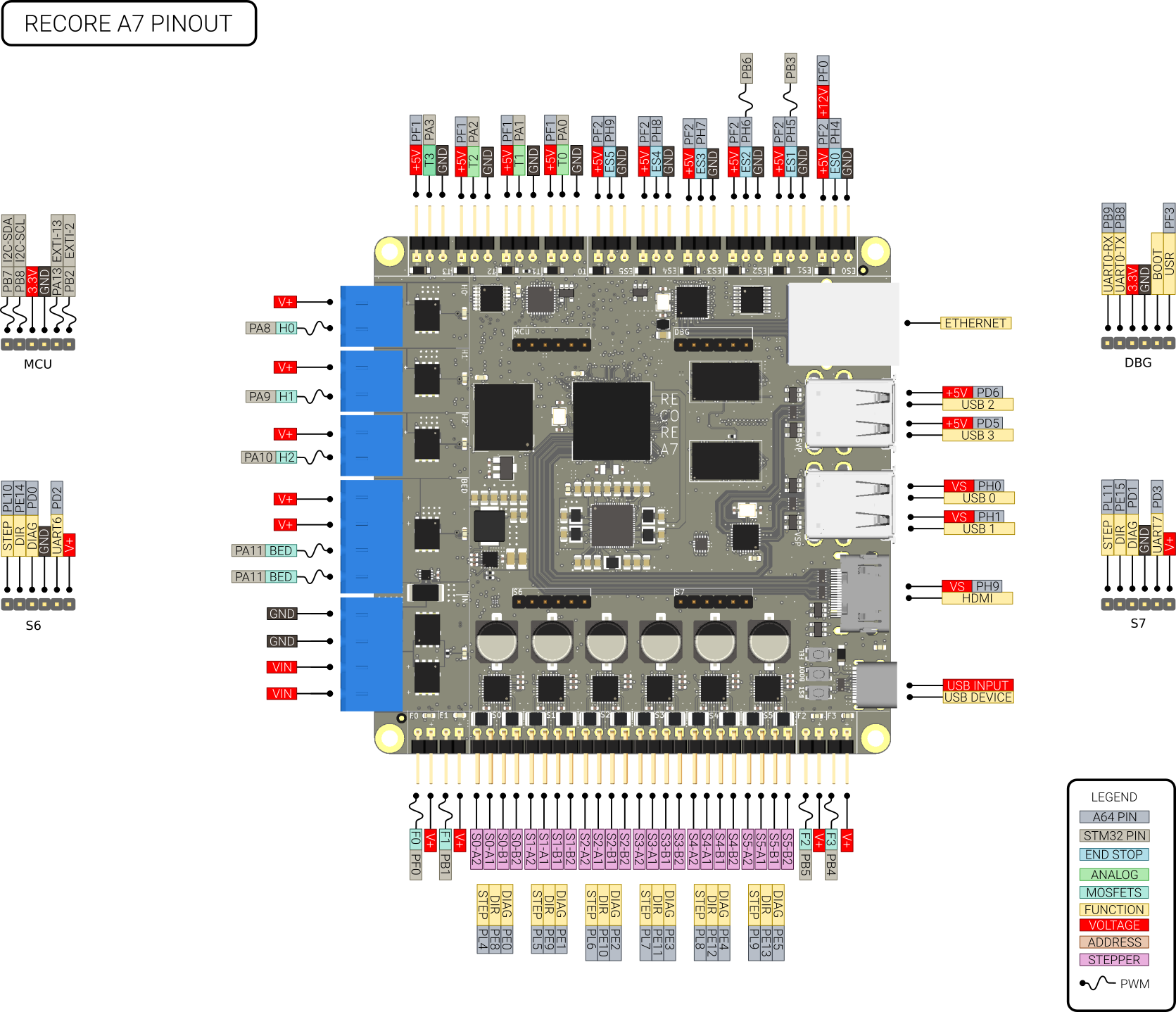

The PrintrBot is done at about 19" * 6" j* 6" for now. I have moved to another build of sorts w/ the Recore A7 and a Monoprice Maker Select Plus printer. Things are working w/ five steppers, a couple enhancements on the build from the older hardware, and it is way faster than the older model PrintrBot 1403.

So, w/out further ado, I would like to post my build if you are indeed for a controller and need a jump start...

