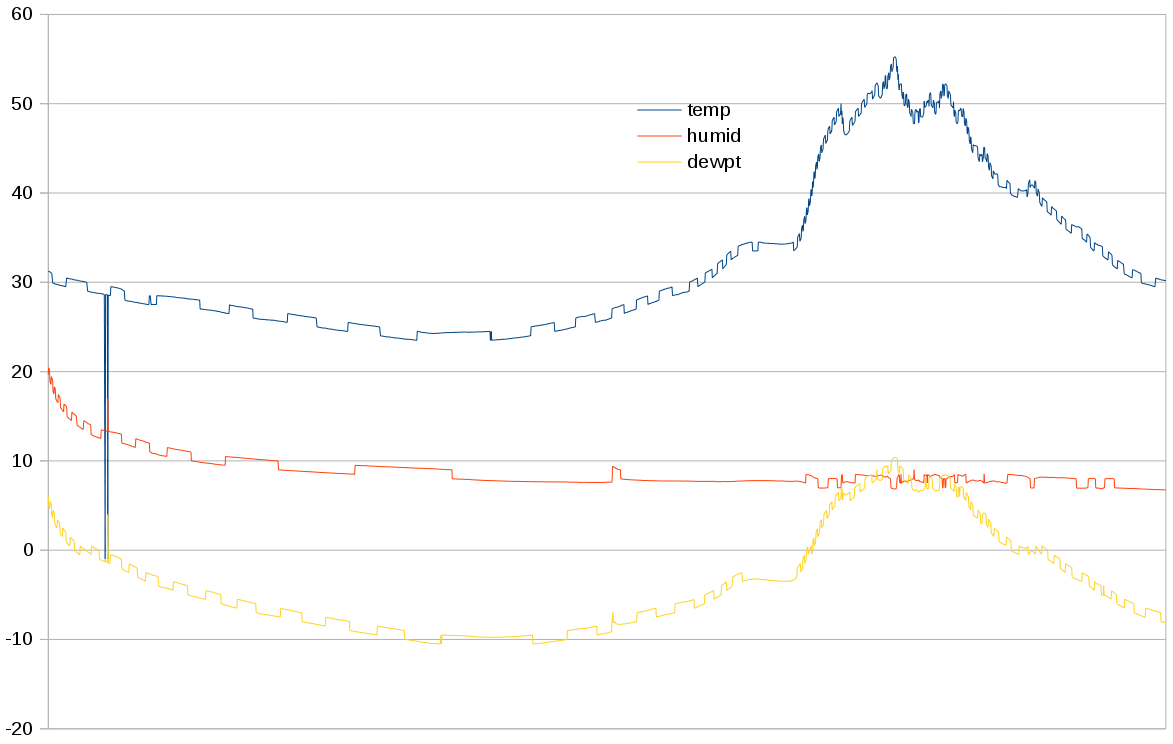

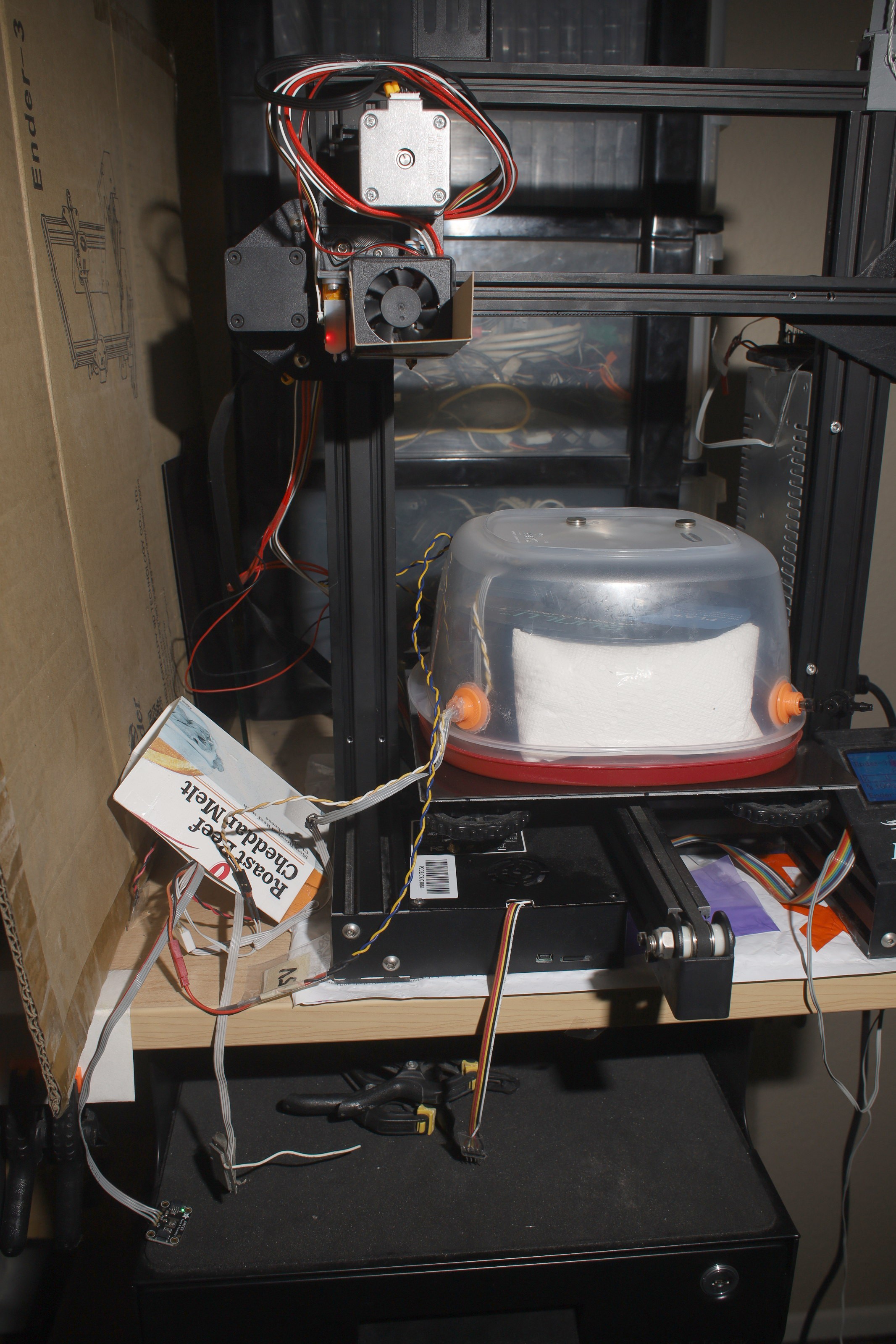

The lion kingdom considered many ideas for drying filament involving peltier coolers which could be repurposed for atmospheric water generation. The simplest solution has converged on a simple solar heated container.

