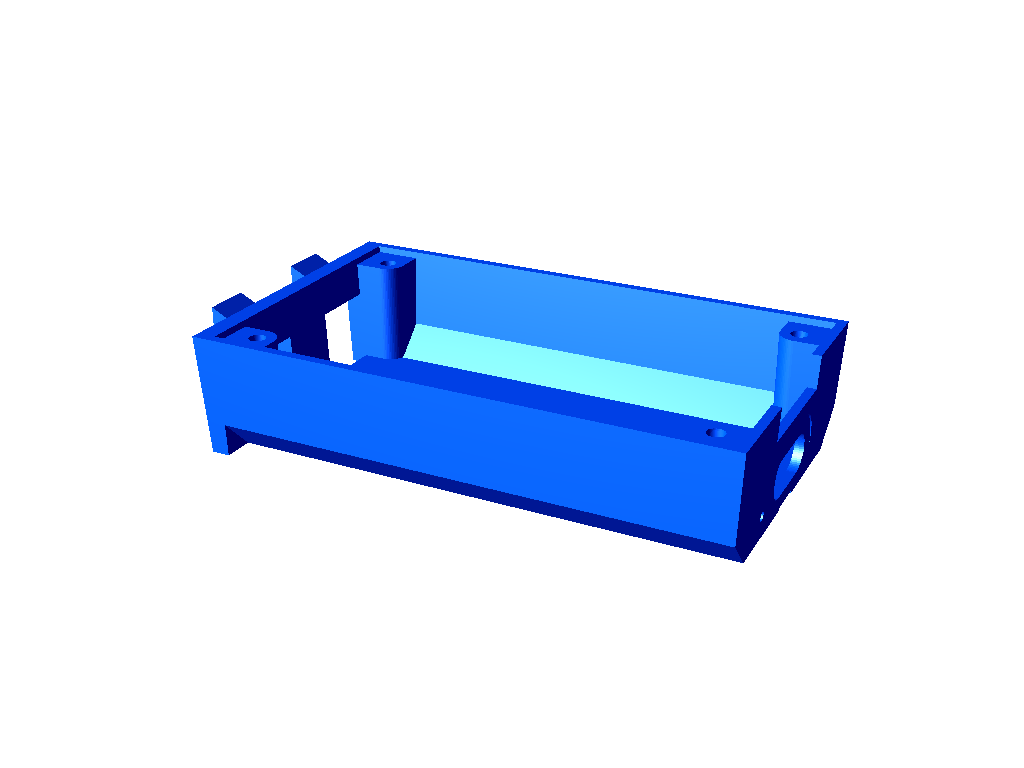

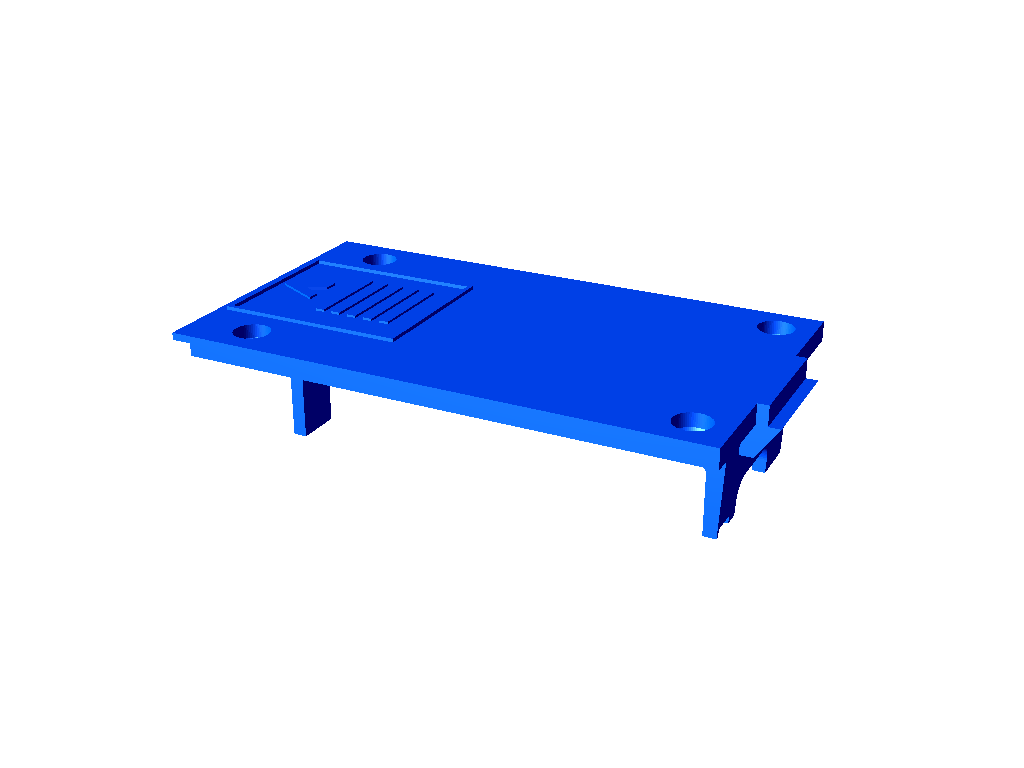

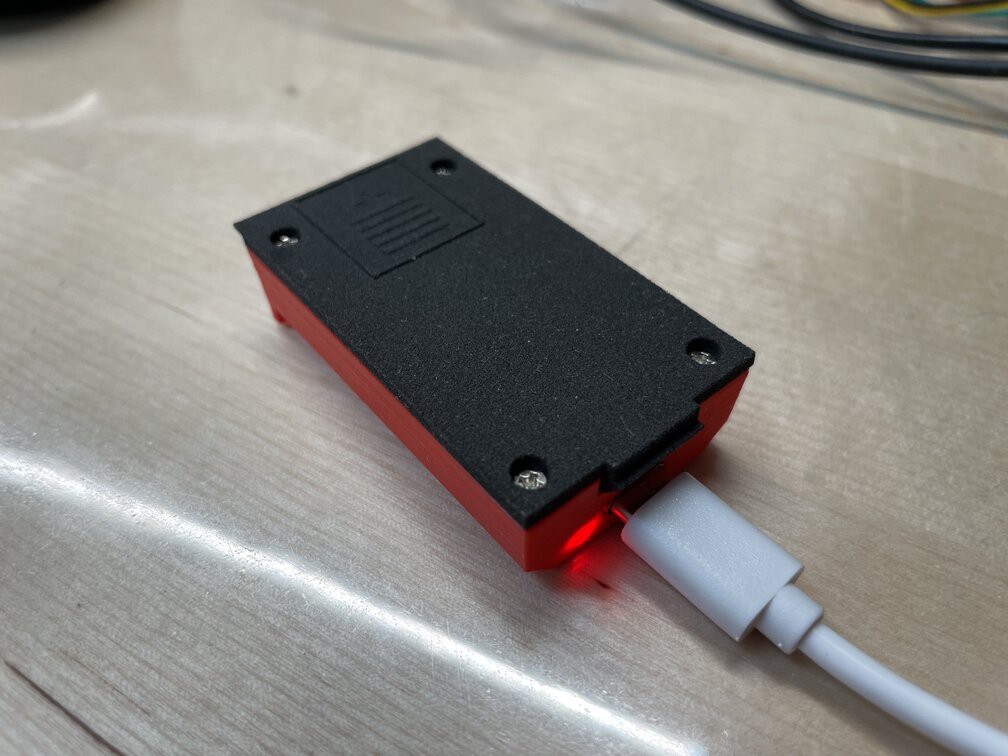

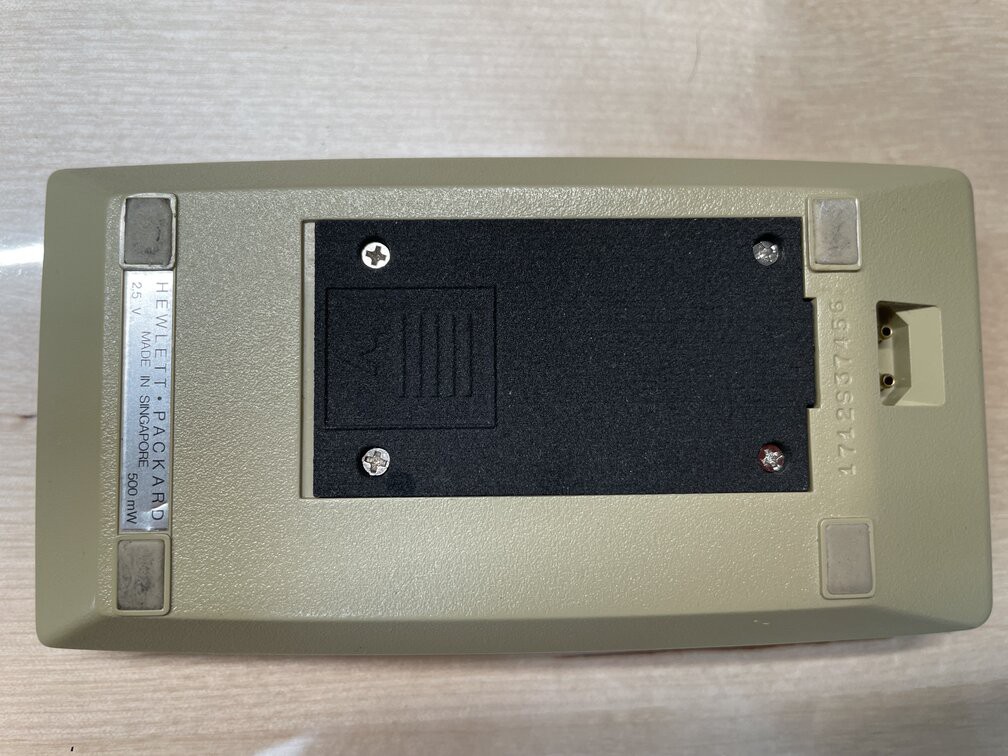

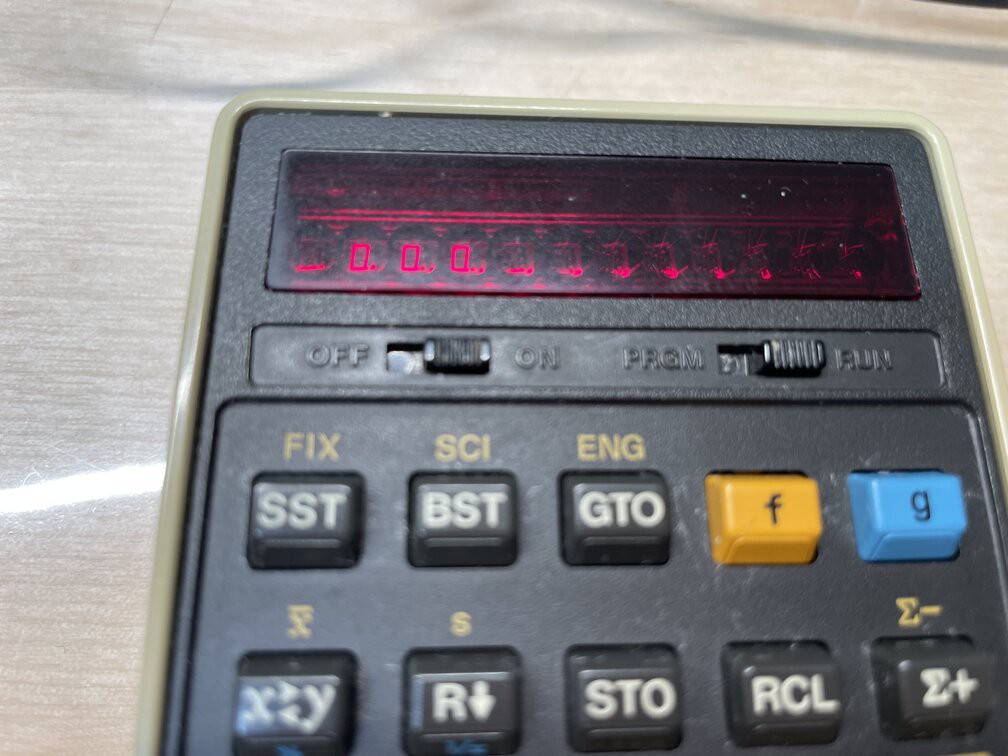

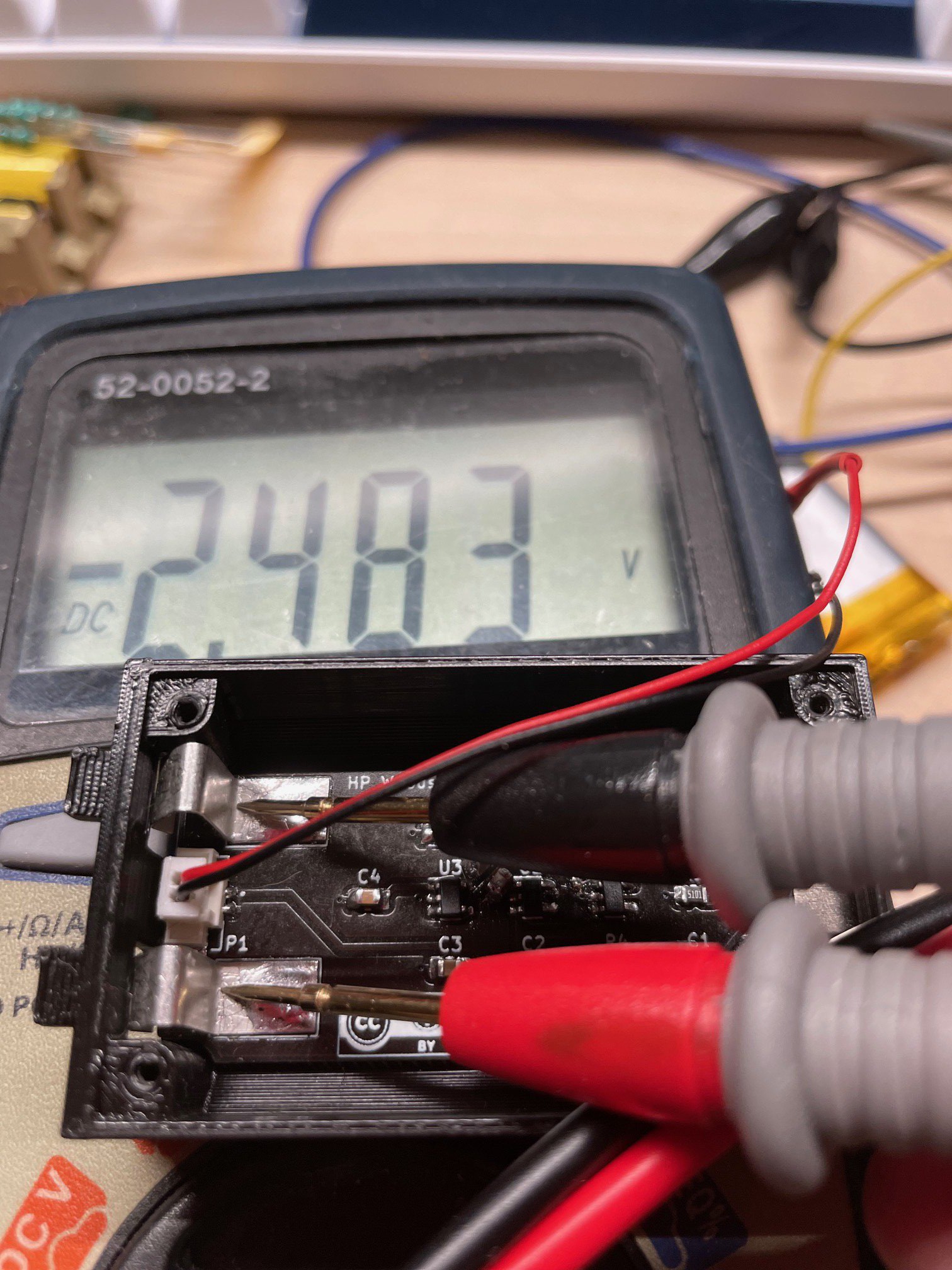

