Problem

The world is switching to green technologies by omitting oil power based technologies to more renewable power technologies. But for those countries like Niger that only have oil to generate income for their country; this might be very dangerous concept that questions their survival. So to balance the scale of safety of the environment with the economics of these countries, we have to make the oil business green instead of omitting it? One of the main environmental risks of the oil business is its transportation. Crude-oil pipelines when ruptured will pollute waters and soil. Natural gas pipelines and product pipelines that contain highly volatile liquids such as gasoline explode in a spill. About half of all pipeline accidents are caused by a third party, builder damaging a pipe while digging. The second leading cause of pipeline failure is corrosion caused by the contact of metal pipe with wet soil or if the fluid is corrosive. The detection of leaks is done by computer monitoring of abnormal flow rates and by flying aircraft along pipelines for visual inspection which is not an immediate diagnosis and usually when there is accident the damage will be done before it is in under control.

Solution

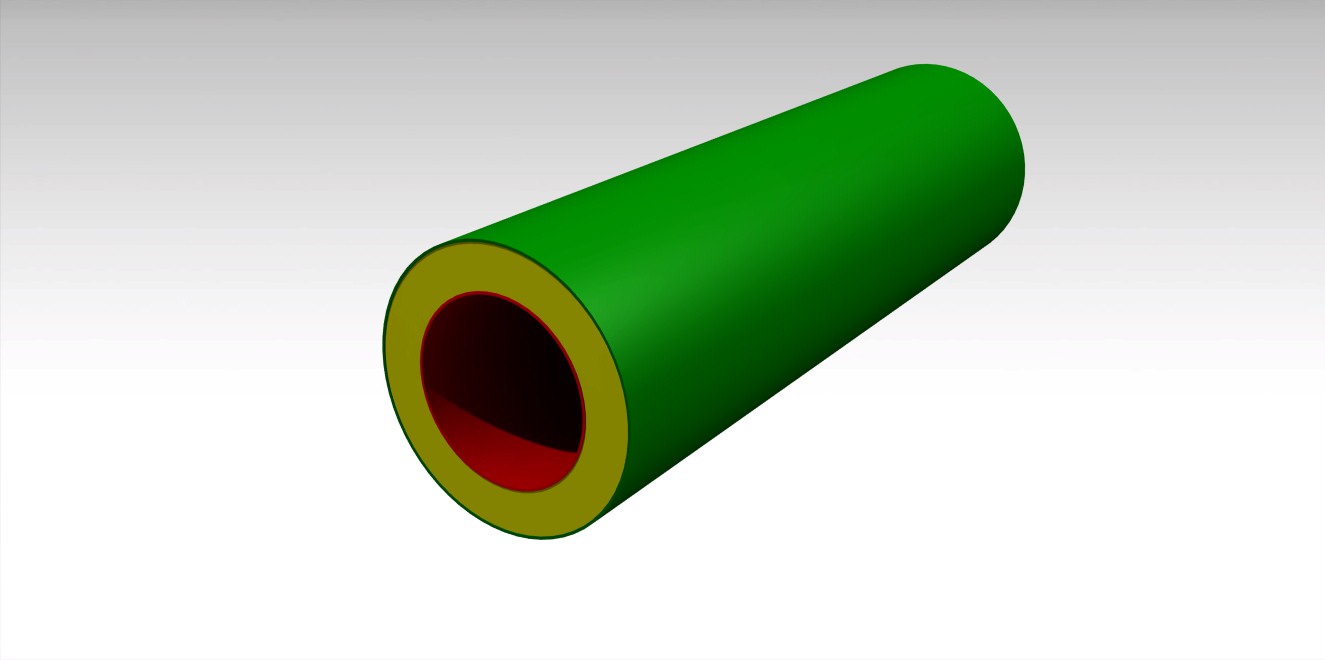

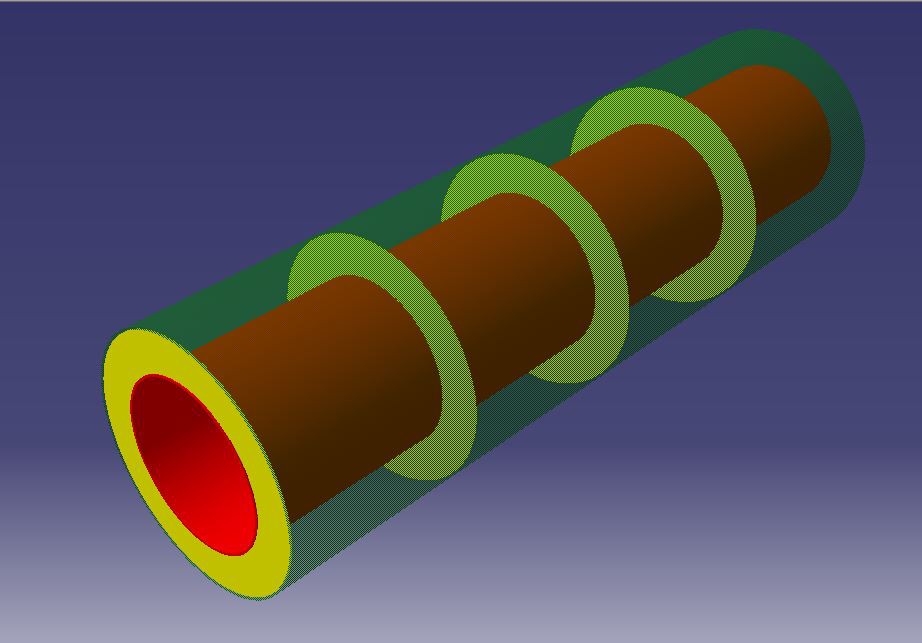

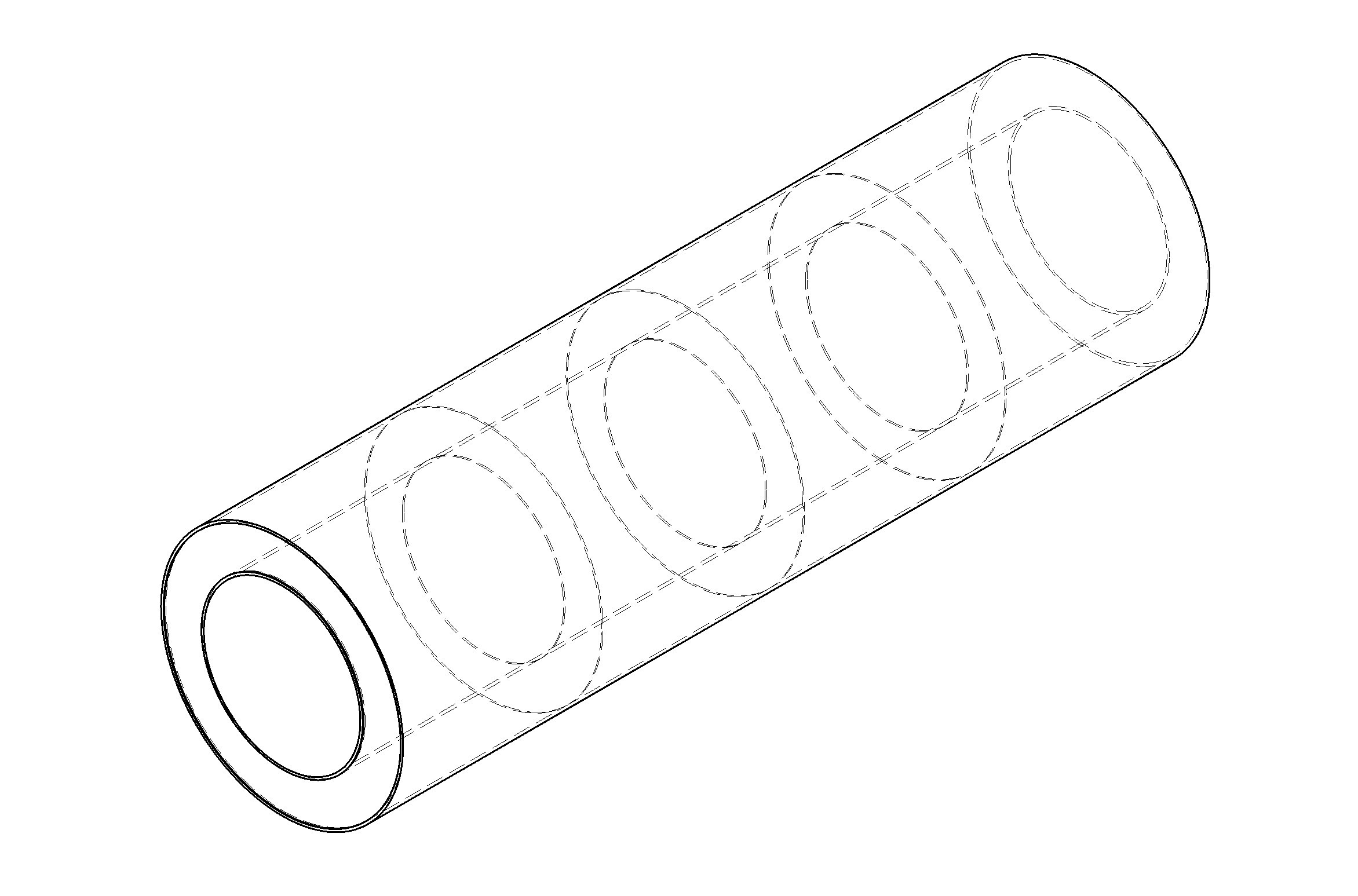

This project is about building a new kind of oil pipeline that avoid immediate oil spillage and give immediate warning to pipe damage with exact location coordinate making the transportation sector of the oil business green. This is done by combination of partitioning, pressure sensor and layering. Meaning this new oil pipeline has a layer (green) in its outer surface with larger diameter