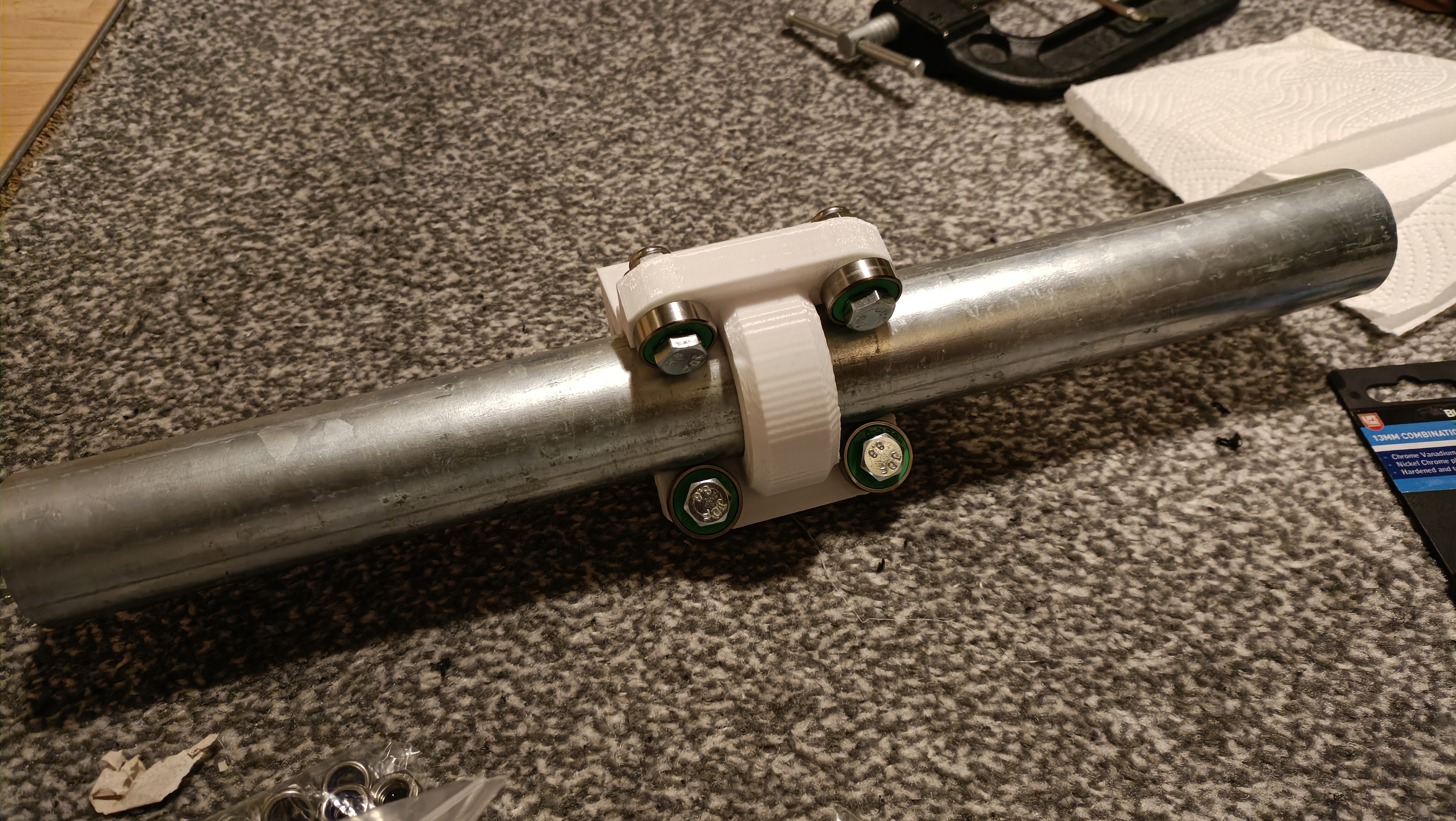

Seems that 42.35mm was a great first estimate to use for this part. Slides ok and very rigid. I'm going to need to improve my supports settings a tad though, as I had to use pliers, a file and a stanley knife to clean up the part.

