WHAT AND WHY?

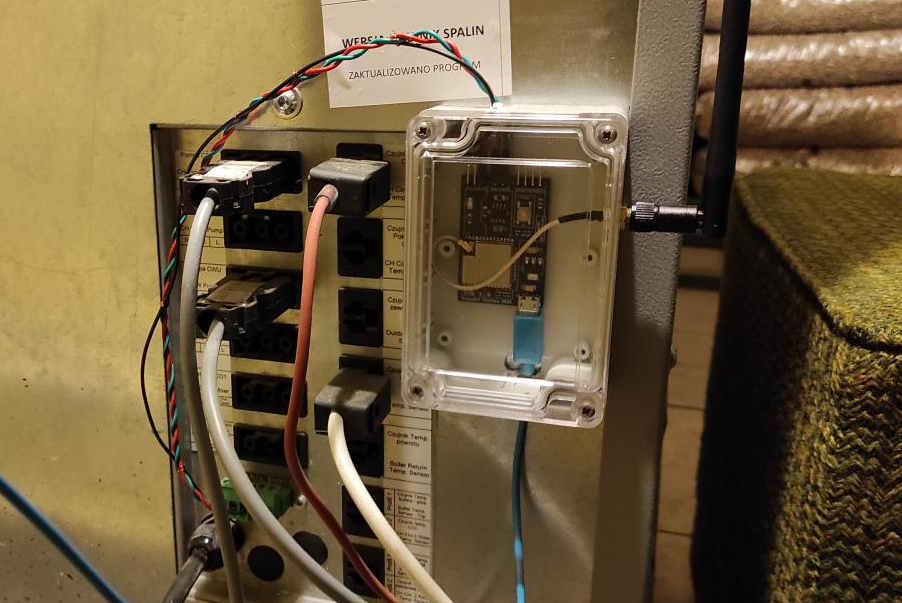

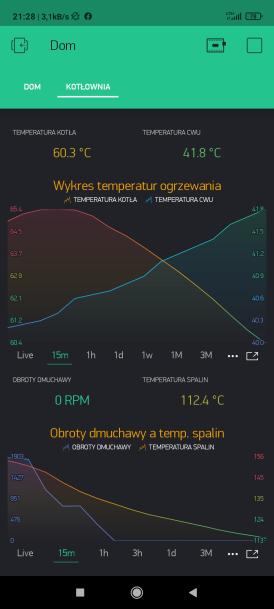

Our old boiler was previously connected to my IoT system. After replacing the boiler with a new one, we no longer have this option. So why not introduce it to a new boiler?