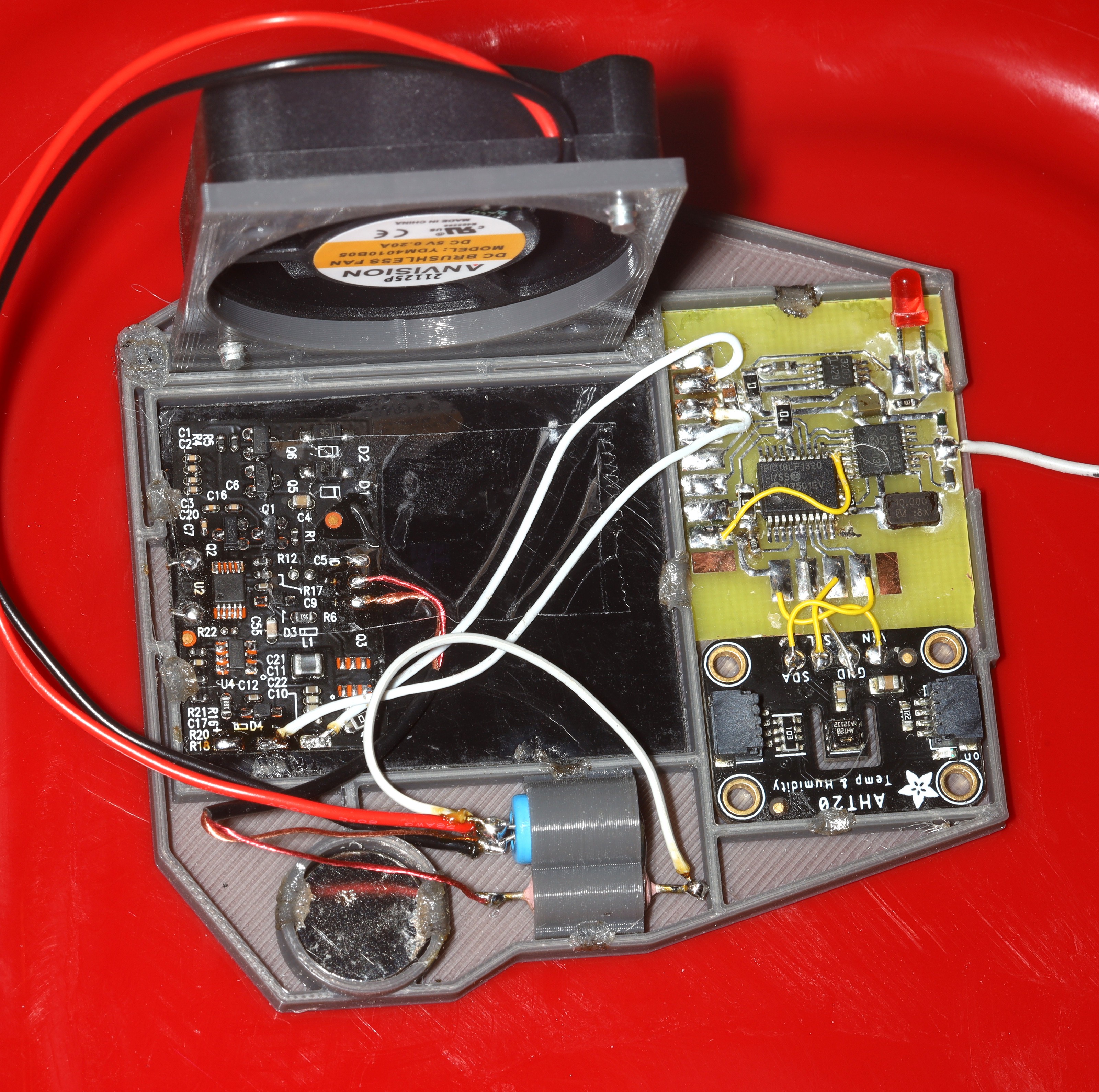

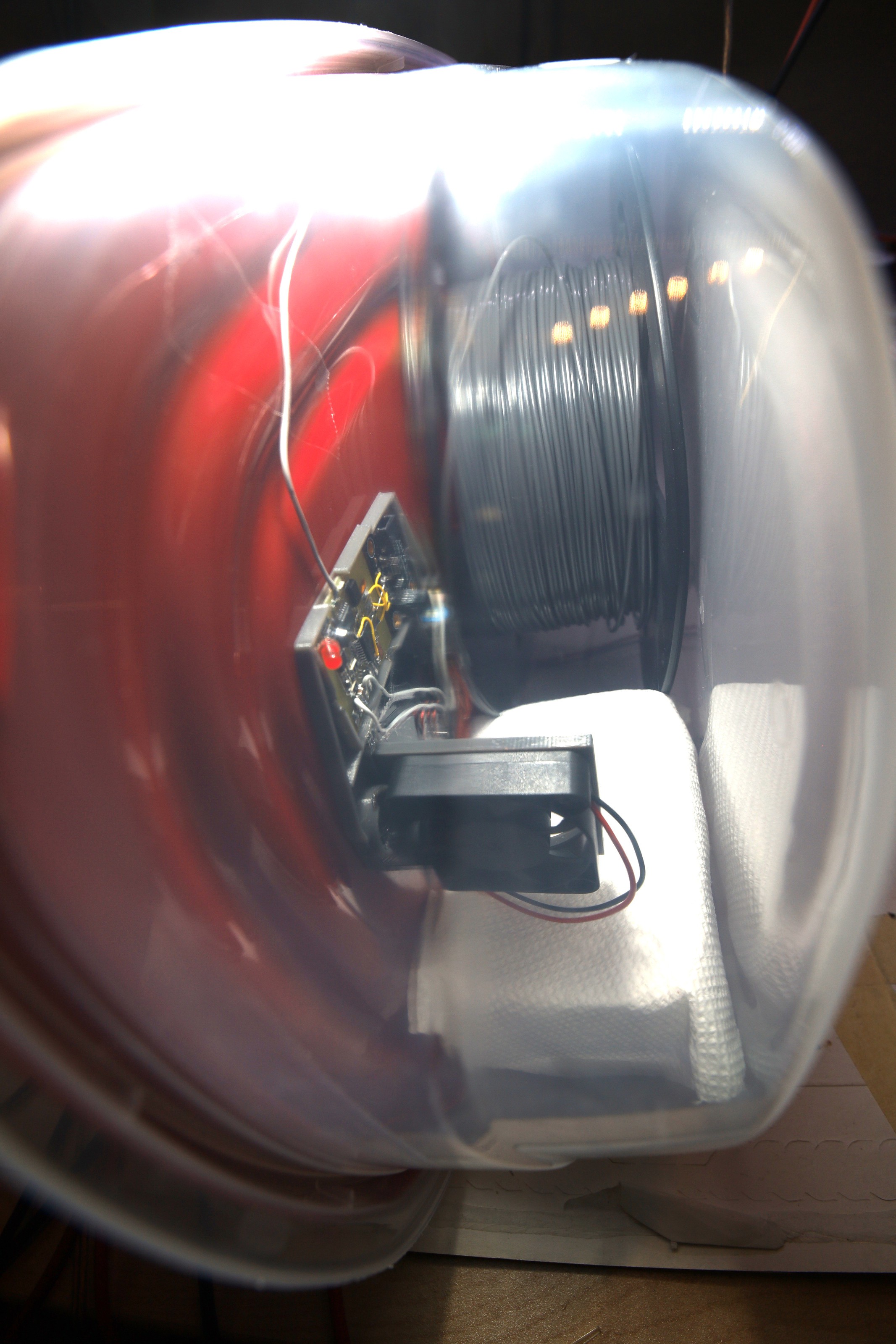

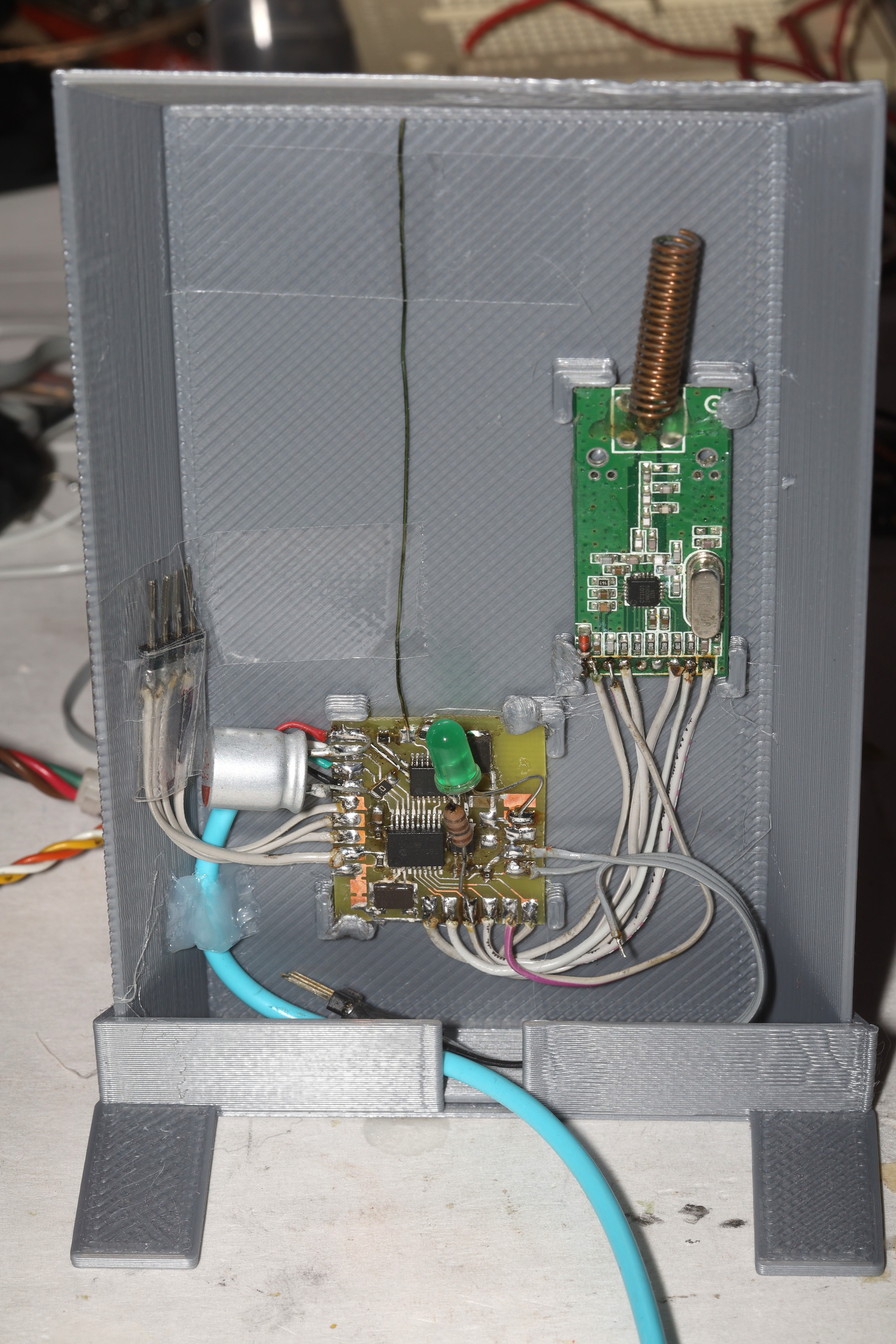

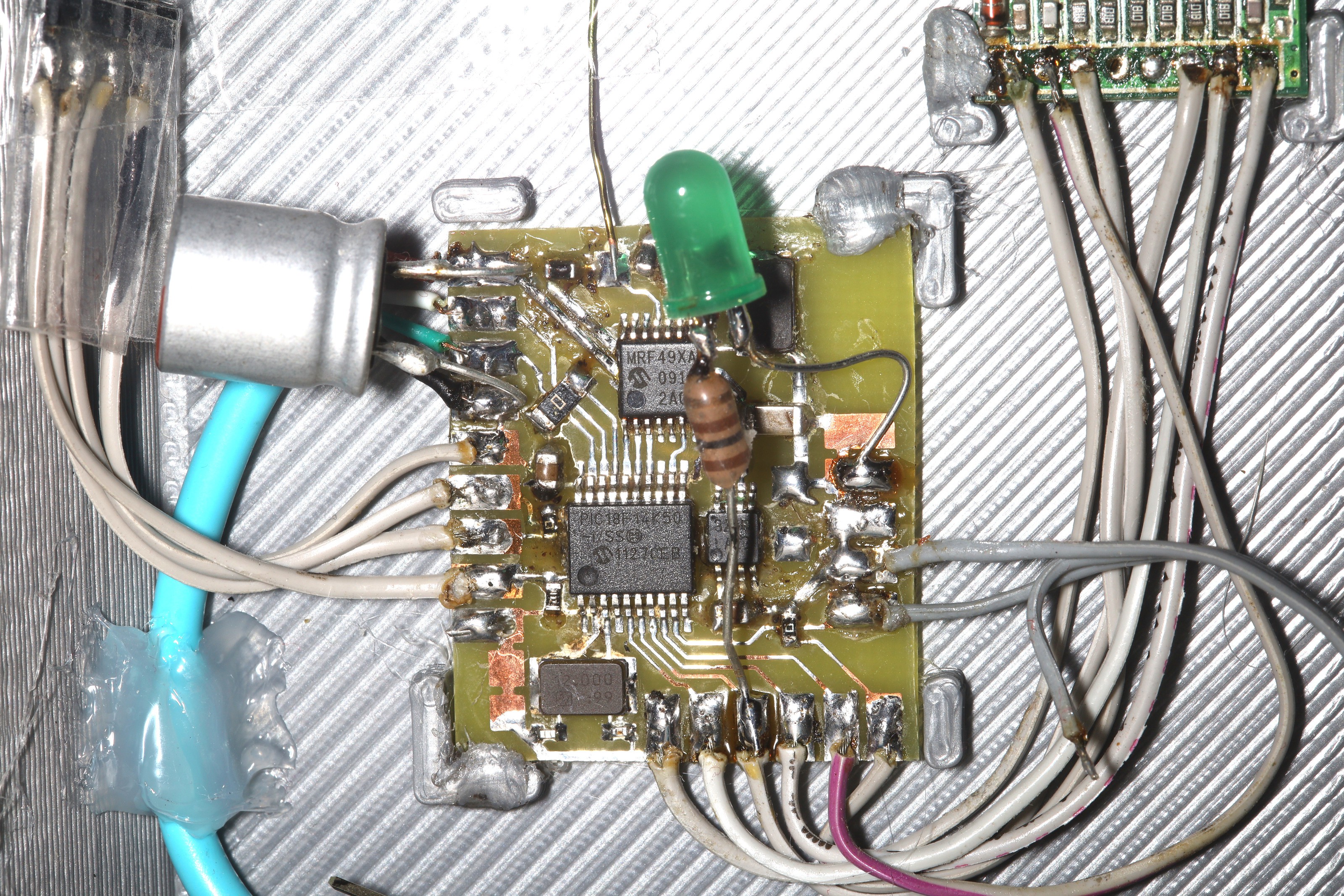

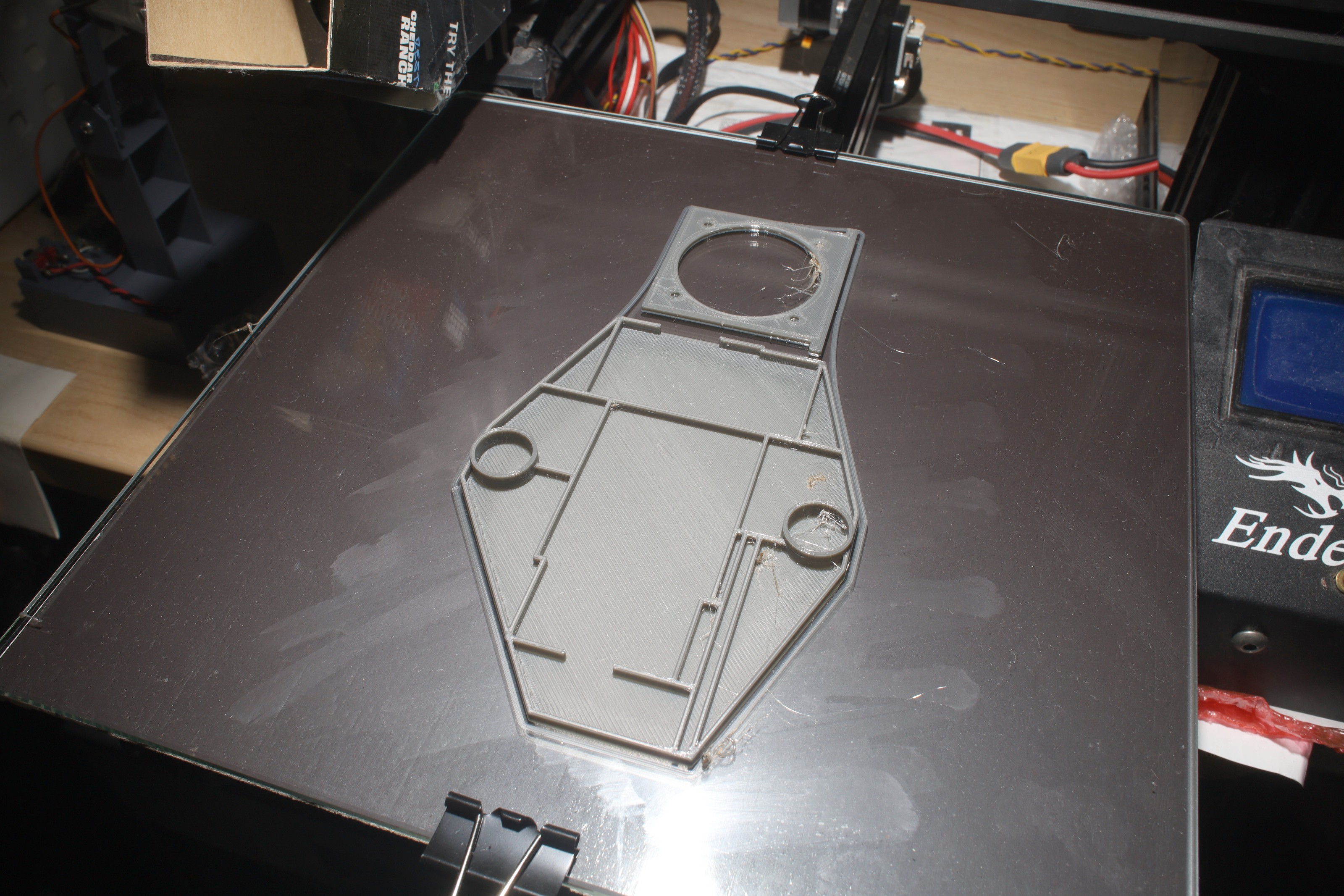

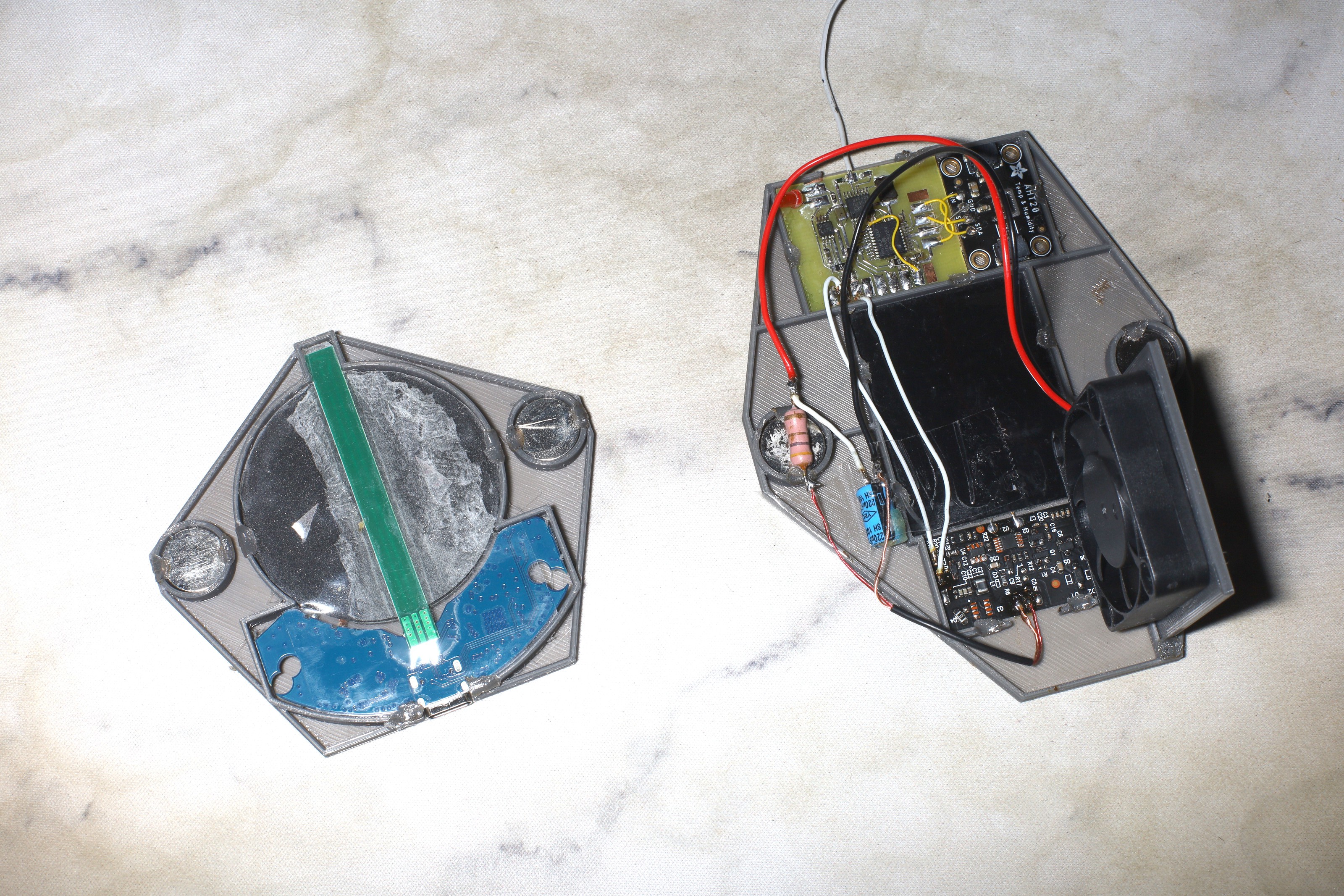

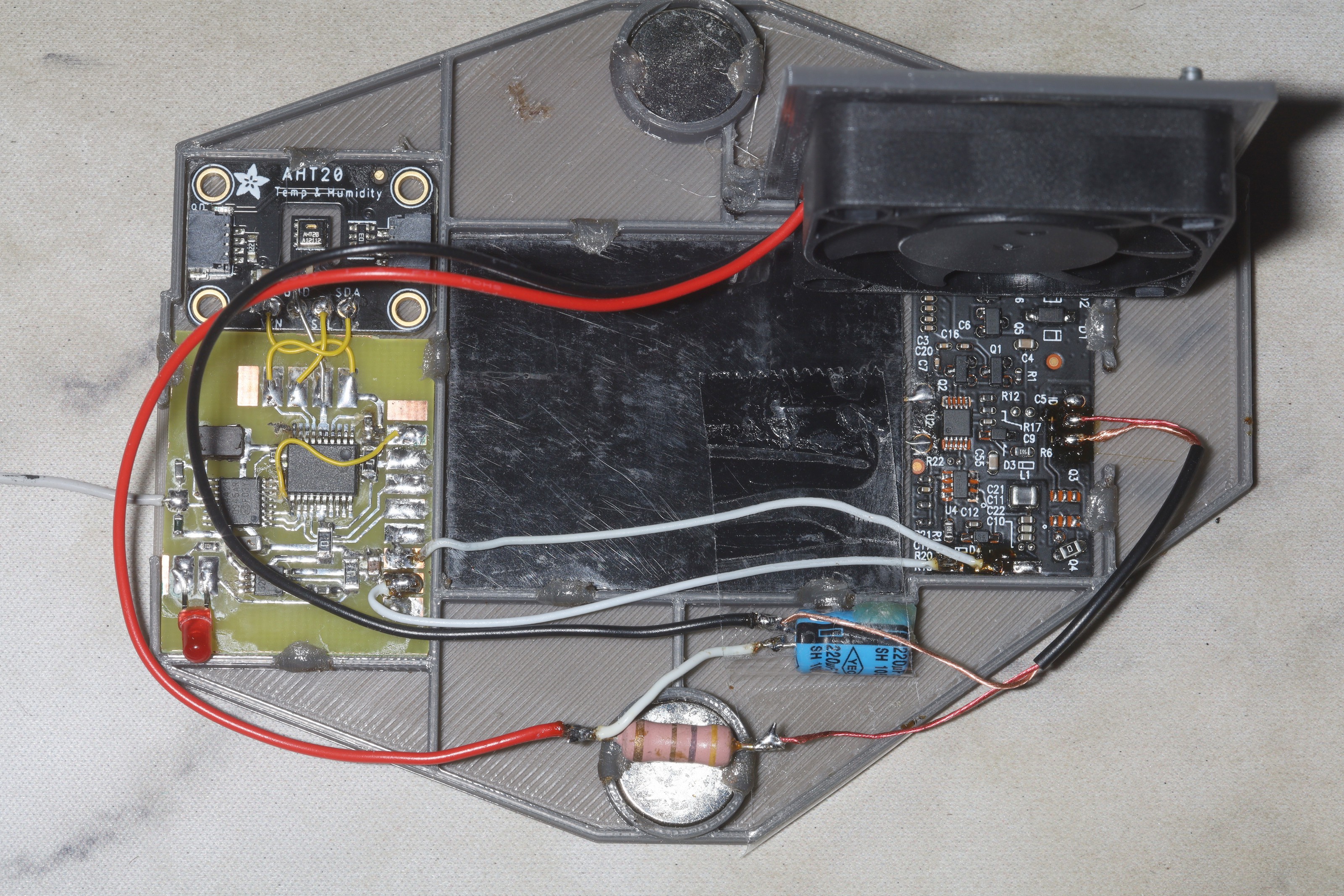

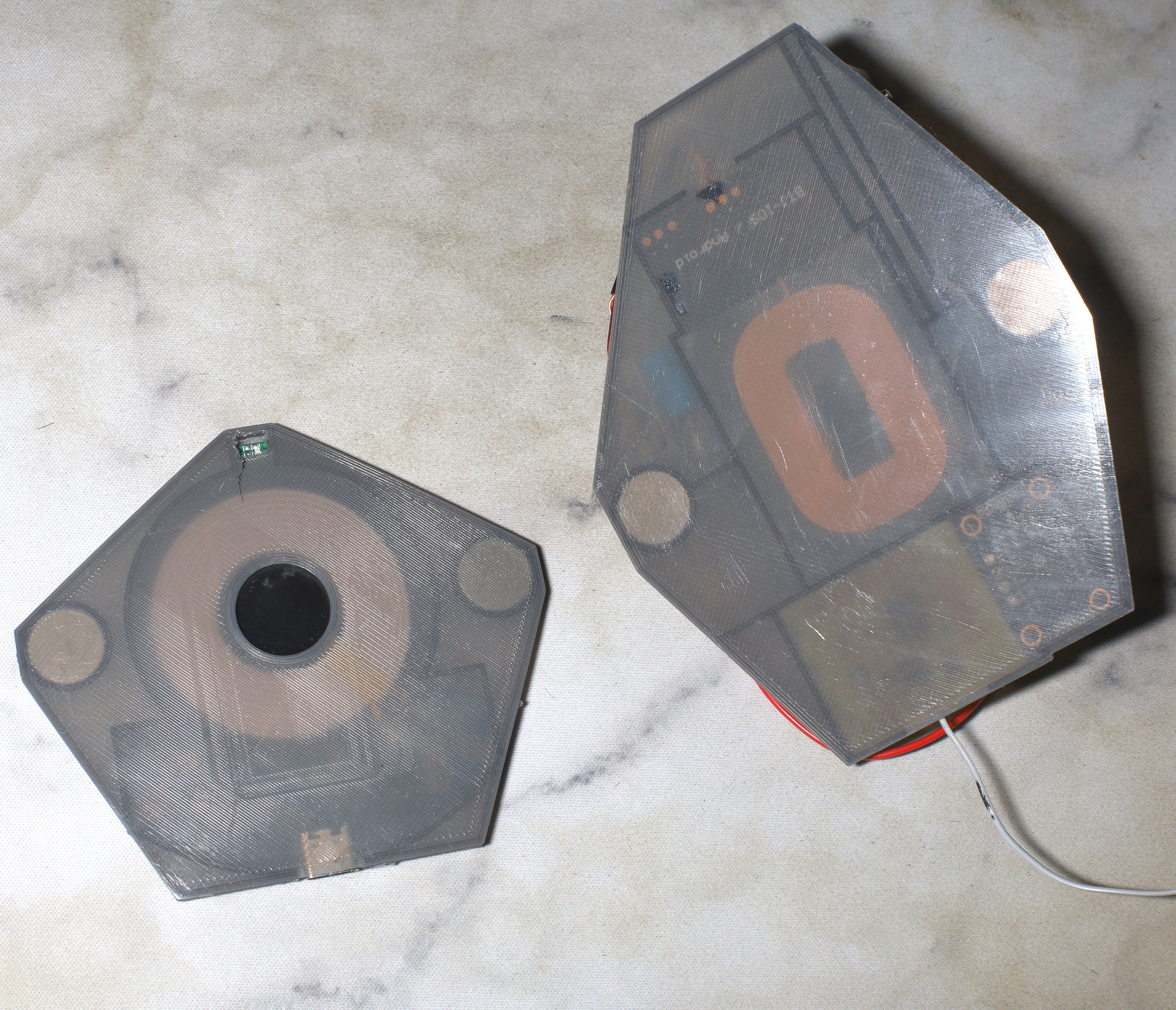

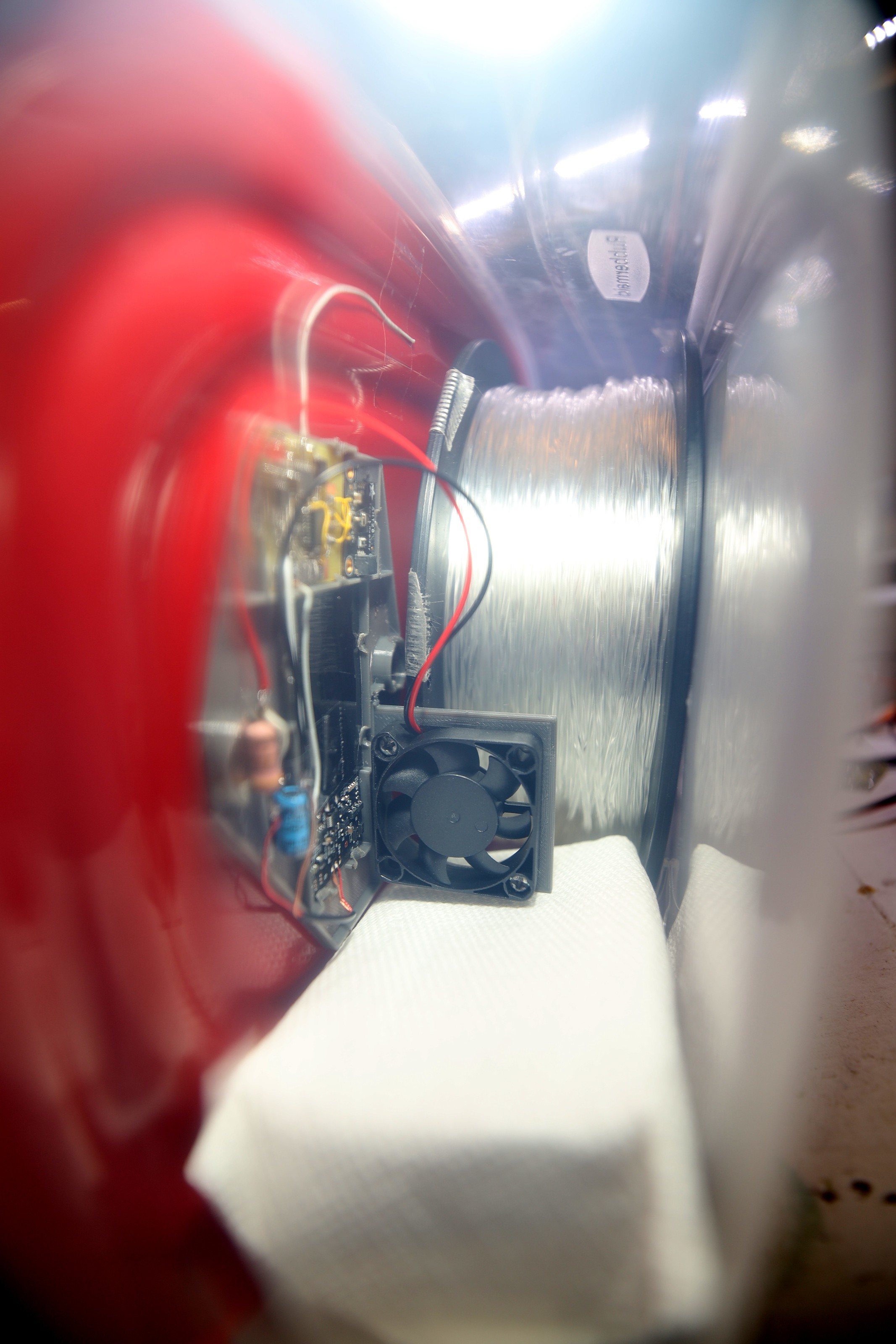

