The keypad that came with the desk is an angled membrane deal which is truly terrible. This interface was fine, 8 hours a day in an office. 16 hours a day at home, it matters. The membrane buttons don't want to stay pressed. Any glitch entails a 1 second delay while the relays click off & on. The desk is constantly switched between working, sitting, eating, & yoga pad heights. It's become clear that 4 presets are essential. Presets are a substitute for better buttons.

Uplift's cheapest keypad with tact buttons & presets is $40. The OEM keypad is on alibaba for $25 in quantities of 100.

https://www.alibaba.com/product-detail/Jiecang-JCHT35J-LED-display-4-memory_60590462942.html

The lion kingdom acquired 4 desks to build out its standing desk empire & they all need upgrades. Spending $160 to upgrade all 4 is unaffordable.

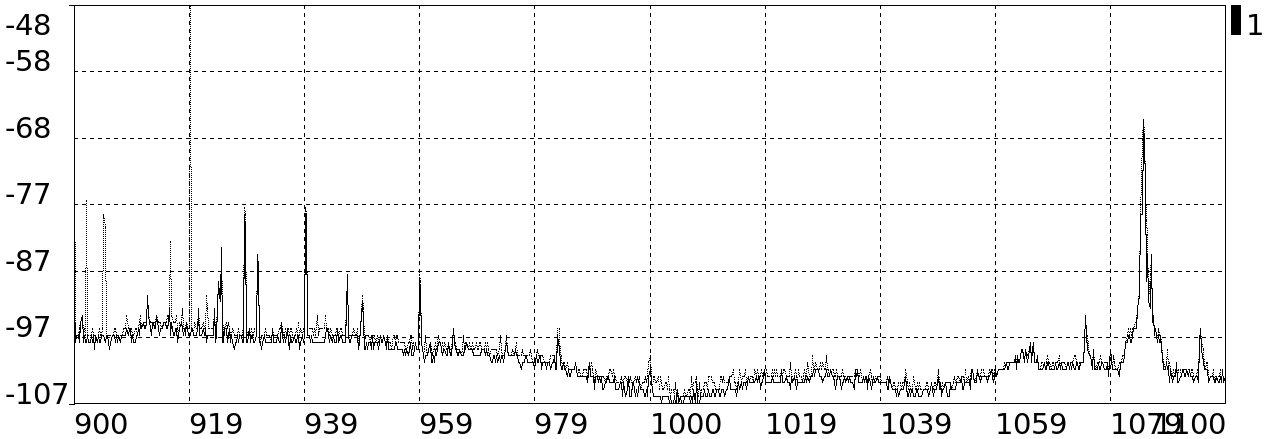

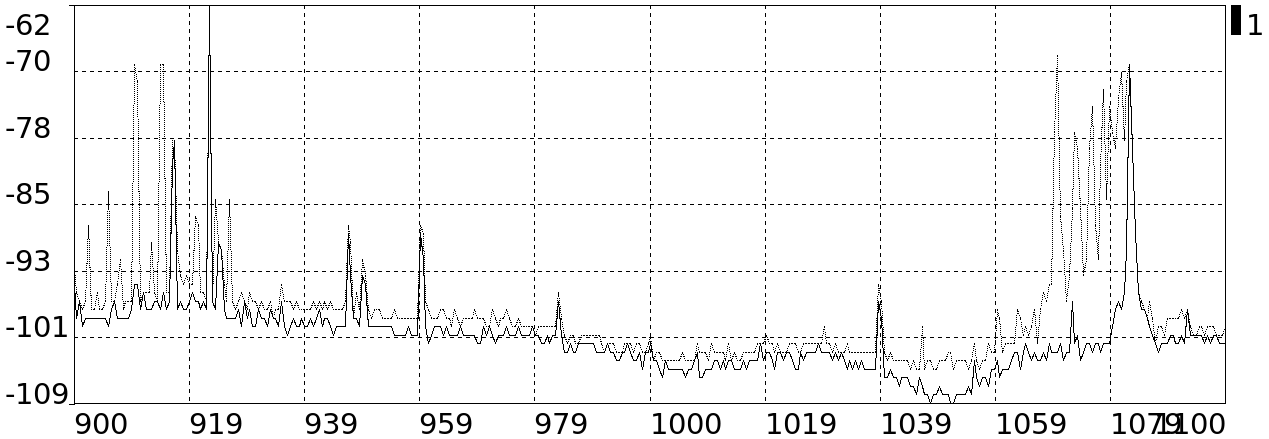

The internet partially reverse engineered the protocol for these keypads.

https://embedded-elixir.com/post/2019-01-18-nerves-at-home-desk-controller/

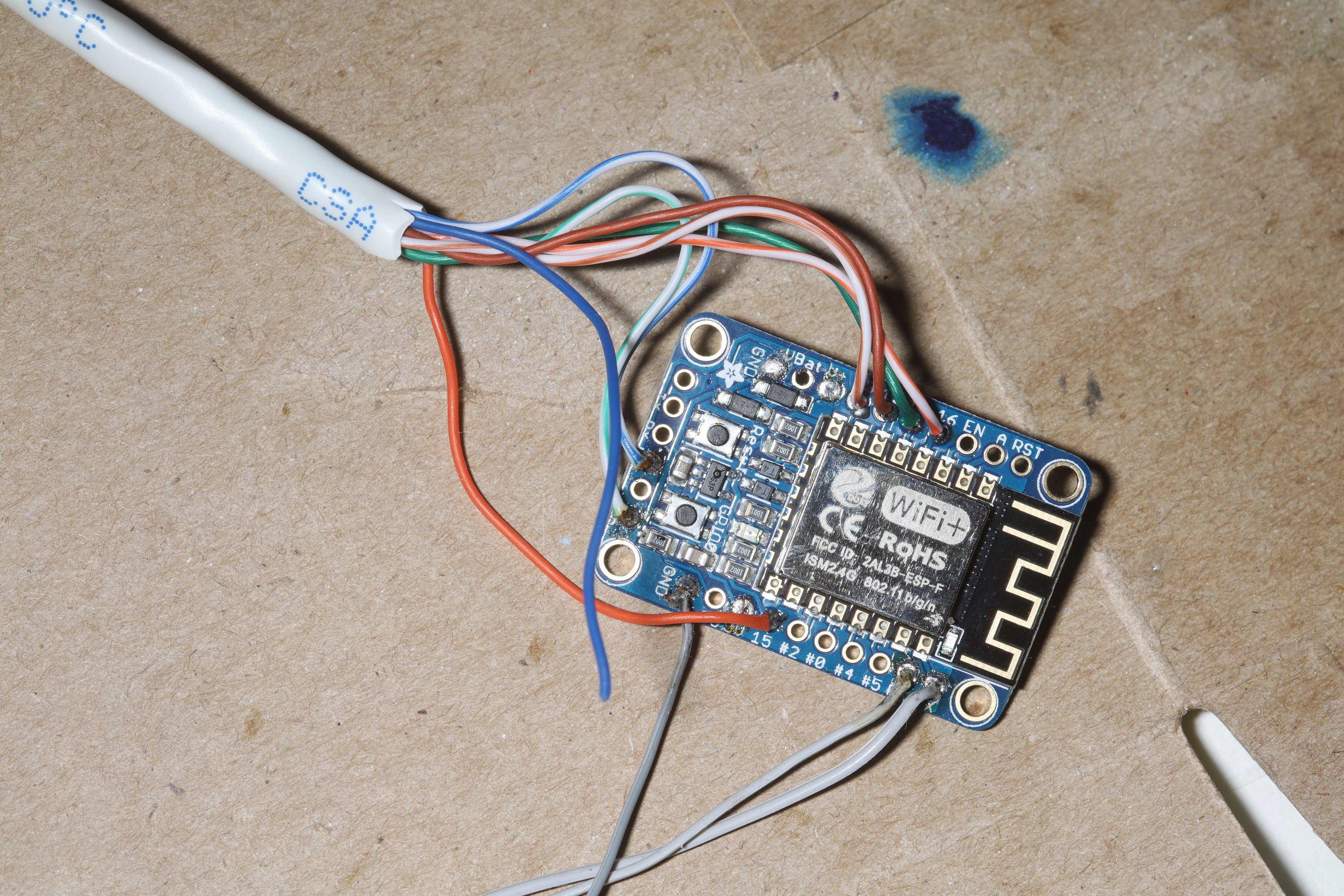

https://github.com/eyadid/uplift-wifi/blob/master/ESP8266-Lua/init.lua

But as usual, there are missing pieces & lions are amazed guys with so few skills are able to afford $4 million starter homes in Wichita. The preset commands remane unknown.

