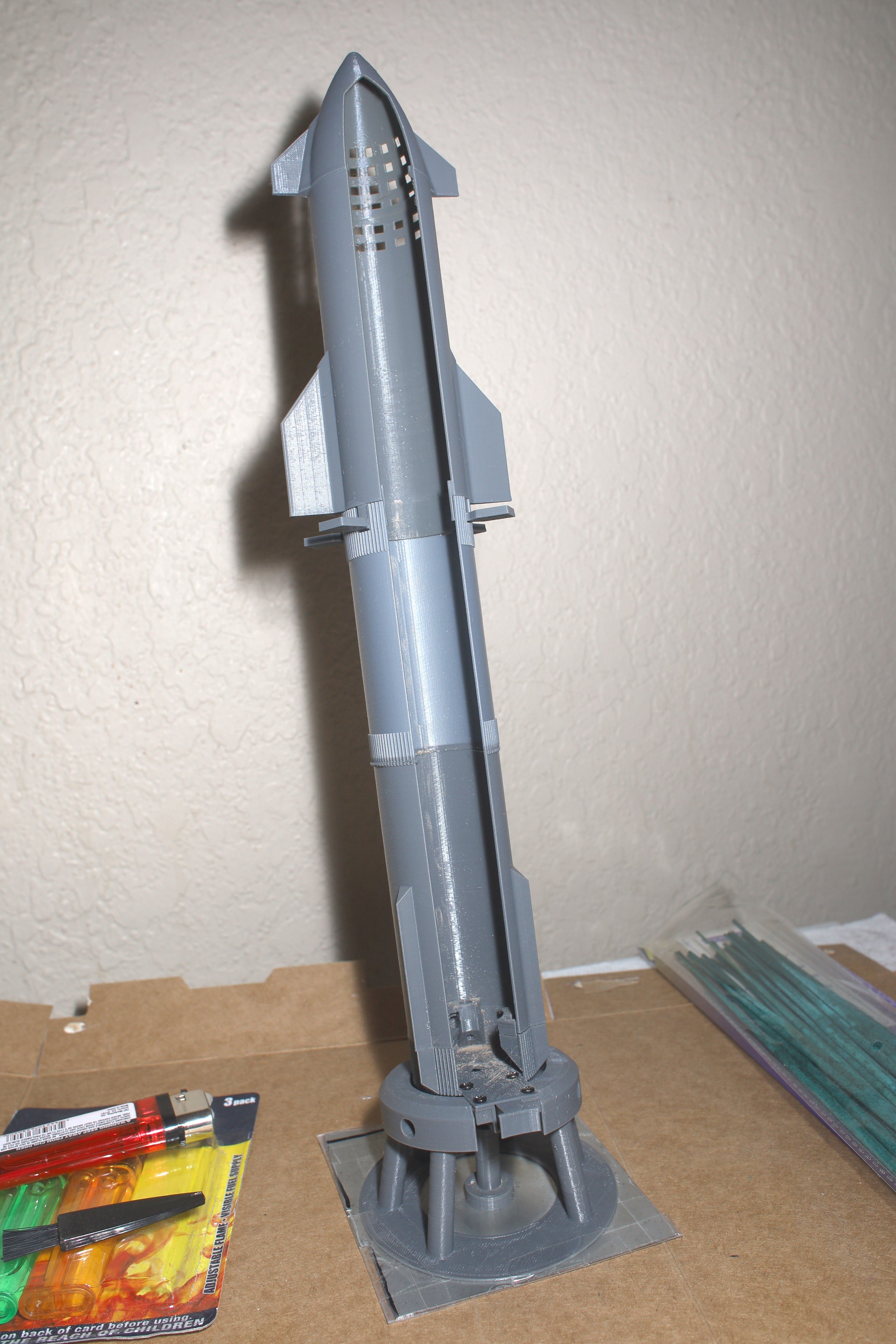

Starship incense holder

Making frankincense multiplanetary

Making frankincense multiplanetary

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

The reduced odor from this design has been a growing problem. The nose cone tends to collect essential oil instead of letting is pass through the holes. The latest theory is to make the ship part optional or leave it out entirely. It would just be a booster. Since the booster has expanded with a hot staging ring, it has enough detail to stand on its own. It would have to be expanded to cover the entire incense height & require a new launch mount.