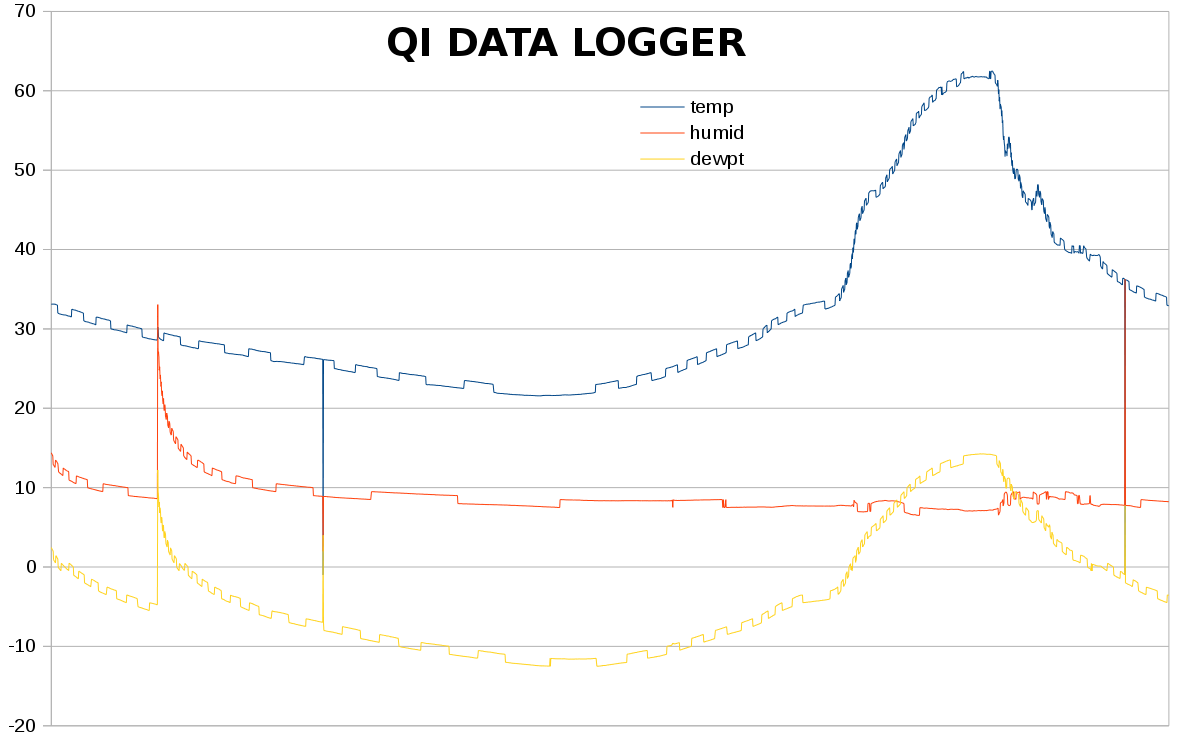

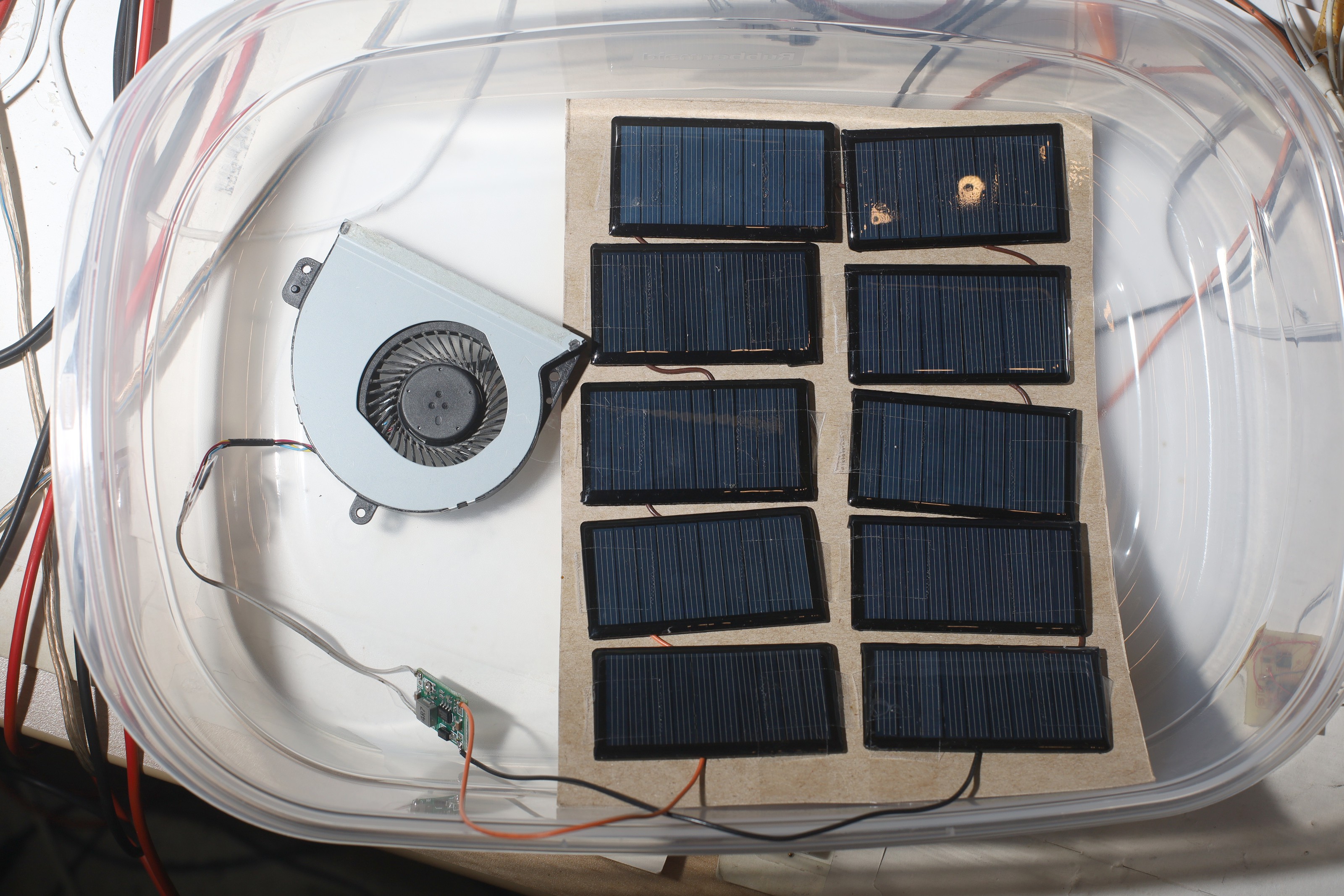

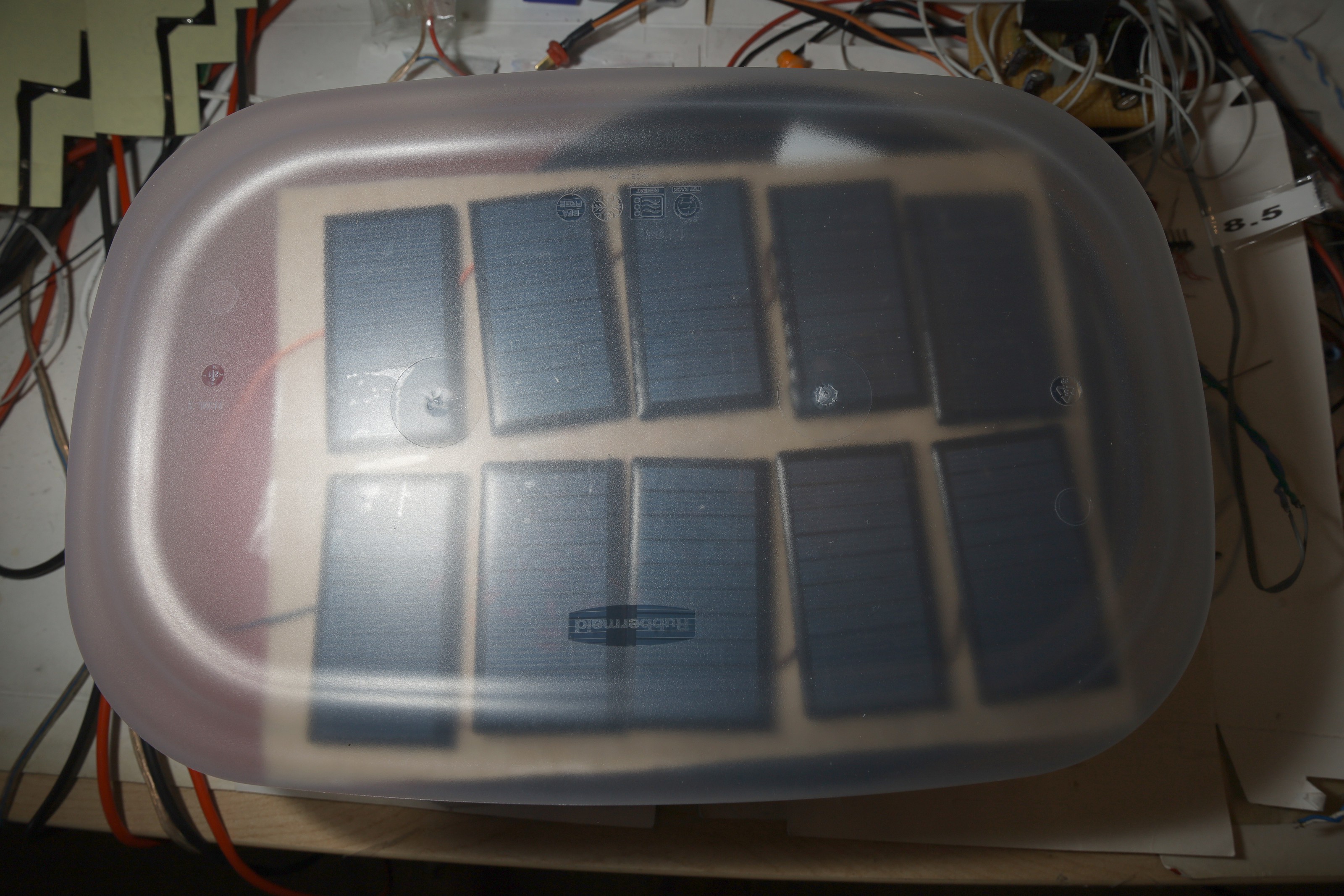

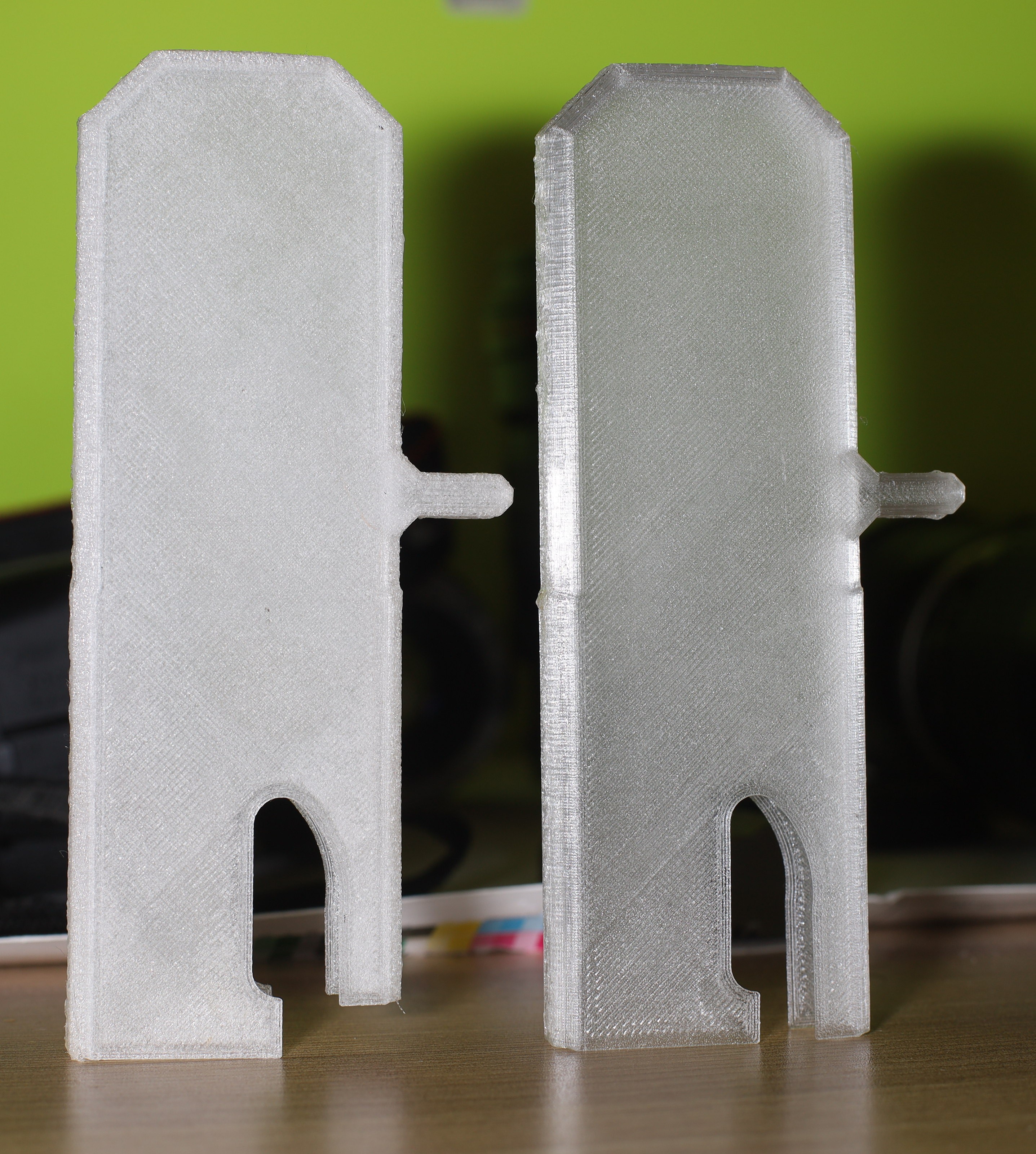

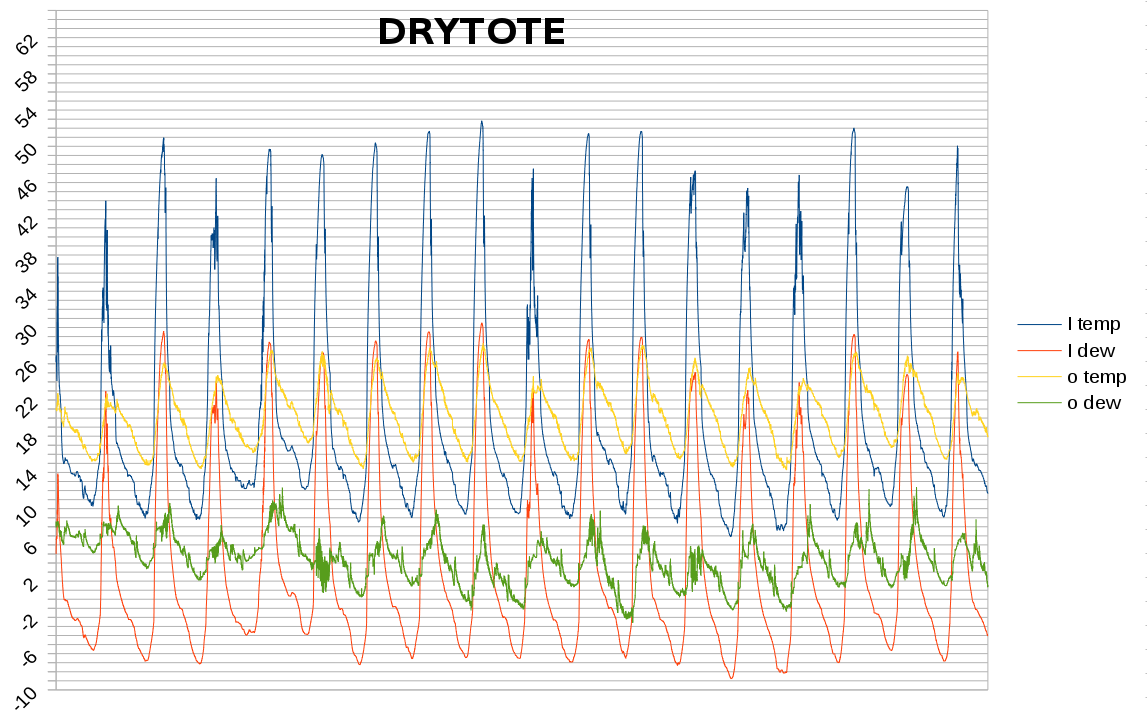

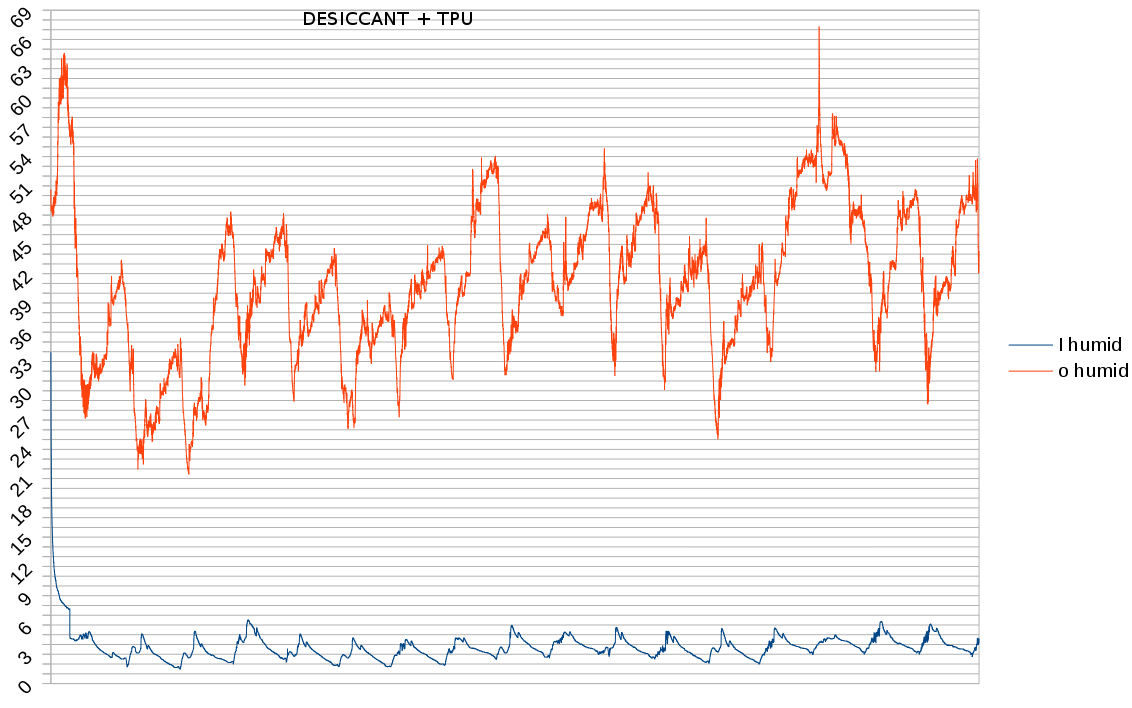

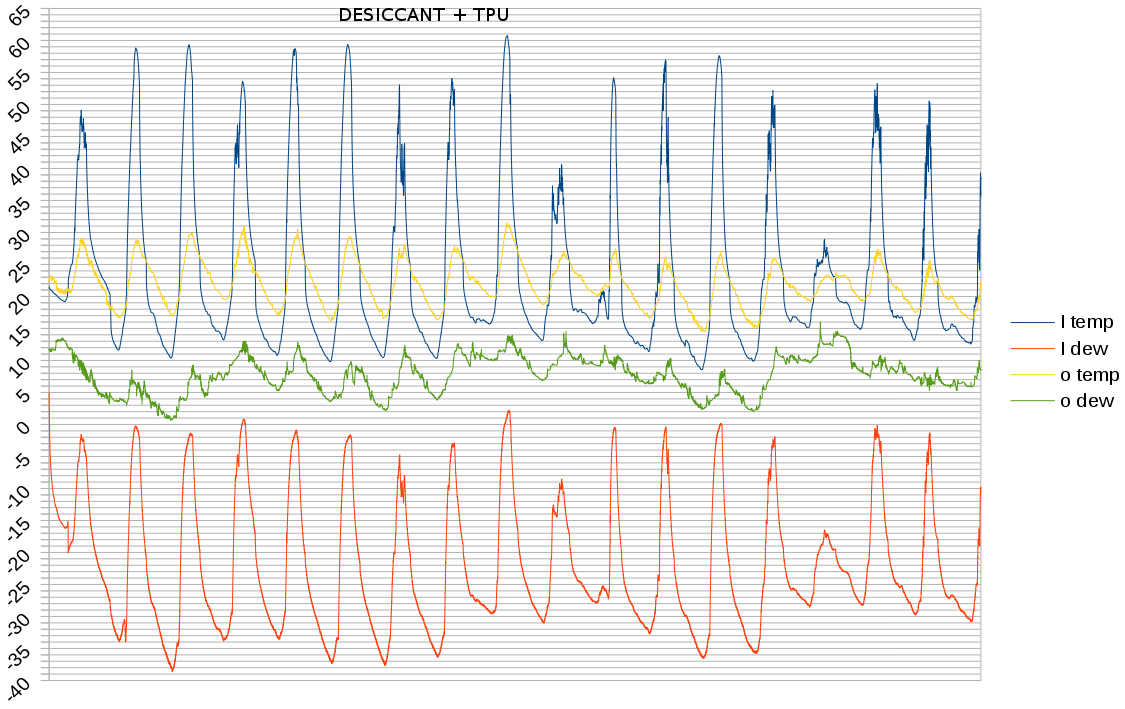

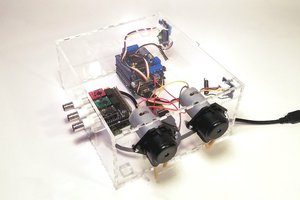

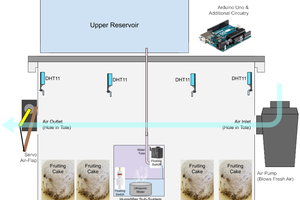

