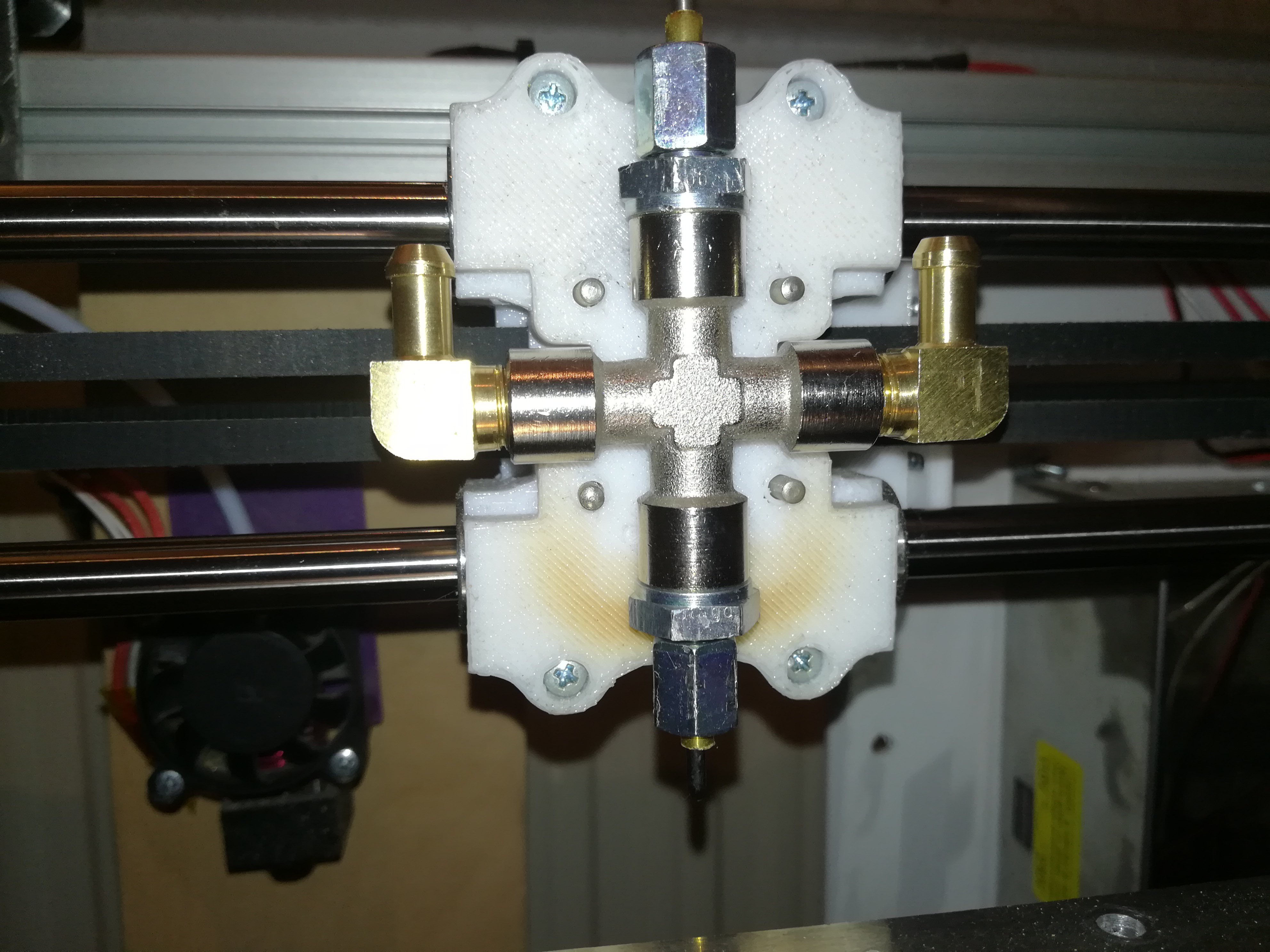

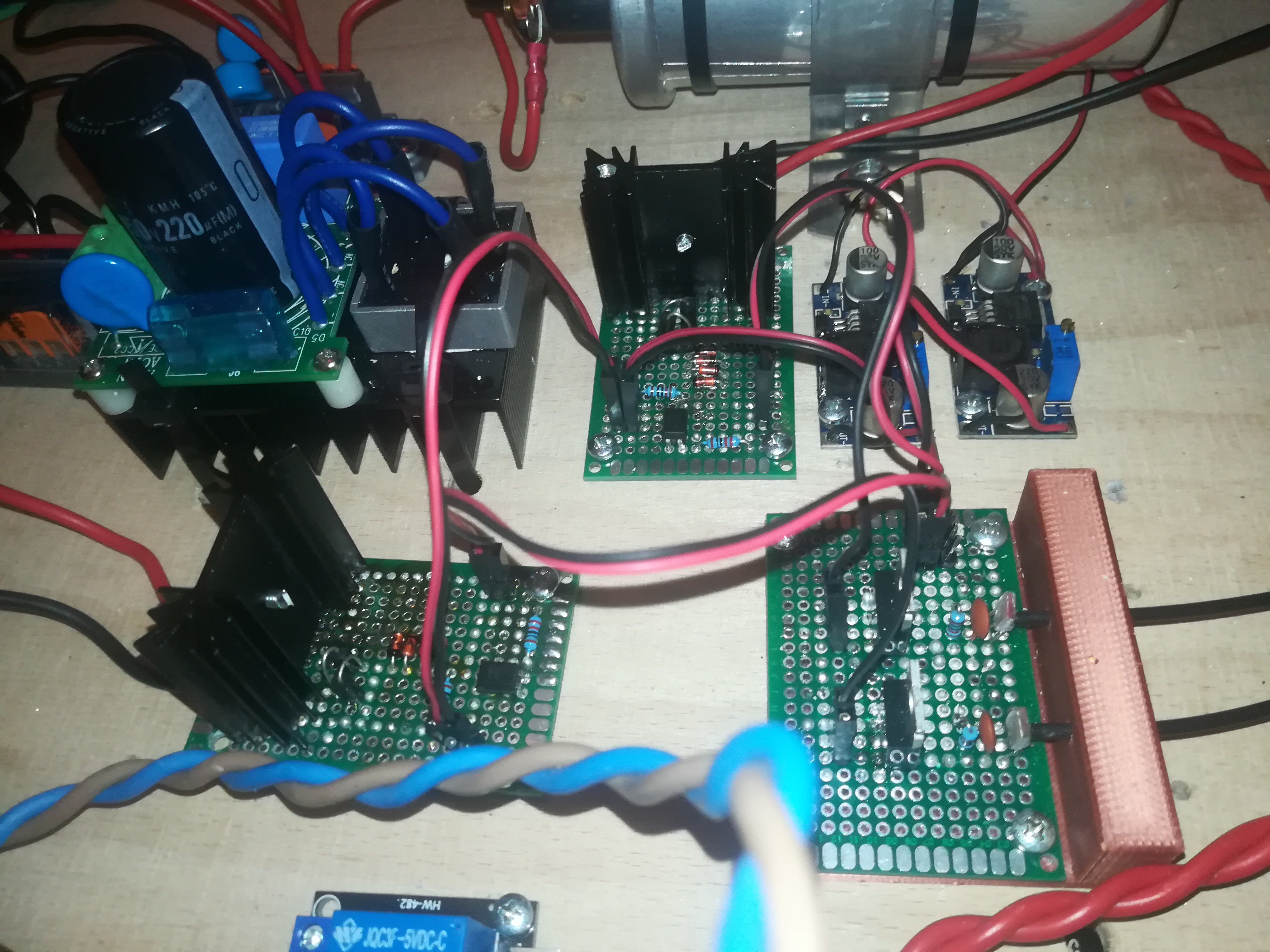

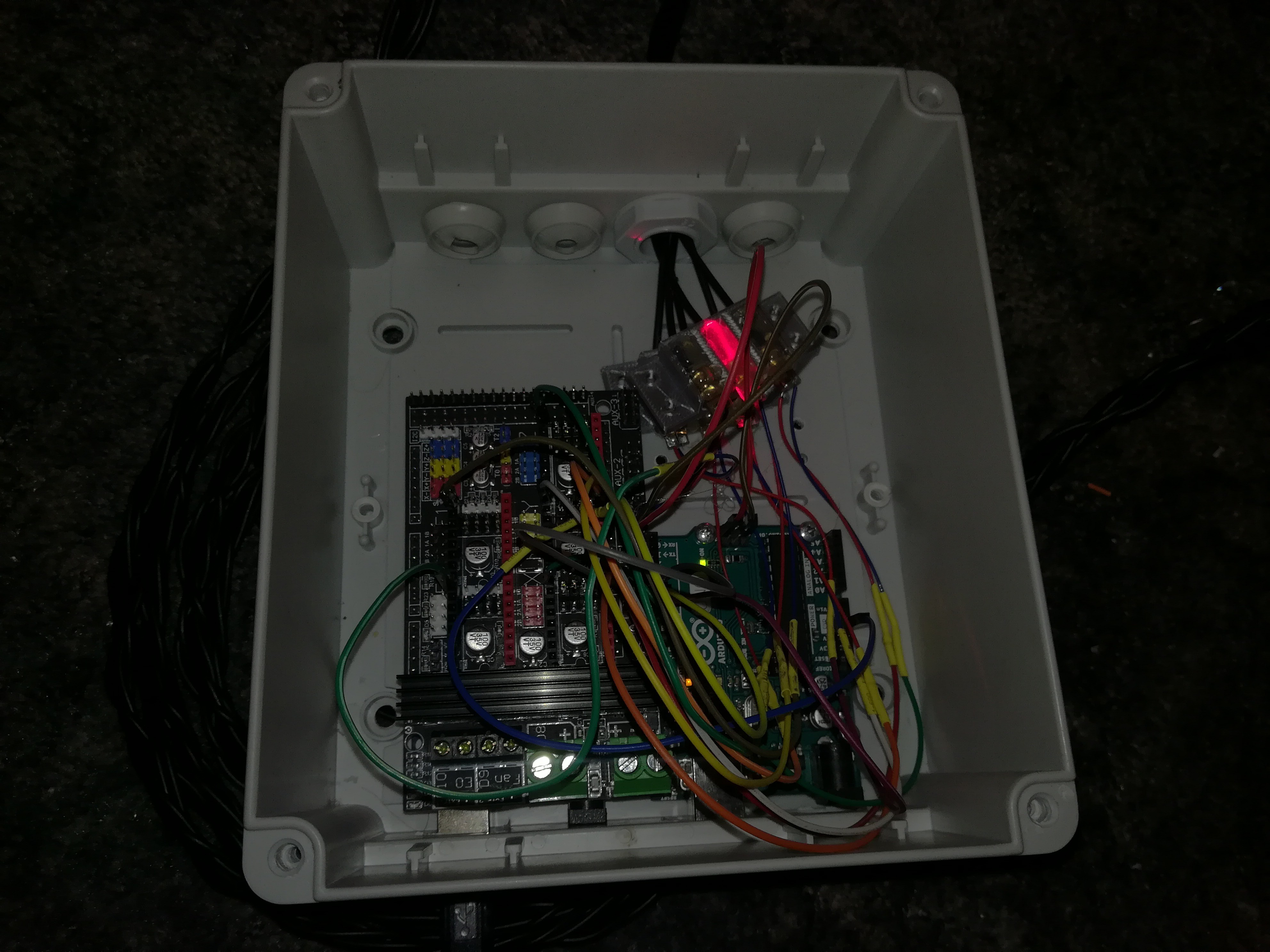

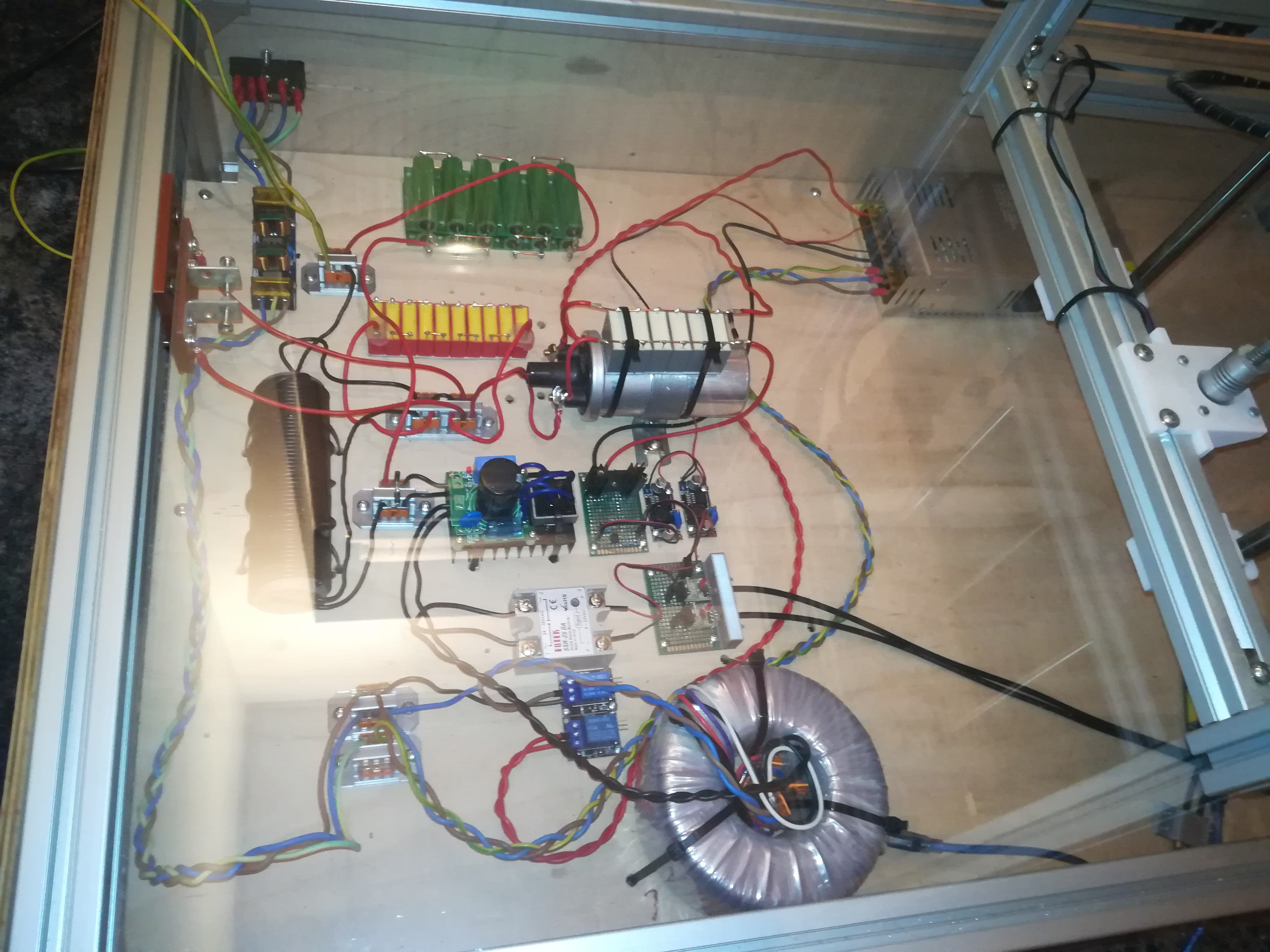

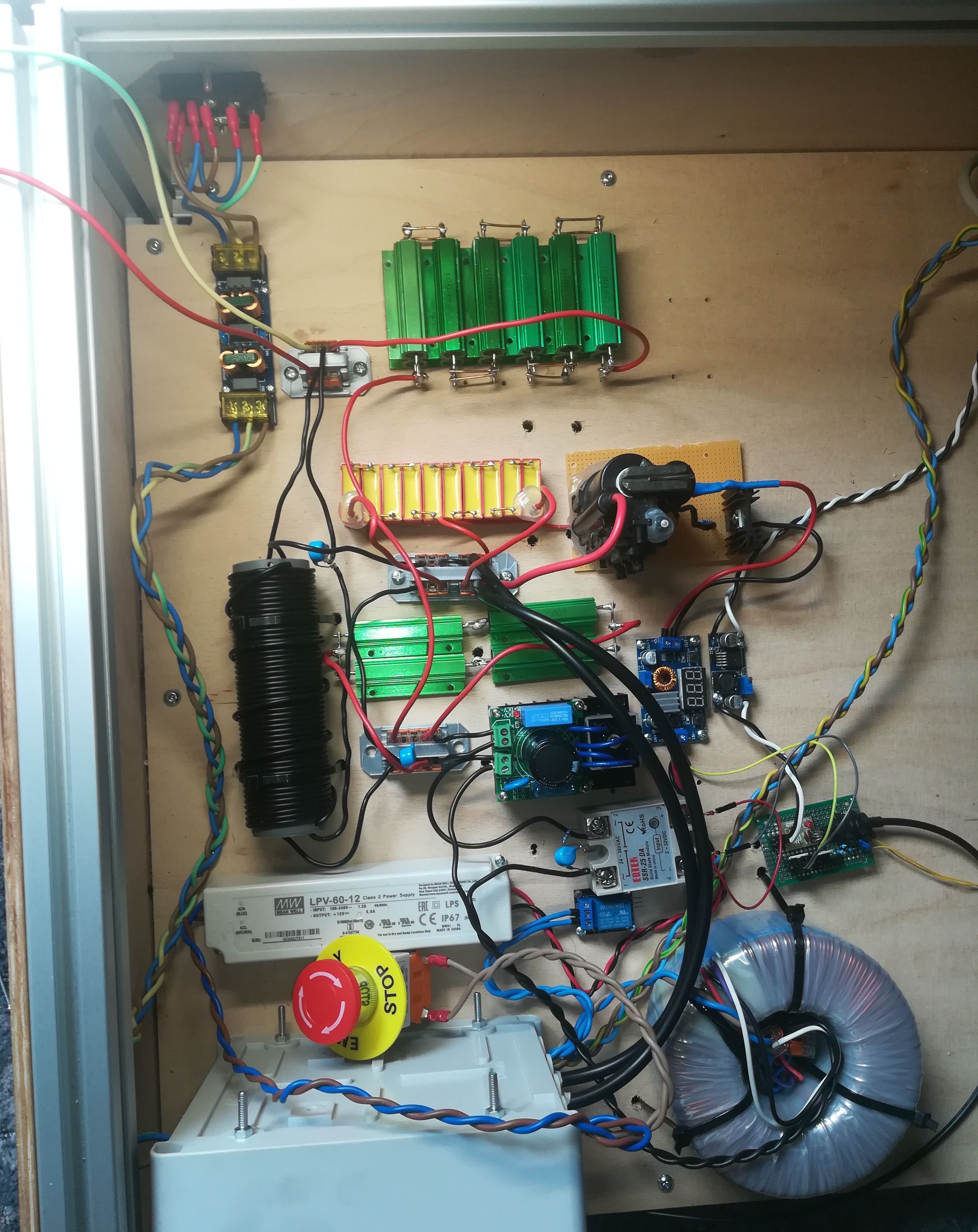

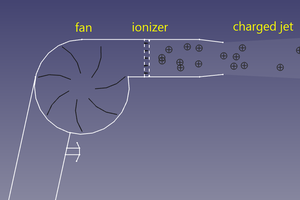

The goal of this project was to build a tool for a plotter or 3D printer that can create an arc for melting metal powder. I could successfully build such a tool, but the quality of the melted metal powder was not as good as expected - due to oxidation.

I could try to use welding wire which should not be blown away by shielding gas (like the powder) or put everything into a closed chamber like planned at the beginning, but letting the gas run for multiple hours long print jobs and also failed prints would be extremely expensive so I have to find another way of protecting the metal from oxidation - what I want to do in another project (https://hackaday.io/project/178590-fighting-oxidation-with-vacuum).