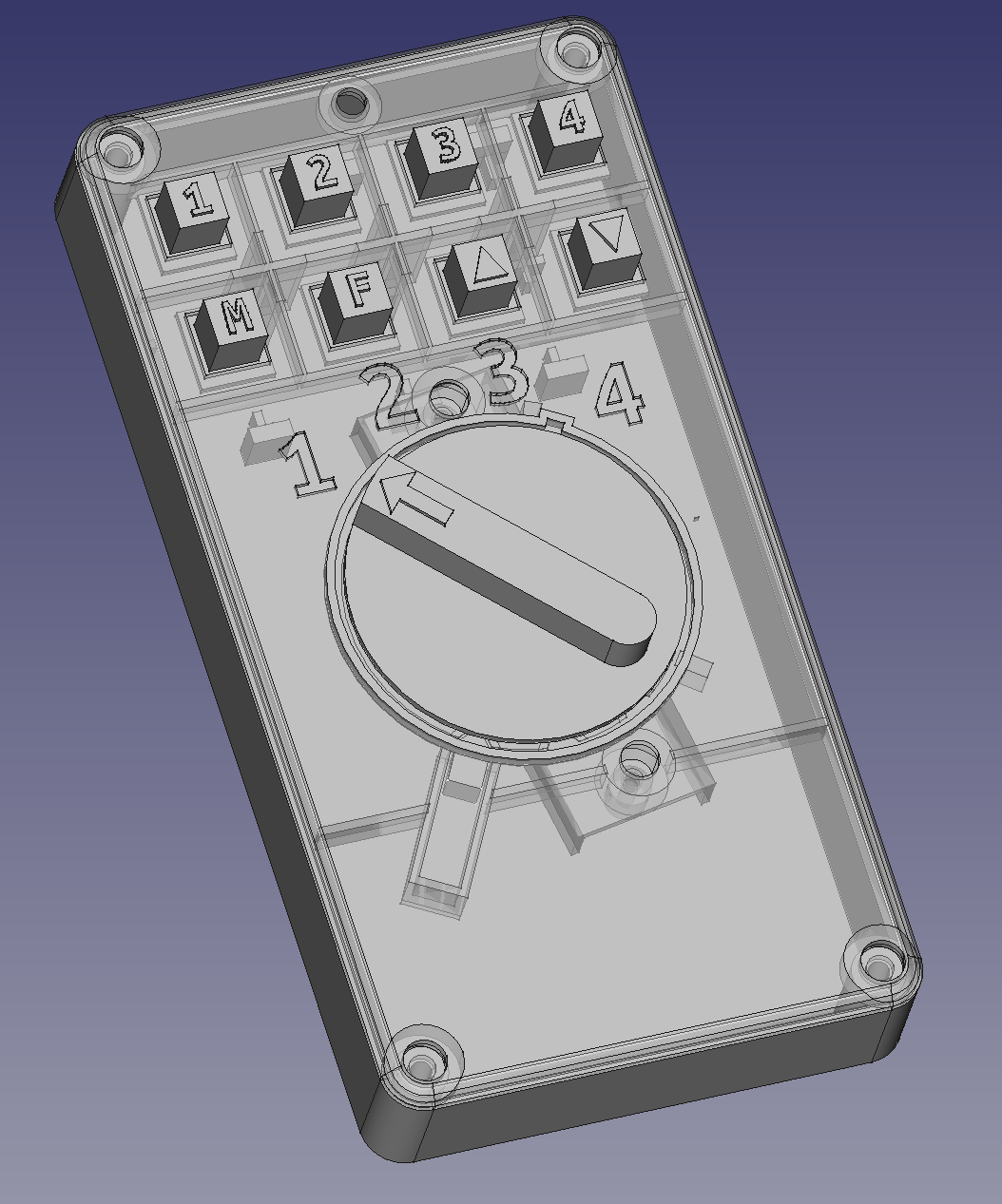

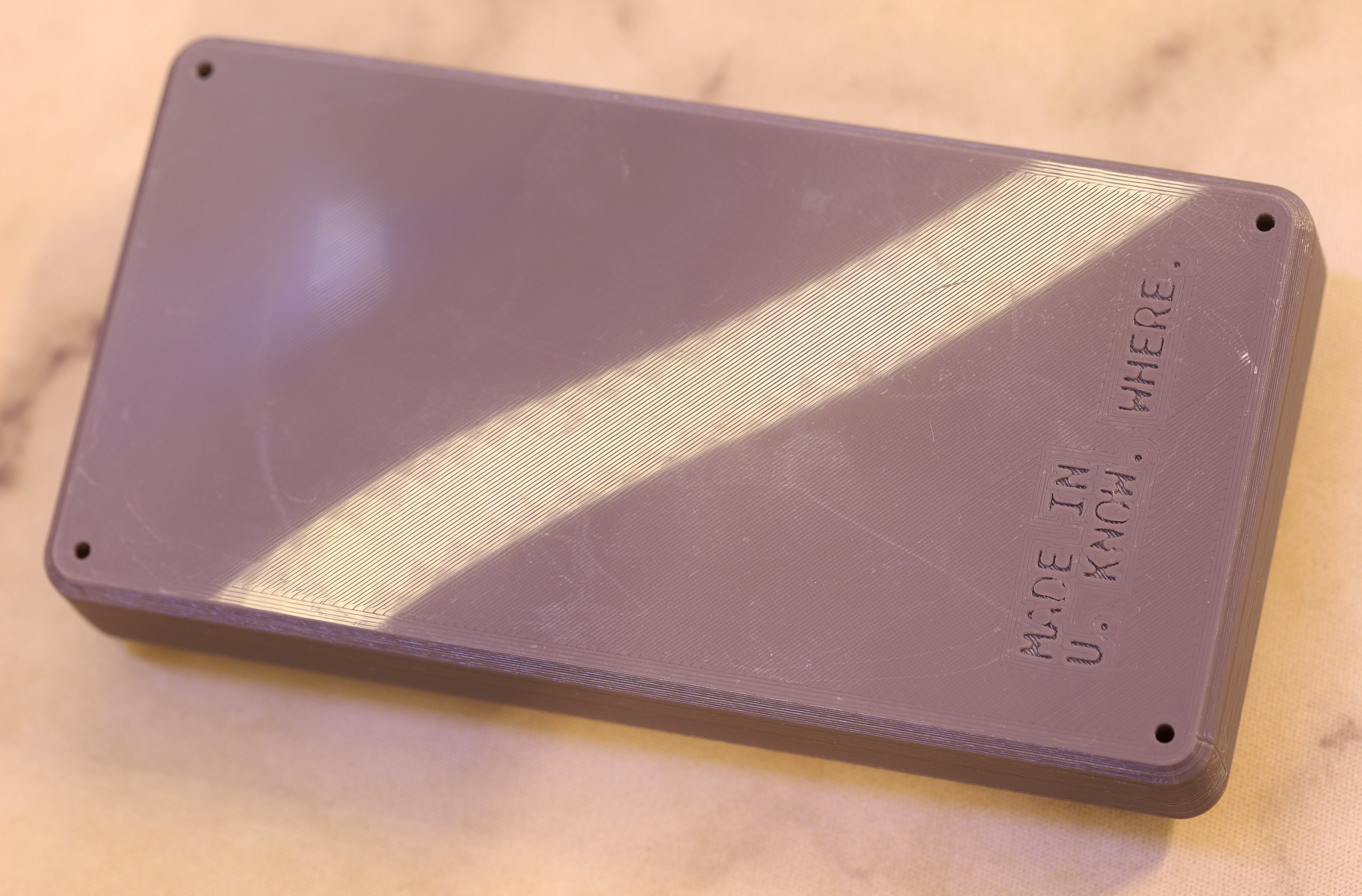

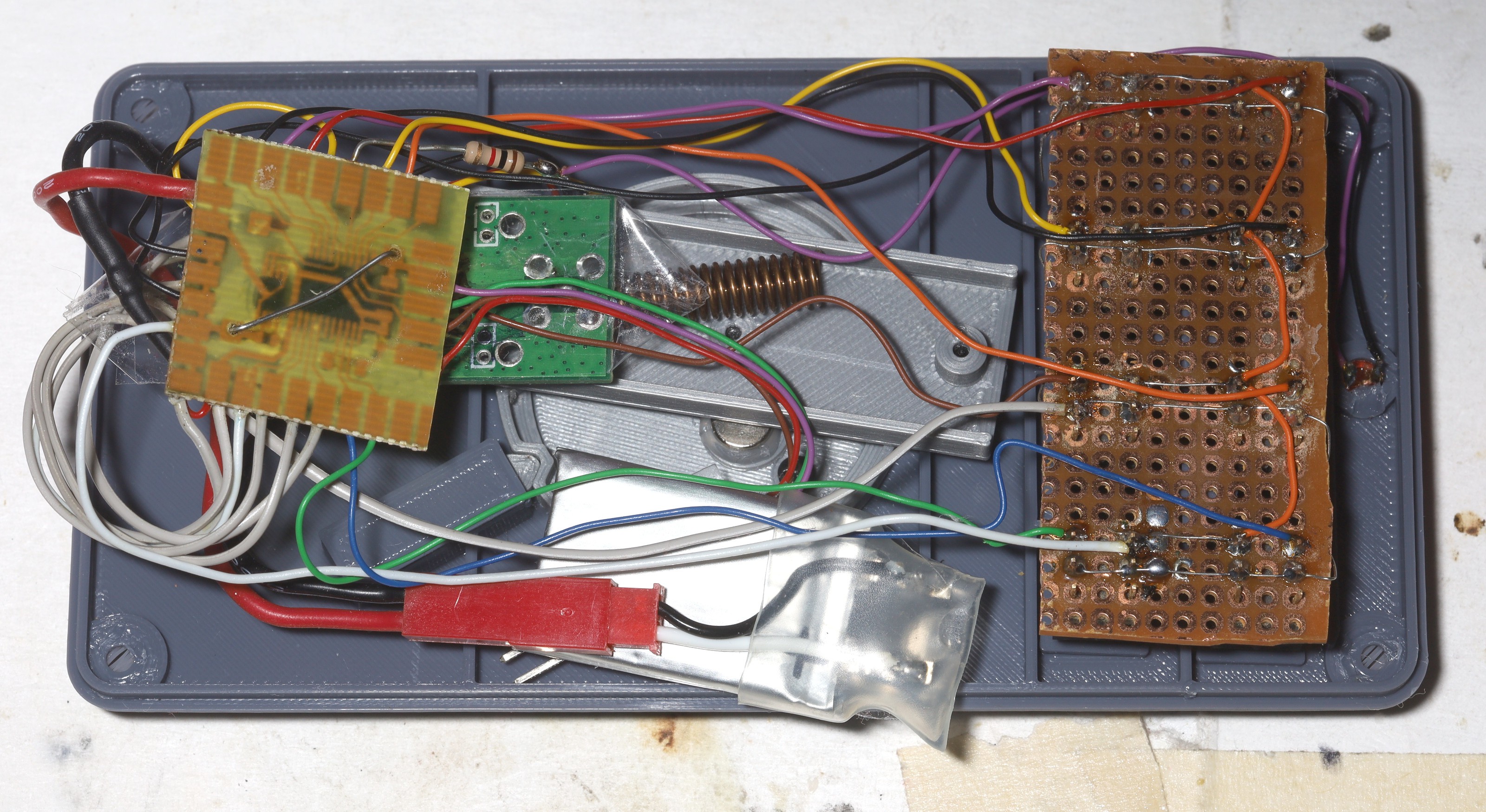

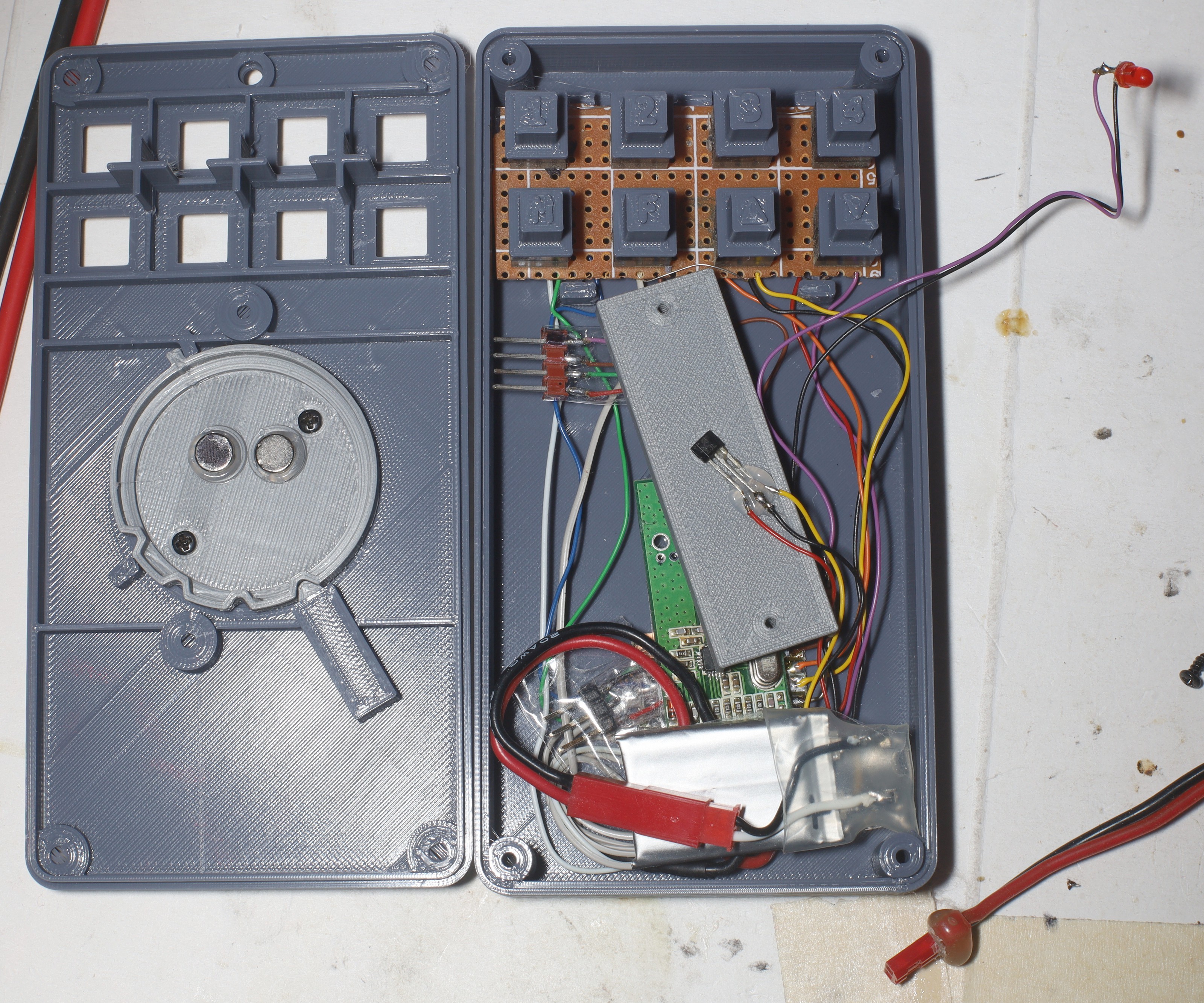

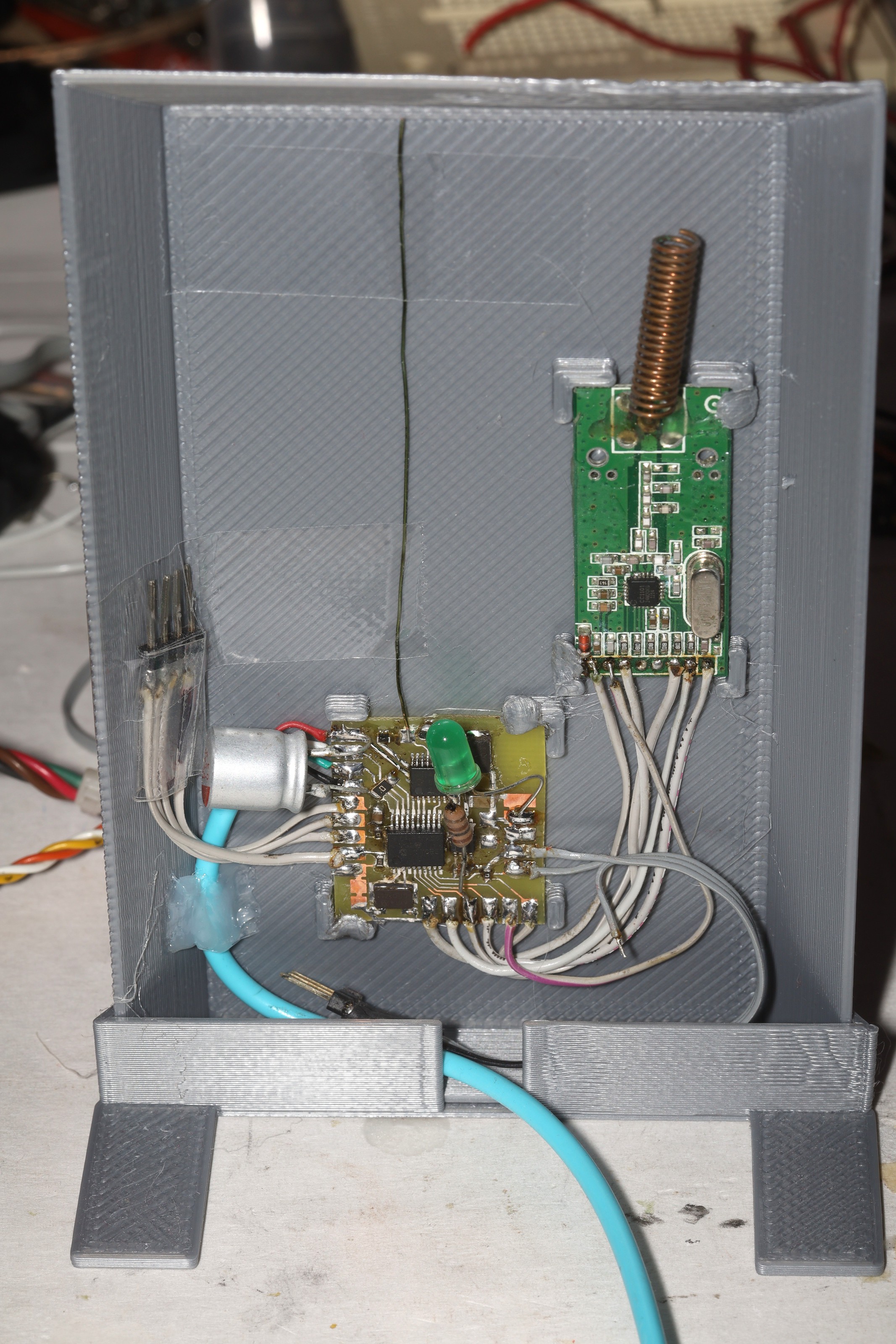

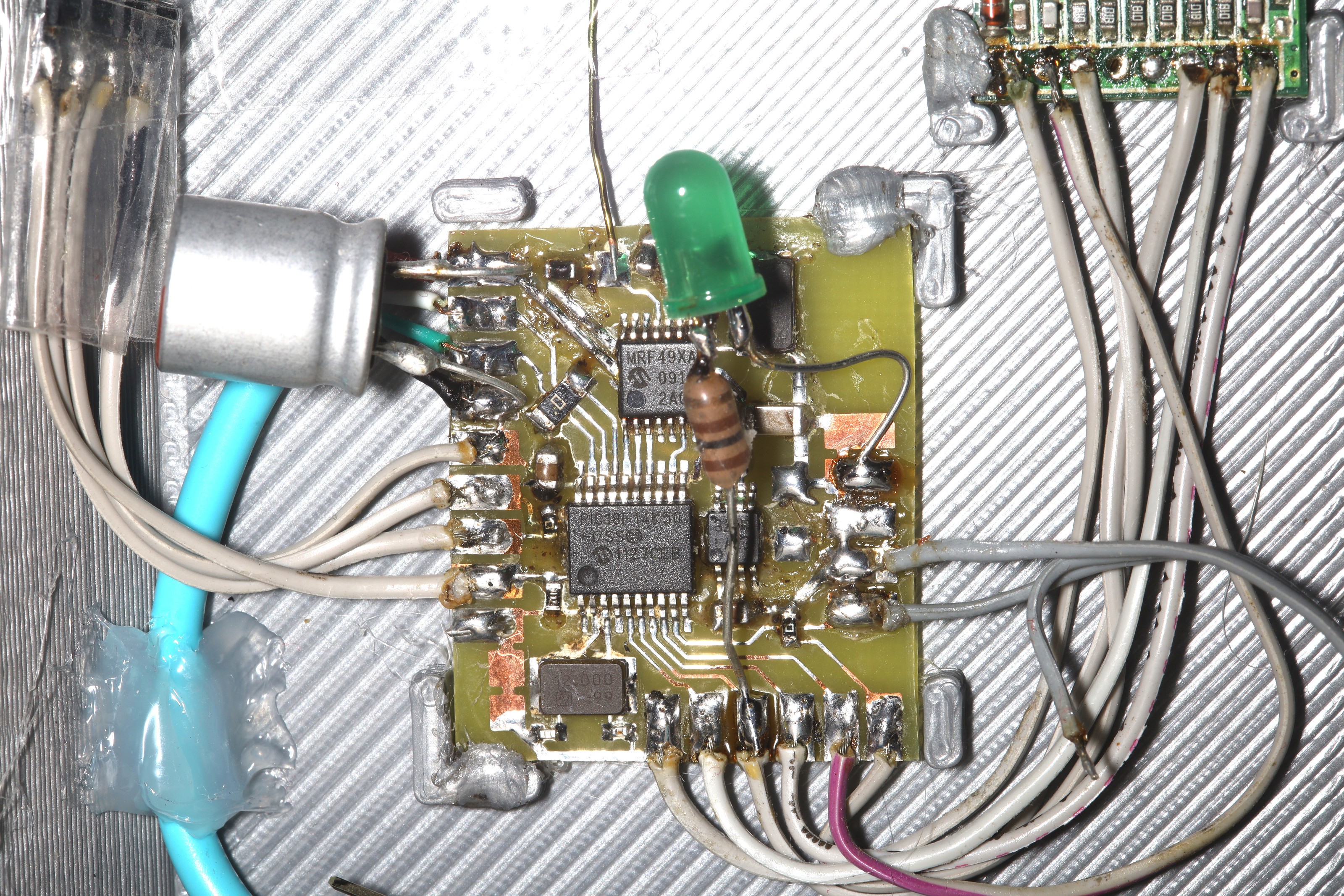

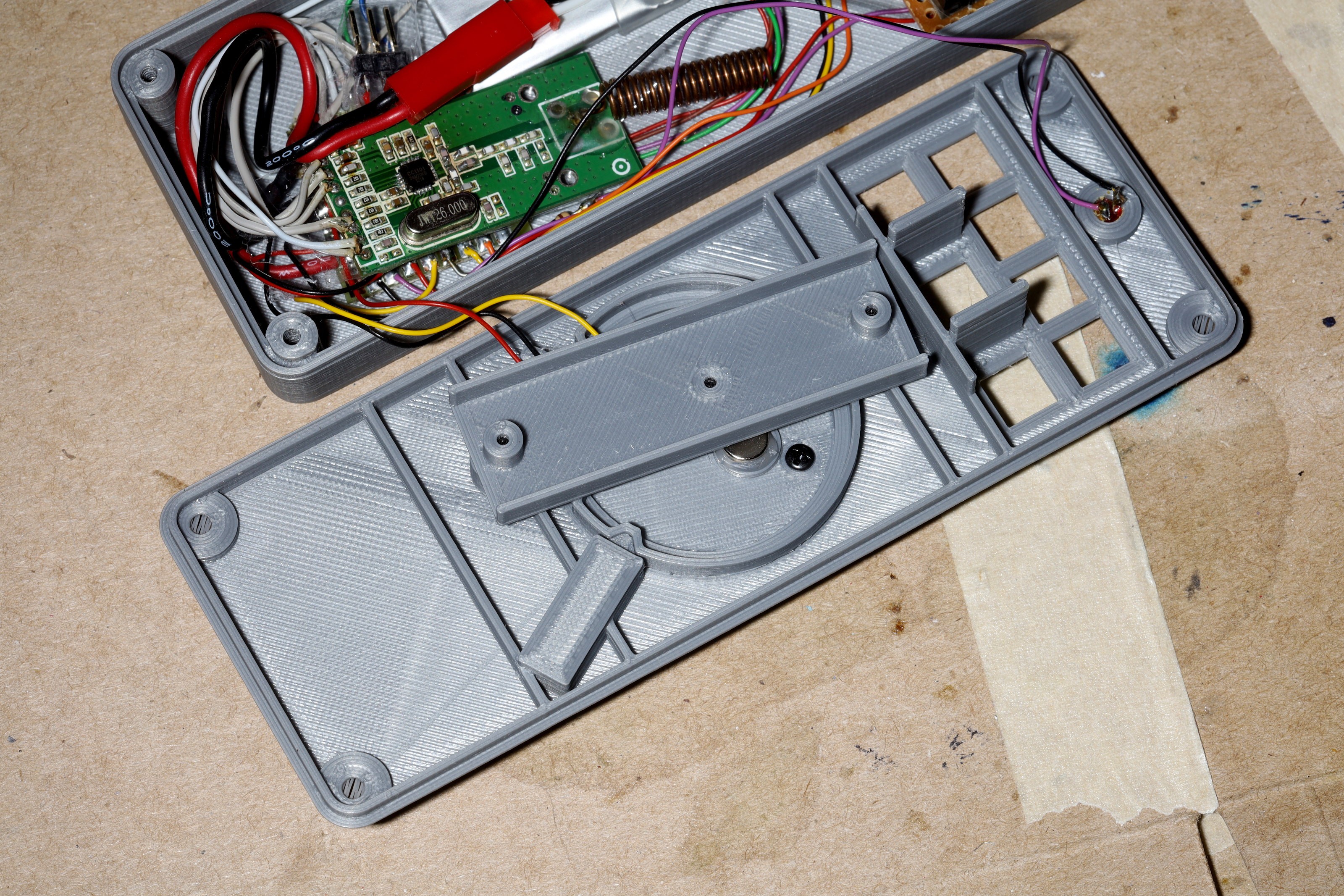