The general idea is a transparent container just big enough to enclose the filament. There would be 2 vents with air tight valves. There would be a fan on the inside to circulate air & a fan outside a vent to force outside air in. There would be a dewpoint sensor inside & outside. The electronicals would be manes powered, but all the heat would come from the sun.

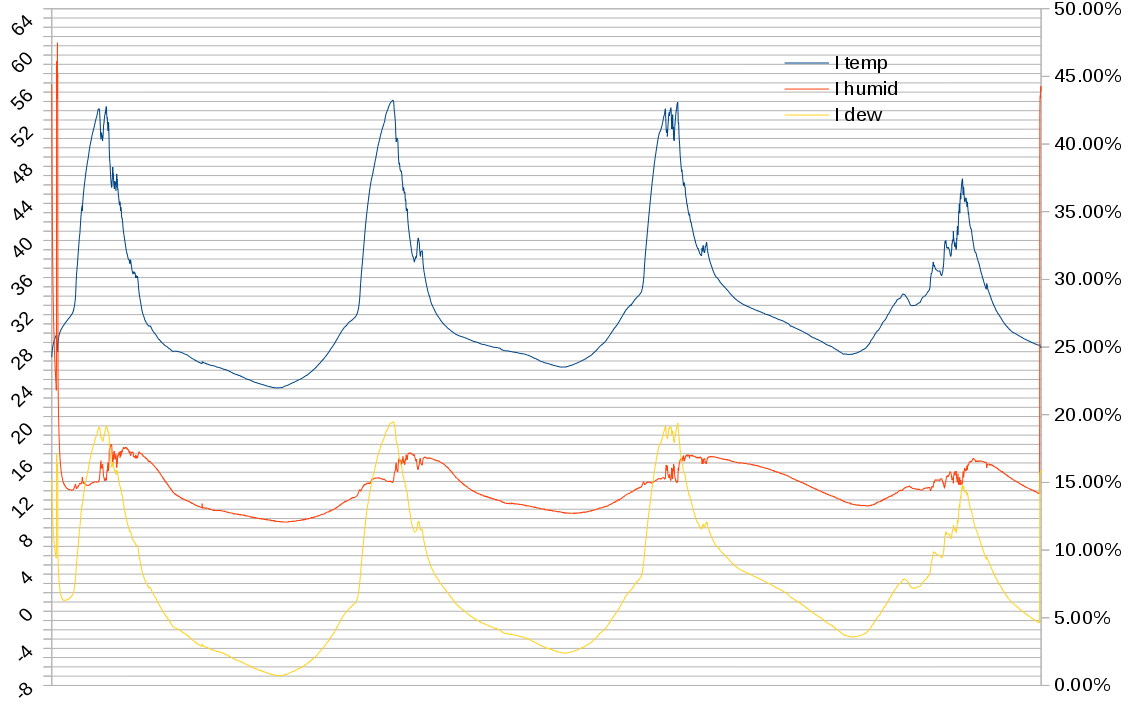

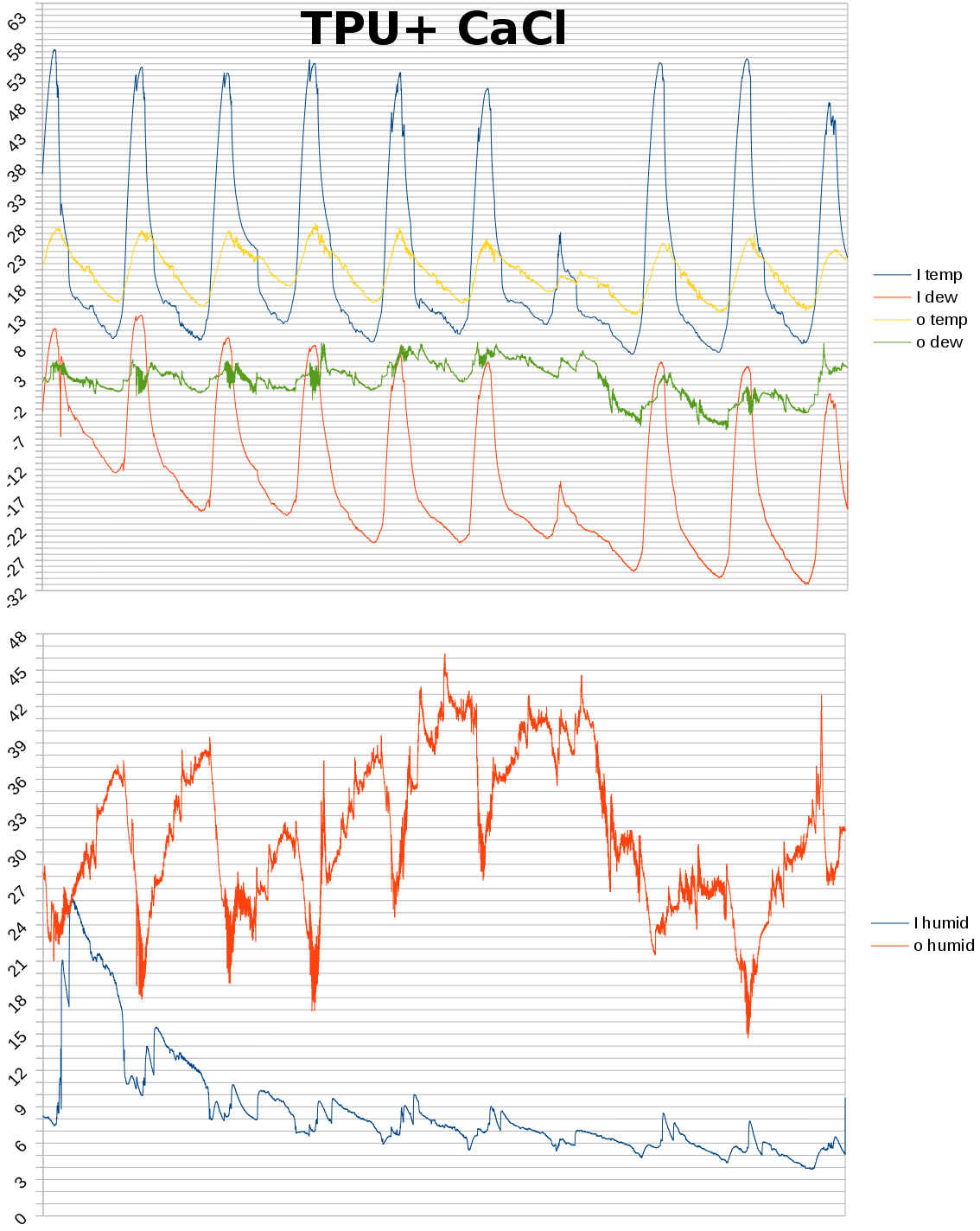