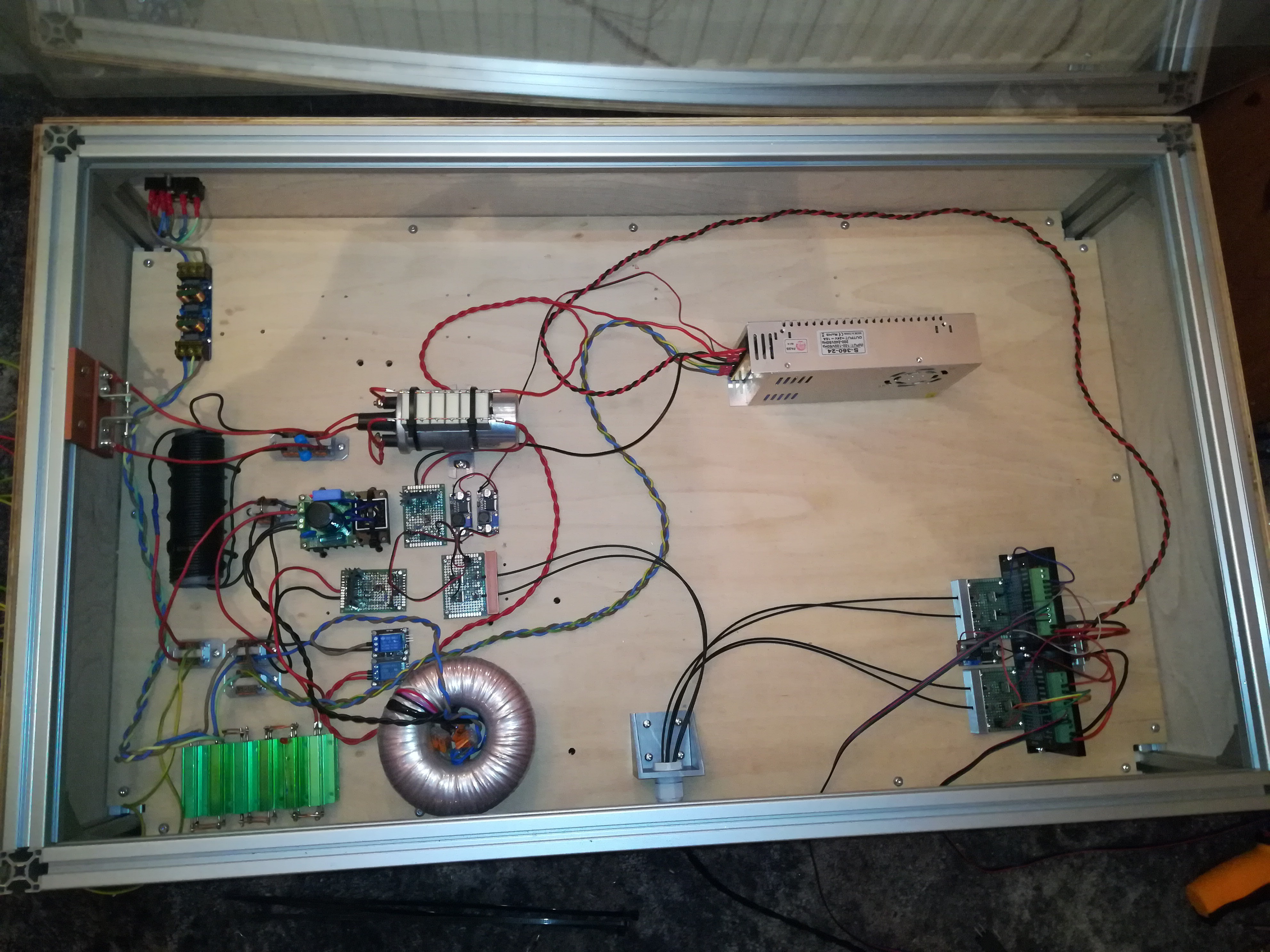

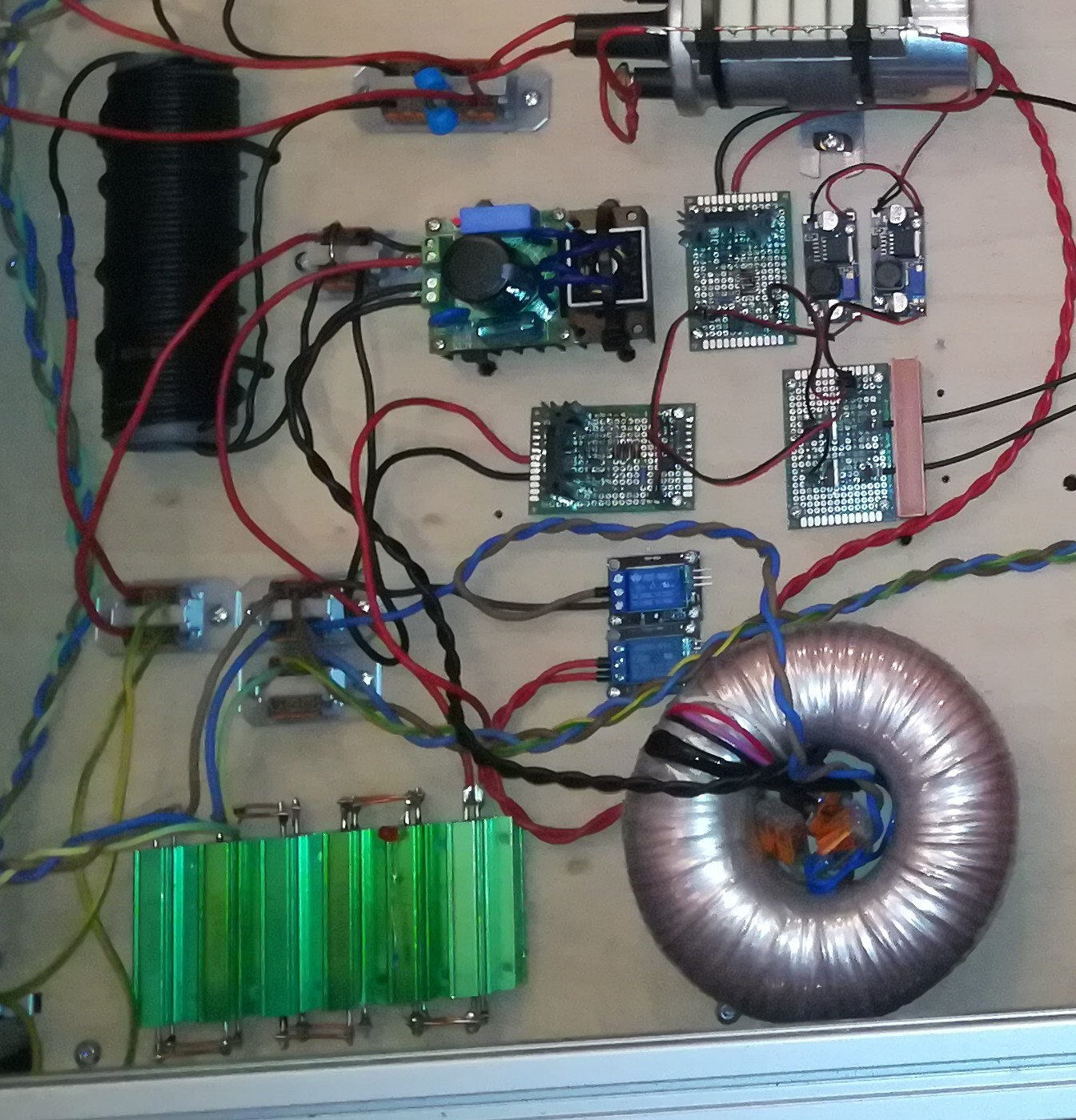

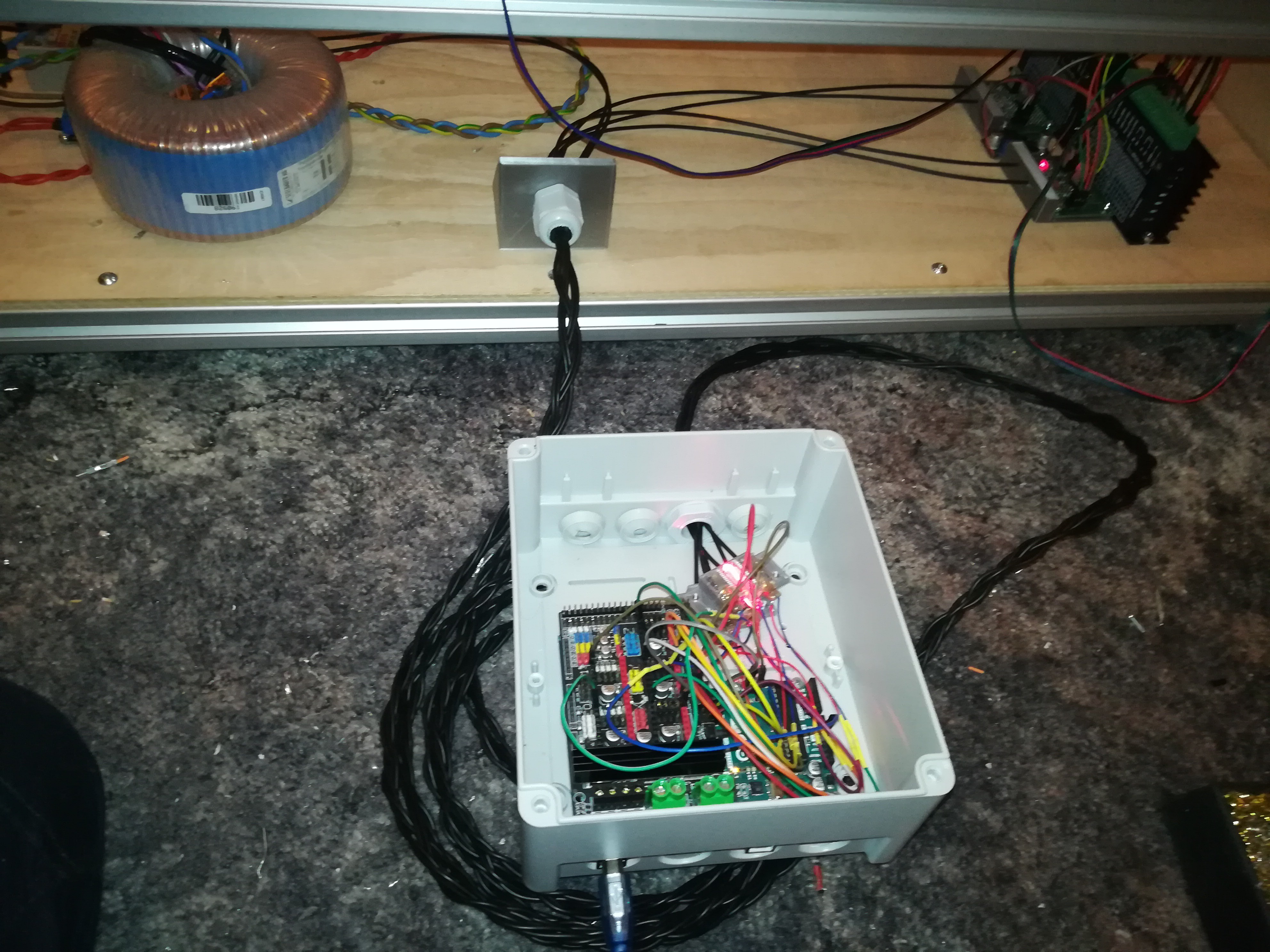

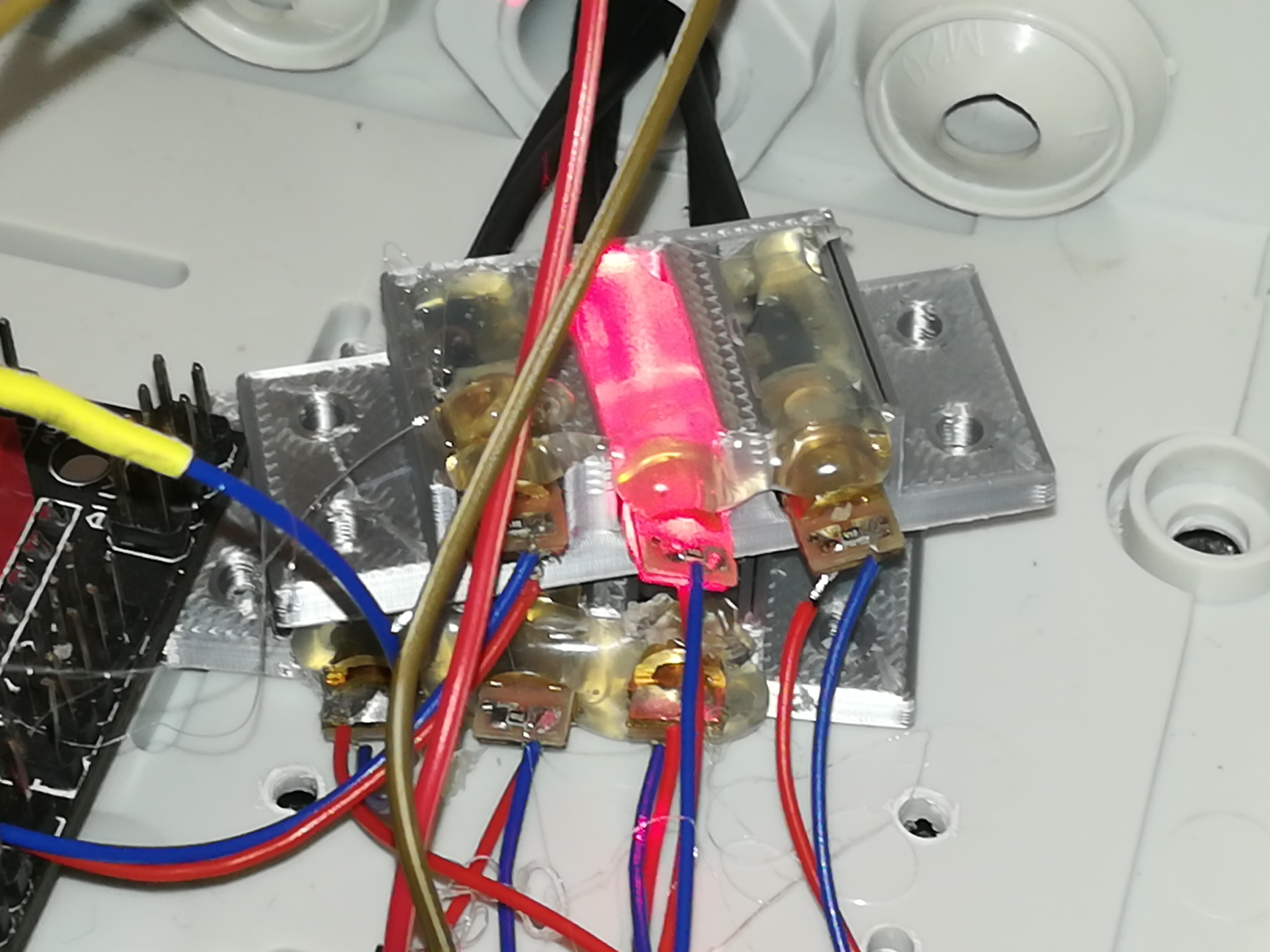

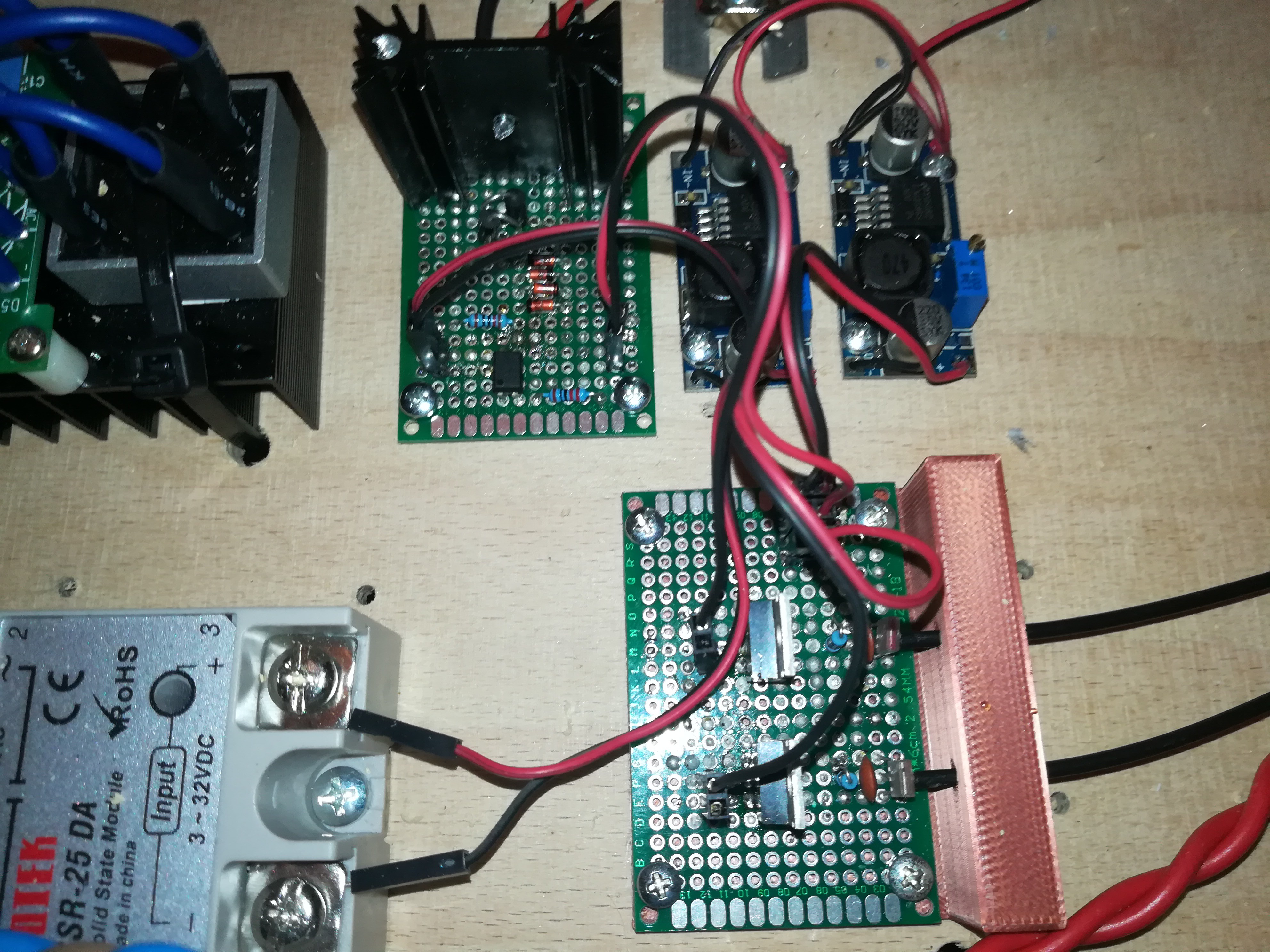

