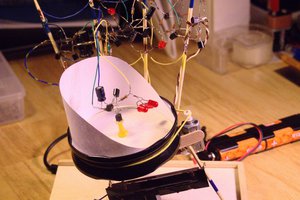

Features of the Circuit:

1.Two modes of operation, turntable mode and shaking mode, any one to be used at a time.

2.Manual speed control for both modes.

3.For turntable mode, clockwise and anticlockwise modes are there, any one to be used at a time.

4.For shaking mode, the to and fro motion time can be controlled manually

In the following steps, we will learn the circuit from schematic to implemenation.

A 555 Timer based Turntable and PCB Shaker Circuit

555 timer with a motor driver to make a rotary turntable driver and a PCB shaker to etch PCBs, in a single circuit .

Sayantan

Sayantan

ElectronicABC

ElectronicABC

bornach

bornach

Chris

Chris

Sagar 001

Sagar 001