Another option is creating the smallest possible hole in the nose cone to allow all the fumes out, then cover up more of the side. The nose cone tends to create a pool of fumes. It would look like 1 of many lunar lander prototypes. This ended up still pooling fumes inside the nose.

Another option is creating a ramp inside the nose to direct the fumes out instead of pooling. This would make it top heavy. It almost needs a ramp system of some kind to guide the fumes out.

There's also angling the existing design 45 deg so the fumes just rise vertically. This increases the risk of outside air blowing the ashes.

--------------------------------------------------------------------------------------------------------

A growing fascination with the starship lighter made lions ponder how such a thing could be incorporated in the incense burner. Obviously no-one is going to tear down a $175 lighter. So much of the exterior is cut out for the controls & air intakes, it's easier to imagine gutting the entire side to stick in a $10 pen torch.

The 2nd stage of a starship incense burner could be a lighter like this while the incense burned in the 1st stage. Maybe you could stack it while the incense burned & destack for lighting. It would need the right air passage to direct the odor out, otherwise it would have to be destacked for burning.

Once the butane ran out, it would be very expensive to refill. That's the mane problem. Lions have used $1 lighters for 20 years. Then, there's the problem of what the purpose is of wrapping a butane torch in a starship enclosure. It wouldn't save any space because instead of a pile of lighters, there's a pile of butane refills. Using a starship shaped thing for lighting a starship incense burner has a certain appeal, but the enclosure would have to be somehow essential for the function of the lighter rather than being a model with a lighter stuffed inside. Maybe another starship model could be a storage container for a bunch of $1 lighters.

There are butane refills of a certain size locally

https://www.walmart.com/ip/Ronson-78-gram-Butane-Fuel/31954646

Finally got around to documenting how to use a starship incense burner.

Another curved incense stick showing the best way to orient them.