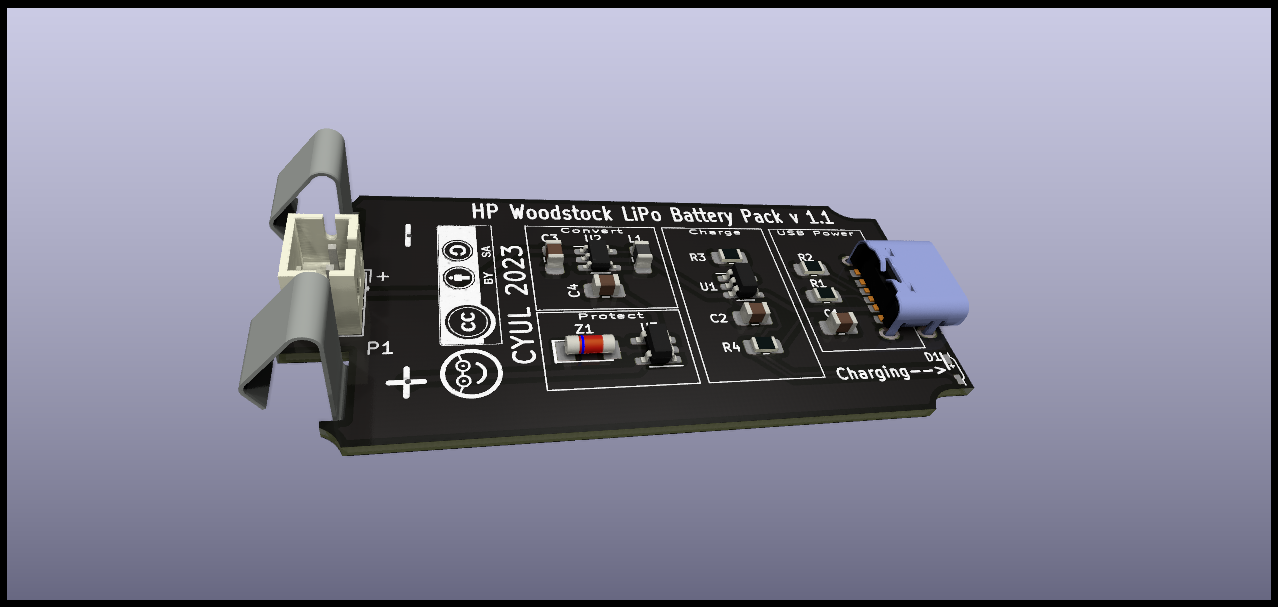

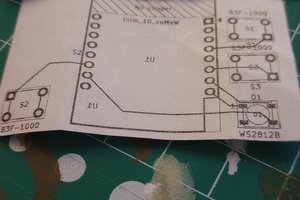

The circuit consists of a size 804030 1000 mAh LiPo battery with its charger, a buck converter that generates 2.5V for the calculator, and a protection circuit (ideal diode + zener). The pack can be recharged when removed from the calculator and sports a USB-C connector (no PD though, it's a dumb USB-2 level connector).

Spring leaf AAA battery contacts are used to connect the output of the converter to the calculator and are mounted on the bottom of the PCB, with the springs on top to meet the rivets on the calculator. To leave enough space for the battery, PCB thickness must be 0.8mm.

Even accounting for power loss in the converter, in terms of capacity, this circuit should be an improvement over the original two AA NiCd cells. And look, Ma, no leaking! Maybe a little fire or a little explosion, because lithium-ion, but no leaking...

CYUL

CYUL

UltraReidar

UltraReidar

Discombobulated8080

Discombobulated8080

Even better option would be LiFePO4 cells IMHO.