THE TARGET

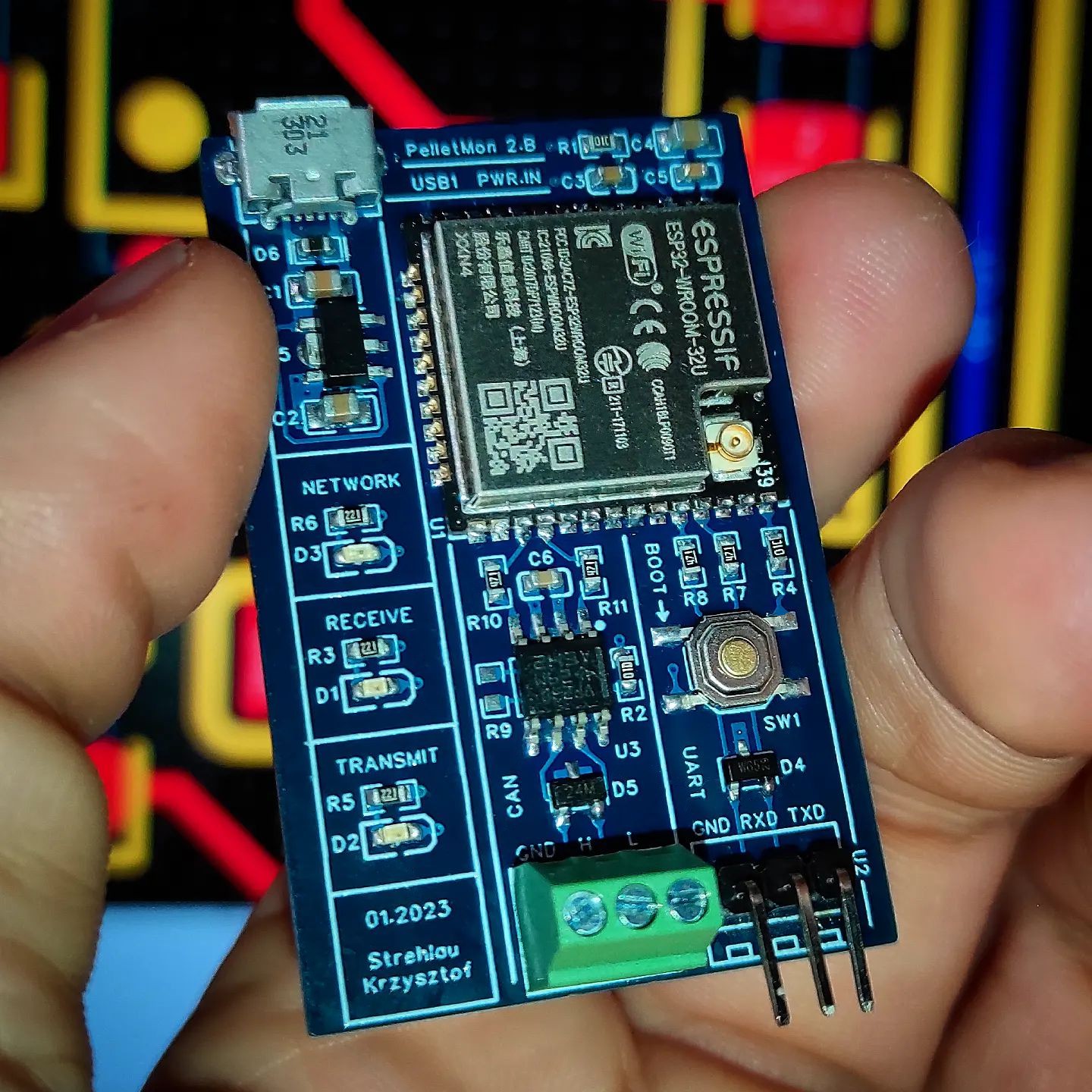

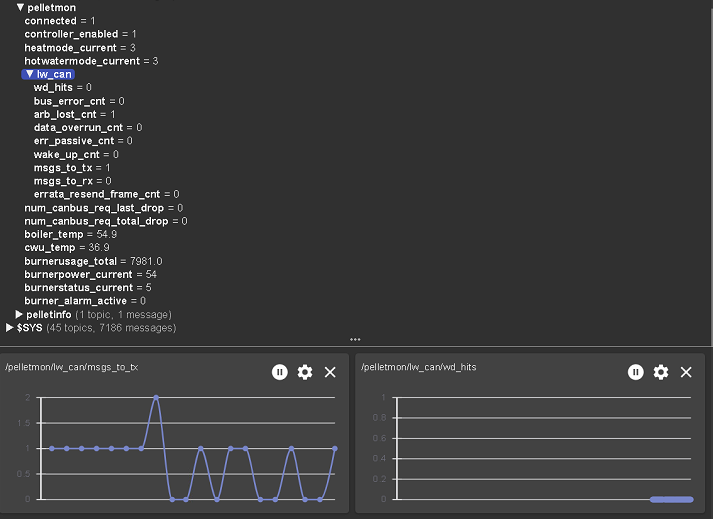

The goal of the project is to reverse engineer the CAN communication of the new boiler and expose real-time data to the IoT. By the way, the HC-SR04 sensor will measure the fuel level in the tank.

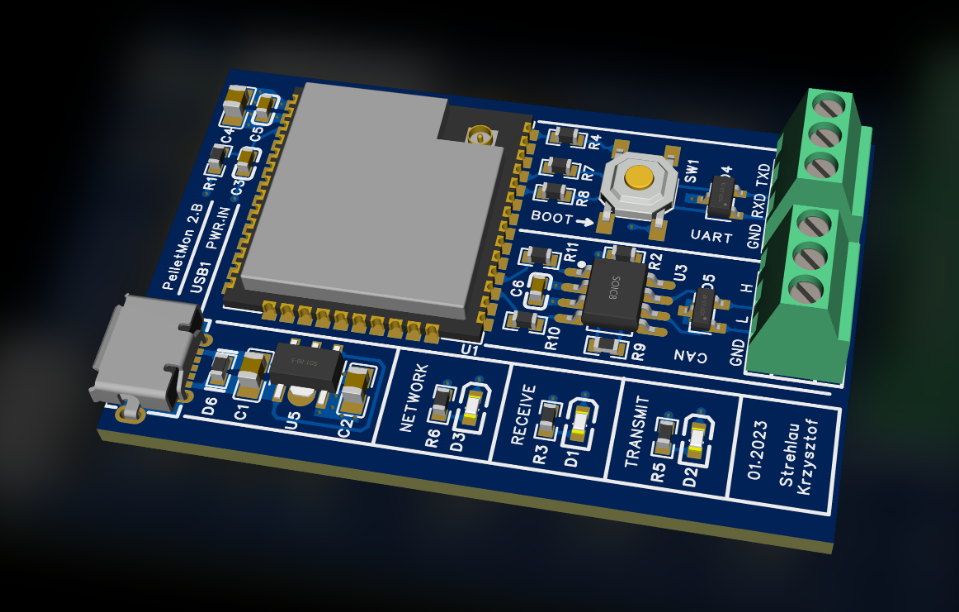

DESIGN

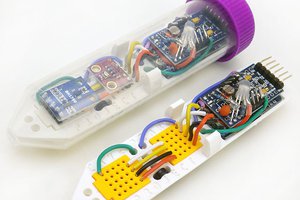

The project will have its own PCB. Communication with the outside world will be carried out using ESP32 and fuel level measurement using HC-SR04. The SN65HVD230 chip will be used as the CAN transceiver. The software will be written in the Arduino environment in C ++ and will be powered with my IoT framework - ksIotFrameworkLib.

h4rdc0der

h4rdc0der

sparks.ron

sparks.ron

Ashwin K Whitchurch

Ashwin K Whitchurch

Ed Mallon

Ed Mallon

Can I just say that this is one of the most beautiful PCB designs i've ever seen