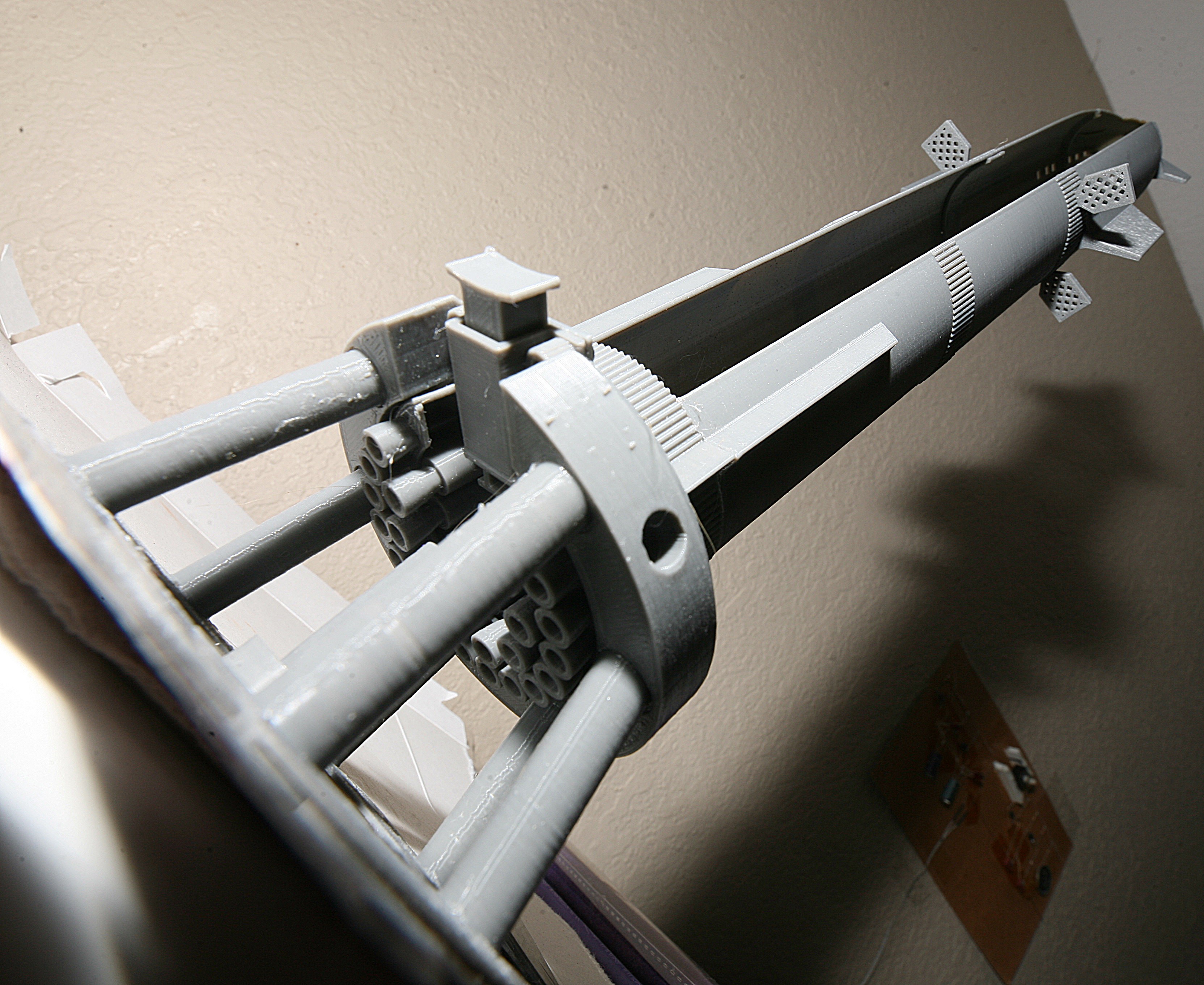

Another thrust structure is printed after another meltdown. A rare stick burns all the way down & melts it. Some brands always burn to the bottom. It's 1 peril of PLA incense burners. It has to be disassembled & reshaped with the soldering iron.

The leading idea is wrapping the stick in some kind of tape to try to stop the flame before it reaches the bottom.

Scotch does indeed stop the flame, but it's yet another step in addition to cleaning after every stick.

