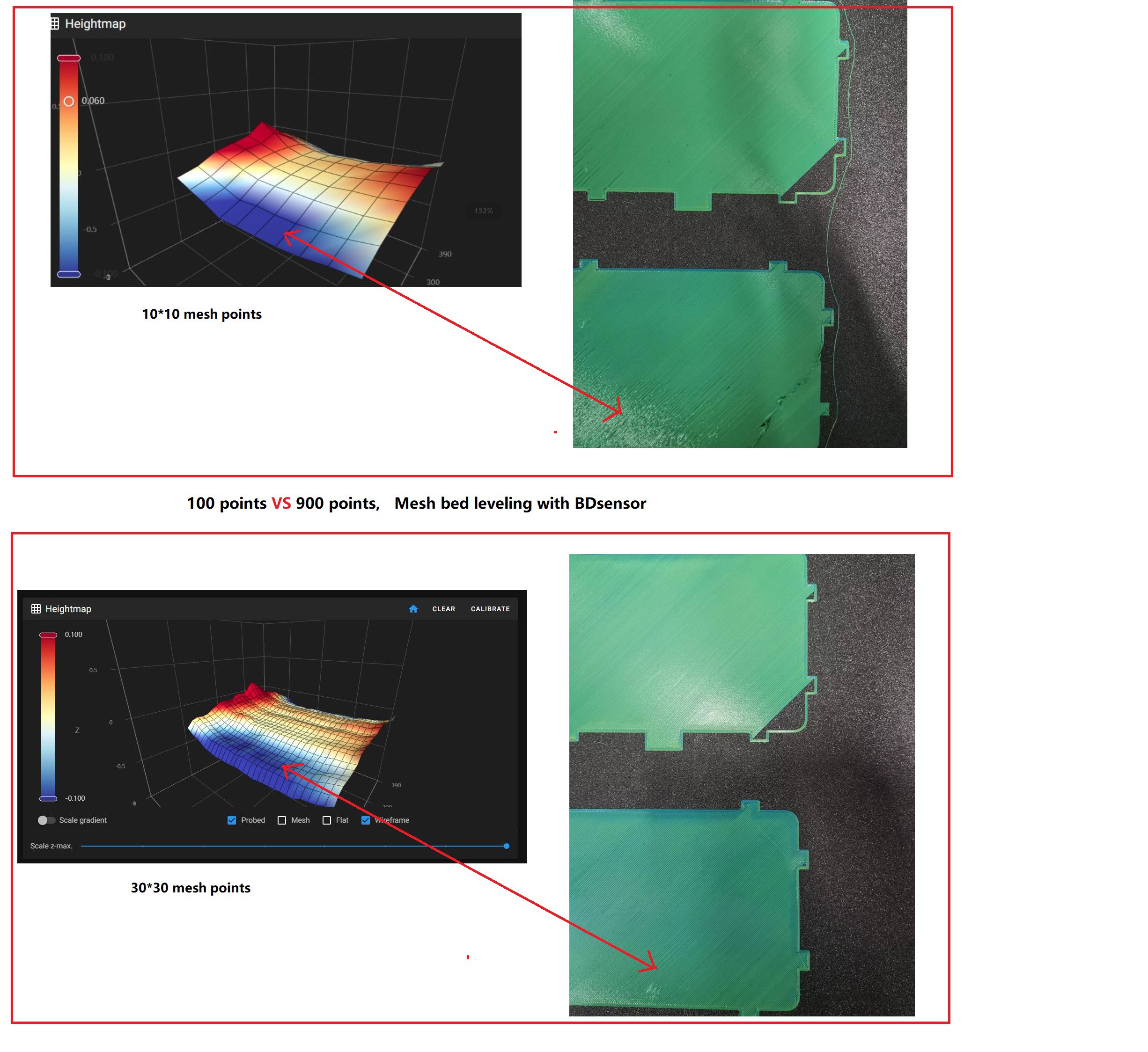

with this sensor the printer can adjust the z axis in real time if the bed plate is not flat in every point,also no need to do probe points before every print.not only the plate not flat itself but also the high and uneven temperature will also cause the plate to expand and contract.

you can do mesh bed leveling like normal proximity sensor but much faster with this sensor, because it's no z axis down and up at every probe point.so you can do more probe points in short time.