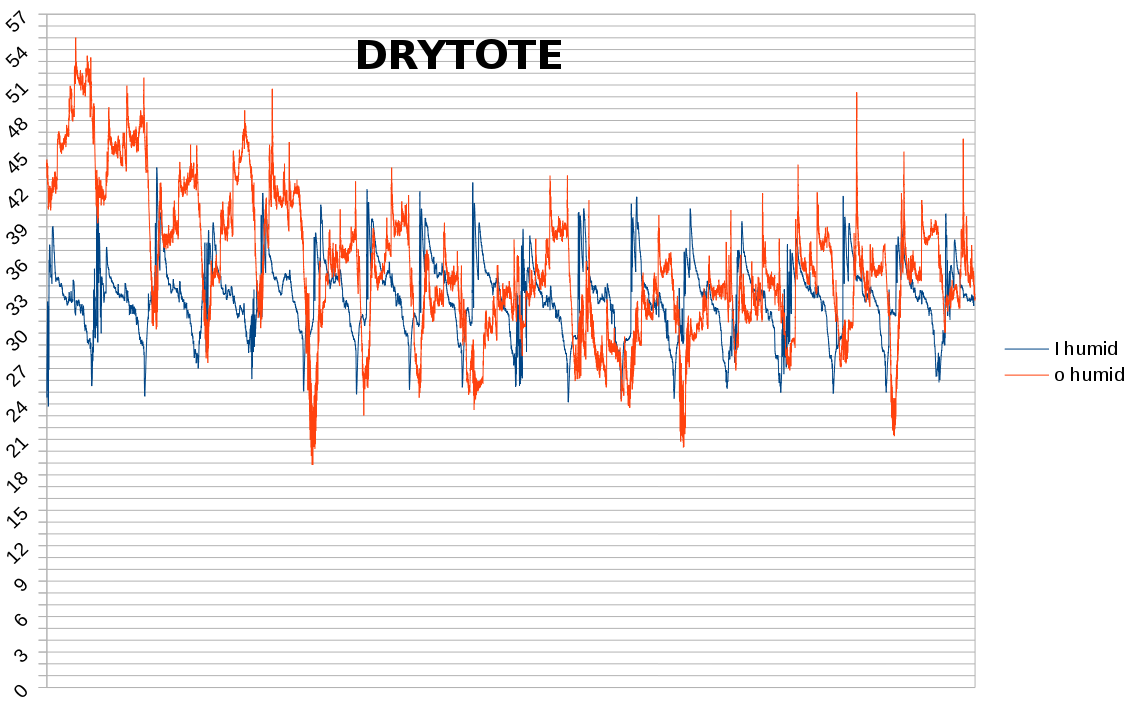

The inside fan would always be on. The outside fan would turn on & the 2 vents would open when the outside dewpoint was lower than the inside dewpoint.

This would entail ordering 3 humidity & temperature sensors. 1 extra would go to a readout on the lion kingdom's weather wall, in order to find an ideal time to use the filament.