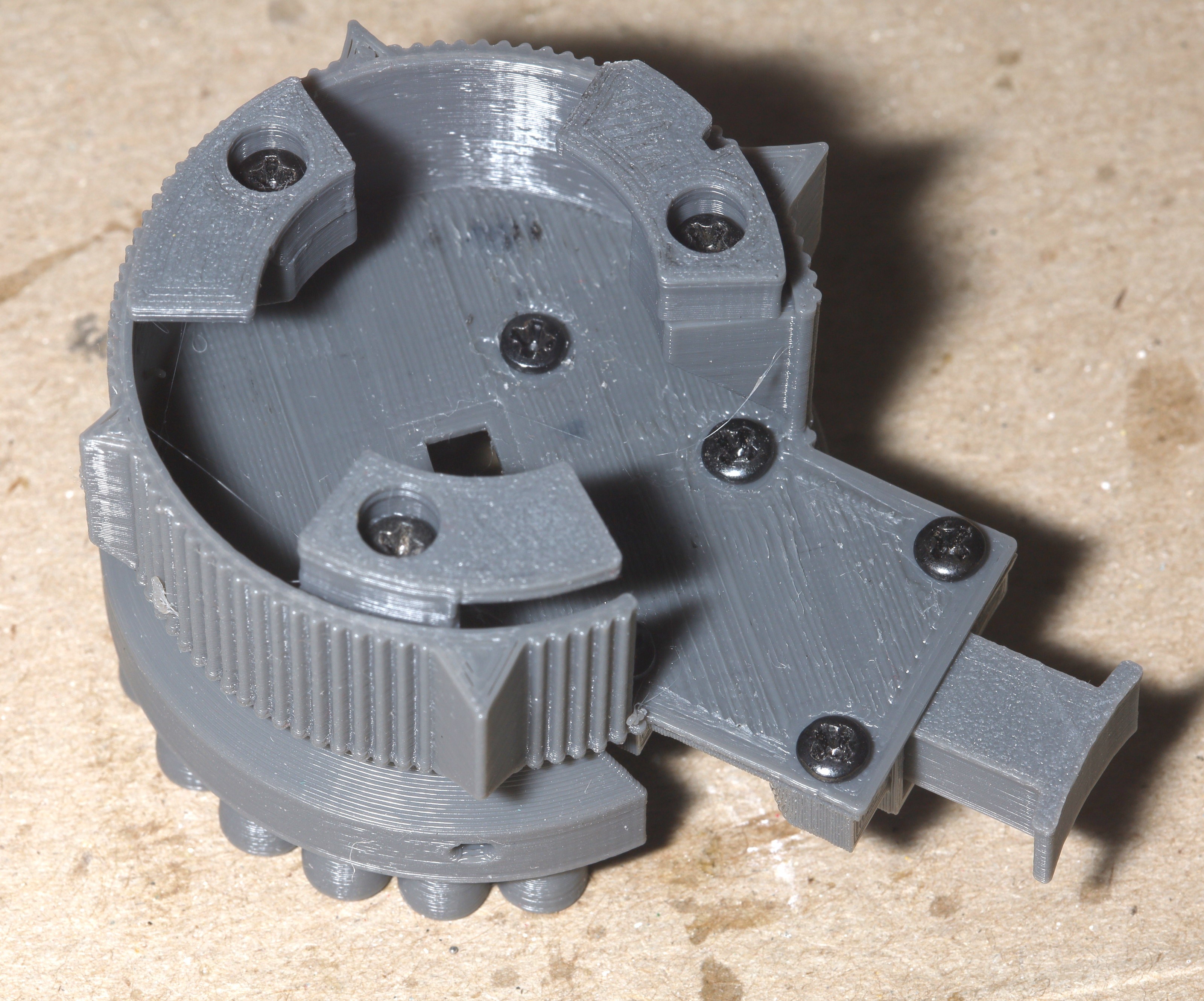

The latest thrust structure has more aligning fiducials which aid in aligning the tabs, but still requires the mark 1 eyeball for perfecting the angles.

There is a desire to get rid of all the farsteners. The plunger has to be removable though.

The final frontier might be Mars, but the final frontier of incense is the backflow starship incense burner. The concept is backflow incense & LED light creating the illusion of an exhaust flame. 3 problems emerge. There's obviously the heat of the cone. It would need a heat shield, maybe a metal plate. The smoke comes out as a narrow stream.