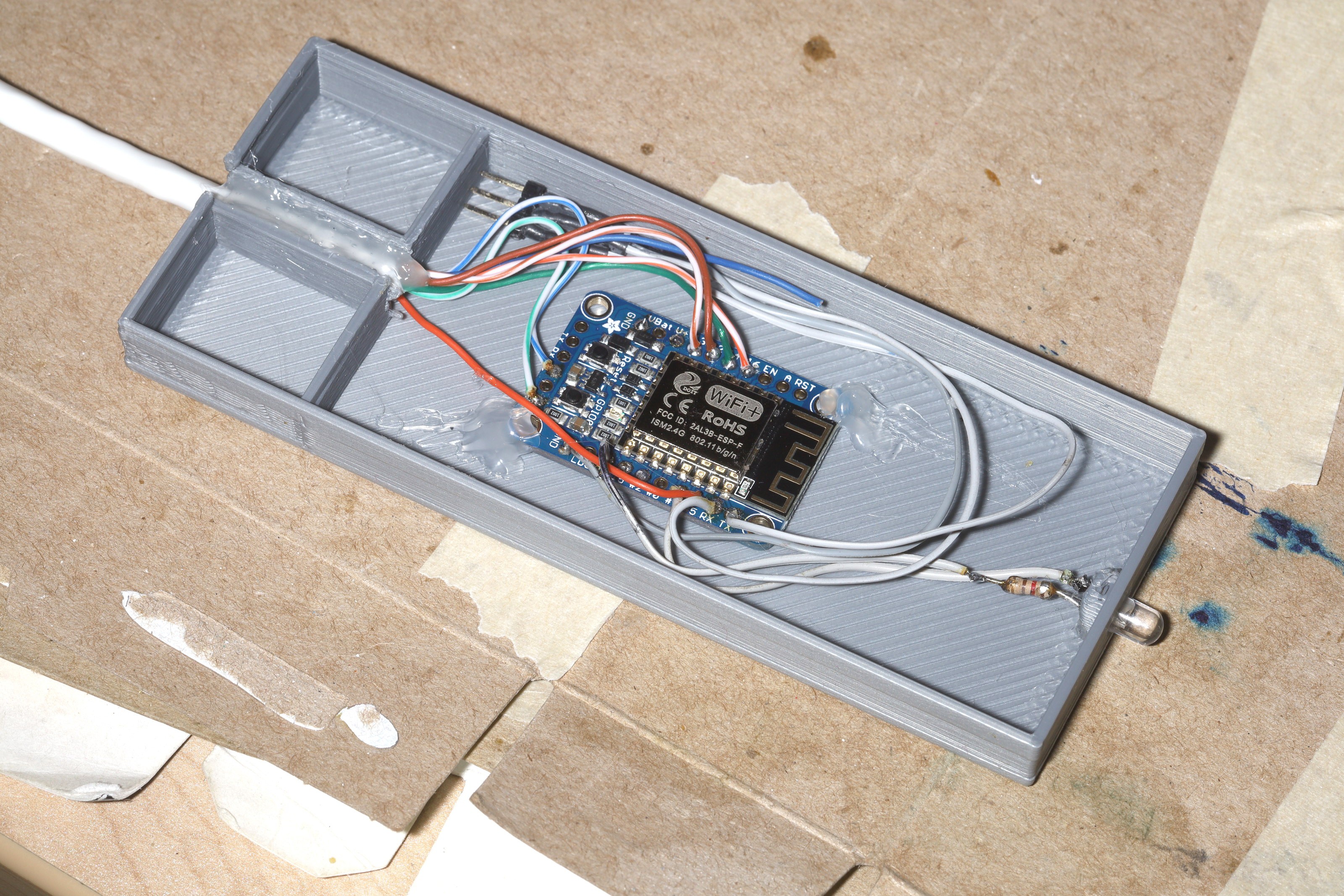

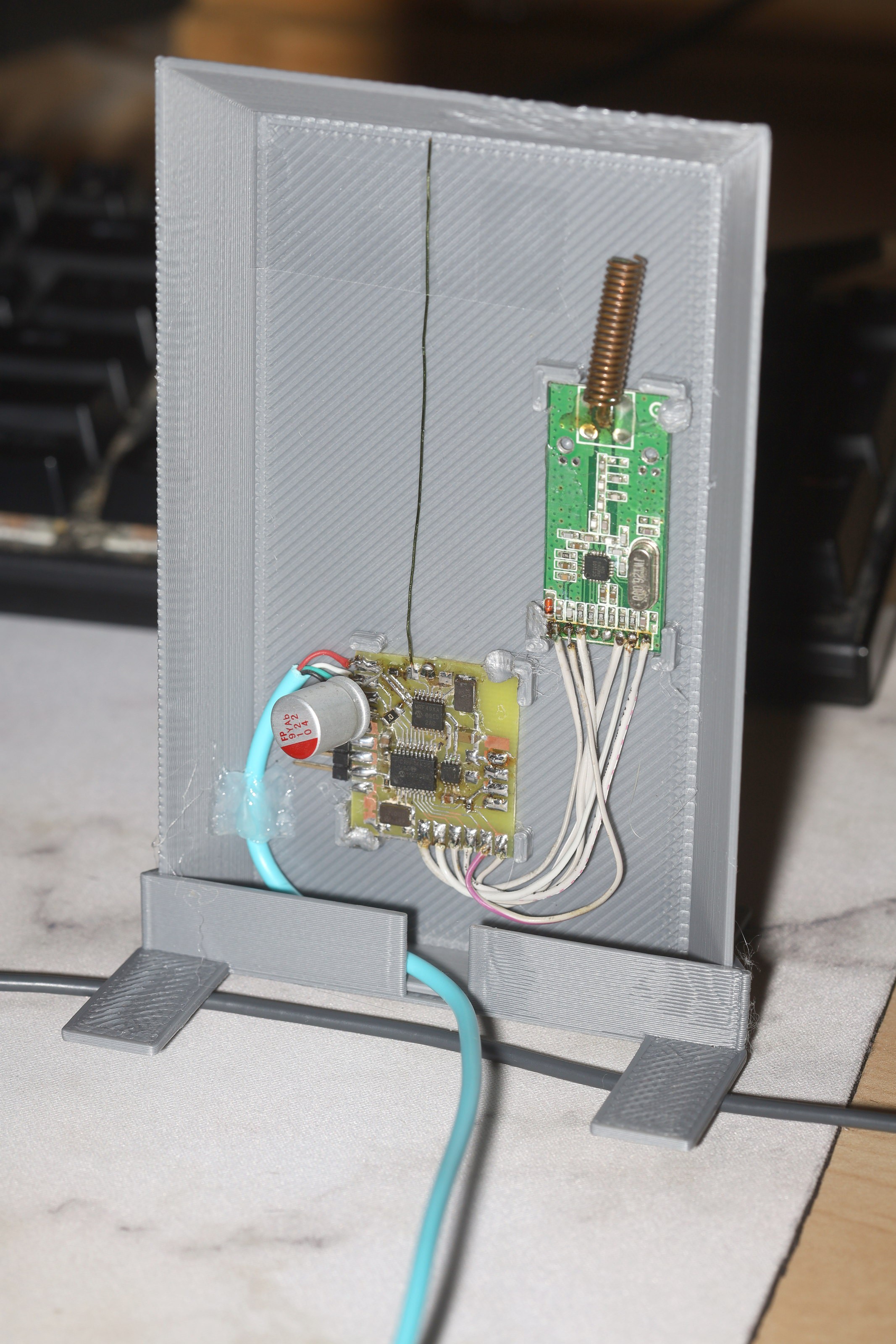

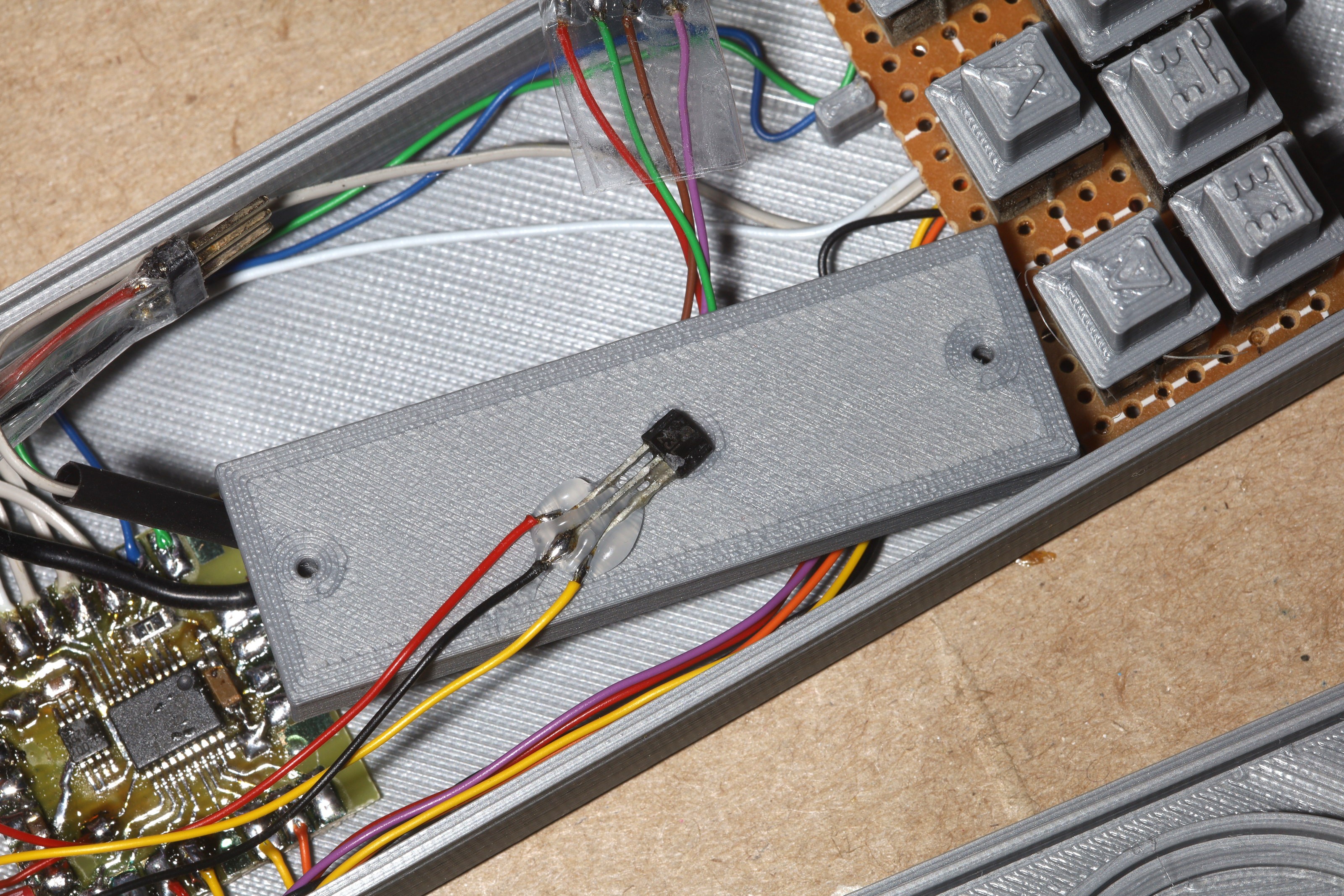

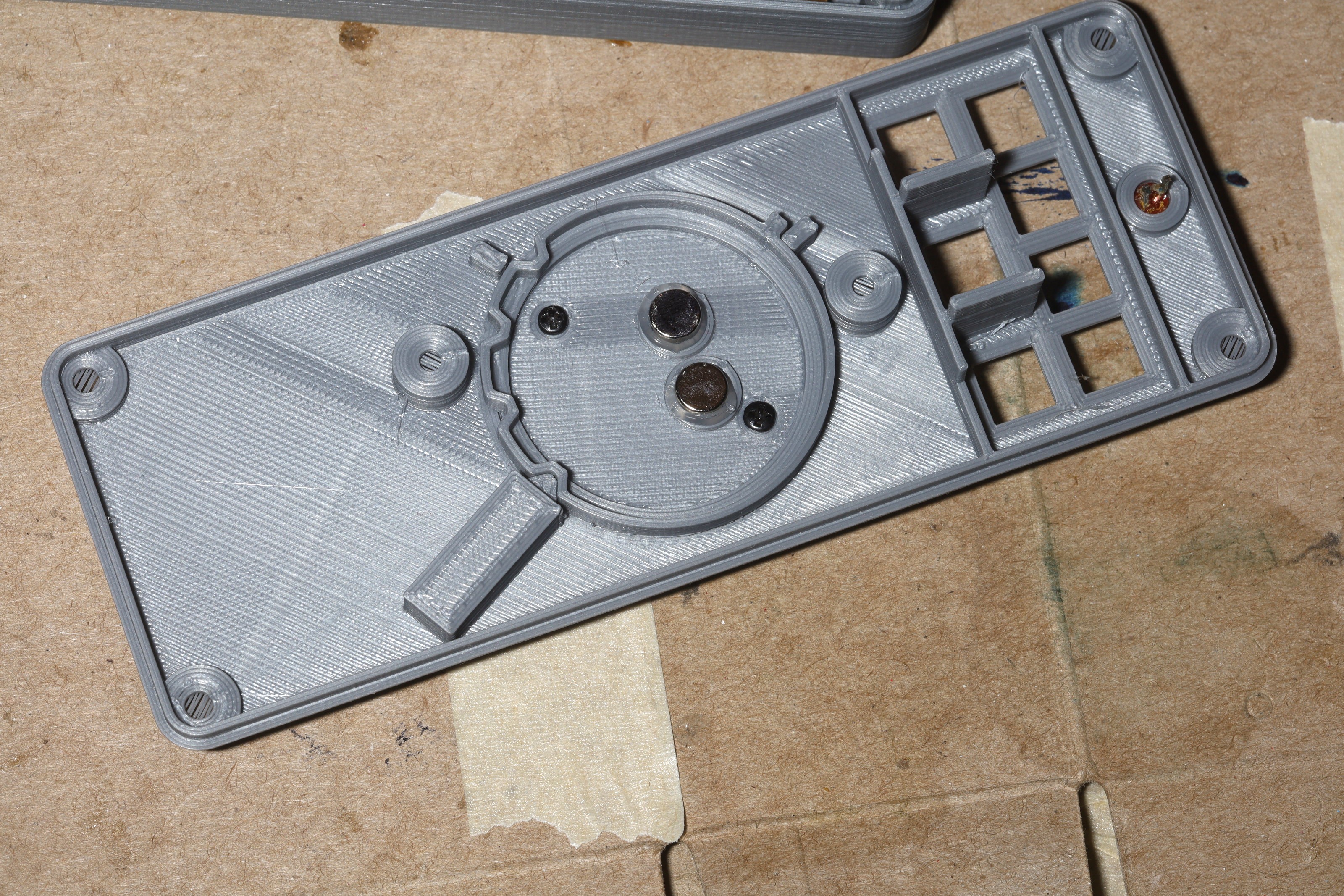

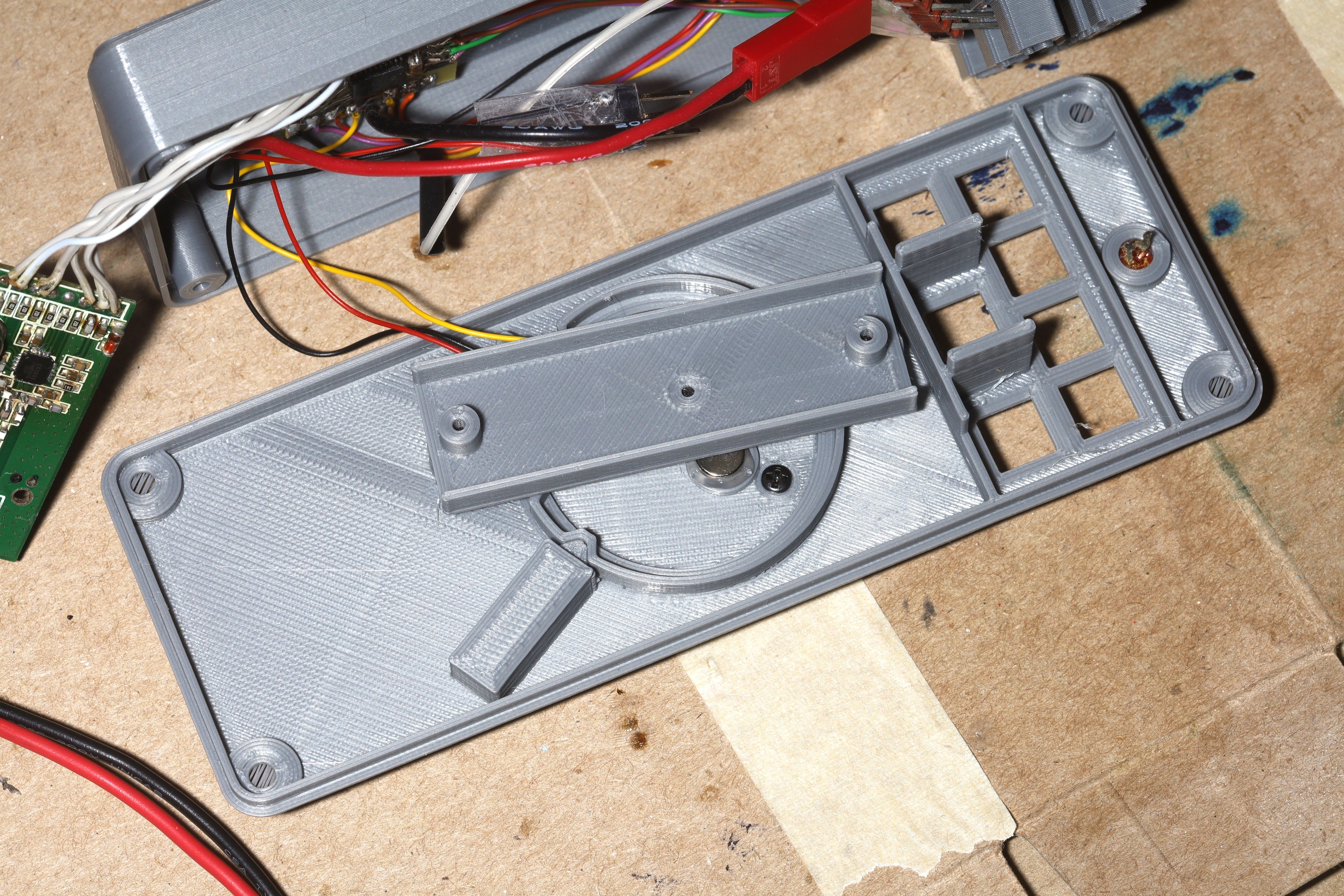

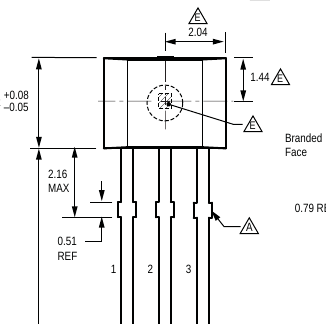

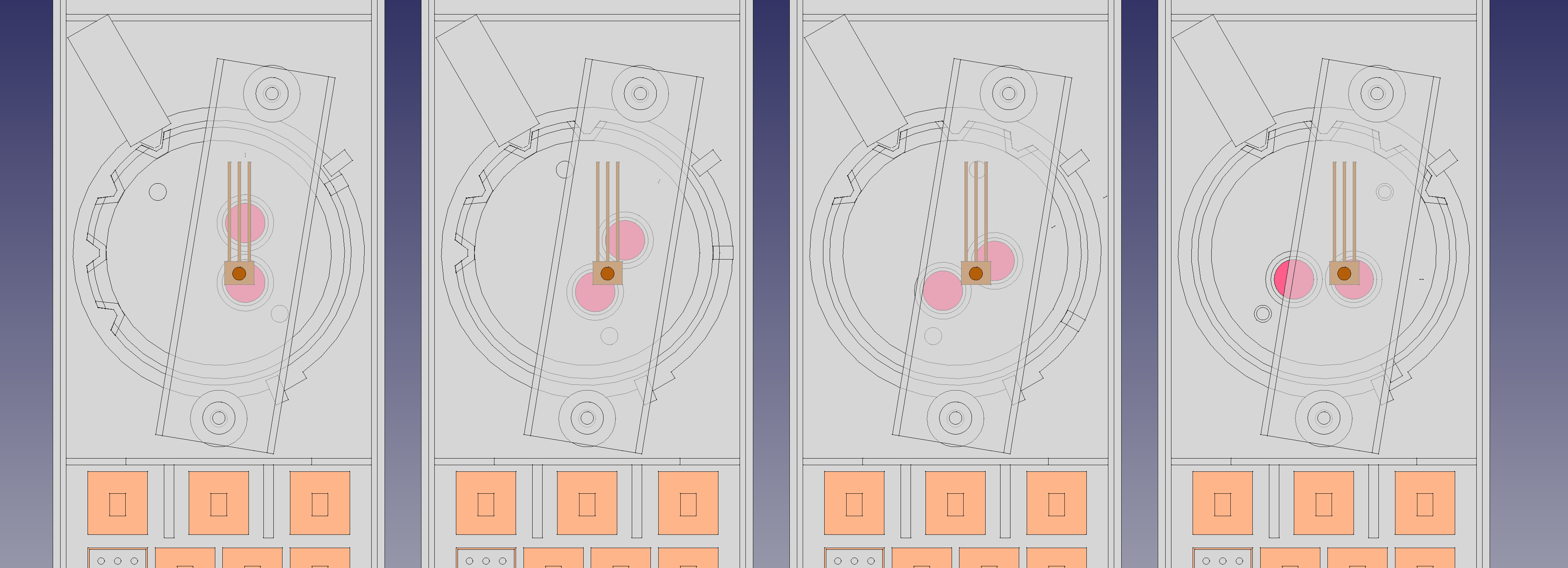