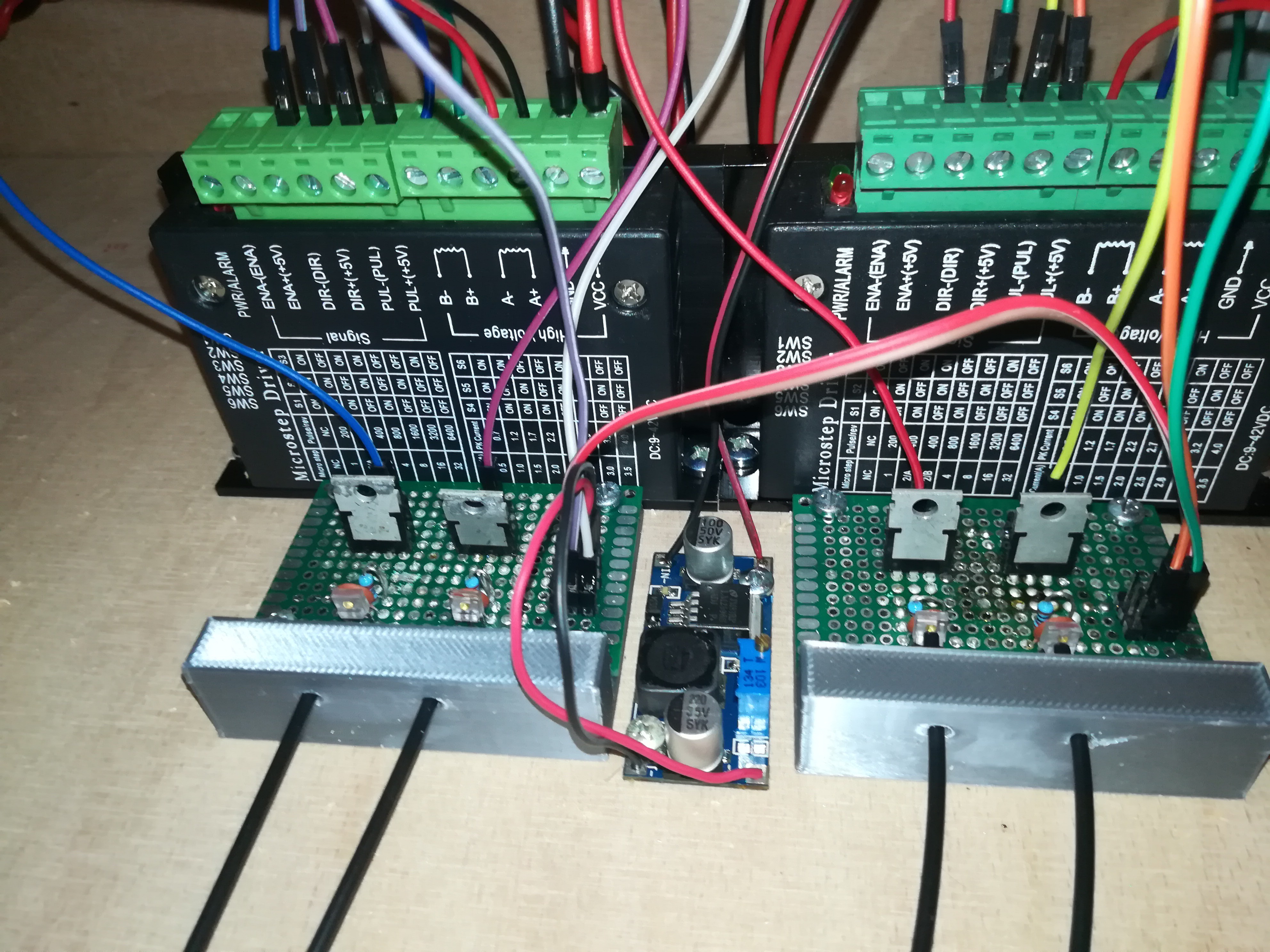

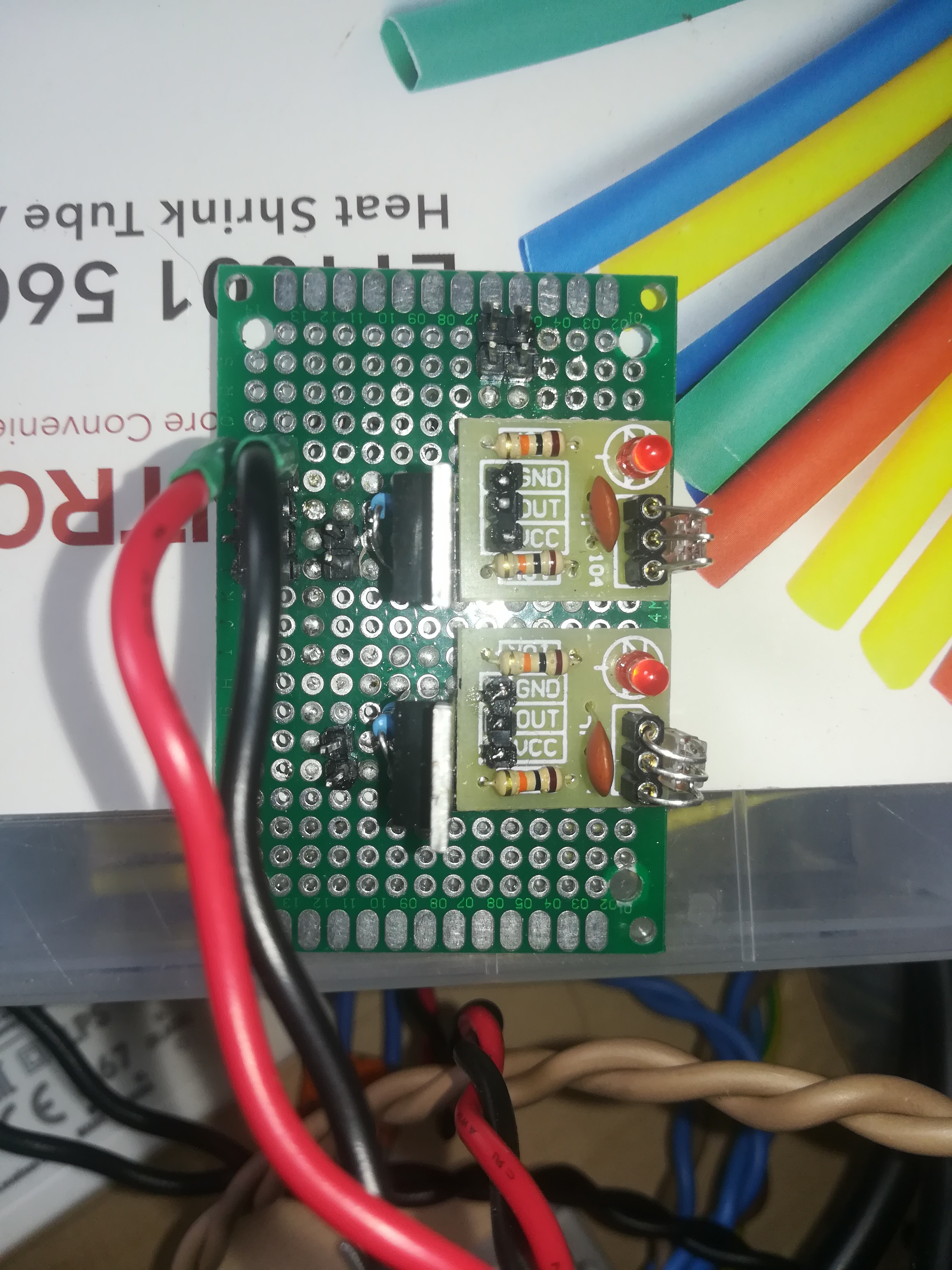

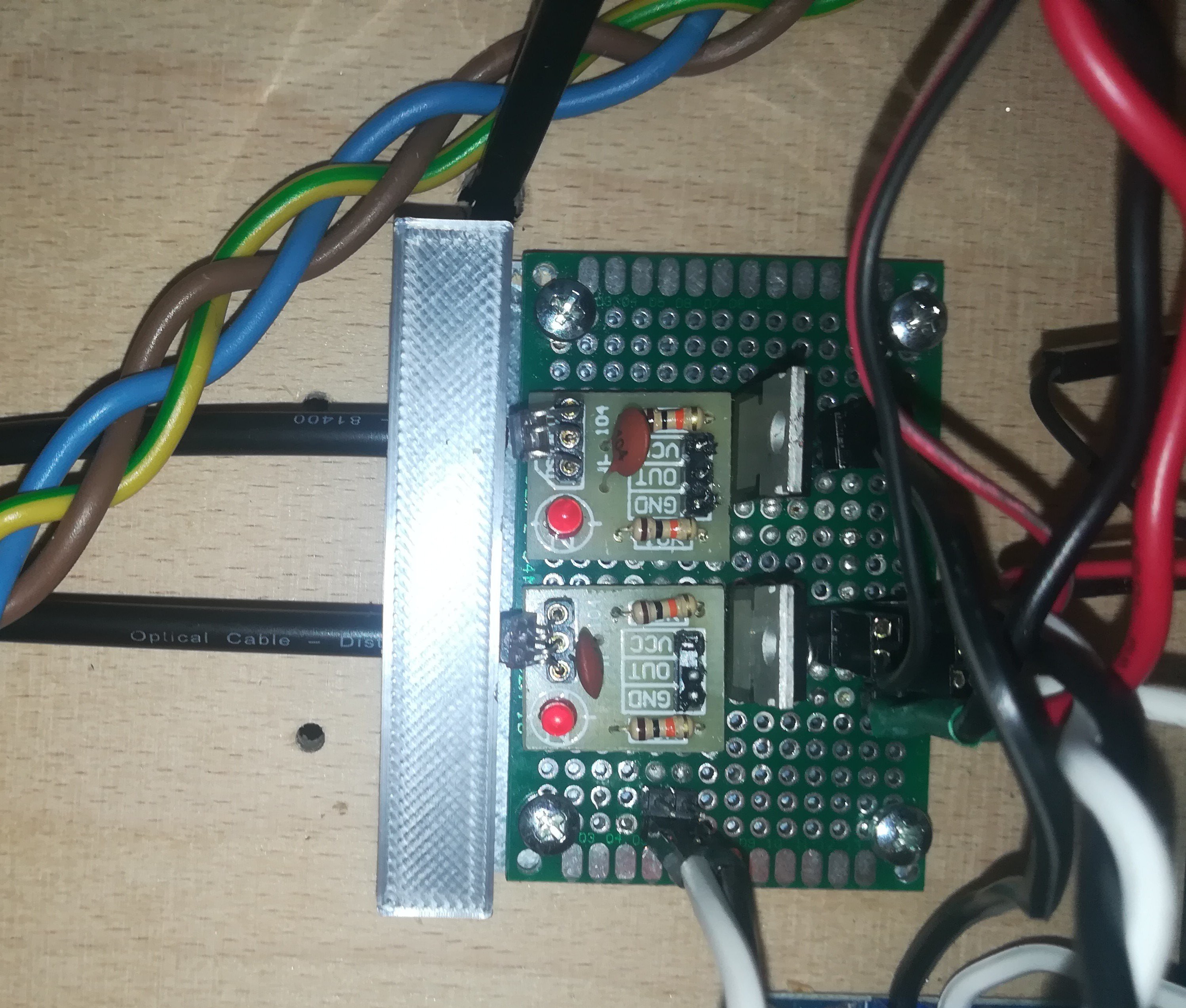

For everyone interested in an arc tool and/or a way to control stepper motors