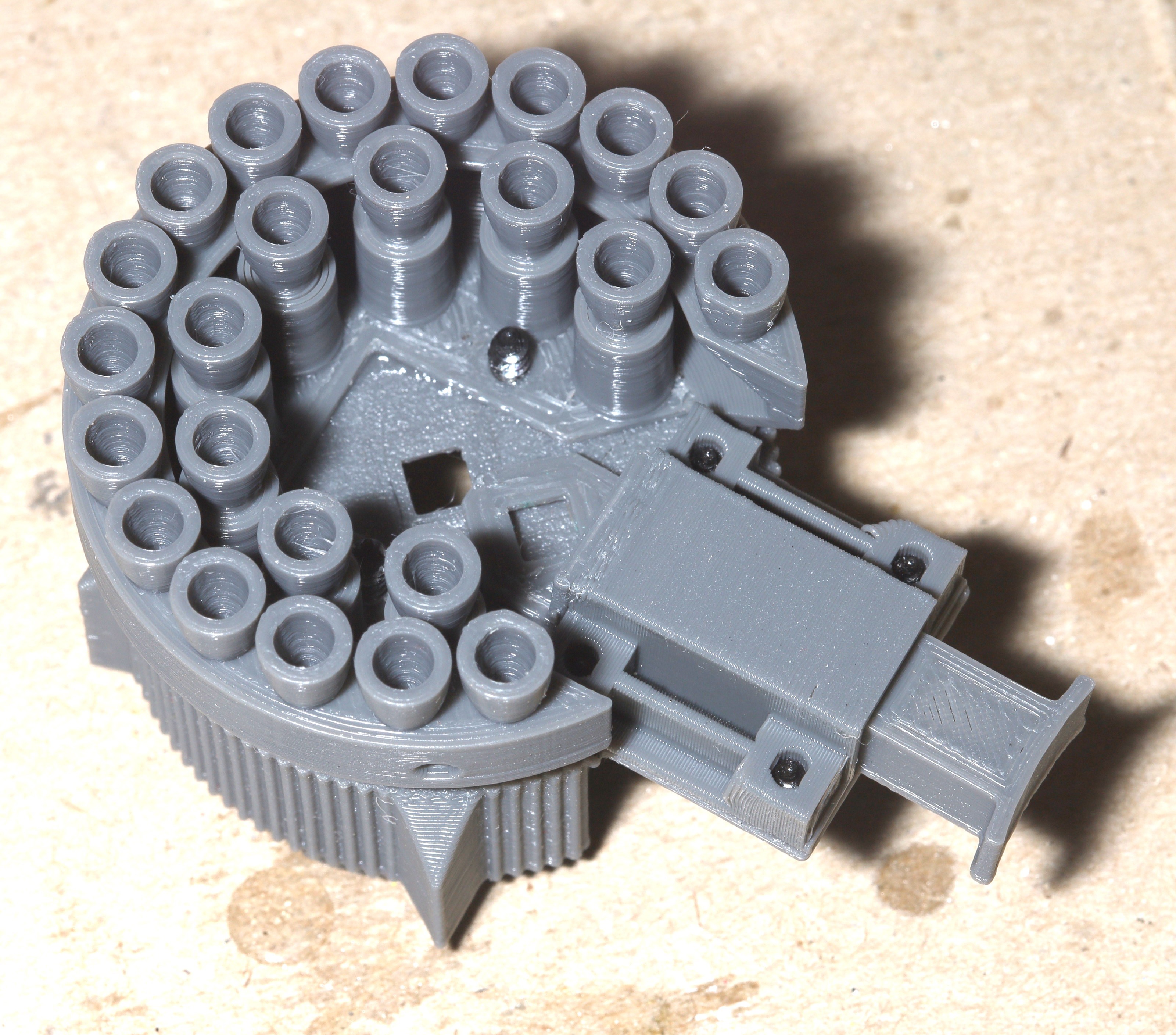

The typical incense holder has most of its structure devoted to spreading the narrow stream into a waterfall. They pool it 1st, then the pool overflows in a wider stream. In the case of a starship, the incense would burn in the 2nd stage. The 1st stage would contain the diffuser, maybe diffusing it into exhaust streams. It probably can't hit 33.

Then, the ambient airflow is going to blow the smoke away so it needs a wind break.

