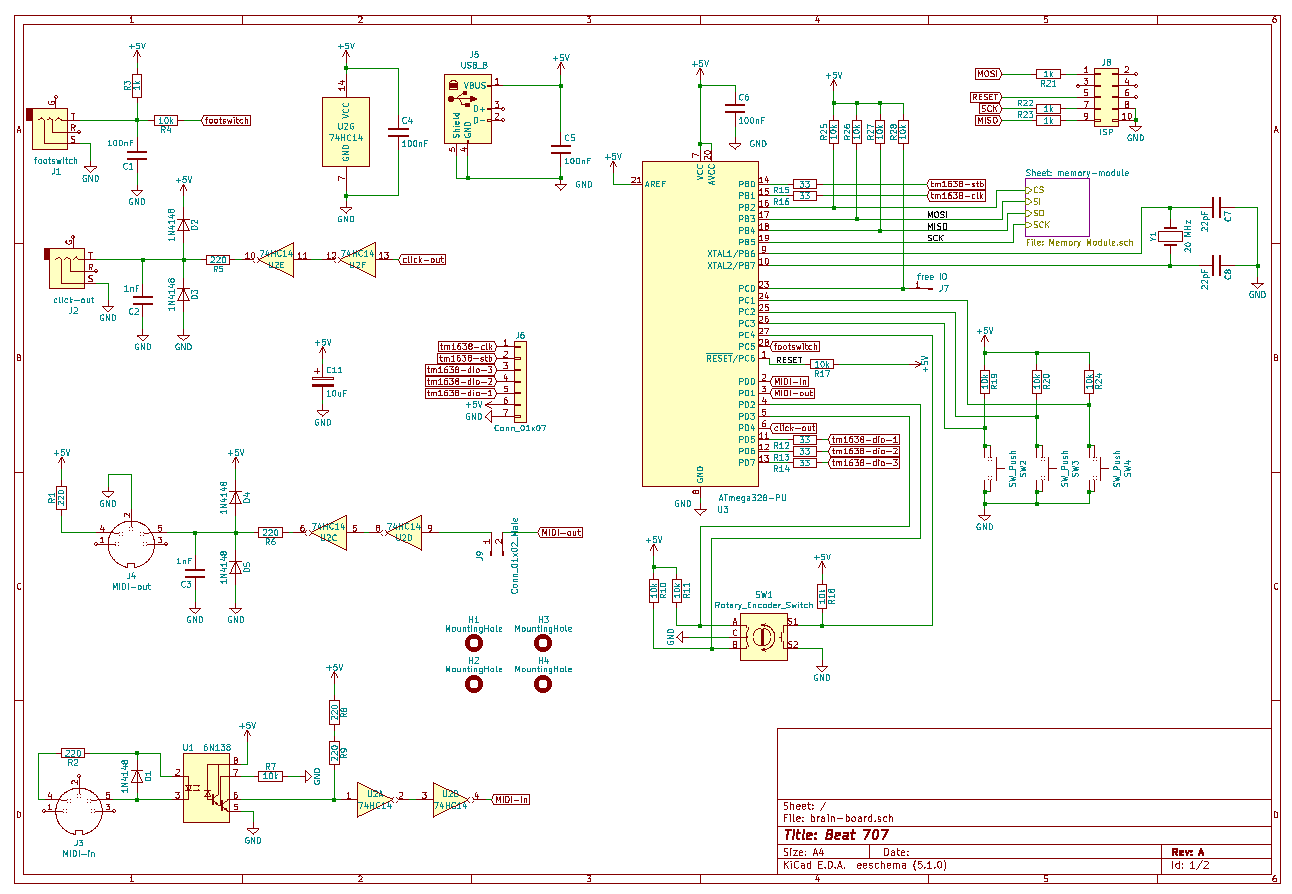

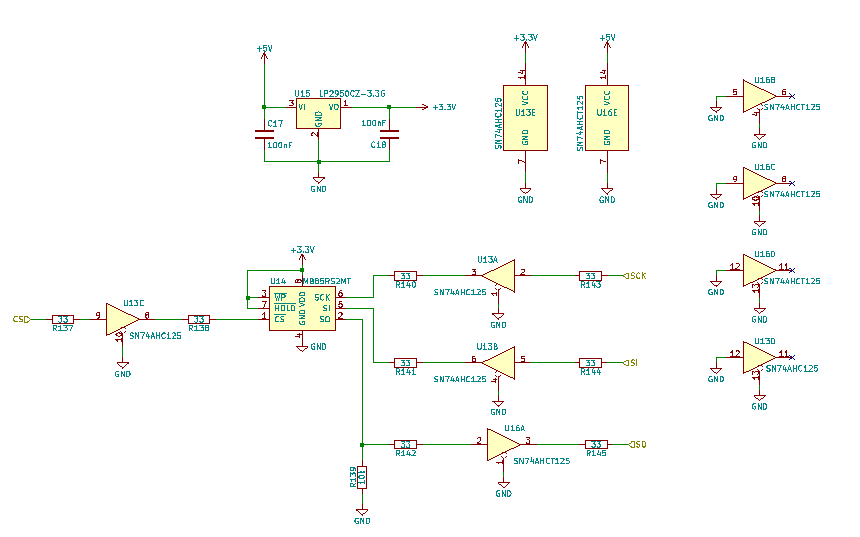

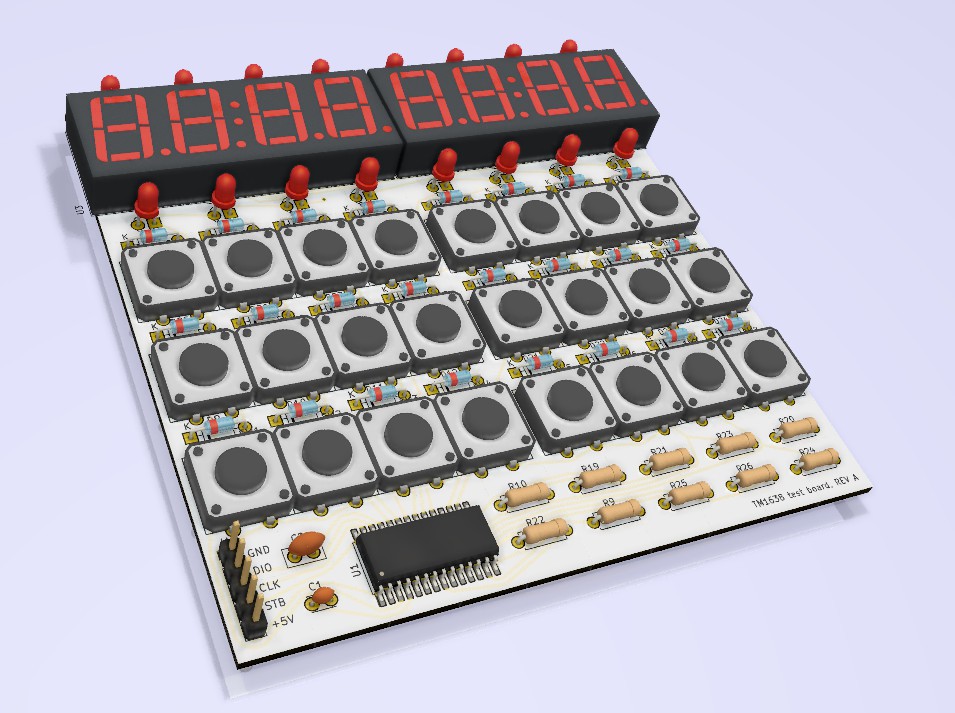

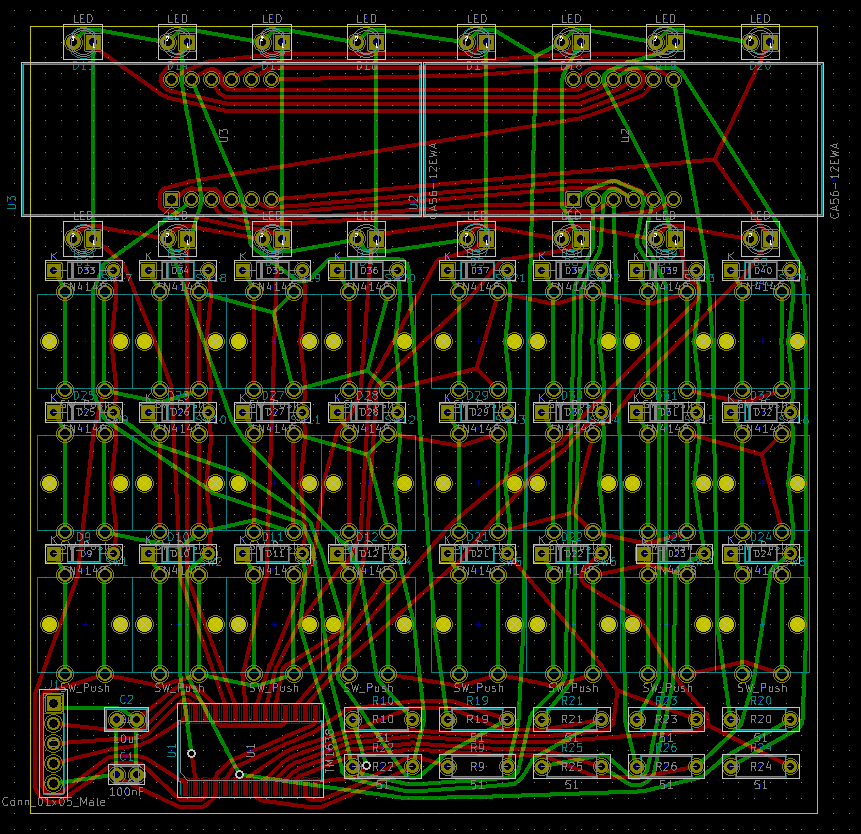