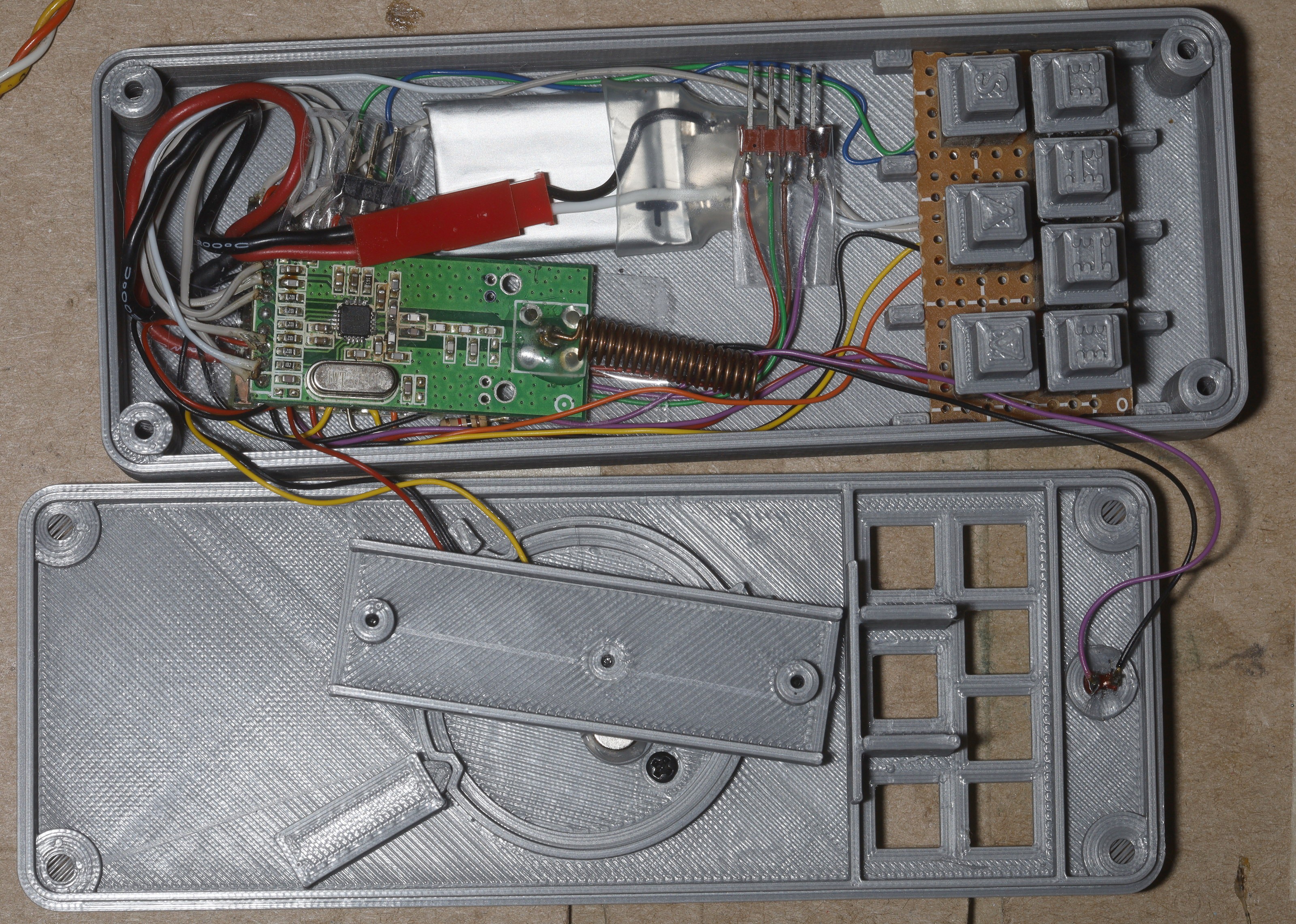

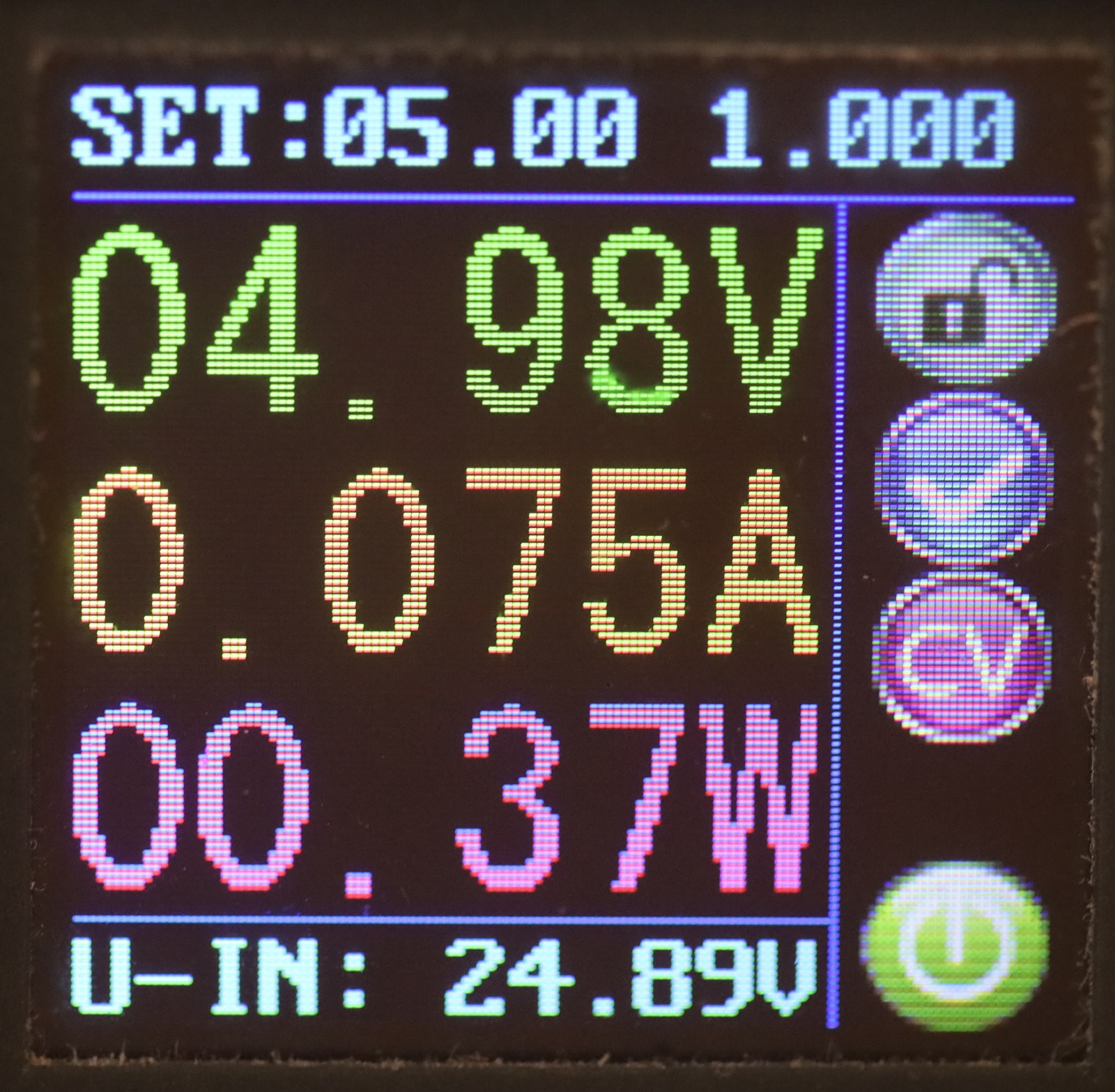

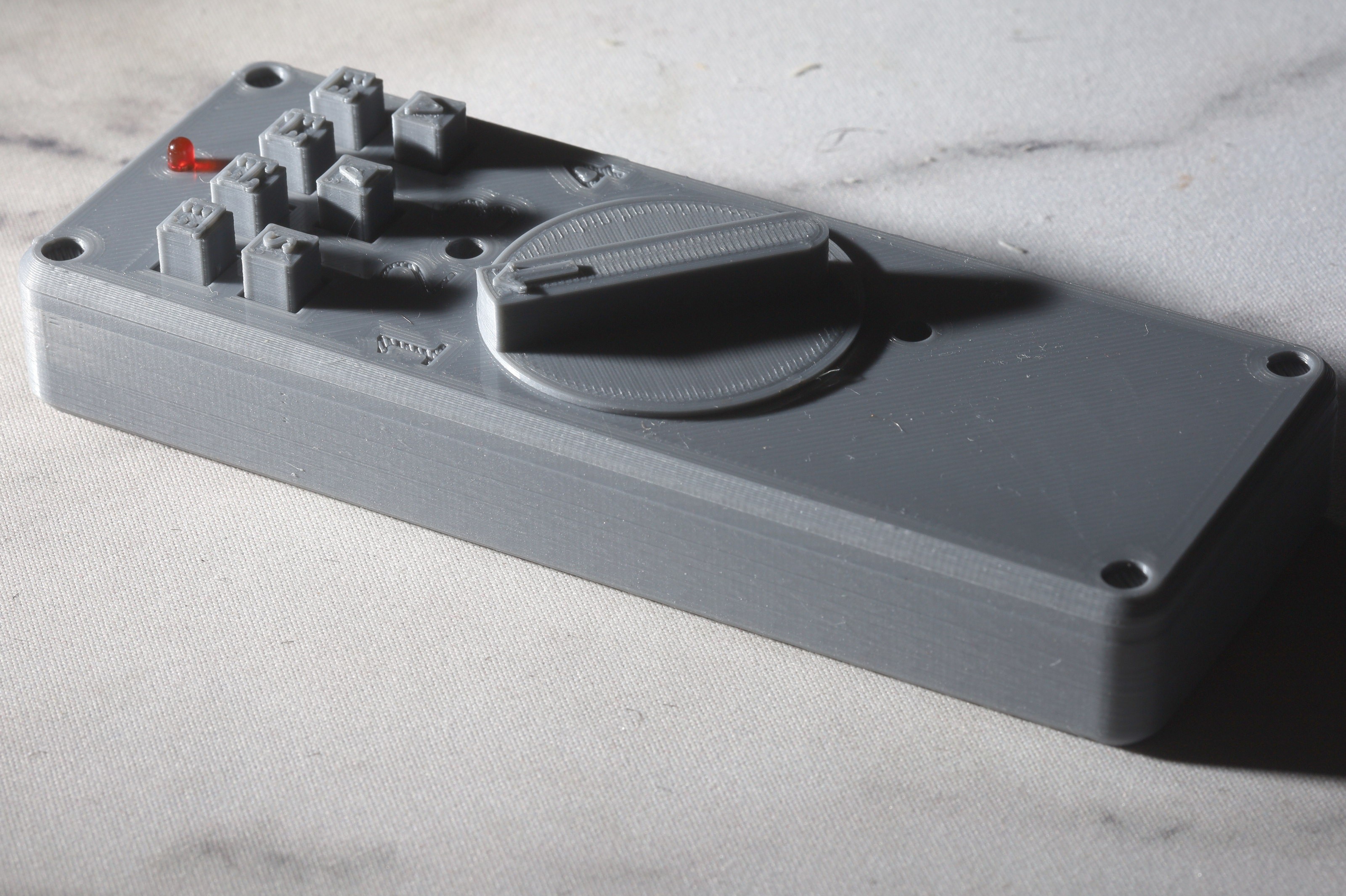

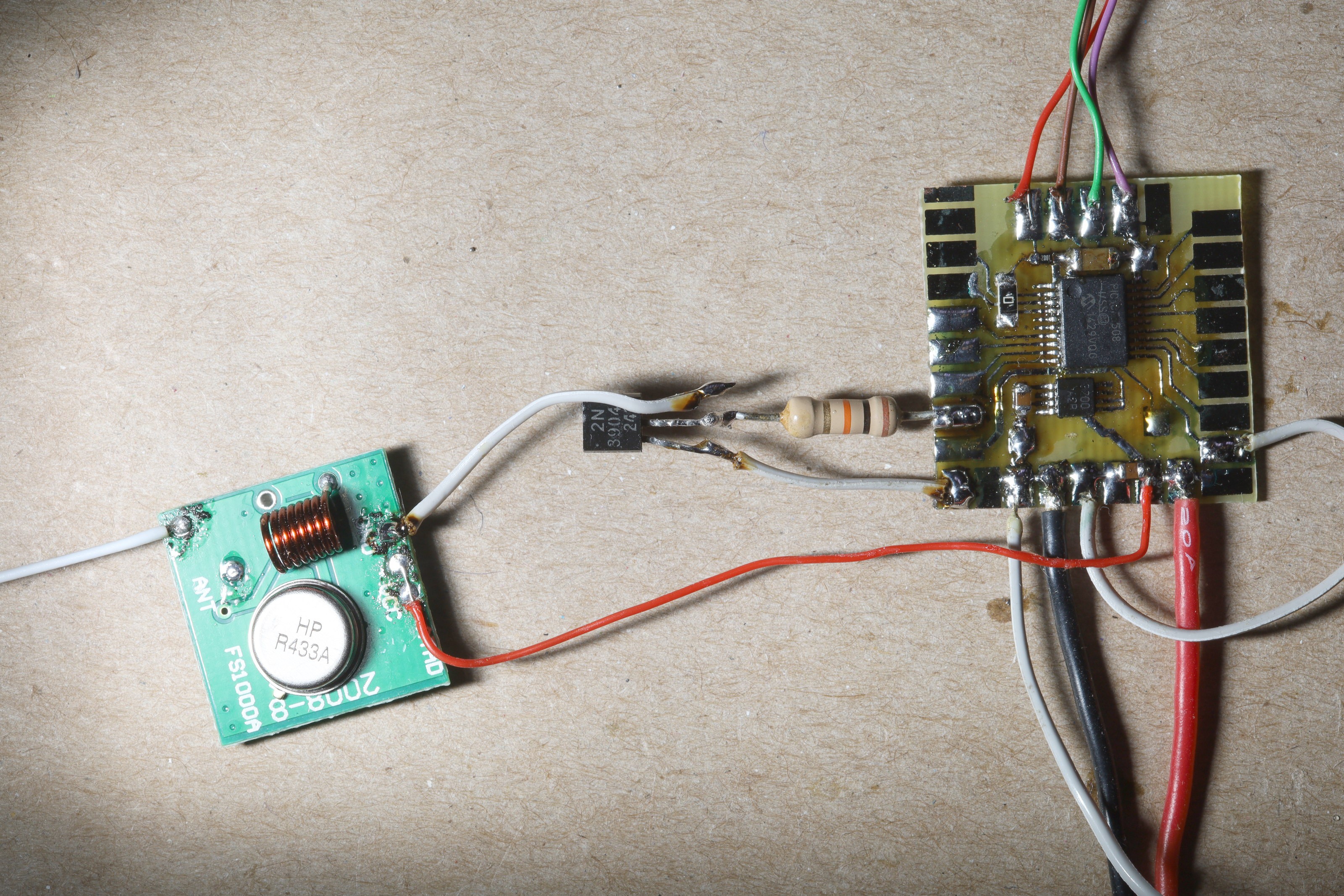

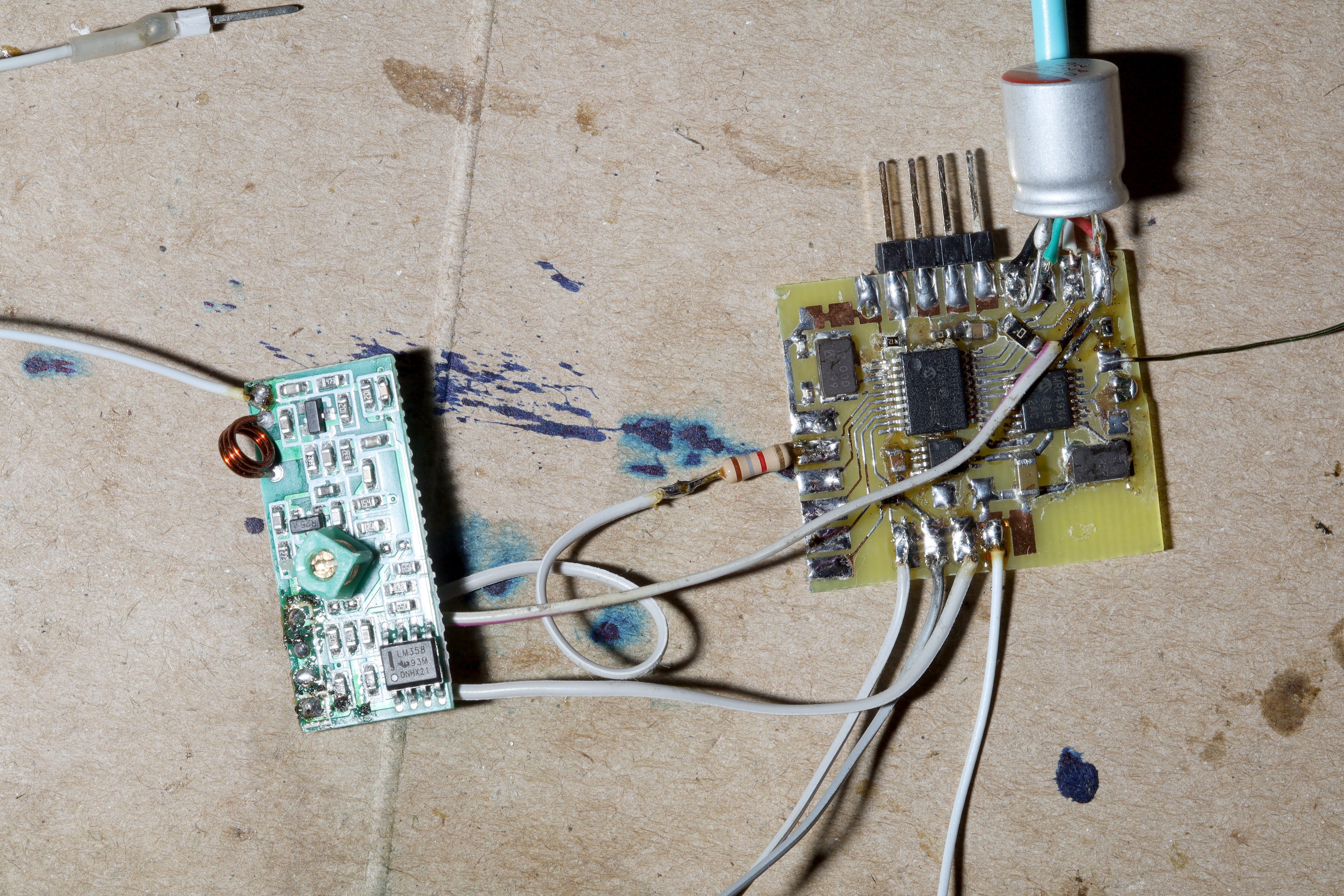

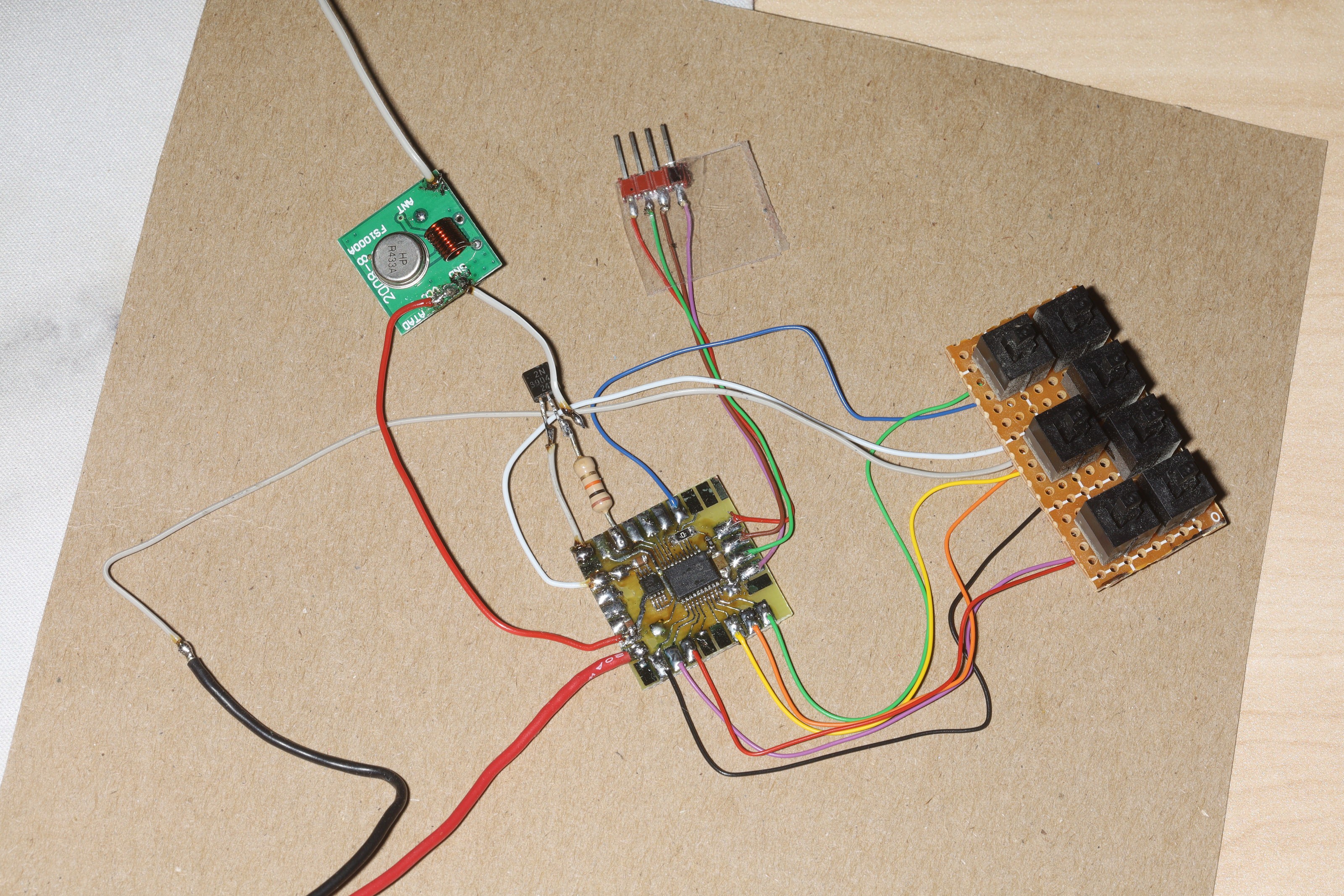

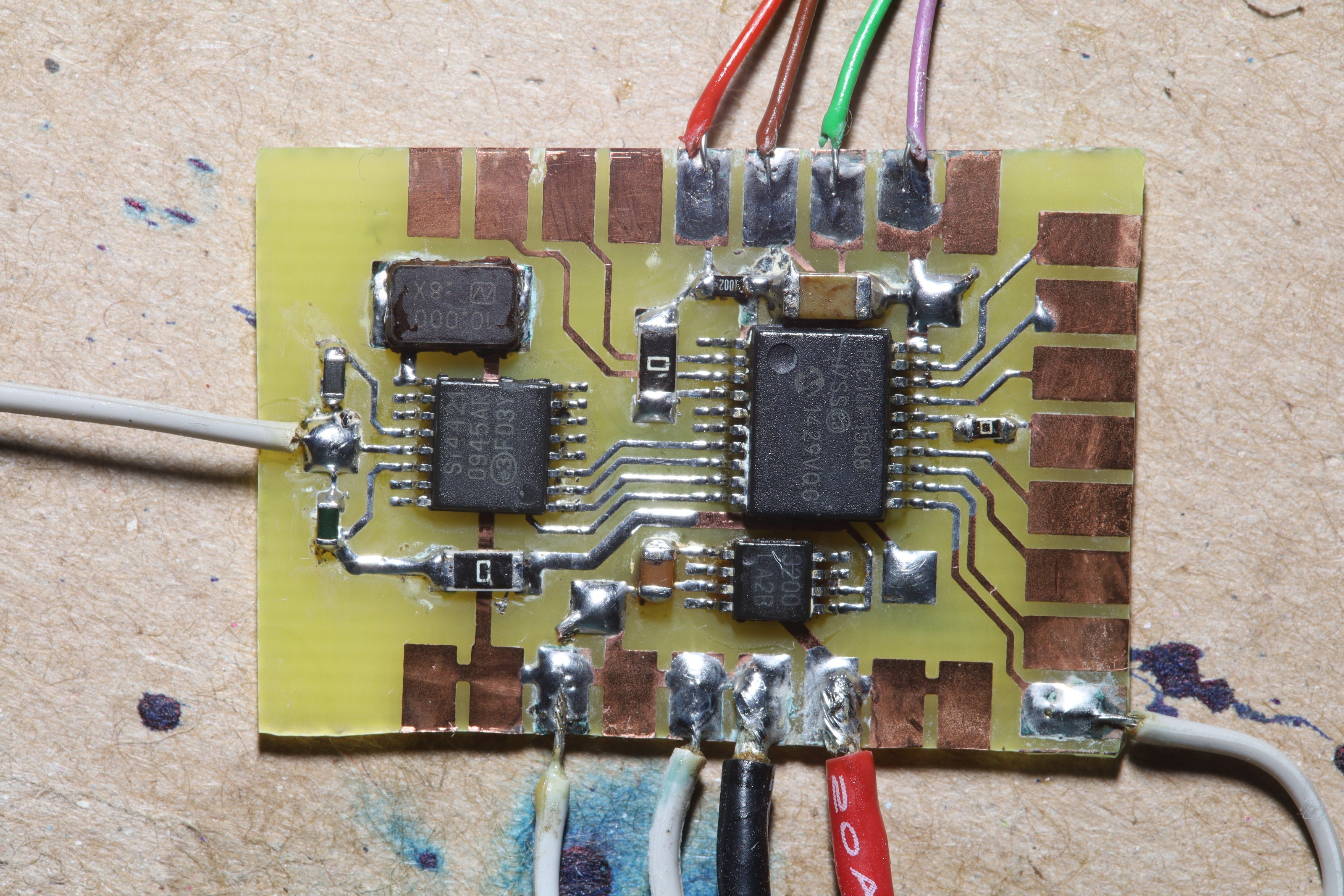