Distance resolution:0.01mm

Operating Range:5mm

Repeatability:+/- 0.005mm

Communication port: I2C

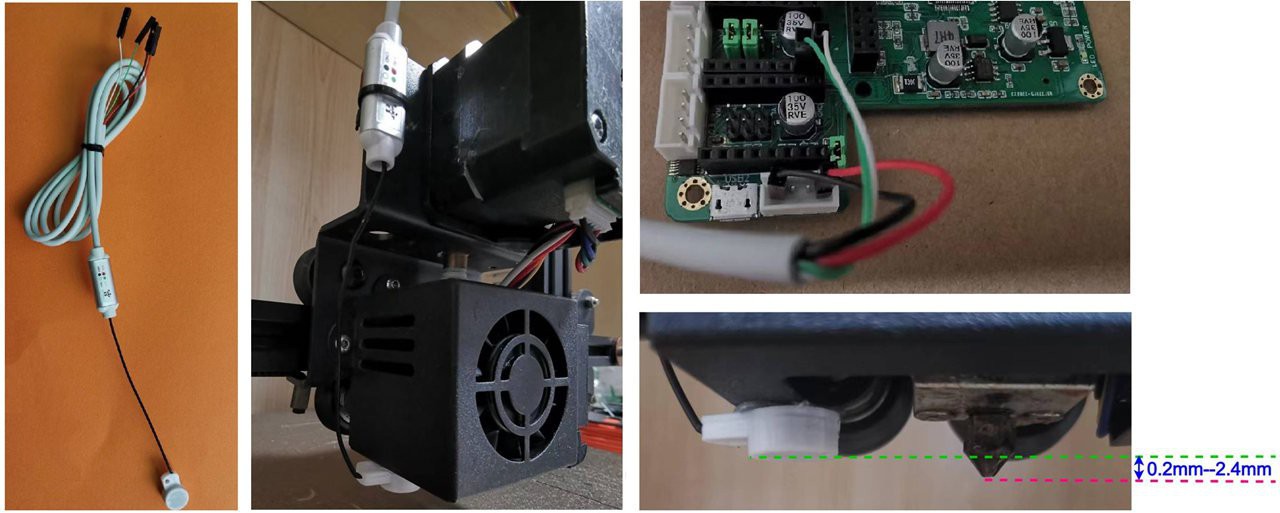

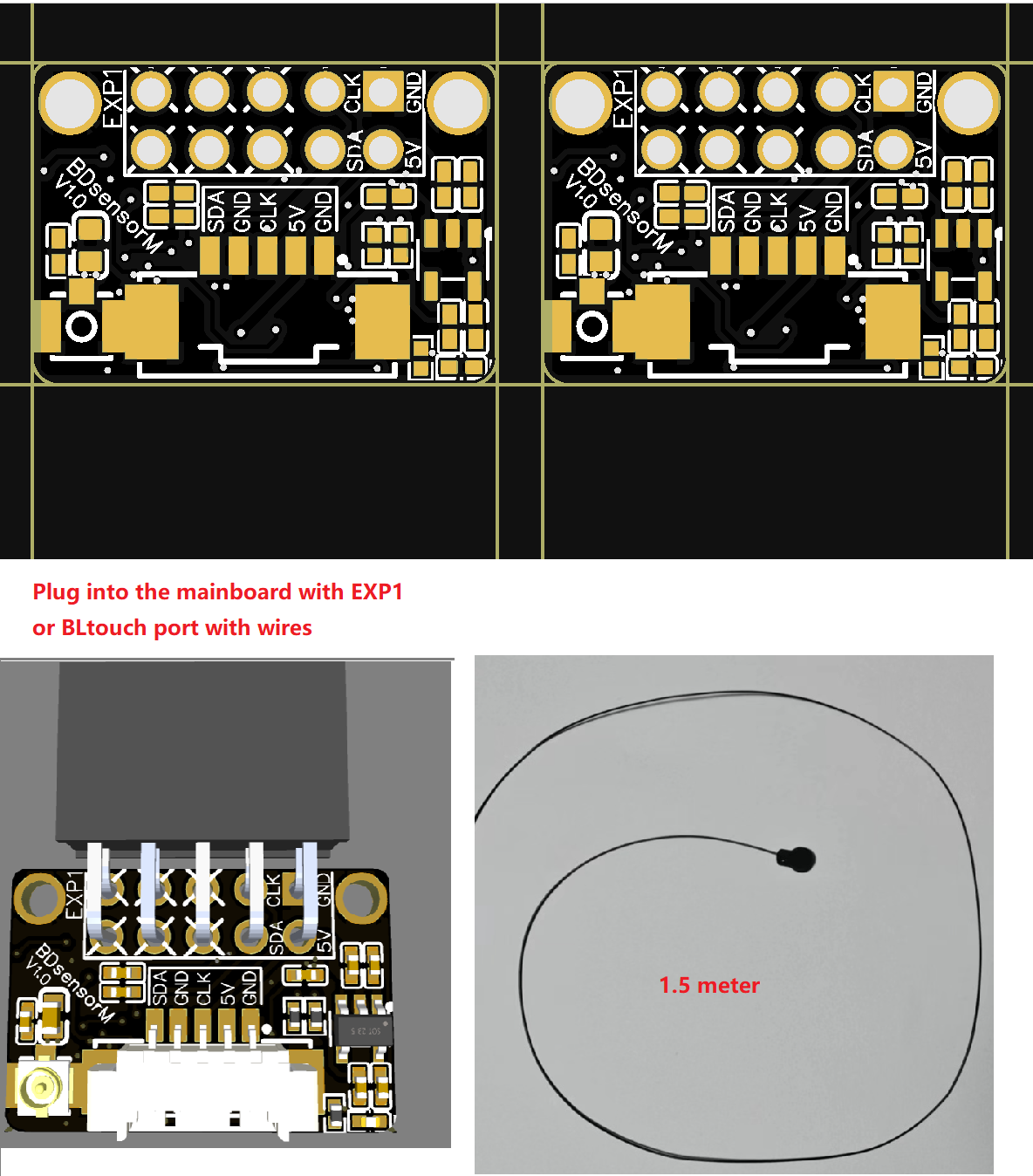

Connection| only 4 wires: GND,5V,I2C_Data,I2C_Clk

Calibrate:

Send gcode M102 to Calibrate, we need to calibrate this sensor before first use or the bed plate have been changed to different materials, Because different metal plates are made of different materials, they may have different electromagnetic properties. normally this process will take about within one minute in 3D printer

