What is the Anthro?

The Anthropomorphic Robot is our answer to the lack of existing full-size humanoid robots available to the general public. What is preventing people from owning their own right now? There are three factors:

- Cost: Even if there were one available right now, it would cost far too much for the average person to own and maintain.

- Availability: Apart from Atlas and Digit, there aren't too many humanoid robots on the market, let alone available to the general public.

- Ease of Use: Research platforms and industrial robots are great for professionals and developers, but aren't suitable for everyone.

Other issues that could arise from other robotic platforms include:

- Closed Source Hardware Design

- Privacy and Data Protection

- Offline and Online Operation

- Customization and Personalization

We aim to solve these issues by developing the Anthro with both the consumer and professional in mind. Here's how we are doing this:

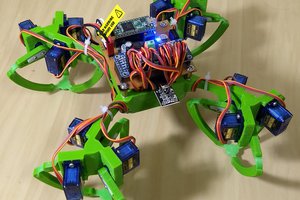

- Develop the Anthro using as many off-the-shelf components as possible. Use 3D-printed parts wherever possible to reduce cost and weight.

- Make the hardware design open-source where applicable. This is to enable third-party developers to make improvements to components. This also allows further customization by the end user.

- Make the design semi-toolless for easy assembly, repair and modification. Training and interacting with the robot will be intuitive and seamless - like talking to another person.

- Harness the power of cloud computing whenever possible. An Anthro can utilize our GPU servers to accelerate visual inference, speech processing, and training.

- Have a respectable amount of onboard computing power. The robot should be capable of operating on its own whenever internet connection is not available.

- Every Anthro should be unique! Users can customize each one's appearance: from material to color scheme. One could also have their Anthros be uniform in appearance for commercial applications.

What will you find on this project page?

This page will focus primarily on the hardware side of the platform. A separate page may be created later for the software/AI side of things. Project logs will start from the beginning of the project (circa 2014), and work their way to where we are currently at, to better show how this project has evolved over the years.

Anthrobotics

Anthrobotics

Peter Buckley

Peter Buckley

Inconceivable42

Inconceivable42

Vipin M

Vipin M

Martin Vincent Bloedorn

Martin Vincent Bloedorn

Push this concept onto Halloween Companies! It’ll be a slam dunk billion dollar day - every Oct 31st! Just to ballpark – how much would the “Erector Set” (frames and gears) set you back {excluding electronics}?