Introduction

CalEarth's mission is to further the research, development, and education of Superadobe, a safe and accessible form of Earth Architecture that provides environmentally and financially sustainable living spaces. CalEarth is engaging in ground-breaking research and education that fundamentally transforms housing options worldwide.

Mission

Increase the demand for sustainable construction by creating a global trend for “Superadobe” homes by flag shipping in the US and Europe.

Key Point:

- Developed countries set the trend for building and lifestyle

Goals:

- Increase market share and mind share of SuperAdobe

- Make SuperAdobe “A thing” in developed countries

- Propagate SuperAdobe outword

Strategy:

- Make construction less labor-intensive for well-resourced deployment scenarios in developed countries.

HDP 2020 Dream Team Initial Concept Review: CalEarth

Summary of three weeks work here.

Pain-points (Chosen)

|

|

Key Research Leads

Profiling of the structure:

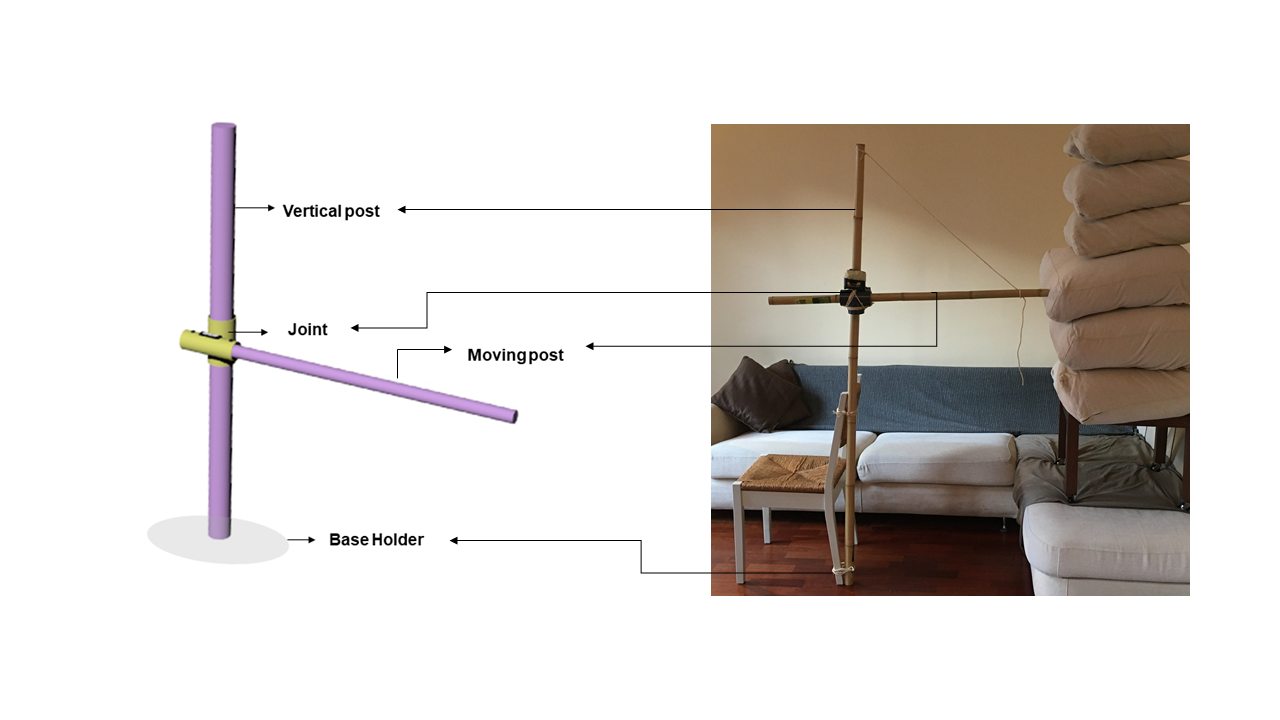

There is dependence on the person doing the “compass profiling task”. The rest of the team members have to wait for this person to indicate where the next layer is placed and how much is the overlap. Finding an alternate way to make the profiling of the domes easy that would save a lot of time and money (as workers are waiting). We’ll be presenting