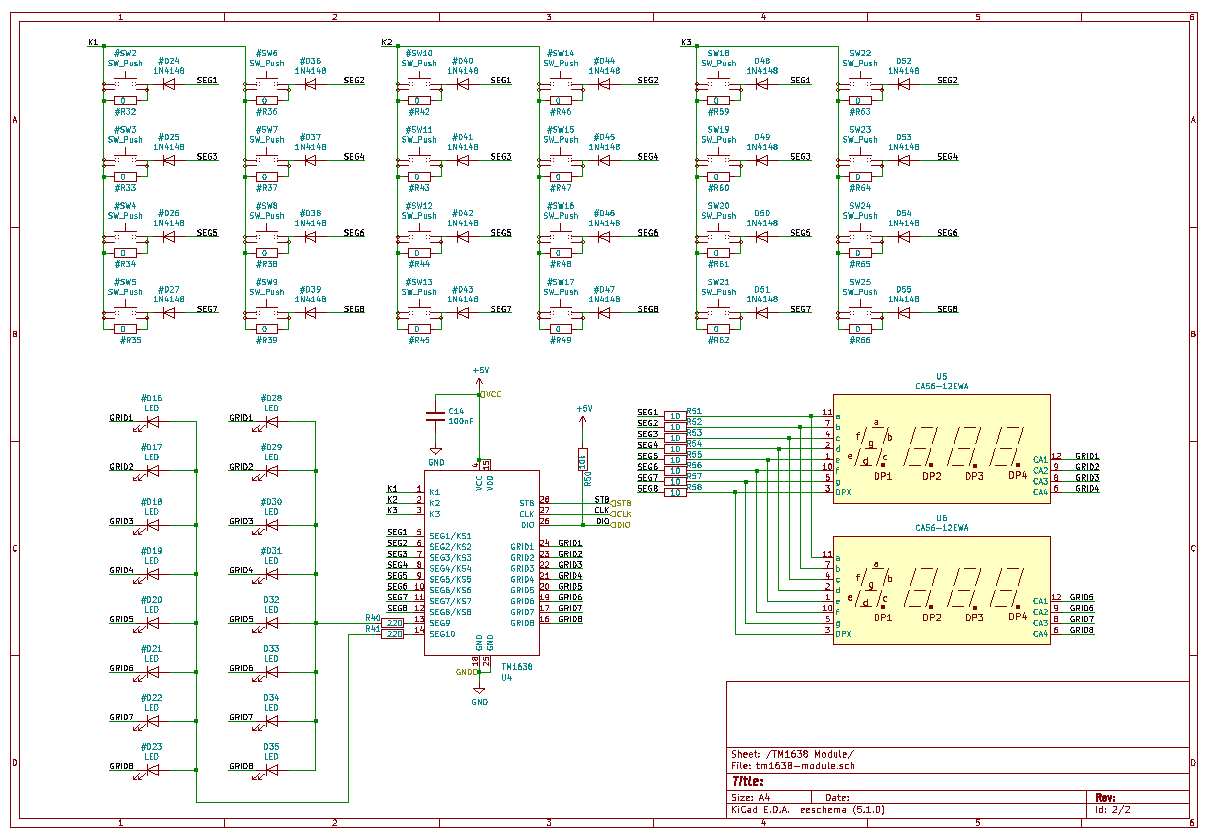

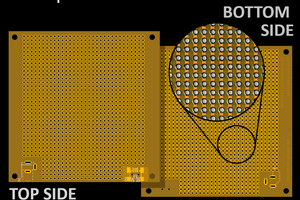

Then Gert asked Frank Buss to develop a professional PCB for it, maybe even to sell it later commercially. But everything will remain open source and open source hardware.

Frank Buss

Frank Buss

Craig

Craig

Torbjörn Lindholm

Torbjörn Lindholm

Koen van Vliet

Koen van Vliet

Bharbour

Bharbour