Why am I doing this?

Wine is best stored at a stable temperature in the mid to high teens (Celsius). This is difficult to achieve when you live in a location where the temperature regularly exceeds 45 degrees in summer. Even a year stored in such conditions permanently changes the character of wine – almost always for the worse.

Fancy climate controlled wine storage cabinets are readily available, however these are expensive, inefficient and almost always prioritise aesthetics over function. I don’t want to look at my wine or show people how great I am. I just want to be able to drink it.

My priorities or storage are:

- Good storage capacity

- Reasonable price to buy / build

- Efficient to run

- Reasonable protection from damage in the event of system failure

Aesthetics is

irrelevant – it will live in a shed.

I believe that an upright freezer is probably the best option for conversion. It is preferable to a fridge because the insulation is thicker and thus it will take less energy to run. A chest freezer would also work, but it would be more difficult to access the contents.

Components

1.) The freezer.

For ease of conversion, I deliberately looked for a freezer with a mechanical thermostat. Conversion of a freezer with an electronic temperature control system should be possible, but replacing a simple mechanical thermostat is the simplest possible circuit.

The freezer I purchased on Gumtree was an Electrolux model EFM3001WA-X 300 litre upright, manufactured approximately 2013. It was in good condition with some minor cosmetic damage on the exterior.

Cost: AU$150

2.) Temperature Controller.

To replace the factory thermostat, I used a modular, programmable HVAC controller. These handy units combine logic, control relays, alarm relays and a temperature display in one easily installed module at a relatively low cost. Temperature is sensed using an external NTC temperature probe. I used a cheap RS Components “RS Pro” branded unit: model number 124-1056.

Cost: AU$140 each. For reasons explained below, I purchased 2 of these.

https://au.rs-online.com/web/p/temperature-controllers/1241056

3.) Temperature Probe

Suitable waterproof NTC thermistor probes with 2m cables were purchased.

I can’t remember exactly which ones I selected, but these are representative.

Cost :AU$10 each

https://au.rs-online.com/web/p/thermistors/1879306

4.) Alarm buzzer / light

An alarm light and buzzer was also required. The 240V one I selected requires a 19mm cut out.

Cost: AU$24

https://au.rs-online.com/web/p/electronic-sounders/8772015

Also required were an adaptable box, electrical cabling, cable glands and a couple of single pole relays and relay holders.

