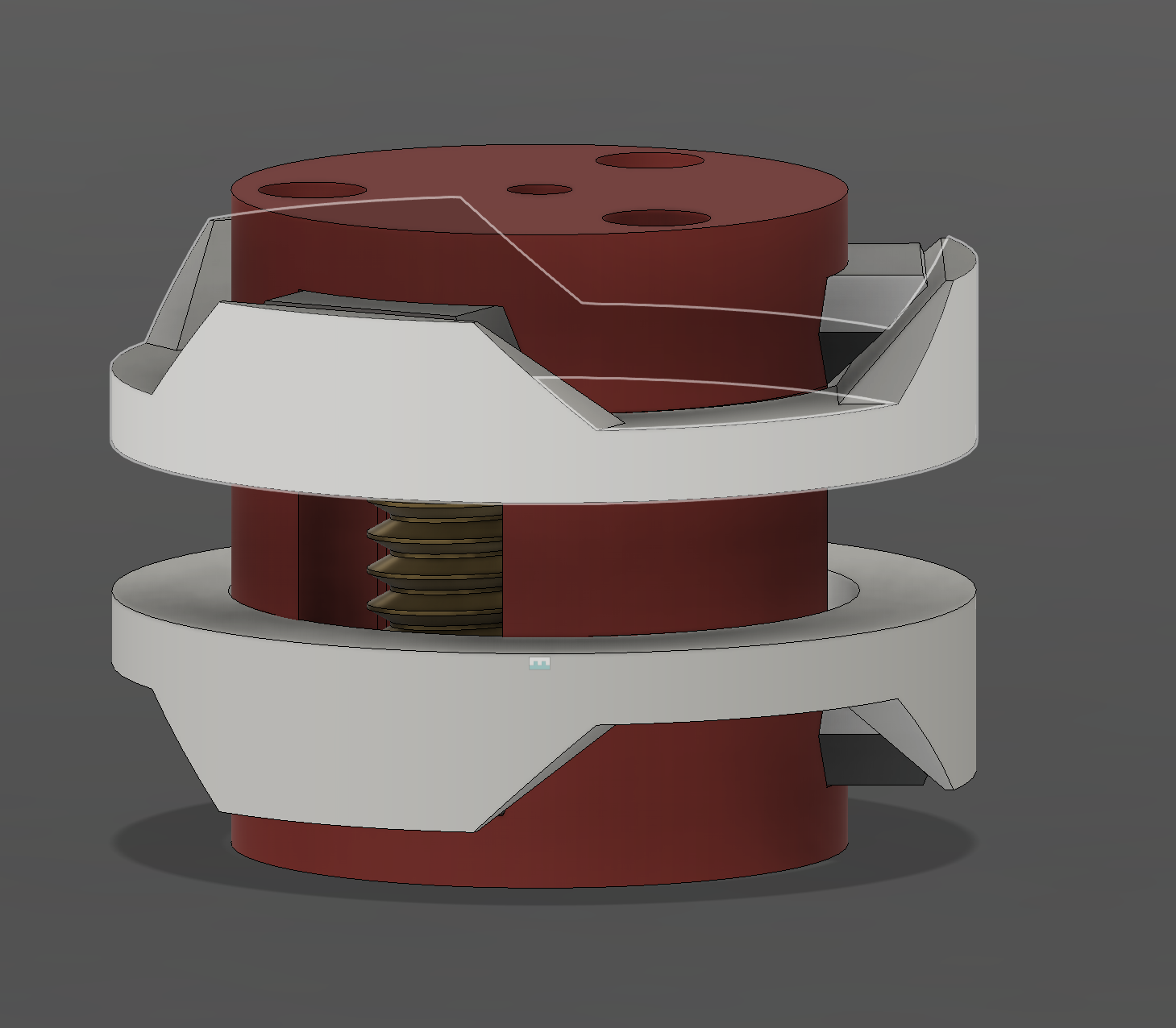

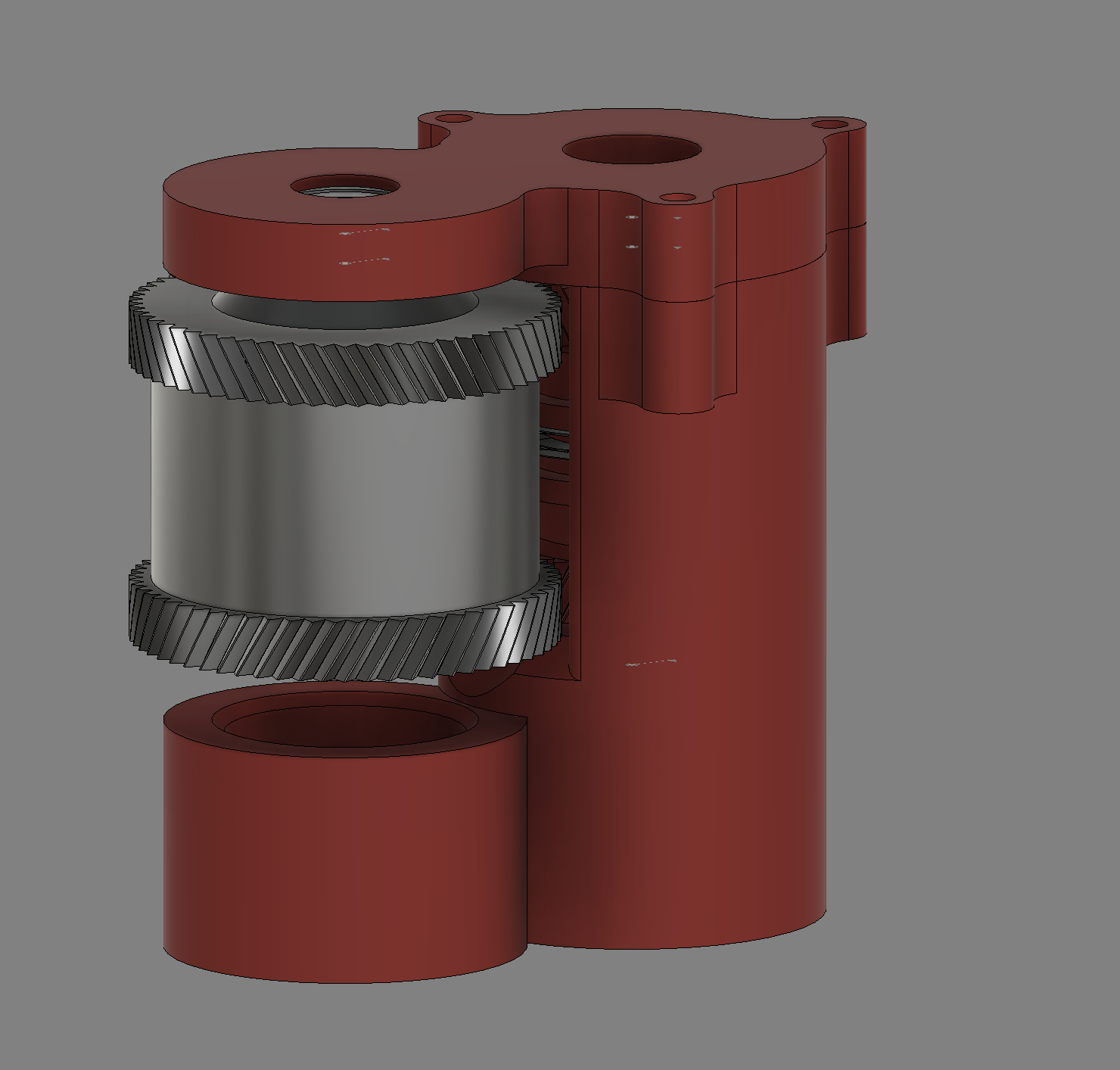

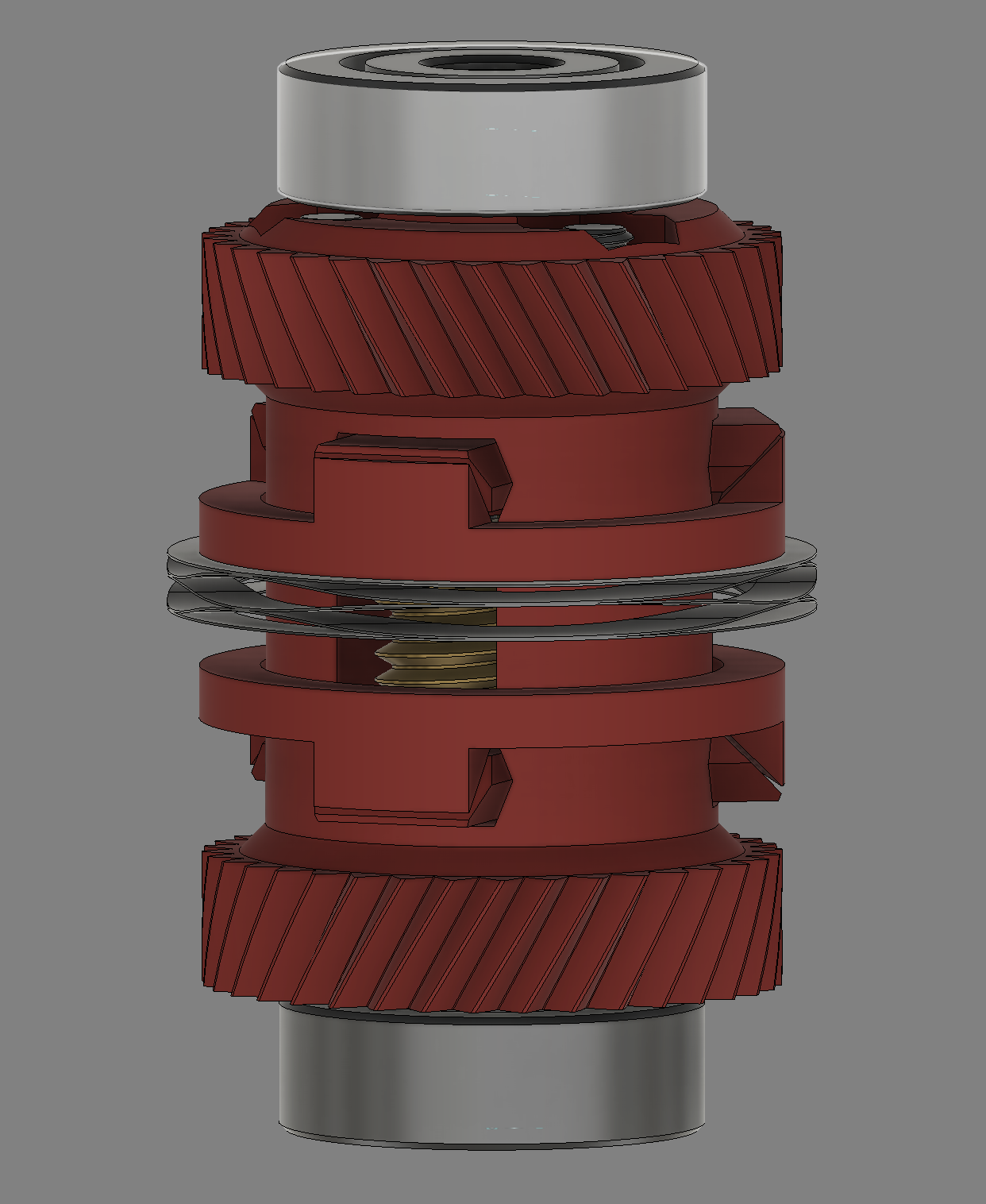

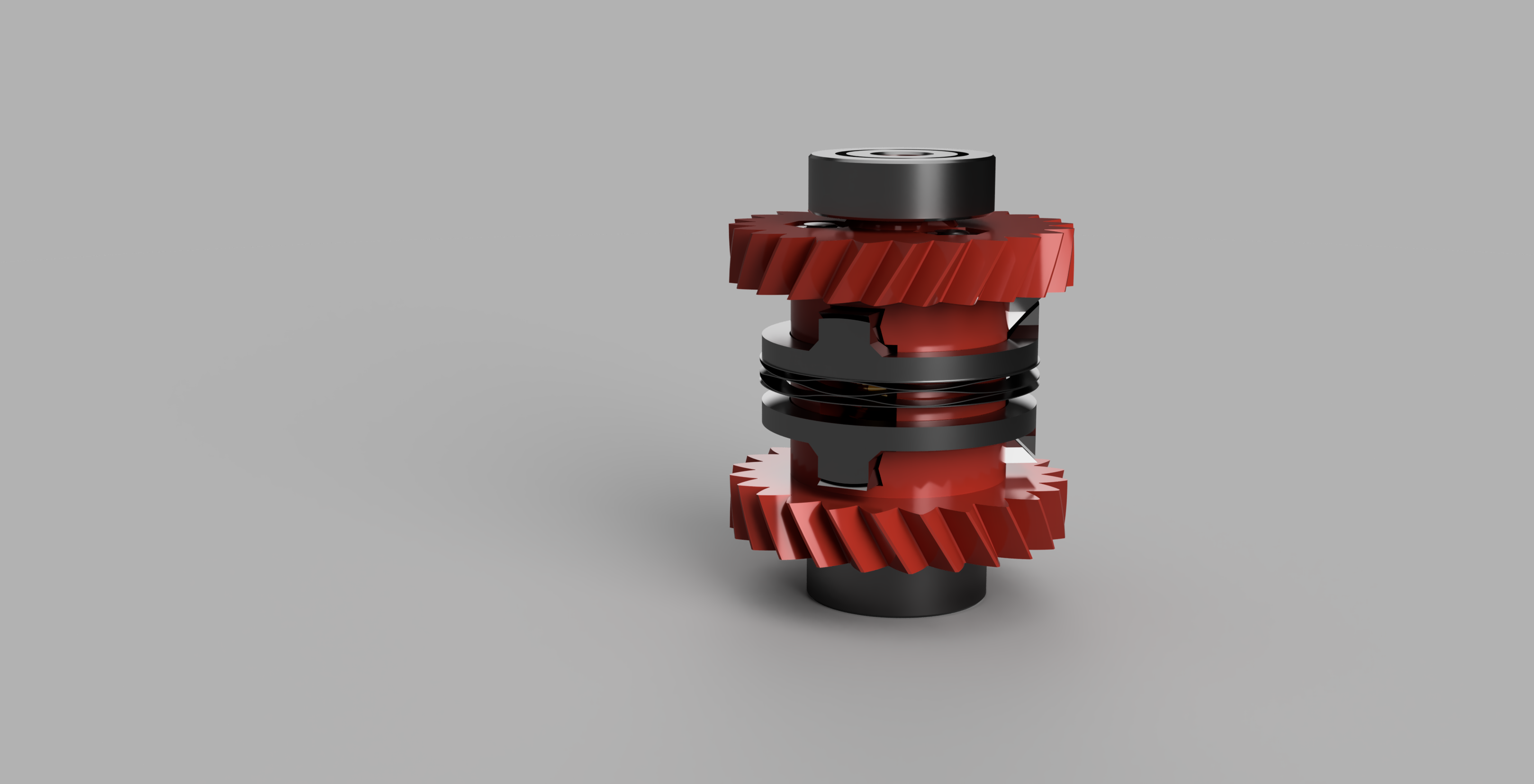

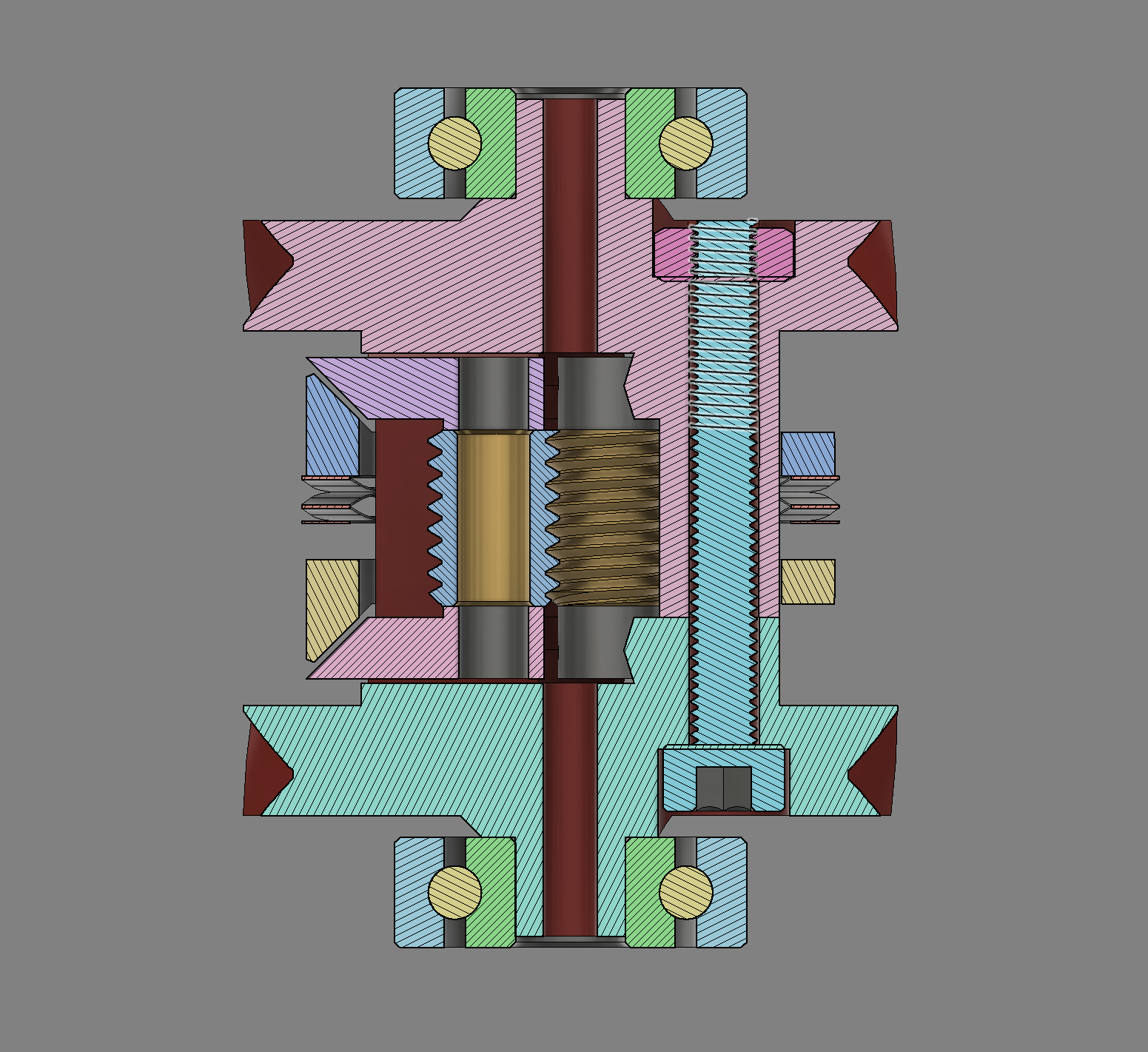

Many designs for this style of extruder that I've seen involve tilted rollers. However, I don't have a lathe, so I need a different option. I'm going for vertical M6 bolts instead of tilted grooved rollers, allowing me to fabricate it without a lathe. Additionally, this means that the contact shape against the filament is linear, unlike the hyperbolic shape of the tilted rollers, allowing a more uniform interface.

I'm also powering it with a brushless motor, because the screws mean I need high speed. For 15 mm^3/s, the main body has to rotate about 1600 rpm. Given that I want to use this extruder for high-speed printing, the main body has to be able to rotate at 6000+ rpm, which is way out of the range of okay speeds for stepper motors.

ReidDye

ReidDye

kristina panos

kristina panos

Alex Rich

Alex Rich

David Tucker

David Tucker

T. B. Trzepacz

T. B. Trzepacz

вы можете использовать термобарьер м6 у него внутренние отверстие на 4мм под тефлоновую трубку