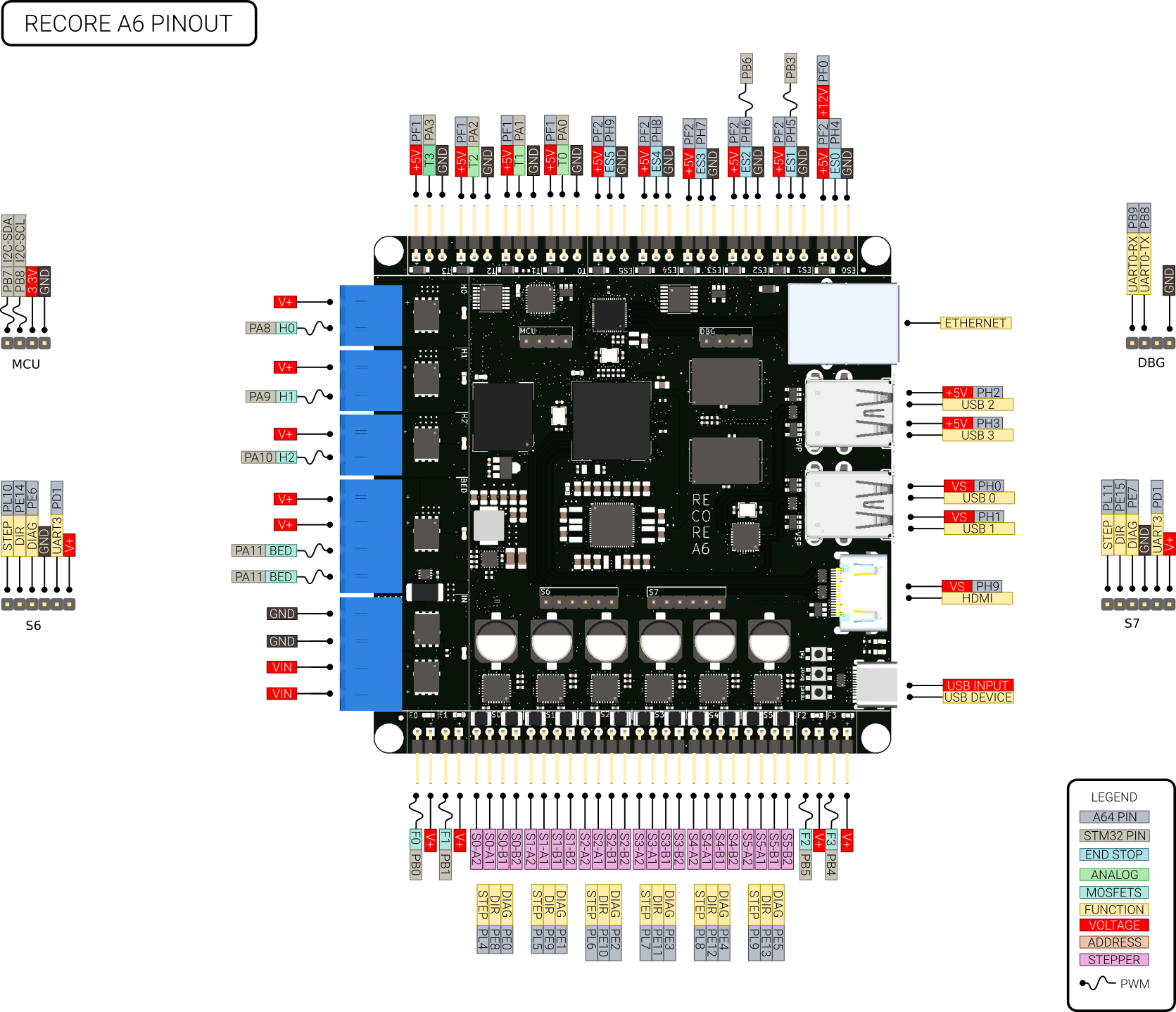

https://github.com/silver2row/Recore_Klipper_Configs.git is my github.com account w/ repo for the A6 on the PrintrBot and the Recore A7 on the Maker Select Plus 3D Printer.

Enjoy and share if noteworthy... I have been printing w/ PETG at a fast pace for sometime now. I like the extra build space and how this mostly metal printer is put together. Tough, sturdy, and full of issues. Got to fix it again...bbl!

Here is a small update. The printer, PrintrBot 1403 Simple Metal, has been partially upgraded. It can now print 19.75" * 6" * 6" or roughly 500mm * 152mm * 152mm. I am still working on the Y_Axis, i.e. as it needs to be equipped to handle the bed build environment.

So, the (19.75" ^ 2) and the Z_axis at around 6" is well in the realm of something I have not done before this time. Large build area on X and Y and something simple for Z. I have an either Capacitive Probe or Inductive Probe handling the homing and Klipper configs for the Z_Axis. Klipper is really some nice source for being able to print large build areas w/ large perimeters.

Although this older printer is very slow and nonmobile at the moment, it can print and to the extent in which I described earlier. I have learned some caveats of the Klipper firmware which has made printing on this printer and others very precise. I have actually been very surprised w/ the assistance of the Klipper people on their discourse and their knowledge of the docs, 3D Printing in general w/ specifics, and all around good service has helped me become more docile when enraged at my lack of understanding.

Okay. So, this is another attempt I have made to incorporate a Monoprice Maker Select Plus w/ Recore A7 controller into a full blown Klipper firmware enabled printer. It is faster than my 1403, e.g. travel and print speeds. It has a larger build environment which has enabled me to print hard to touch prints at such speeds. Now, I am sure there are more able printers w/ better do-dads and gadgets at higher expenses. I am not disregarding this fact. Both printers for me so far are much fun to the point I actually have built them up and outward in parts and so on.

I reached out to the Slice Engineering and Swiss-Micro. Both companies if not the same have had parts where I can basically tear down my printer, exchange matching parts, and switch some firmware sections in the configs, print, and then enjoy a relaxing beverage.