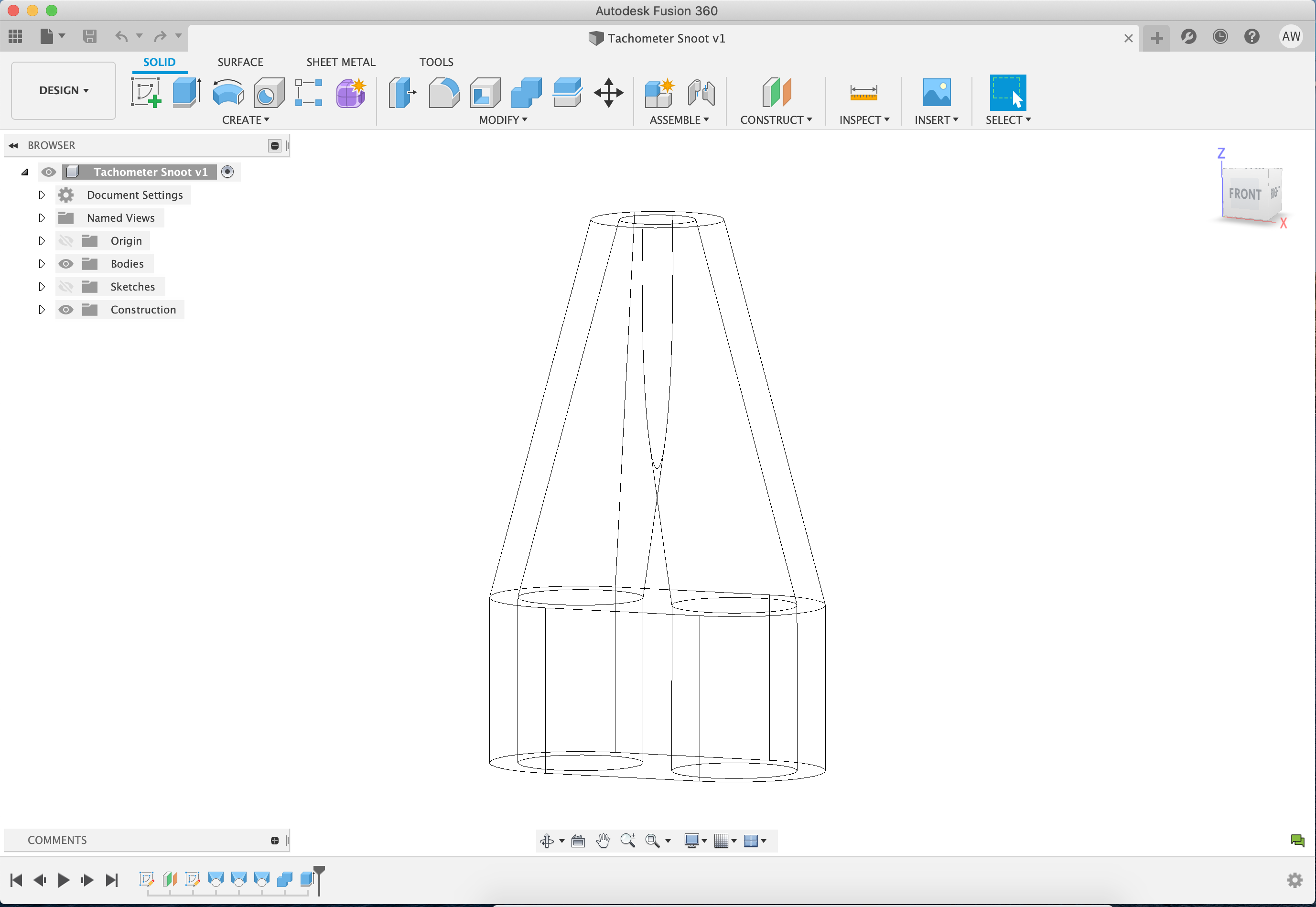

- The “LIDAR Compass” concept; a high-tech highly-integrated highly-flexible approach (still relatively cheap at ~$350)

- The “Pipe Sail” concept; a relatively minor variation on construction and usage of the current sail concept. ($ 35)

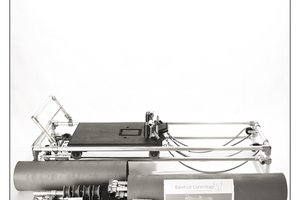

Make the build appealing and less labor intensive: Develop compacting and filling tools that are automated. These concepts include

- A bag funnel to assist in bag management and earth loading to hopefully streamline handling

- An Earth Extruder which could automate both filling and potentially packing as well,

Supplyframe DesignLab

Supplyframe DesignLab

joseph

joseph

Lee Cook

Lee Cook

Daniel Grace

Daniel Grace