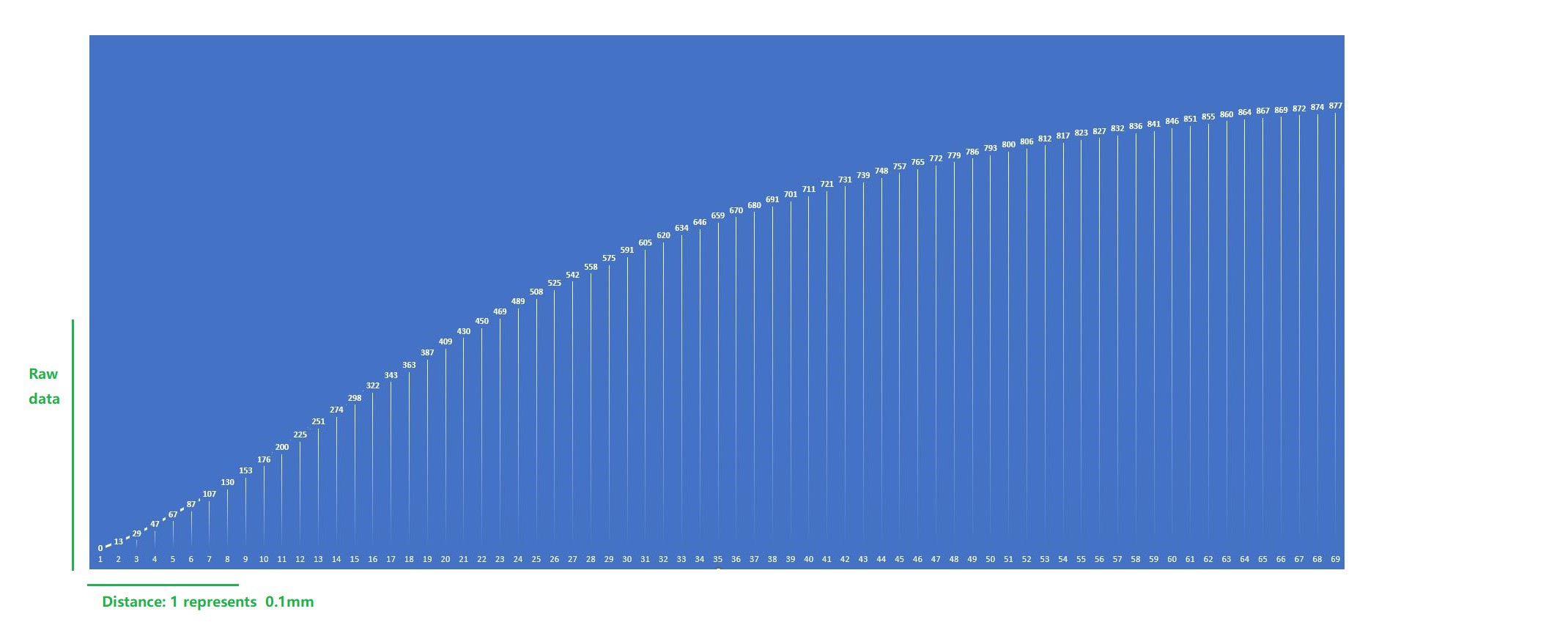

Here is the data diagram of this sensor, we can see that the distance resolution can be 0.005 to 0.01mm below the 5mm

mark

mark

Minimum Effective Dose

Minimum Effective Dose

CaptMcAllister

CaptMcAllister

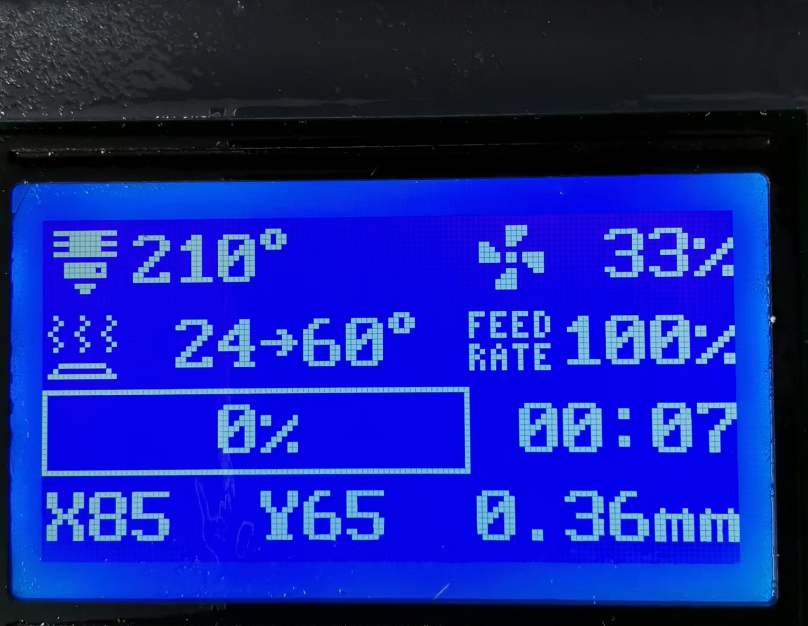

I bought one and installed it on my Ender 3 Pro. I used a customized mount that positioned it 15mm directly behind the nozzle. It calibrated fine, but when I attempted to level via G28, it only scaled the first 2 of five lines and froze the printer. When I attempted to print with the real time leveling (M102 S4), it started printing at 0mm (Against the bed) instead of the expected 0.2mm. I tried adjusting the Z Offset, but nothing worked. I'm at a loss.