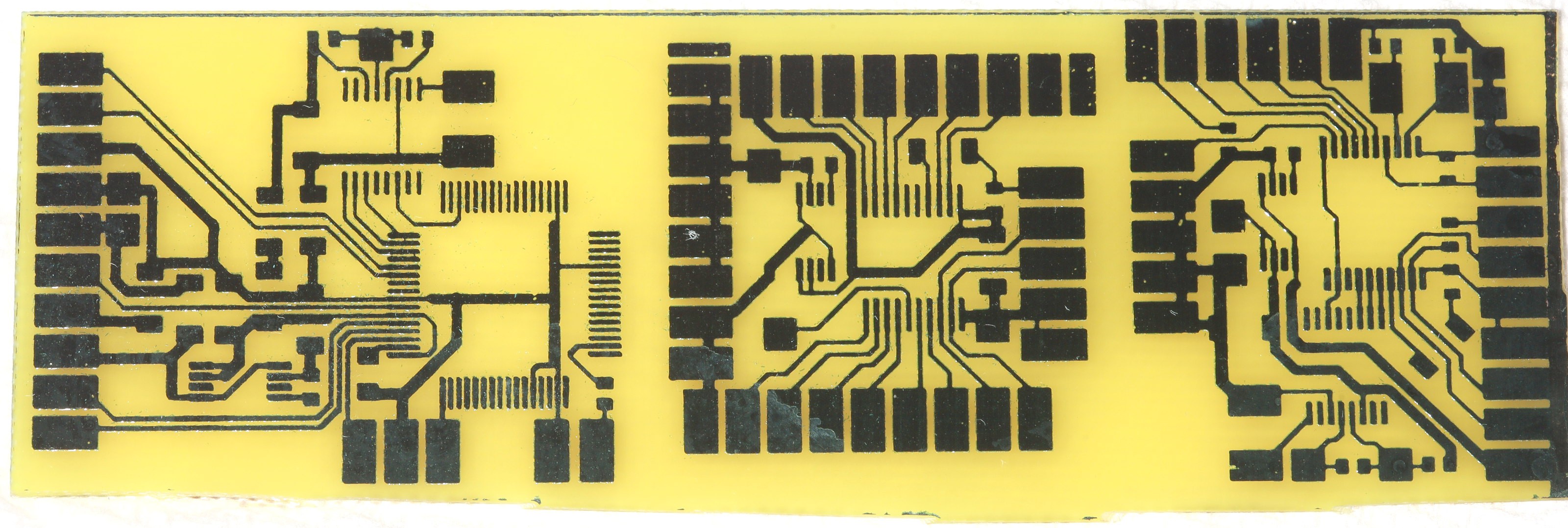

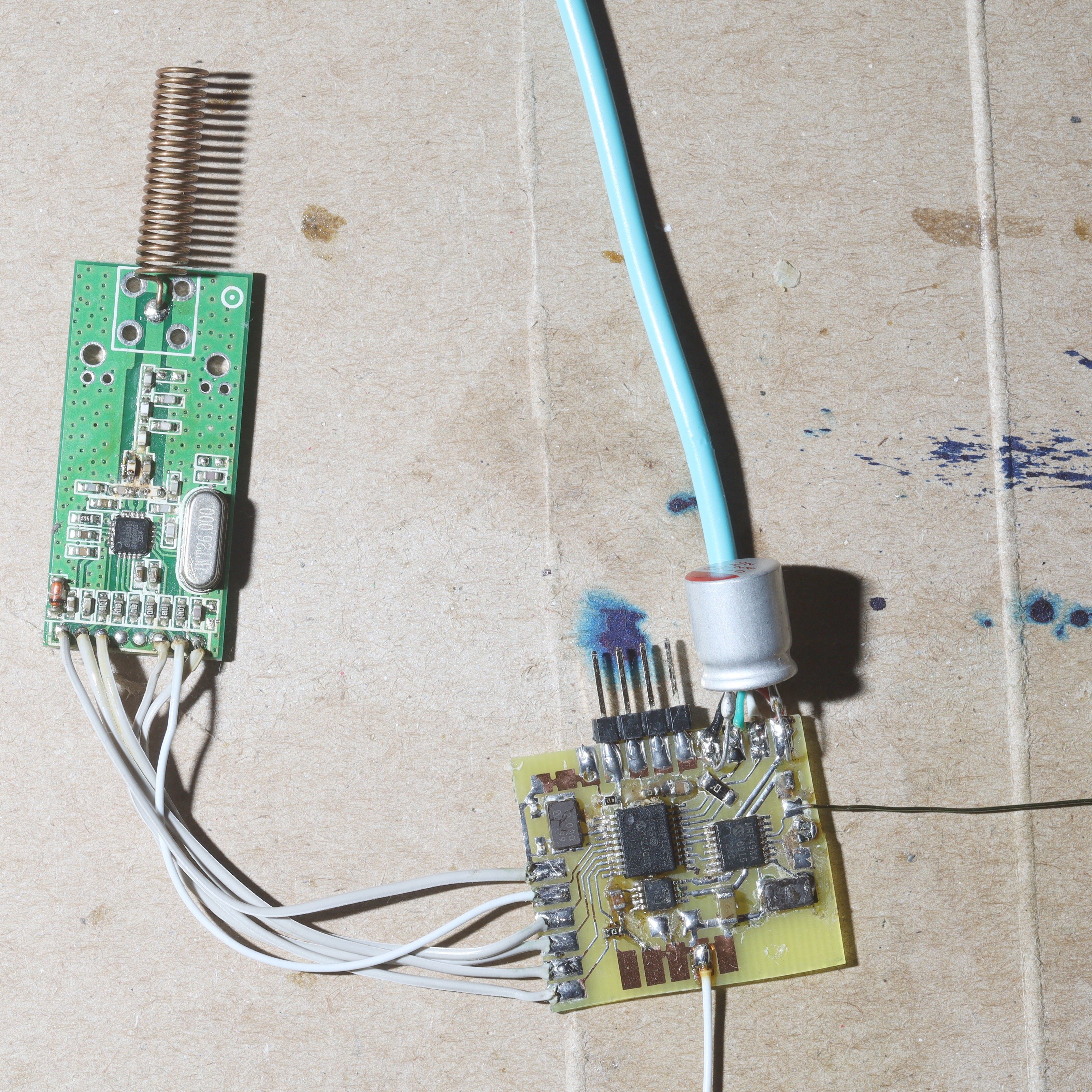

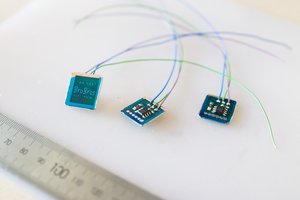

Custom keypad ideas range from a single IR control with a dial selector for the desk, 5 presets, 1 set button, 2 direction buttons using high quality MHPS2283V