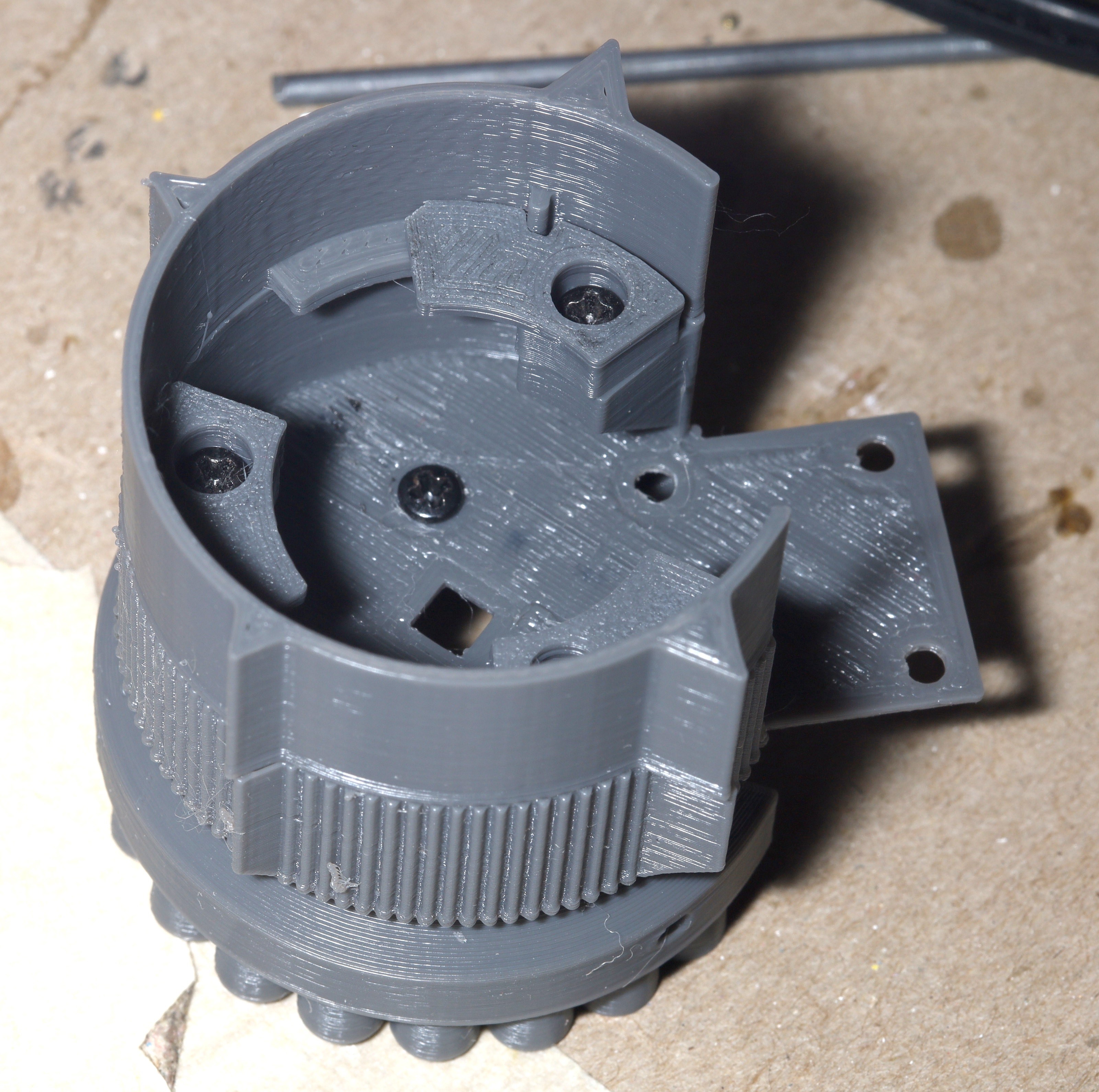

A completely encircled thrust structure is required to contain the ashes. It might even force the ashes to the back. There's a strange flow of air currents.

The curved incense sticks have to be put in sideways to catch the ashes. Sticks which are too thin to stand up have to be doubled with a toothpick or wire.

Light the incense by 1st fully assembling it, then using the manipulator to angle it outside. Light it & use the manipulator to angle it inside before it drops ash everywhere. Many a lion has accidentally left it outside after lighting it, leaving a pile of ashes outside the starship.