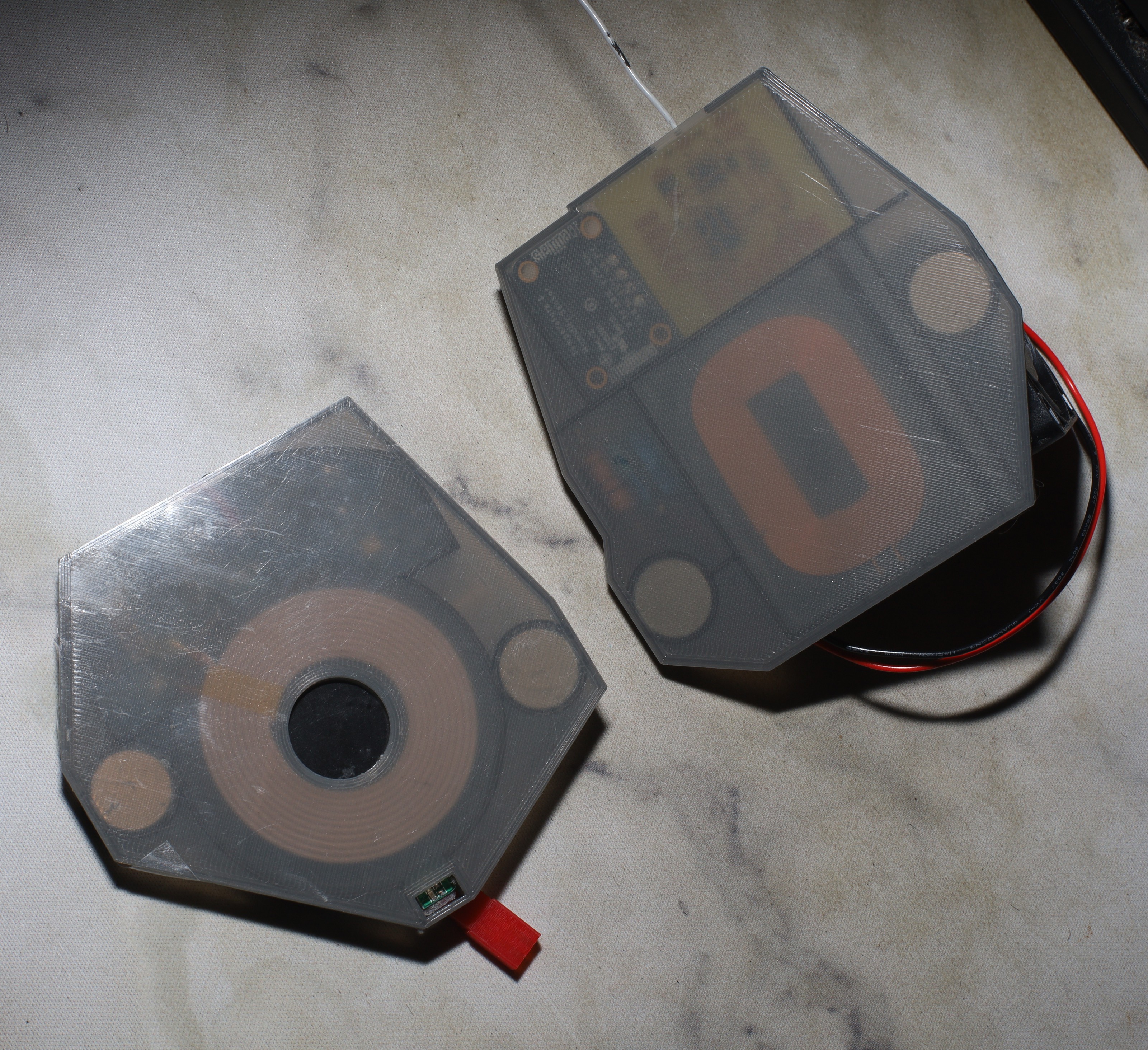

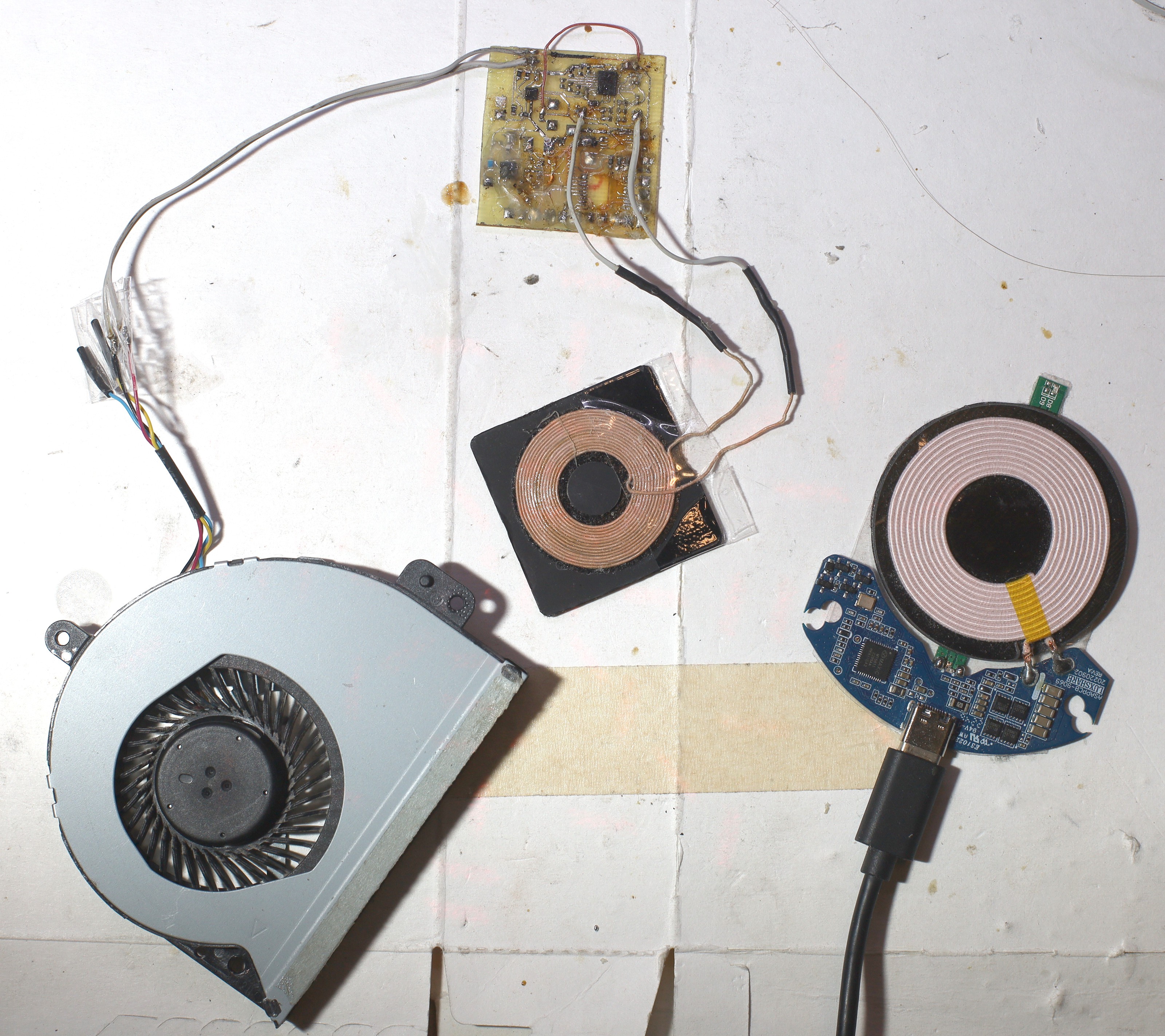

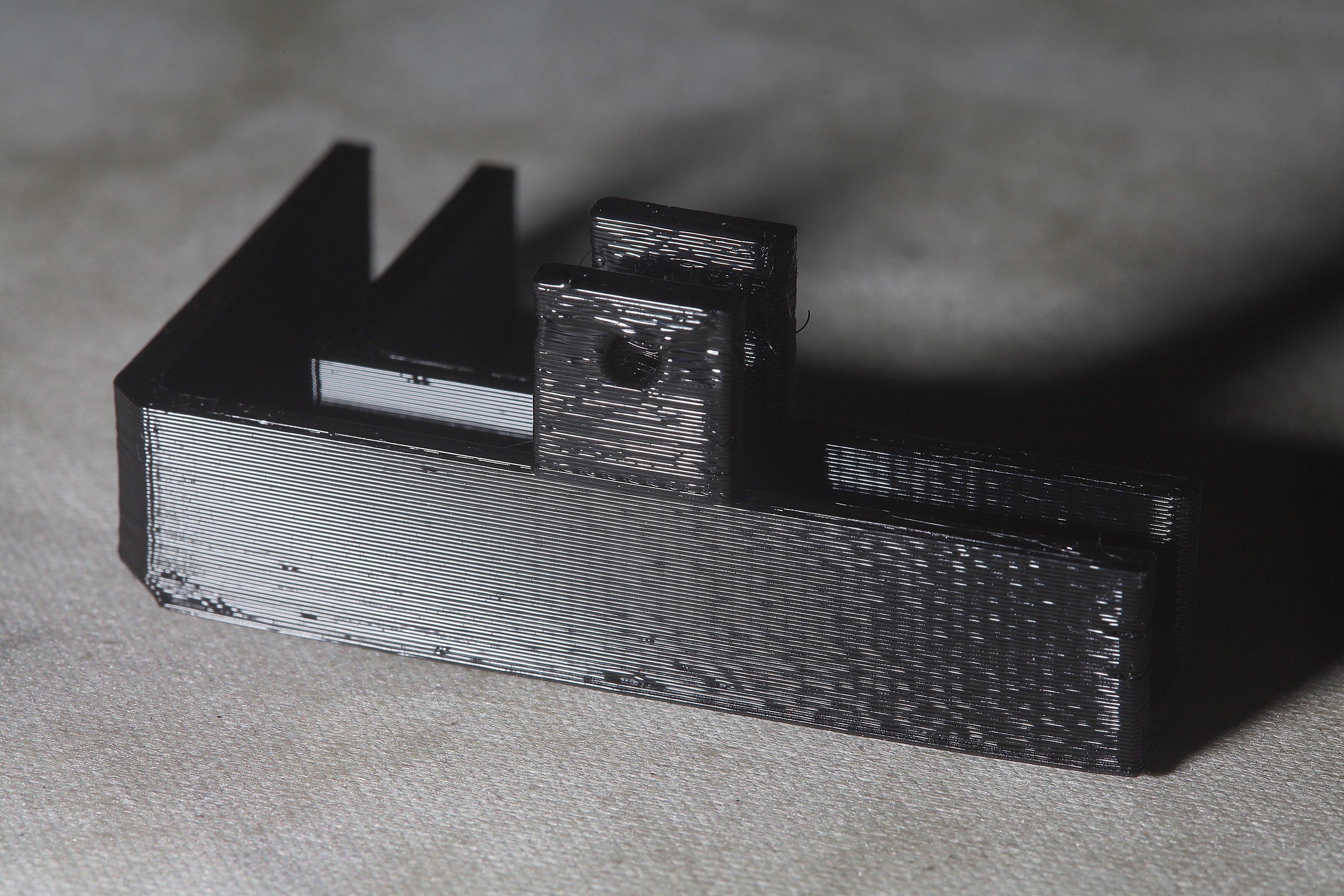

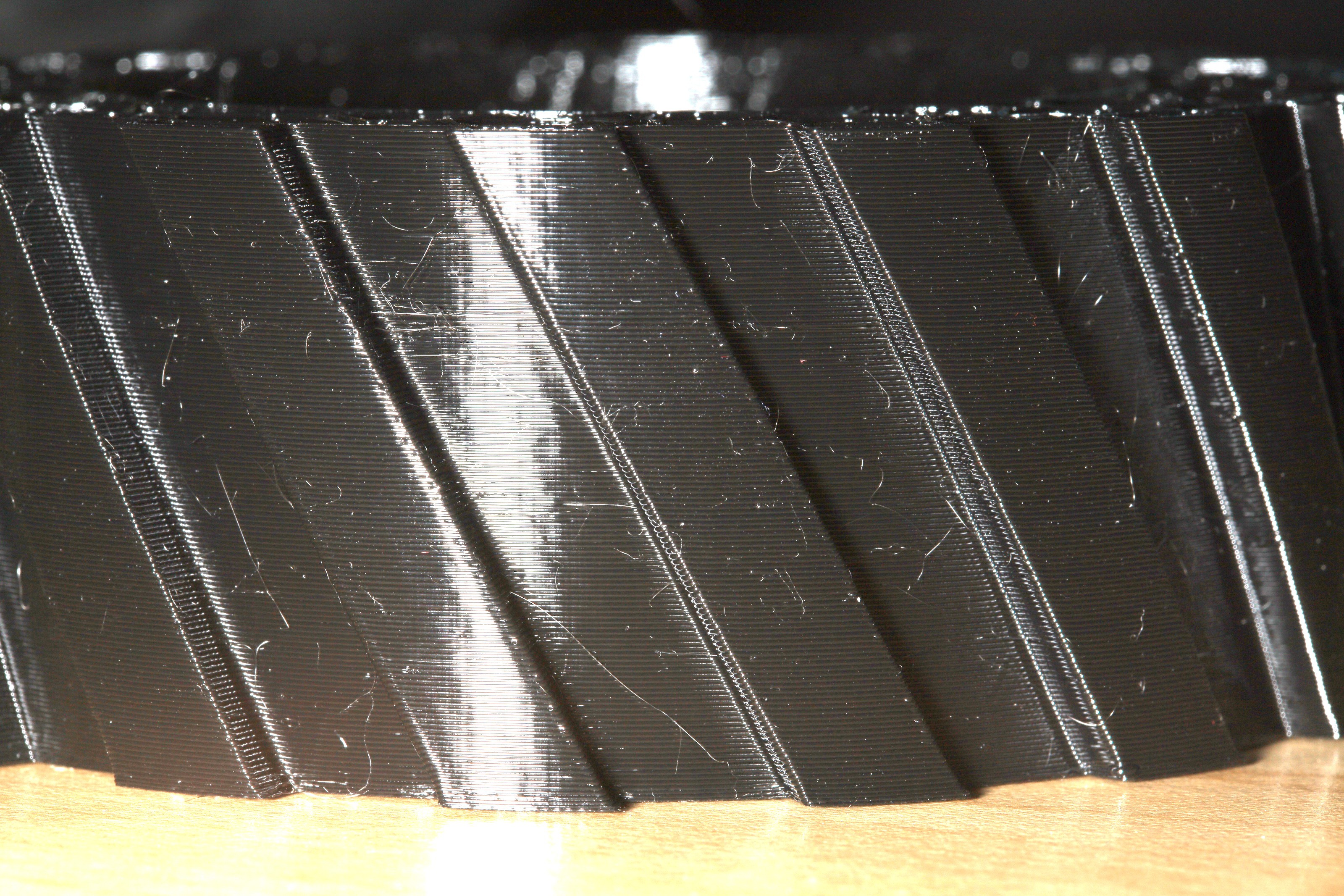

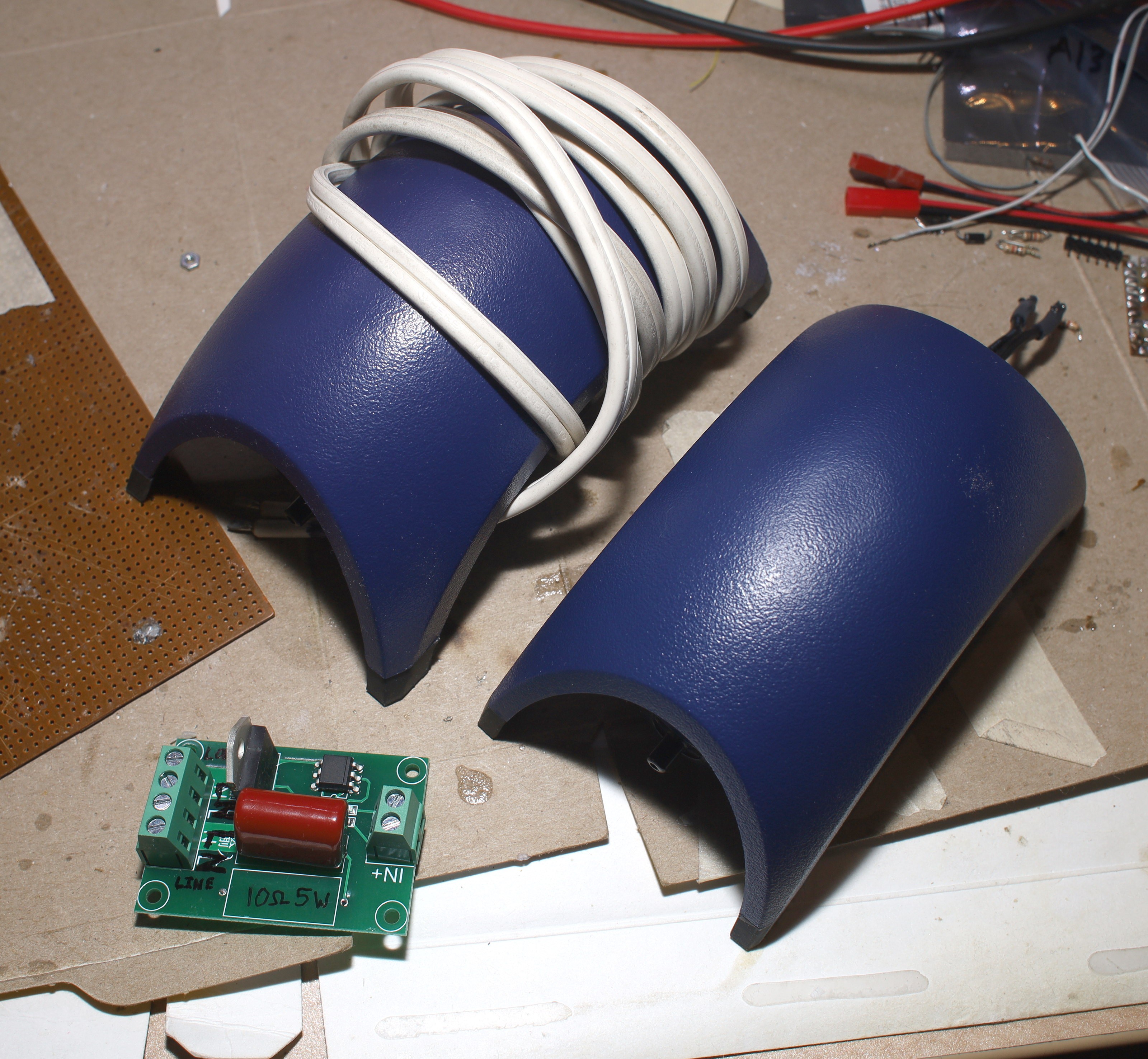

The mane problem is air tight valves big enough for a fan. They must be air tight when the outside dewpoint is higher than the inside dewpoint. The lion kingdom is keen on using its 2 Nidec blowers from 22 years ago. They have small outlets which would reduce the valve size.

The easiest solution might be an aquarium air pump

https://www.amazon.com/Pawfly-MA-60-Aquarium-Gallon-Accessories/dp/B073DWVX5P