buttons. Making a physical control for every desk would entail 32 buttons & a lot more fabrication work. There's a compromise between quality of the buttons & number of controls. Any upgrade would involve keeping the stock membrane controls for local use. The custom control would be for the presets. The IR receivers would bolt onto the membrane keypads. A TV remote with dome buttons probably wouldn't be good enough at sustained button presses.

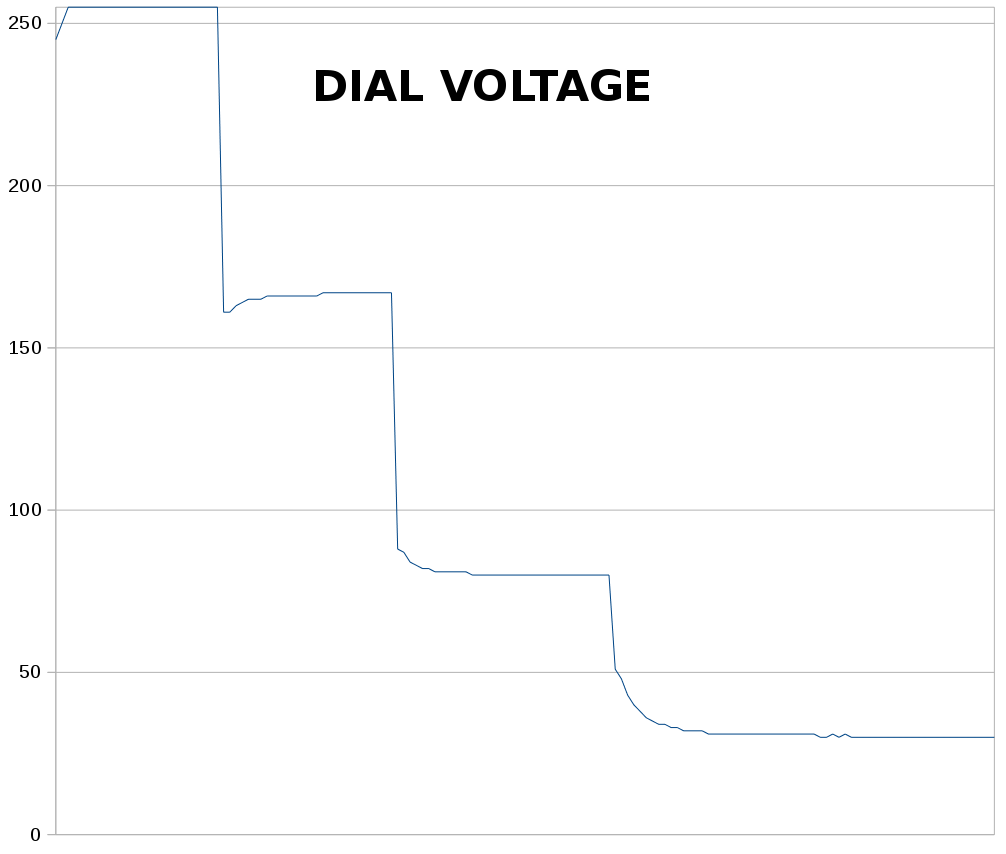

The lion kingdom could burn $40 on an uplift keypad to reverse engineer & use in just 1 desk. Presets can also be simulated by reading the status bits. There must be a better way of selecting the desk than a dial, possibly an orientation sensor or a laser.

lion mclionhead

lion mclionhead

danjovic

danjovic

Christoph Tack

Christoph Tack

Stephen Holdaway

Stephen Holdaway