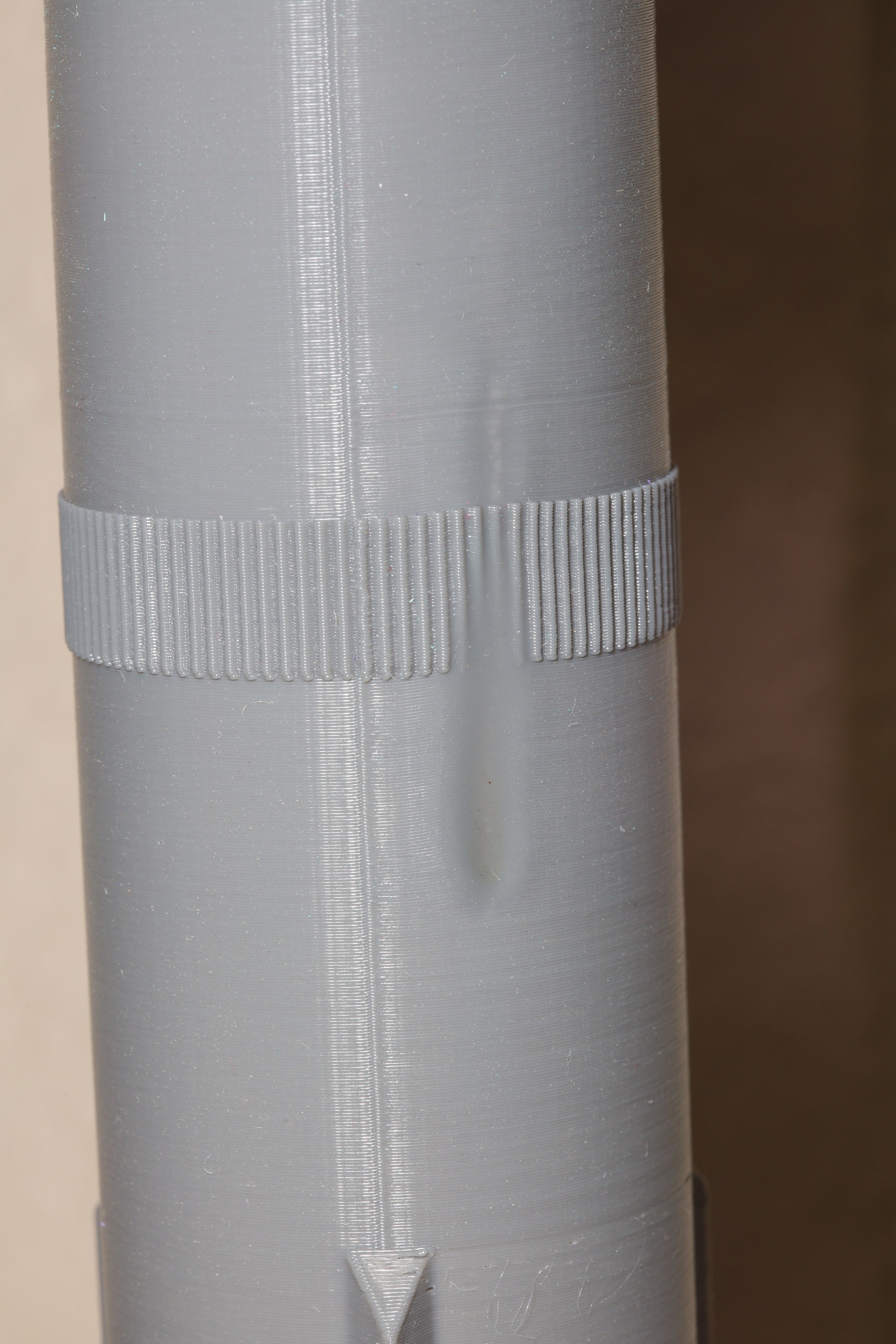

This one has a notch allowing the rocket to lock by rotating. It's the most convenient of all tab designs & doesn't accidentally release.

This one has a notch allowing the rocket to lock by rotating. It's the most convenient of all tab designs & doesn't accidentally release.

The thrust structure was cut open to allow ash to be poured out without destacking. It still doesn't all come out without destacking & it's not as visually accurate. It still has to be destacked to change incense sticks.

Periodically, ashes fell outside the thrust structure so that was a fail. It needs to be a complete circle.

The leading idea is 3 tabs which rotate into slots. The problem is progressive stretching of PLA, printing the tabs with supports & enough precision. There could be horizontal tabs which screw into the existing magnet positions. As the tabs wore out, they could be replaced. It would eliminate the supports. It's all a bit janky without metal.

A few printouts had problems staying in place. The tabs aren't big enough to flex into locking notches. A spring would be required for a rotating mechanism to stay in place.

It became clear over many prototypes that the booster can flex. Instead of rotating, it could flex to insert the tabs into the slots. It's just never going to be tight without springs or magnets. There could be spring loaded ball bearings in front.

The trick with the flexible booster concept is to 1st insert the rear tab while putting the front tabs on top. Then insert the front tabs by bending them out. Remove the front tabs 1st by bending them out & putting them on top. Then press back to remove the rear tab. How long it lasts is a matter of experimentation. It may be that the tabs can be a lot less aggressive. It takes 13 hours to print a new rocket with different tab sizes. A temporary adhesive might get it down to 8 hours. The chines don't line up as well as they did with magnets.

The tab mechanism was a pain with a fully printed booster. There's no way it would be practical with incense loaded. The booster tabs can't be less aggressive because they stick to the bed.

Less aggressive tabs can be printed in for the thrust section without reprinting the booster. Another idea was making the bottom tabs rotate into position, but the screws would loosen. The screws can be temporary, since the thrust section isn't hard to print.

A new single piece engine section with temporary screws for gluing was finally designed. It was surprisingly indistinguishable from the multi piece engine section. The temporary screws leave holes which can be filled with hot snot.

The ship was glued without the booster so the booster could be reprinted. The booster might actually stay attached to the grid fins without glue or with hot snot. It stays pretty attached with friction.

A slightly modified tab section was printed to make it easier to get the booster on. It may eventually be easier to leave the rocket permanently stacked if a bigger hole for the ashes is designed.