with optical cables you could have a look on this project. The welding circuit could also be used to build a cheap TIG welder.

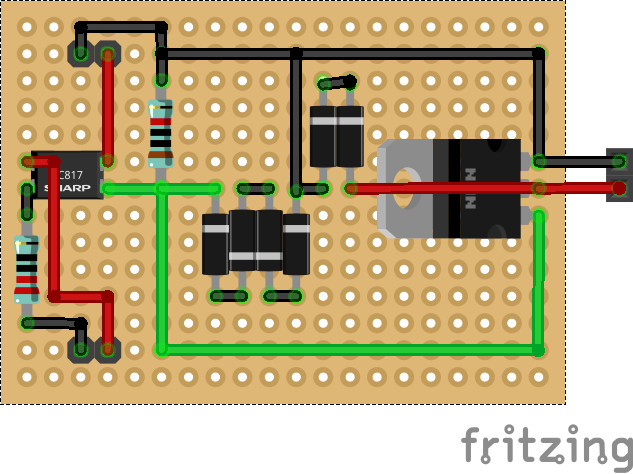

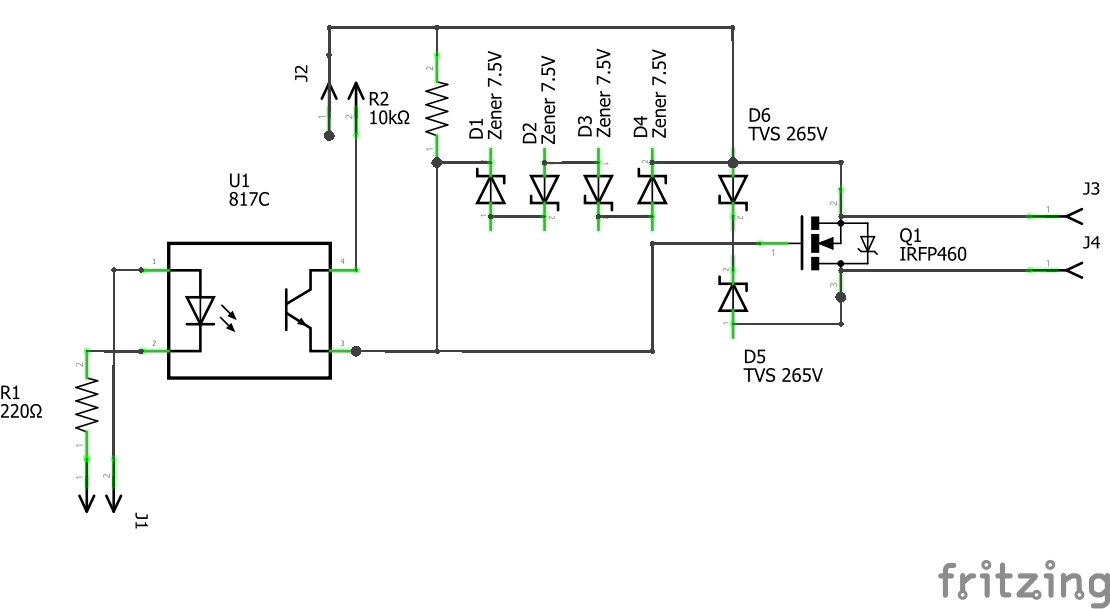

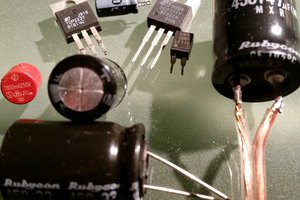

IRFP460 Baord with ESD Protection

Dominik Meffert

Dominik Meffert

DeepSOIC

DeepSOIC

CapitanVeshdoki

CapitanVeshdoki

I've got an article coming out on metal additive manufacturing at JPL, and the printed parts on the Perseverance rover. A lot of the methods they use for printing remind me of this. Watch out for the article, you might pick up something from it.