With a 2in1out nozzle you get a dual colored extrusion with one color at each side. Same toothpaste effect as with di-chromatic filament, here is a video showing the effect.

So the color of the print becomes view dependent because different colors facing the outside of the perimeter.

By "rotating the nozzle" you can control which colors end up on the outer wall WHILE printing. So any angle between 0-360 gives you a slightly different color even though you are extruding with a constant 50/50 mixture. This Halftoning effect could be used for very quick color changes without any purging of the nozzle.

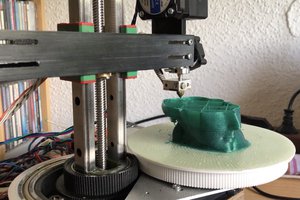

Idea here is to rotate the bed instead of the nozzle to avoid rotating the whole hotend assembly.

Also the bed can freely rotate >360degree...the drawback being that you have to do additional compensation moves in XY for every new angle introducing a small pause.

First had the idea when seeing one of these waterjet cake cutters that use 2 belts to rotate a gear.

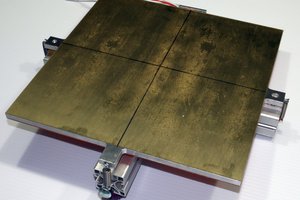

Then tried Nuri Erginer PnPAssist design using two leadscrews instead of belts, liked the idea of the leadscrews being rail and drive at the same time, but for my case I needed something faster for the compensation moves.

Settled for something very similiar to Nuri's v2 of PnPAssist.

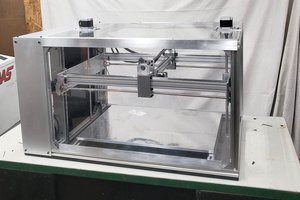

It's an H-bot design with one linear and one rotary axis. (thang010146 illustration to the rescue)

The frame is from a Cube3 printer. Very nice and minimalistic printer design from 3D Systems.

Once the plastic chassis comes off, you are left with a machined Alu frame, branded Mgn9 rails,

Gates belts, removeable magnetic build plate, belted Z axis, 24v power supply (only 5A, no heated bed), and a super mini 25x25cm overall footprint.

Not bad for a 2013 consumer machine. A premium kit (ebay 200$) if you are looking to build your own printer.

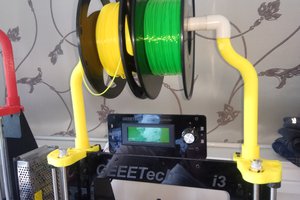

Original extruder design is pretty strange and is integrated into the filament cartridge itself including the nozzle that gets plugged into the heatblock with every new cartridge. (nozzle looks like a 3.5mm audio plug, see gallery)

Extruder motors are part of the printer luckily, 2x big nema17 motors actively cooled with two radial

blower fans. That's the price for having a throwaway and ungeared extruder, I guess.

I switched the original y-axis with the H-bot mechanism that holds the bed. So Y axis consists of Y and A now.

It runs Marlin 2.0 configured with an addtional rotary axis. Marlin currently supports up to 6 linear axis.

G-code and texture to angle mapping + compensation moves for the rotation are done with an unreleased part of the nozzleboss add-on, so no firmware integration.

While looking into rotating nozzles I came across this share-worthy variable width rotating nozzle.

heinz

heinz

Shane Hooper

Shane Hooper

Mark Rehorst

Mark Rehorst

Nice call to share that Sculpman hotend. Shame that they are only in contact with companies and thus would never see the llght of day outside a one-off industrial printer.