The correct chines were designed.

The accumulation of ashes on the magnets has been a growing problem. Living on an iron planet, everything that burns contains iron. A snapping mechanism would be nice. Maybe there could be another spring mechanism. The easiest solution is to never destack the booster. Empty the ashes & replace the incense sticks with the booster stacked. It could be printed in 1 piece to make accessing the full stack easier or it could use more permanent, non magnetic farsteners. A brush would be required to clean it when stacked but it already requires a brush to clean the magnets. A test might be gluing the full stack.

Helas, it's not practical to change incense with the booster stacked. It would need a tool. Emptying the ashes would make a mess. There are twisting tabs which could take less room than magnets.

No more melting & no more sticks have burned to the bottom so far, but some have gotten close & they always burned to the bottom before the starship.

It does melt. There could be an inner liner of some kind.

When it burns all the way down, as many sticks do. It really needs metal parts.

Backlit when the incense is half burned is where the venting happens.

Anyways, the windows & the pointiness got unbearable so a new 10 hour print began. It's always going to be an approximation because the real thing constantly evolves & burning incense has certain needs. Some ashes were going through the windows so those got raised.

It would be easier if the ship was removable, but it would be heavier. It would be nice to remove it from the launch mount without screws, but it would require more magnets.

Tilting it slightly proved very effective at containing the ashes, except when it was facing into the wind. Facing into the wind causes a few flyaways. Tilting it 20-33 deg would totally eliminate the ashes. The problem is attaching the 2 segments when it's tilted over 20 deg. The top has to be removable to light it. Magnets wouldn't do the job. A hook mechanism would be wobbly. A spring loaded mechanism would be complicated & detract from the visual appeal.

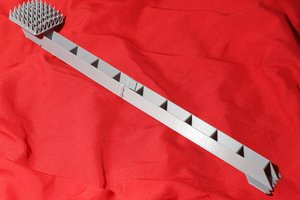

The next item is adjusting the angle of the incense. Part of the plan is integrating the top of the clamp into the rocket to avoid trapping ashes in it. The bottom clamp is a V pocket that moves to adjust the angle of the incense. It's stuck to the floor of the launch mount by a magnet. The launch mount would bolt onto a metal platform.

The updated clamping should allow more engines to be modeled, but the aft dome was manely sacrificed to the incense clamp. It turned out the ashes stick to everything no matter how curved the aft dome is.

The upgraded thrust structure with 24 of the 33 engines & clamp was a lot harder to build. It could have been a lot easier by using a larger section of infilled PLA. The aft dome could easily be flattened, allowing the engines to be printed as 1 block of infilled PLA with temporary farsteners to align it with the aft dome. Instead, 3 PLA sections are glued together & it's all very fragile. There's a lot of void space which can't be cleaned. Normal animals don't even bother with temporary farsteners. The thrust structure is hidden inside the launch mount so it's really more about complying with injection molding requirements than anything practical.

The spring mechanism was optimized to a point. It wants to break off when the spring is tensioned & probably has to be made bigger.

Note to future lion that flush magnets can't be installed by paw. The only way to get them in is by pressing them in with a knife & sliding the knife off. Lions have been struggling to hot glue flush magnets since 3D printing began. The magnet place needs .5mm extra radius & 1mm extra depth for the hot glue to flow. Trying to install them by paw just gets them stuck diagonally.

Another struggle has been reducing the amount of material in the launch mount. The giant donut needs a top plate for visual appeal, an inner plate to bolt the rocket on, a bottom plate to glue the stilts on, & an outer plate for visual appeal. That makes infill the cheapest solution. The injection molding technique would involve gluing the bottom plate on a hollow top 3 plates.

The stilts could be hollow, but infill makes them a hair stronger. They get a lot stronger by gluing to the donut.

Double sided tape was the easiest way to stick the launch mount on a sheet of tin.

Magnetic V pocket worked quite well to align the stick vertically. It only takes a small motion & the piece is stable. No XY table or screws are necessary. You wouldn't want to move the entire launch mount around the V pocket since that would take more tin.

The object of the tilt was of course trapping ashes.

The final tilt ended up 10 deg. Looks like it's venting in this one.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

lion mclionhead

lion mclionhead