& aquarium check valves.

https://www.amazon.com/Pawfly-Aquarium-Valves-Plastic-Non-Return/dp/B01N92AXHF

The valves could be closed by gravity when the pump is off, but they may only be water tight instead of air tight.

Valves closed by gravity & opened by air pressure would still be ideal. Lions haven't had any luck with flaps of material.

Adafruit has an air pump.

https://www.adafruit.com/product/4700

& air valve.

https://www.adafruit.com/product/4663

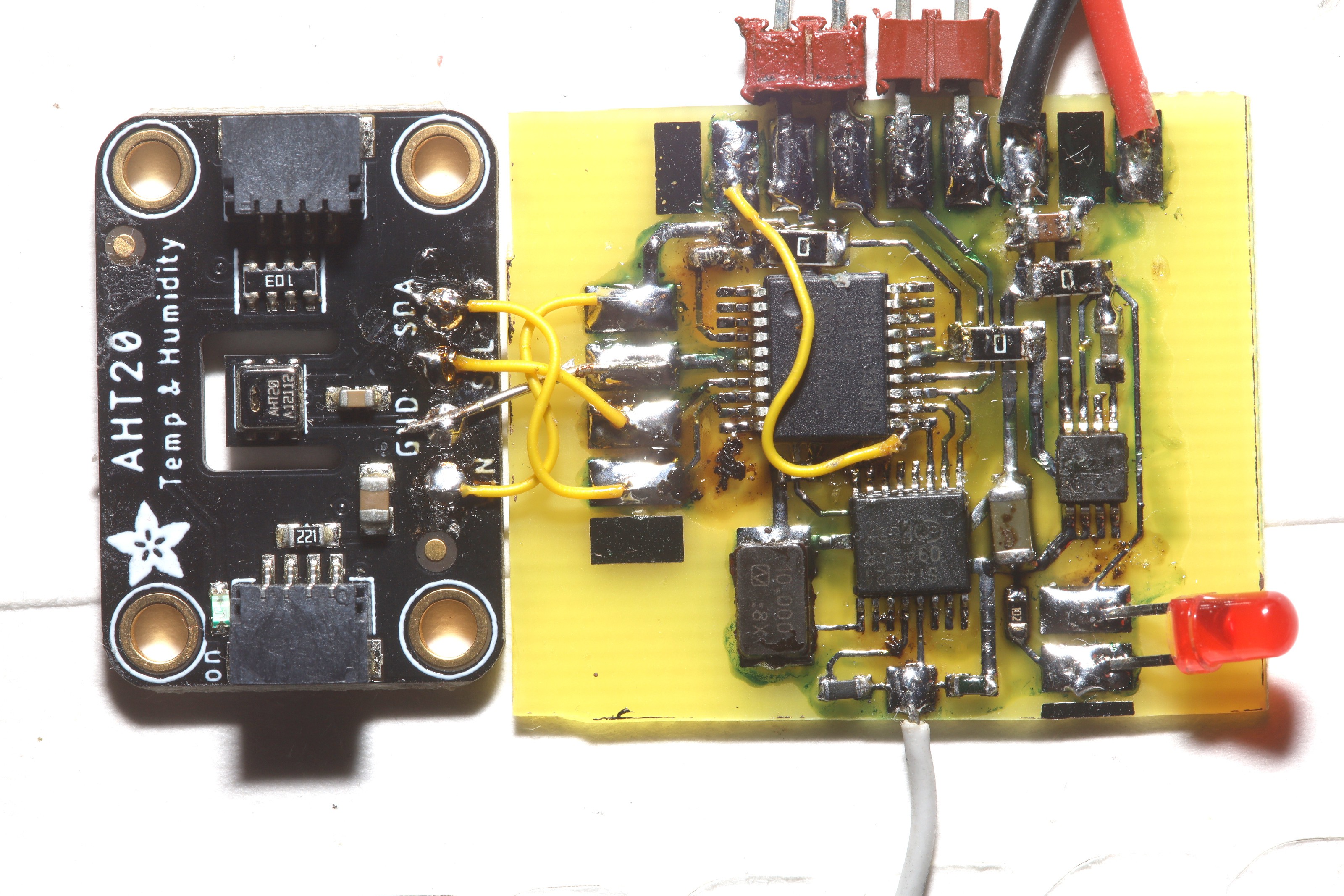

Temperature & humidity sensor:

https://www.adafruit.com/product/4566

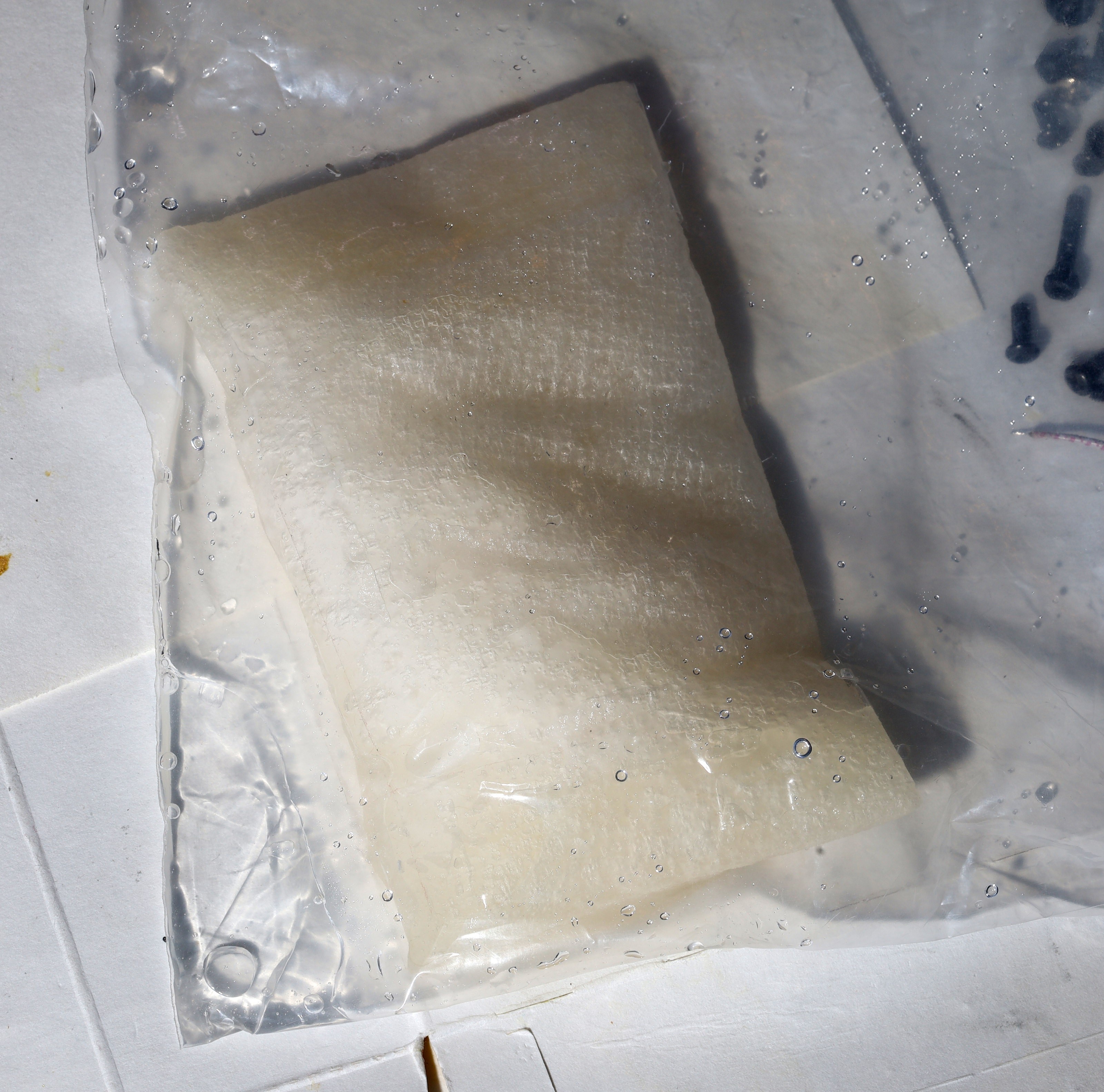

Airtight container:

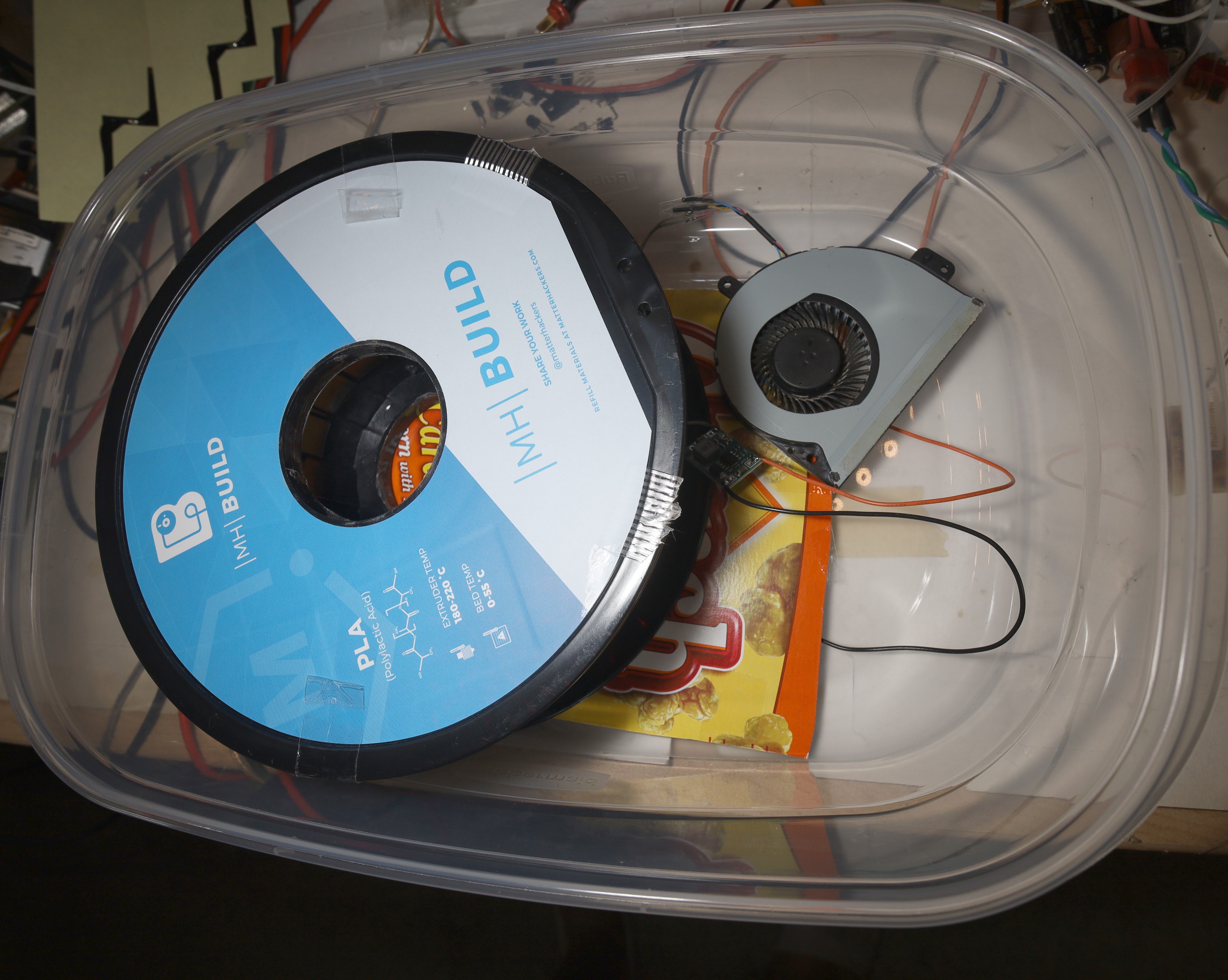

https://www.amazon.com/Rubbermaid-Storage-Container-Racer-1777161/dp/B000WEMFOS

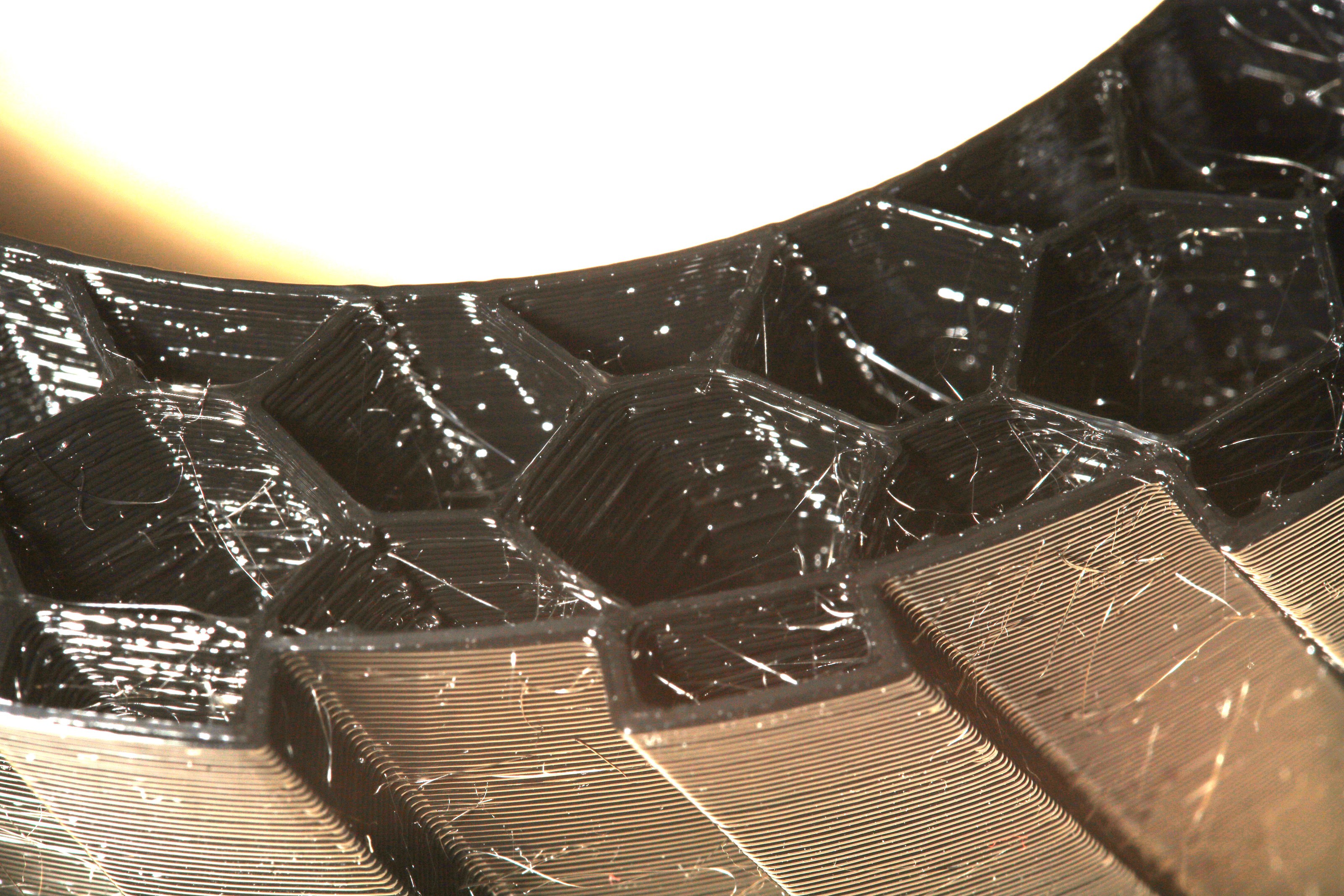

This was the best match for a 1kg 60x200x200mm roll. It stretches slightly to make it fit.

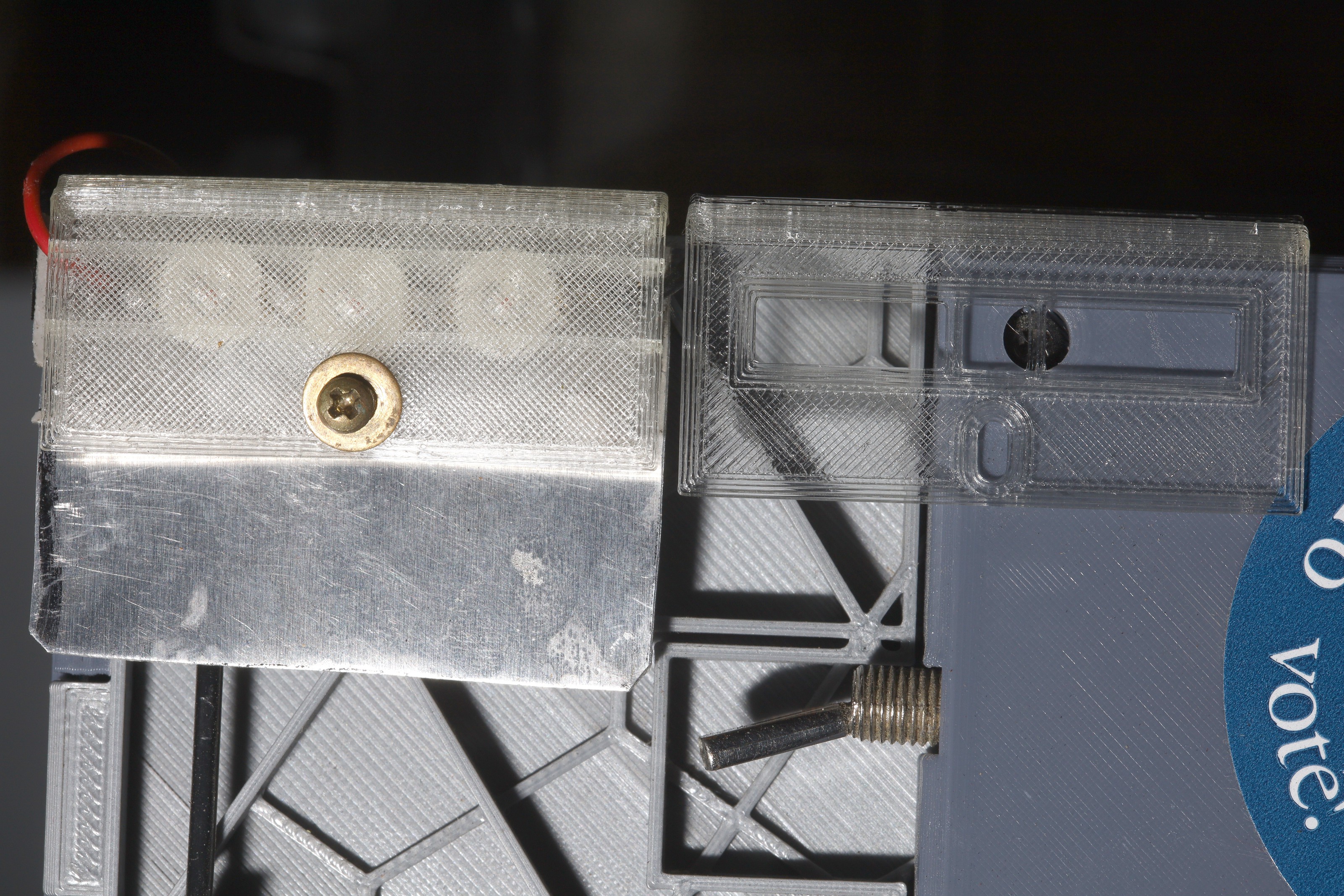

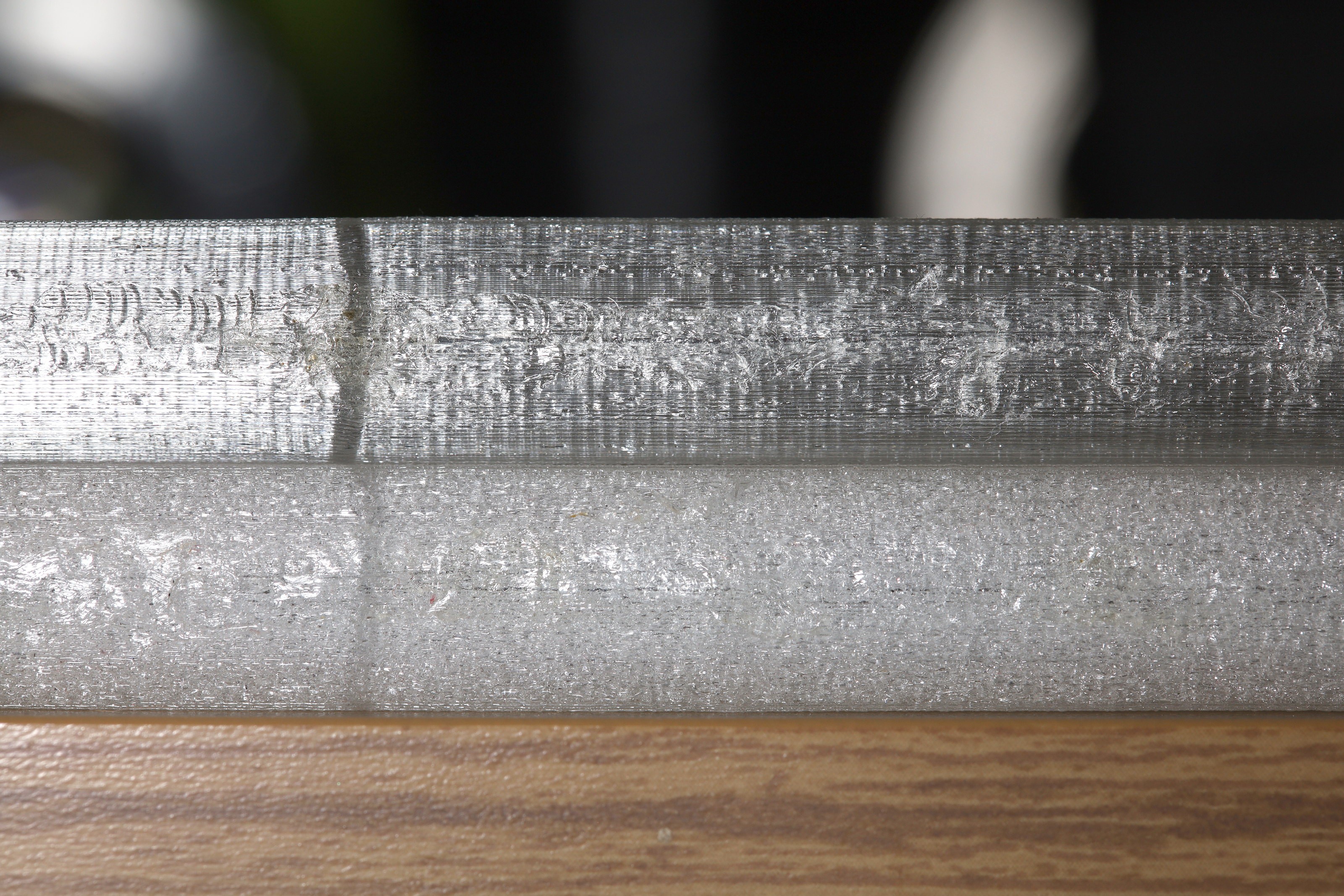

The tubing is the same 3mm ID silicon tube that the lion kingdom got for its humidifier air conditioner. There's still the problem of making an airtight seal between the tubes & the filament container. It might involve printing farsteners which can be stuffed with a lot of goo.

Of course, the cost has to be weighed against buying a new roll of filament every time it gets wet.

lion mclionhead

lion mclionhead

Scott Paterson

Scott Paterson

Silas Waxter

Silas Waxter

A very simple passive valve is a tube of polythene (i.e a plastic bag) or nylon fabric, with it's axis horizontal, and a vertical flange plane at one end. When you turn the fan on, it straightens out and air flows. When you turn the fan off it folds over and closes.

This works better arranged as a long flat tube than a round one. Fortuitously this is kind of how ziplok plastic bags already come.

These can be better than a flap valve, where it is quite hard to get a very light flap to seal when closed.

Quite a good way to collect solar heat is to suck your inlet air through a black fabric (that the sun heats). You don't need a cover glass, because the thin layer of heated air on the outside is being sucked in, instead of being lost when you have a solid black surface. It could also be a dust filter.

I would think that only very low flow rate would be needed, so perhaps just having a solar panel inside the box directly connected to a small fan would do the whole job