Total cost of these miscellaneous items would be less than AU$100

Modifications

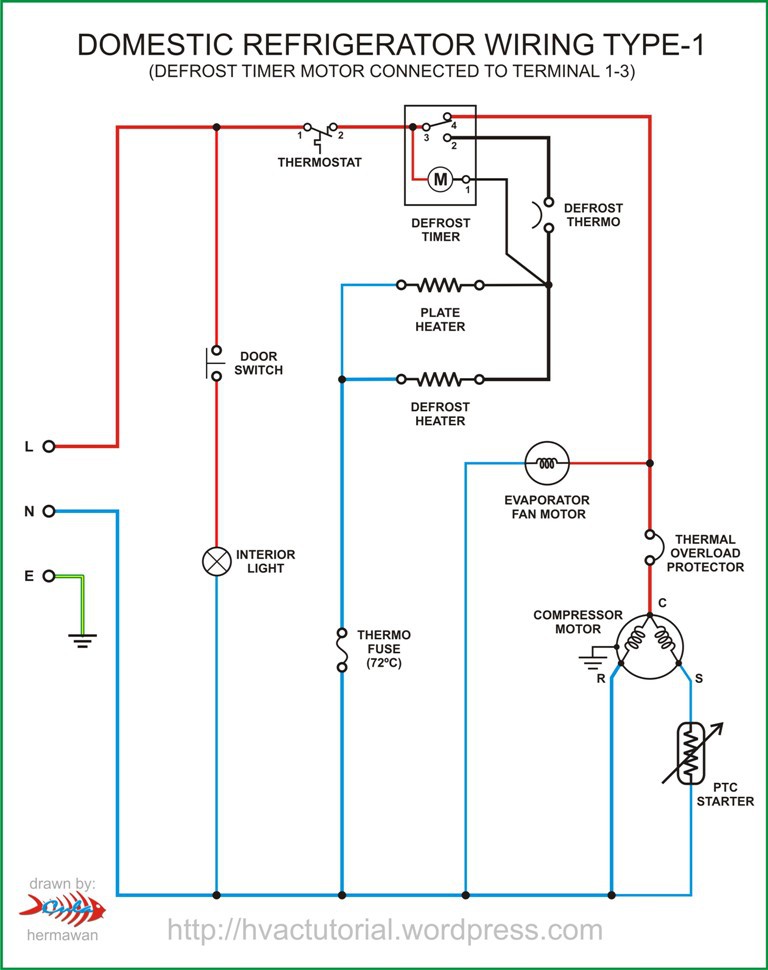

The original freezer circuit was essentially the same as this standard one:

Only two changes to this control wiring were required:

- Replacement of the mechanical thermostat with the programmable HVAC controller.

- Rewire of the internal fan (evaporator fan) to run continuously instead of only when the compressor is running.

1.) Thermostat replacement.

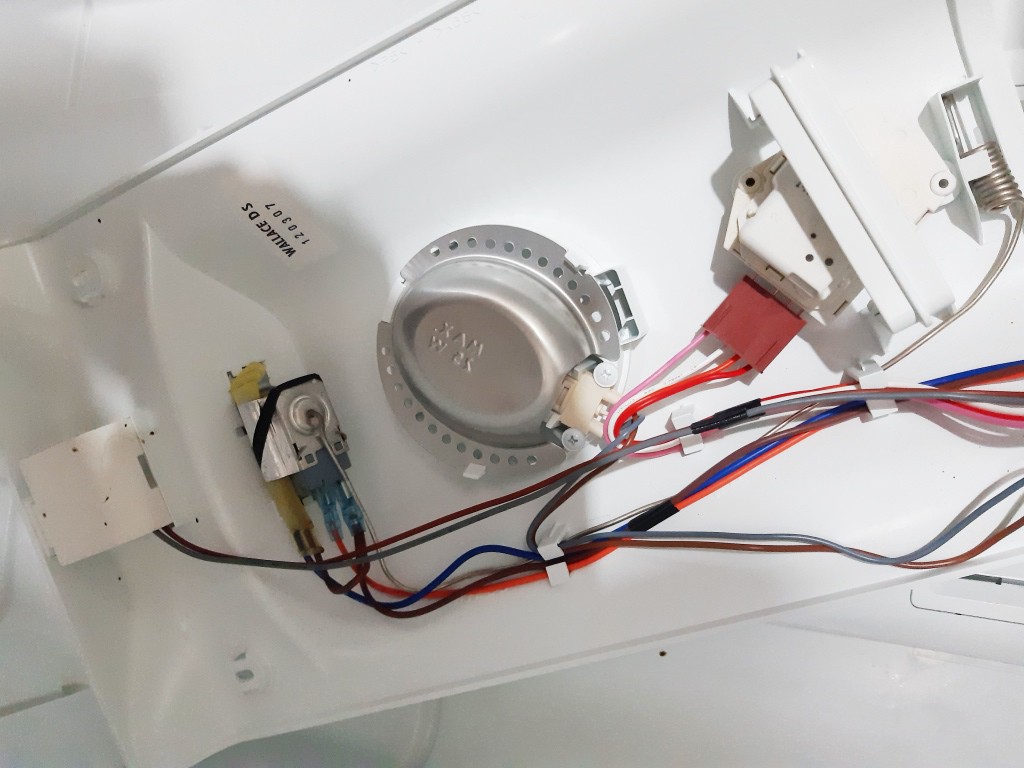

The simple design of this freezer had the thermostat, defrost circuit, light and door switch circuits all housed in a single moulded housing at the top of the compartment, making it nearly ideal for modification.

Connection to

the supply, compressor, defrost element and internal fan (evaporator fan) are by 4 x modular plugs built into the main fridge body, making it relatively

easy to remove the entire control compartment to do the work.

The final design uses 2 x interposing relays for control of the compressor and these were easily accommodated in this control compartment, along with a “chocky ...

Read more » Mild Lee Interested

Mild Lee Interested

Andrew Shevchuk

Andrew Shevchuk

Tim Bishop

Tim Bishop

Jeff Thomas

Jeff Thomas