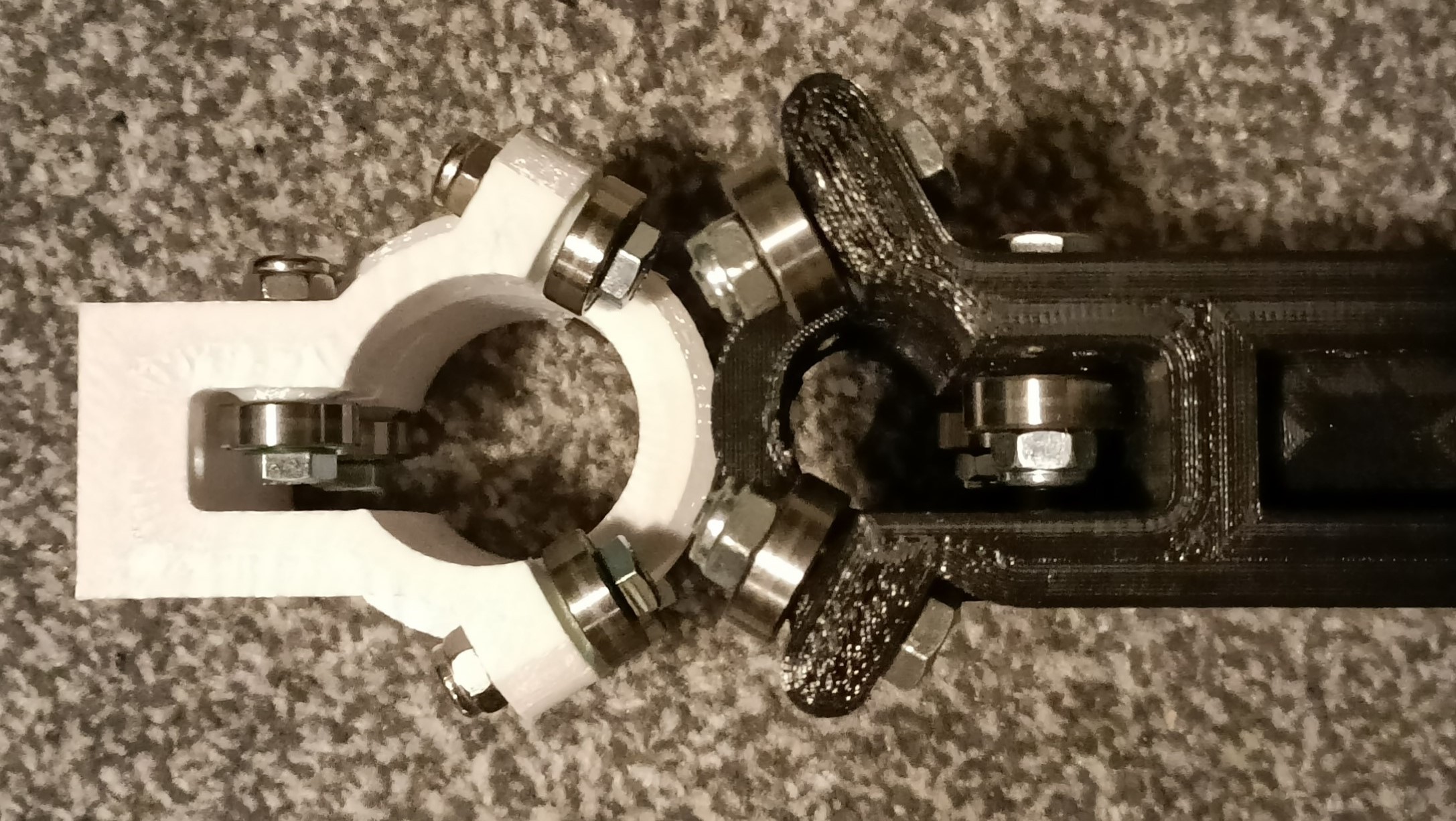

It's interesting seeing the difference between the current test version and one from years ago when I was working on the SecSavr Space.

It's interesting seeing the difference between the current test version and one from years ago when I was working on the SecSavr Space. Anyway, as it turns out, the shinier tubes I have are 42.7mm. They still work, but it's noticably harder to move and louder. I took some measurements and it was 52dB and 58dB for the matte 42.4 and shiny 42.7mm, manually trying to move at around 300 - 350mm/s. (the tube is 400mm so I was going from end to end in 1 second)

Anyway, as it turns out, the shinier tubes I have are 42.7mm. They still work, but it's noticably harder to move and louder. I took some measurements and it was 52dB and 58dB for the matte 42.4 and shiny 42.7mm, manually trying to move at around 300 - 350mm/s. (the tube is 400mm so I was going from end to end in 1 second)Lastly, I tried packaging tape on one of the matte tubes and there's a slight improvement in noise. Friction seems to have slightly increased too.

Oh and I tried detergent, wet wipes, iso alchohol and hand sanitizer to get rid of the oil that's on the bearings. A bit of it came off, but just rolling the bearings on the tube got it off. Now the bearings aren't sticky and move pretty nicely.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.