Years ago, the Royal Rife machine mystified people throughout the Midwest, with claims of being able to cure or treat many diseases, but most researchers did not believe the electromagnetic signals from the device could have an appreciable effect on biological systems. Since then, some experiments have demonstrated an appreciable effect of RF on biological systems [1],[2],[3],[4]. Unfortunately, most armchair experimenters back then did not proceed with intellectual rigor or specify a possible biological mechanism, and so the credibility of the device was damaged.

In recent decades, the key importance of bioelectric fields has been recognized by researchers like Michael Levin. To be clear, his research is largely focused on active ion pumping by cells for inter-cellular communication via the gaps between cells, in a manner similar to the way neurons communicate, by sending signaling molecules and by sensing the power required by ion pumps on the receiving cell with various biological pathways. Evolutionary theory supports that there should be an evolutionary intermediate between normal cells and neurons, so Michael's hypothesis makes sense, but these mechanisms shouldn't

But it also got me thinking: what if biological pathways in the cell can sense electric fields in other ways? In principle, an electrostatic field

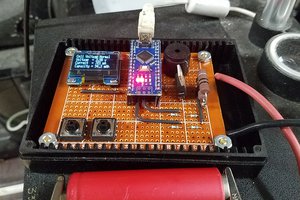

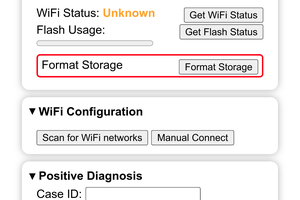

This project looks at altering the conformational structure of enzymes using radiofrequency. To test this, we are creating a Faraday cage out of machined brass (files will be uploaded) and placing our enzyme sample inside the cage before subjecting it to a wide range of frequencies. The sample will contain a colorimetric enzyme test (e.g. amylase and starch, HRP and TMB, GOx) to test the effectiveness of the RF at different frequencies. The RF scanning is performed by a HackRFOne Radio Emitter. This project has the implication of proving that proteins can be altered through radiofrequency rather than chemical medication.

Michael Perrone

Michael Perrone

Bonez

Bonez

MarkRD

MarkRD

Shranav Palakurthi

Shranav Palakurthi