Also...

I went and broke some dear parts from Slice Engineering. I contacted them about it. I was not in the mood nor the market to get reimbursed or gyp the system. I wanted them to understand the complexity of my issue as it pertained to their parts. All in all, they listened and sent warm regards. Luckily, I ordered two of the throat-hotend-MK10 attached parts.

The MK10 seemed to be a popular make and model. Not so much from what I can tell. I have been savagely researching more and more USA MFG. in 3D Printing, smaller part manufacturing, that tends to learn towards what I have already purchased. Inevitably, I have found Slice and Swiss to handle most of what I already do.

Outside of those two companies, I found COEX3D. It seems they mfg, here in the states, filament and have access to an older Dupont filament of choice called Hytrel. Anyway, I do not normally handle such rubbery materials, i.e. as I print for rigidness while having a longer-lasting effect to the entire finished part.

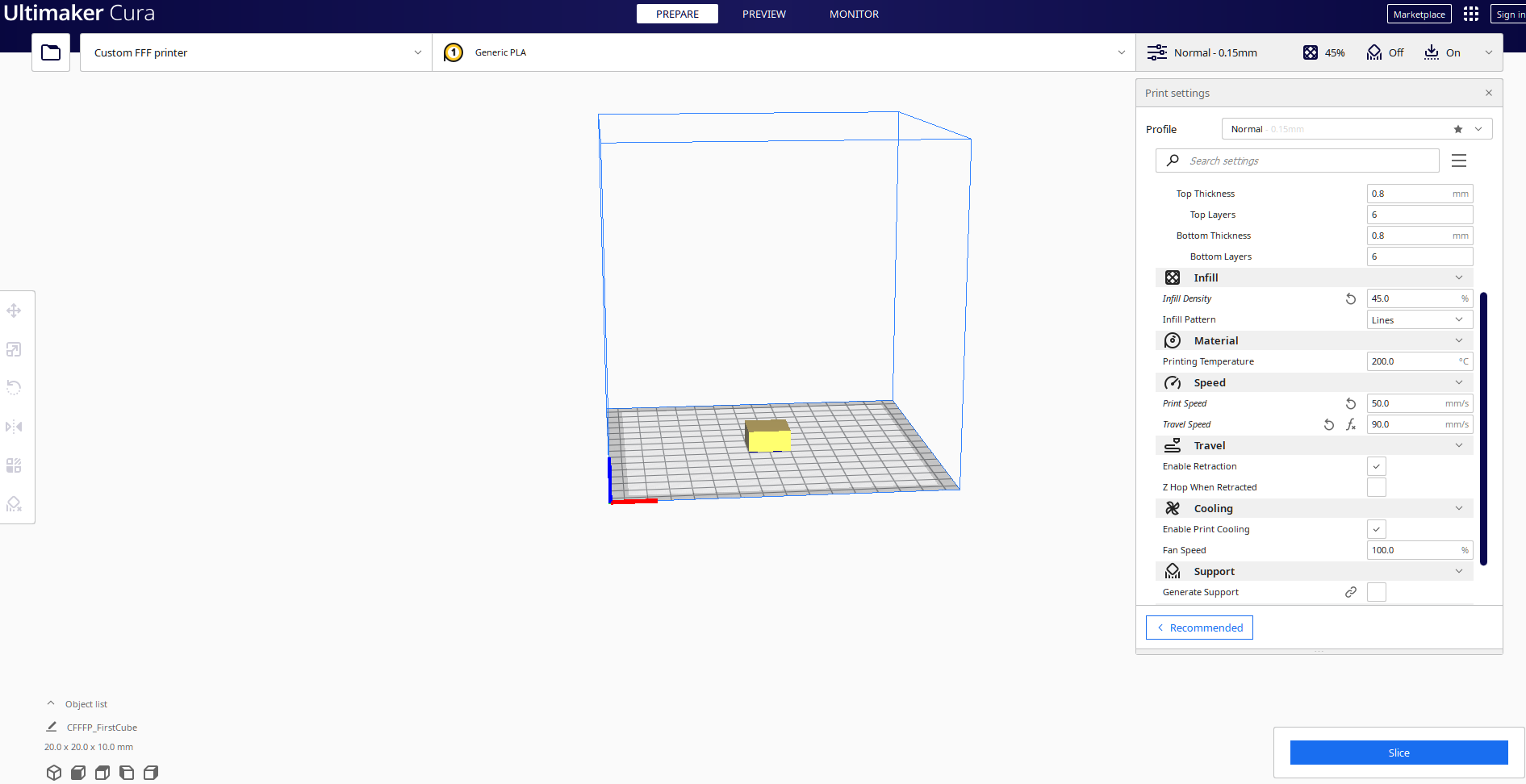

For instance, four to six bottom layers, a 45% infill w/ lines, and four to six top layers. Sometimes I double...

Read more » silver2row

silver2row

Mike

Mike

Timo Birnschein

Timo Birnschein

marble

marble

Finally tuning adjustments in my slicer CURA source and on the Recore via klipper should make for some wood craving ooze to be made. I have never printed in wood type spools. I cannot wait. Send rations.