than the pipe (red) which transports the oil. Between the two layers of the pipes there will be nothing but a compressed air. The outer layer is separated by a series of partitions (yellow) which is welded with the inner layer of the pipeline with some kilometers. Inside each partition there will be one pressure sensor which has distinguishing digital signatures based on their sequence of installation. When there is small hole or a crack on the inner pipe at location A due to corrosion, the compressed air will push the oil back to the pipe acting as a first defense system from spillage. In that process the compressed air will start to lose its pressure which will trigger the pressure sensor X that is installed at location A which will be used to locate the coordinate of the damage for immediate response. When the pipe line is damaged because of third party, there will not be any immediate spillage because of the layering and the pressure sensor will be automatically triggered since the compressed air will lose the pressure which will be used to locate the coordinate of the damage for immediate response.

Note that in case of failure of the pipeline there is a man hole on the outer layer pipe line for operators to get in and fix it.

The main down side of the design is the cost addition for the pipe line because of layering and partition but if you check how much money oil companies lose because of spillage due to many factors including from natural phenomenon to human activities like piracy, you will understand how this solution is very worthy the cost which makes it financially feasible.

Anteneh Gashaw

Anteneh Gashaw

Dominik Meffert

Dominik Meffert

Claudio G. Hutte

Claudio G. Hutte

Fabien Royer

Fabien Royer